Beruflich Dokumente

Kultur Dokumente

CNG Fuel Cylinder Inspection Manual: ENP-558 Rev. G: October 2019

Hochgeladen von

Rasool MohammadiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CNG Fuel Cylinder Inspection Manual: ENP-558 Rev. G: October 2019

Hochgeladen von

Rasool MohammadiCopyright:

Verfügbare Formate

CNG Fuel Cylinder Inspection Manual

ENP-558

Rev. G: October 2019

ENP-558 Rev. G (Downloaded Copy is Not Controlled) 1 of 33

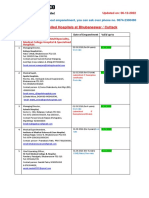

Table of Contents

I. Proprietary Statement ....................................................................................................... 3

II. Trademark Notice .............................................................................................................. 3

III. Preface .............................................................................................................................. 3

IV. Warning Statements Used in this Manual ......................................................................... 3

V. Obtaining Product Support, Service or Parts .................................................................... 4

1. Safety ................................................................................................................................ 5

1.1. Qualified Personnel ........................................................................................................... 5

1.2. Safety Equipment and General Safety Rules .................................................................... 5

1.3. Emergency Response for Gas Leaks ............................................................................... 5

1.4. Vehicle Fire Procedures .................................................................................................... 6

1.5. Emergency Shut Down Procedure .................................................................................... 6

1.6. Inspect Cylinders Immediately If: ...................................................................................... 6

1.7. CNG Inspectors: Certified vs Qualified ............................................................................. 7

1.8. Inspection Interval Confusion ............................................................................................ 7

1.9. CNG System Inspection Recommendations ..................................................................... 8

2. Agility Fuel Solutions CNG Cylinders .............................................................................. 10

3. Preparing for Cylinder Inspection .................................................................................... 11

3.1. Tools and Supplies .......................................................................................................... 12

3.2. Inspection Overview ........................................................................................................ 13

3.3. The Six Damage Types ................................................................................................... 13

3.4. Cylinder Boss and Mounting Blocks ................................................................................ 17

3.5. Non-Structural Anomalies ............................................................................................... 19

3.6. Damage Level Examples ................................................................................................ 20

4. Damage Level and Disposition ....................................................................................... 25

4.1. Repairing Level 2b Damage ............................................................................................ 26

5. Venting (Defueling) and Refueling Cylinders .................................................................. 26

5.1. Refueling Defueled or New Cylinders ............................................................................. 27

5.2. Conditioning Cold Cylinders: A Special Condition ........................................................... 27

6. Cylinder Decommissioning and Destruction ................................................................... 28

7. False Indications of a Cylinder Leak ............................................................................... 29

8. CNG Cylinder and System Inspection Regulations, Codes and Guidelines ................... 30

9. Glossary .......................................................................................................................... 31

10. Natural Gas Vehicle Cylinder Inspection Record ............................................................ 33

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 2 of 33

I. Proprietary Statement

The information provided within this document is proprietary and confidential. All prior versions,

including updates and revisions forwarded separately, are also proprietary and confidential. The

information provided by Agility Fuel Solutions to its customers is solely for the use of those

customers. No portion of this manual may be reproduced or distributed without prior written

consent of Agility Fuel Solutions. Agility Fuel Solutions reserves all rights, including intellectual

property rights, contained within this publication.

II. Trademark Notice

Agility® and TUFFSHELL® are registered trademarks of Agility Fuel Solutions.

III. Preface

This manual contains specific inspection information for Agility Fuel Solutions CNG vehicle fuel

system cylinders. It does not apply to cylinders made by other manufacturers.

This manual does NOT cover vehicle fuel system inspections or maintenance procedures. Refer

to “Truck and Tractor CNG Fuel System Operation, Maintenance & Inspection Manual,” ENP-

516 for system details.

IV. Warning Statements Used in this Manual

Personal injury or death will occur if procedures are not followed.

Personal injury or death may occur if procedures are not followed.

Damage to equipment, fuel system or vehicle is possible if instructions are not

followed.

Best practices or hints to help an operation or procedure go smoothly.

ENP-558 Rev. G (Downloaded Copy is Not Controlled) 3 of 33

V. Obtaining Product Support, Service or Parts

Fuel system in- or out-of-warranty product support can be obtained by calling the Agility Fuel

Solutions Customer Care Hotline at +1 949 267 7745. Toll free: +1 855 500 2445.

Customer Care and parts assistance: parts@agilityfs.com

Visit our website for more information, including CNG and LNG fuel system videos.

Agility Fuel Solutions

http://www.agilityfuelsolutions.com/

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 4 of 33

1. Safety

If the vehicle has been in an accident or fire, cylinders and system must be

examined by a qualified inspector.

1.1. Qualified Personnel

CNG systems should be maintained and inspected exclusively by trained personnel. As with all

pressure vessels, CNG storage and fuel delivery systems can be dangerous.

1.2. Safety Equipment and General Safety Rules

1. CNG safety signage should be visible at all applicable locations as stipulated by federal,

state and municipal law.

2. Natural gas rated fire extinguishers should be accessible and visible throughout all

servicing and fueling areas. Be sure all fire extinguishers are charged and up to date.

3. Areas designated for CNG fueling systems must have adequate lighting that complies

with NFPA and other applicable codes.

4. Search for leaks using only certified leak detecting solutions and equipment such as

Swagelok Snoop®. Any other product or solutions are unacceptable.

5. Use tools that are in good working order with proper calibration.

6. Wear appropriate attire and personal protective equipment (PPE) while servicing or

maintaining any CNG system.

7. Never use an open flame as a source of illumination near a CNG system.

8. CNG fuel systems are to be serviced in designated areas that comply with all federal,

state and municipal laws and regulations.

9. CNG servicing and fueling areas must be well ventilated.

10. Do not stand or walk on cylinders. The slippery surface creates a fall hazard and surface

damage may occur from debris stuck in shoe treads and soles. Always wear fall

arrestment PPE when working on high or tall fuel systems.

1.3. Emergency Response for Gas Leaks

If the vehicle has sustained damage or a gas leak is detected:

1. Do not approach the vehicle if any sources of ignition may exist such as fire, sparks,

electrostatic charges, lights or electronic devices.

a. If ignition sources may be present, vehicle fuel cabinet doors should remain

closed.

b. I if no ignition sources are present, keep the vehicle and fuel cabinet doors open

to prevent gas accumulation.

2. If the vehicle is indoors, move the vehicle outside and away from any ignition sources.

3. Do not use road flares.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 5 of 33

4. Do not smoke or allow anyone else to smoke near the vehicle.

5. Turn the ignition switch off, set the parking brake and turn off the battery at the main

disconnect.

6. If it is safe to do so, close the main shutoff valve and the cylinder valves. Check the fuel

system near the damaged area for leaks by smell, sight, and sound. CNG is odorized.

7. Keep traffic and pedestrians away.

8. Beware that gas may continue to leak once ignition is turned off and the manual shutoff

valves are closed.

9. Verify leak locations with suitable methane detection fluid.

Leaks must be repaired by a qualified technician.

1.4. Vehicle Fire Procedures

1. Always call 9-1-1 first.

2. Get passengers out of the vehicle as quickly as possible.

3. Evacuate the area.

In case of fire, thermally activated pressure relief devices (PRDs) protect cylinders

from rupturing. PRDs typically activate between 212°F and 220°F and will release

high pressure CNG which may ignite and add to the fire.

1.5. Emergency Shut Down Procedure

1. Turn the ignition switch to “off” and set the parking brake.

2. Turn off the battery disconnect switch.

3. Shut off fuel at 1/4-turn valve on the FMM.

4. Inform emergency personnel.

1.6. Inspect Cylinders Immediately If:

1. The vehicle has been in an accident.

2. The fuel cylinder or vehicle has been subjected to fire, impact, excessive heat or any

other means that may have caused external or internal damage.

3. Unusual behavior is observed. This may include but is not limited to, emission of natural

gas odor, unexpected loss of gas pressure, snapping or hissing sounds, rattling and any

indications of loose parts.

4. The fuel cylinder has been transferred to another vehicle or the cylinder installation has

been altered significantly.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 6 of 33

A. Cylinders involved in an accident or incident should be depressurized prior to

inspection.

B. Failure to perform regular or emergency inspections may put the vehicle and

its operator at risk of serious injury or death.

C. For cylinder leaks, see Section 7.

1.7. CNG Inspectors: Certified vs Qualified

Agility Fuel Solutions provides Agility-specific CNG fuel system training but does not have a

certified or certification program. Agility recommends inspection and service technicians receive

training and certification by third-party organizations such as CSA and NGVi (Natural Gas

Vehicle Institute).

CNG fuel system inspectors are certified by CSA or NGVi after passing a written examination on

CSA standards, NFPA 52 “Vehicular Natural Gas Fuel Systems Code” and NGV industry best

practices.

An acceptable alternative to the certified status is a CNG fuel system inspector who is qualified

and trained as described by the Compressed Gas Association (CGA) in its publication CGA C-

6.4 “Methods for External Visual Inspection of Natural Gas Vehicle (NGV) and Hydrogen Gas

Vehicle (HGV) Fuel Containers and their Installations.”

A qualified inspector must have at least one of the following qualifications: (a)

two years’ experience conducting container inspections on the type of cylinder

being inspected; (b) supervision by a person with two years’ experience

relevant to the type of cylinder being inspected; (c) approved by manufacturer

of the container being inspected; (d) certified as an inspector by one of the

organizations with specific OEM-approved training centers with fuel gas

cylinder standards’ recommended inspection guidelines; (e) certification as an

inspector by a state or nationally recognized organization that tests for specific

knowledge of applicable fuel gas cylinder standards’ recommended inspection

guidelines; or certification as an inspector by the authority having jurisdiction.

1.8. Inspection Interval Confusion

Based on cylinder manufacturer recommendations and industry standard practices, visual CNG

cylinder inspections should be performed at a frequency of 3 years or 36,000 miles, whichever

occurs first. This is based on common passenger car or light-duty applications, where lower

mileage per year is common. This inspection frequency is applied to all CNG vehicles

regardless of final use application, which results in greatly varying actual frequency from a time-

based perspective.

High mileage vehicles, such as over the road trucks, may accumulate 36,000 miles in several

months; well in advance of the anticipated 3 year time-frame. However, because heavy-duty

vehicles are often subject to more demanding duty cycles than passenger cars, performing

cylinder inspections at 3 year intervals would not be appropriate.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 7 of 33

1.9. CNG System Inspection Recommendations

Because of this confusion, Agility Fuel Solutions recommends a practical alternative schedule

for detailed fuel system inspections, which includes cylinders – at intervals selected by the fleet

manager or vehicle owner.

These guidelines are intended to be consistent with the pending Recommended Practice (RP)

from the American Trucking Association’s Technology & Maintenance Council and the

recommendations from the NGVA Technology Committee Working Group on CNG Fuel System

Inspections, of which Agility is a member and active participant. The working group is working

closely with DOT, NHTSA and FMCSA to update FMVSS 304 to be consistent with the ATA-

TMC (RP) and Agility guidelines.

Agility Fuel Solutions Recommends the Following

1. The common recommendation of every 3 years or 36,000 miles, whichever occurs first,

OR

2. After every 1 year, regardless of mileage

A practical approach to inspection and maintenance of the fuel system would be to match

intervals and procedures with other vehicle maintenance tasks, such as engine oil and filter

changes and the yearly DOT inspection.

Regardless of which interval is selected, Agility recommends all inspection

routines include a daily walk-around visual inspection, and the use of the

inspection categories as outlined in the Agility Fuel Solutions “Truck and Tractor

Operation Manual,” ENP-516.

Some states have specific requirements for CNG fuel cylinder inspections, so the

alternative schedule is not applicable.

1. Arizona: Inspection is required when the vehicle is placed into service and then

annually. Inspection must be performed by an individual trained by the system

manufacturer.

2. Kentucky: Inspection is required every 36 months or 36,000 miles, whichever comes

first, and after collision. Does not state who performs the inspection.

3. Oklahoma: Inspection is required every 36 months or 36,000 miles, whichever comes

first. Inspection is performed by a certified technician.

4. Texas: The owner of the vehicle must prove that the container meets the inspection

criteria of FMVSS 304. (Every 36 months or 36,000 miles, whichever occurs first.)

5. Utah: Inspection is required every 36 months or 36,000 miles, whichever occurs first.

Inspection must be performed by a CSA certified technician.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 8 of 33

6. West Virginia: Does not state the frequency of inspection, however, all CNG activity

must be overseen by a CSA certified technician. Note, this legislation is not signed into

law yet.

7. Ohio: Coming soon

NOTE: Inspections must be performed by qualified inspectors using guidelines from the fuel

cylinder manufacturer in addition to the guidelines listed in this manual.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 9 of 33

2. Agility Fuel Solutions CNG Cylinders

Agility Fuel Solutions all-composite (Type 4) fuel cylinders are used to store CNG in vehicles.

The cylinders are made with a polymer liner, metallic bosses and a high strength composite

wall. The composite wall comes in the following construction types:

TUFFSHELL® ACF: All-Carbon Fiber reinforced in an epoxy resin. The all-carbon fiber

cylinders may or may not have an external coating (paint). See Figure 1.

TUFFSHELL®: Hybrid composite cylinders consisting of carbon and glass fibers reinforced in

an epoxy resin, see Figure 2.

Figure 1. Agility Fuel Solutions TUFFSHELL® ACF all carbon Type 4 cylinder cut-away

view. The external foam cap provides an additional layer of protection.

Figure 2. Agility Fuel Solutions TUFFSHELL® hybrid composite Type 4 cylinder cut-away

view.

All cylinders meet DOT FMVSS 304, ANSI/CSA NGV2, Canadian CSA B51-Part 2, METI/KHK,

and NFPA 52 requirements. They are also compliant with and can be certified to ISO 11439 or

other national or international standards.

All standards in this manual are referred to as “applicable standards” or “standards.”

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 10 of 33

3. Preparing for Cylinder Inspection

Composite fuel cylinders may be faulty without showing significant surface

damage. Since the inspection depends primarily on visual observation, the

surface of the cylinder must be accessible, clean and well illuminated. Removal of

paint or fiber for visual inspection is not permitted unless damage depth is being

determined. This may require removing small amounts of material for an accurate

evaluation.

A record of the inspection (by cylinder serial number) should be made or updated if an

inspection is performed on a cylinder or cylinder hardware. A sample record sheet is presented

in the Reference Section.

Cylinder surfaces should be clean and free of dirt or other debris that impede inspection.

Remove shields or covers as needed to ensure maximum access to the cylinder surface. It is

not necessary to remove the cylinder from the vehicle if the vehicle protects visually

inaccessible surfaces and there is little potential for damage.

Various vehicle and highway legislative agencies require warning and informational decals for

CNG fueled vehicles. Cylinder manufacturer labels must be in place and legible. If Hexagon-

Lincoln or Agility Fuel Solutions labels are damaged or missing, contact Agility Fuel Solutions

Customer Care for replacement labels.

The guidelines in this manual also apply to Hexagon Lincoln CNG, Brunswick and General

Dynamics, Lincoln Operations Type 4 cylinders and may not be appropriate for cylinders from

other manufacturers.

Note: For cylinders manufactured after July 1999: If the label is missing or damaged, the serial

number of the cylinder is etched on one of the bosses, and a replacement label can be supplied.

If the cylinder label is not attached to the cylinder, and the manufacturer and

serial number are not available or cannot be verified, the cylinder must be

condemned.

Figure 3. The CNG cylinder manufacturer’s label must be in place and legible.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 11 of 33

3.1. Tools and Supplies

Figure 4. A few of the tools needed for cylinder inspection.

Common hand tools are needed for CNG cylinder and inspection.

1. Depth gauge/micrometer

2. Leak detection fluid

3. Inspection mirror

4. Flashlight

5. Borescope

6. Creeper

7. Rags or shop towels

8. Coin for tap test

9. Notepad and vehicle record

10. Camera

11. Personal protective equipment

(PPE), including eye protection, hard

hat, reflective vest and fall

arrestment harness as needed

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 12 of 33

3.2. Inspection Overview

Cylinder inspection consists of four primary elements.

1. Service History: The inspector reviews cylinder inspection and service records.

2. Visual Examination: Examining and measuring cylinder surface cuts, scuffs, scratches,

surface distortions, material removal, discoloration and deterioration.

a. Includes inspection of cylinder bosses, bushings and mounting blocks.

b. See Section 3.4.

3. Tap Test: Because damage (delamination) may occur within the cylinder wall upon

impact, the tap test is used to detect hidden damage by tapping the cylinder and

listening for sound differences. The tap test must be limited to the main portion of the

cylinder and not the dome ends. This test should be performed by a registered or

experienced inspector. Any uncertainties shall be resolved by removing the cylinder from

service and returned for factory inspection.

4. Factory Inspection: Cylinders known or suspected to have been subjected to a

potentially damaging incident or show evidence of damage not acceptable, should be

removed and may be sent to Agility Fuel Solutions for more extensive evaluation.

Contact Customer Care for assistance.

3.3. The Six Damage Types

There are six types of composite cylinder damage. Damage depth determines damage level.

3.3.1. Cuts, Scratches and Abrasion

Cuts cause deep fiber breaks and loose fibers in the damaged area.

Scratches in the composite surface less than 0.010 inches (0.25 mm) in depth can cause minor

fiber breaks.

Abrasion is caused by an object rubbing against the cylinder surface. Light load abrasion

appears smooth and polished, while high loads appear as a group of parallel gouges or cuts.

High load abrasion should be examined using impact damage inspection criteria.

Cut, scratch and abrasion damage can lead to composite unraveling, see below.

Unraveling is level 2b damage. Contact Agility Fuel Solutions Customer Care if

any unraveling has begun.

A. Cylinder damage pictures in the following pages show painted TUFFSHELL

ACF cylinders. Measurements for assessing damage and damage types for

un-painted cylinders is the same. Damage Level 1 and Level 2A is repairable,

as indicated in Section 4, “Damage Level and Disposition.”

B. For CNG system inspections, see Agility publication ENP-516, “Truck and

Tractor Operation Manual.”

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 13 of 33

Figure 5. Cuts, scratches and abrasion can cause the outer surface to unravel or lift,

creating Level 2b damage, which requires factory inspection.

3.3.2. Impact

Evidence of cylinder damage within the wall is considered major and should be

condemned.

Agility Fuel Solutions cylinders are resistant to damage from minor impacts. However, severe

structural damage can be caused from major impacts. Impact damage may be incurred during

shipping, installing or while in service (vehicle accident).

Since composite cylinders tend to return to their original shape after an impact and typically do

not dent like an all-metal tank, a simple visual check is not enough.

Impact damage differs from other forms of damage because severe damage may be hidden

within the wall (delamination or fracture) as well as the cylinder surface. This is particularly true

if the object impacting the cylinder is blunt and relatively smooth.

Known areas of impact and zones of detectable surface damage must be inspected for

evidence of damage within the wall.

1. Permanent deformation of the surface resembling denting of an all-metal tank.

Cylinders with deformation or denting should be investigated immediately for Level 3

damage.

Note: This condition does not include highly localized imprinting on the surface that might result

from impact by a small stone or other debris. This minor type of damage may not exceed Level

2a damage to be acceptable for use. (Refer to the Damage Level and Disposition Table.)

2. Softness or deflection of the wall. The cylinder wall should be rigid and not easily

deformable. Cylinders exhibiting this condition have Level 3 damage and are to be

condemned and destroyed. If damage is localized to the dome areas only, the dome wall

may be repairable.

3. Damage to cylinder bosses. Impact to the ends of the cylinder, including the valves,

plumbing and pressure relief devices, should be investigated to ensure composite

damage has not been sustained.

4. Localized surface crazing. Cylinders with circular, oval or linear zones of crazing on

the composite surface. Surface crazing may be accompanied by a change in coloration.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 14 of 33

Each area with these indications should be subjected to the tap test. Questionable areas

should be subjected to factory inspection.

Note: Small random hairline cracks in the resin surface parallel to the reinforcing fibers are

common in composite pressure cylinders and are not a cause for concern.

5. Differences in sound during a tap test.

Only a registered or experienced inspector should perform the tap test. Any

uncertainties that result from the tap test shall be resolved by removing the

cylinder from service and inspected by the factory.

The tap test is a method to identify delamination within the composite wall and should be

performed only when the composite surface has been impacted.

The tap test is performed by tapping the composite surface with a quarter or similarly size metal

object grasped between the fingers. The tapping sound near damaged areas will sound different

from un-damaged areas. The tap test must be confined to the main portion of the cylinder. False

indications may be heard if the tap test is performed in the dome (end) areas.

Differences in sound are evidence of damage within the composite wall. Cylinders with this type

of damage must be removed from service. Cylinders may be subjected to further field

evaluation, factory inspection at Agility Fuel Solutions or condemned and destroyed.

Surface damage associated with impact loads may include cutting, gouging, scraping, scuffing,

chipping, punctures, fiber breakage, loose fibers, resin cracking or change in coloration or

appearance. The surface must be carefully examined for these types of indications. Accurate

depth measurement of damage requires removing all loose fibers associated with the damage.

Once the loose fibers are removed, the damage level can be determined using the

measurements for cuts, scratches and abrasion.

3.3.3. Fire and Excessive Heat

All NGV fuel cylinders manufactured under NGV2 or ISO 11439 have a maximum service

temperature of 180°F (82.2°C). Excessive heating may occur if the cylinder is involved in a fire.

Evidence of fire or heat damage includes darkening, charring or soot on the cylinder surface.

Severe exposure may result in resin removal and loose fibers. Other signs of heat damage are

melting of the plastic on the labels and discoloration of the bosses. This is considered Level 3

damage and must be removed from service and condemned.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 15 of 33

Figure 6. Fire damage. Fire or excessive heat is Level 3 damage and must be condemned.

3.3.4. Chemical Damage/Chemical Attack

The materials used in cylinder construction are resistant to chemical agents encountered in the

normal fuel cylinder environment. However, chemical damage indicated by blistering, swelling,

softening, resin removal, or fractures is Level 3 damage and must be removed from service and

condemned.

Minor discoloration and etching is considered acceptable provided the chemical has been

removed and the cylinder surface cleaned.

3.3.5. Weathering

The cylinder may show degradation after prolonged exposure to sunlight and weather, resulting

in discoloration or flaking. This condition is Level 1 and may be reworked by hand filing or

sanding. For painted cylinders, paint the area with a polyurethane paint. For non-painted

cylinders, apply a thin layer of epoxy.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 16 of 33

Figure 7. Weathering damage is Level 1 and can be repaired.

3.3.6. Gas Leakage

Leaking cylinders must be removed from service. Contact Agility Fuel Solutions Customer Care

to report the condition and obtain additional testing and disposition information. Cylinders with

confirmed gas leaks must be condemned and destroyed.

Bubbles may be observed on the composite surface for several hours after

pressurization, usually after first-time fill or if the cylinder is nearly empty. The

bubbles are caused by air trapped between the liner and composite being forced

through the composite (permeation) when the cylinder is pressurized and the liner

expands. Refer to Section 7 below.

3.4. Cylinder Boss and Mounting Blocks

Refer to Figure 8. For severe duty vehicles, the cylinder sliding boss must be inspected daily as

part of the drivers’ pre-drive visual check. Look for removal of the black anodized coating: This is

an indication of cylinder boss wear.

A complete inspection of the cylinder boss, mounting blocks, and bushings must also be made at

regular intervals. This item is part of the broad category called “cylinder mounts” in inspection

interval documents and guidelines.

See Section 3.2 “Inspection Overview” and Section 9, “Natural Gas Vehicle Cylinder Inspection

Record” – “Cylinder bracket and mounting condition.”

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 17 of 33

3.4.1. Boss Wear

Boss wear up to 0.050-in. (1.27mm) is acceptable for continued service. Boss wear over 0.050-

in. (1.27mm) up to 0.125-in. (3.175mm) of wear requires cylinder re-work. Boss wear greater than

0125-in (3.175mm) requires cylinder replacement. Figure 9. Contact Agility Customer Care for

assistance, and refer to Field Service Bulletin ENP-652, “CNG Cylinder Boss Wear, Inspection

and Repair.”

Sliding block

Temporary

support sling

Fixed block

Figure 8. Cylinders with sliding blocks should be checked for excessive wear.

Note: temporary support sling is needed only when lifting a defueled cylinder.

Figure 9. Cylinder boss wear measurement point.

Boss wear up to 0.050-in. (1.27mm) is acceptable for continued service.

Wear from 0.050-in. (1.27mm) to .125-in. (3.175mm) can be repaired in the field.

If wear exceeds 0.125-in. (3.175mm), contact Agility Customer Care for further

instructions.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 18 of 33

3.4.2. Delrin Bushing

Cylinder block

Delrin bushing

Retaining plate

Retaining ring

Figure 10. The Delrin bushing allows cylinder movement in some cylinder mounting

systems.

On some systems, a Delrin bushing (part number 240105-01) is incorporated into one of the

cylinder mounting blocks to accommodate normal cylinder movement. This is called the “sliding

block.” The other end is fixed and does not normally move, it is called the “fixed block” and does

not include a Delrin bushing.

The bushing will normally wear over time and should be replaced if excessive wear is discovered

during the inspection process, to prevent damage to the cylinder.

If there is evidence of excessive cylinder movement, contact Agility Customer Care for assistance,

and refer to Field Service Bulletin ENP-638, “Cylinder Mounting Block Bushing Replacement, Part

Number 240105-01.”

3.5. Non-Structural Anomalies

Frequently, cylinders may exhibit superficial anomalies that have no effect on the structural

quality. Non-structural anomalies include:

1. Fiber gaps on the surface of the dome area, see photo below. Fiber gaps do not include

loose fiber that has separated from the surface of the composite.

2. Resin and paint runs which may appear as a hard circle or spot on the cylinder surface.

3. Excessive resin on the composite surface.

4. Splices on the external TUFFSHELL wrap.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 19 of 33

Figure 11. Fiber gaps and resin runs are superficial and not a defect.

3.6. Damage Level Examples

Always measure damage to determine damage level. Although damage type may

be the same (such as gouge), the depth determines level classification.

Figure 12. Level 1 damage (use a depth gauge to verify) can be repaired. Damage depth:

0-in. ≤ 0.010-in. (0mm ≤ 0.25mm). Painted cylinders can be repaired with a coat of

polyurethane paint. Un-painted TUFFSHELL ACF cylinders can be repaired by applying a

thin layer of epoxy resin.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 20 of 33

Figure 13. Level 2a damage can be re-worked. If loose fibers are present, remove them by

sanding the area and apply a coat of polyurethane paint or epoxy. Damage depth: 0.011-

in. ≤ 0.035-in. (0.26mm ≤ 0.89mm).

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 21 of 33

Figure 14. Level 2b damage may or may not be repairable. Damage depth: 0.036 in. ≤

0.050-in. (0.90 mm ≤ 1.27mm). An example of a “lifted fiber” appears at the bottom center,

and requires special consideration, see Section 4.1.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 22 of 33

Figure 15. Level 3 damage cannot be repaired. The cylinder must be condemned.

Damage depth, gouge or impact: >0.05-in. (>1.27mm).

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 23 of 33

Figure 16. A cylinder exposed to fire or excessive heat is classified as Level 3 damage

and must be condemned.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 24 of 33

4. Damage Level and Disposition

Depressurize and DEFUEL the cylinder before any rework on the cylinder and/or

related hardware is performed.

Damage Depth Un-Painted Painted

Level Damage Type Measurement Cylinders Cylinders

Level 1 Minor damage 0 ≤ 0.010-in. Coat with Paint with

inconsequential for safe 0 ≤ 0.25mm thin layer of polyurethane

cylinder operation epoxy paint.

Level 2a Loose fibers, cut, scratch, 0.011 ≤ 0.035-in. Rework: Rework: Remove

abrasion 0.26 ≤ 0.89mm Remove loose fibers or

loose fibers rough edges of a

or rough cut or gouge by

edges of a hand sanding.

cut or Paint with

gouge by polyurethane

hand paint.

sanding.

Apply thin

layer of

epoxy.

Level 2b* Loose fibers, cut scratch, 0.036 ≤ 0.050-in. Remove cylinder from service

abrasion, unraveling 0.90 ≤ 1.27mm and contact Customer Care for

factory inspection and possible

rework.*

Level 3 Gouge damage > 0.05-in. Remove from service and

> 1.27mm condemn.

Level 3 Impact damage Not applicable Remove from service and

condemn.

Level 3 Fire damage, fire exposure Not applicable Remove from service and

condemn.

Level 3 Chemical Damage / Not applicable Remove from service and

Chemical Attack condemn.

*See Section 4.1

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 25 of 33

Cylinders inspected using these guidelines will have one of four dispositions:

1. No damage or Level 1: Acceptable and may remain in service.

a. TUFFSHELL ACF cylinders: Re-work with paint or epoxy to match the cylinder: Use two-

part epoxy such as Do it Best Super Epoxy (387002), PC Products SuperEpoxy, or

similar.

b. TUFFSHELL cylinders: Re-work with paint.

2. Level 2a: May be reworked in the field and the cylinder can be returned to service.

3. Level 2b: Cannot be fully assessed in a field inspection and must be factory inspected.

4. Level 3: Must be condemned, removed from service and destroyed.

4.1. Repairing Level 2b Damage

Level 2b damage must be identified / confirmed by Agility Cylinder Engineering

before rework is started. Contact Customer Care for verification and assistance.

Examples of Level 2b damage can be seen in Figure 14. The example at the bottom center is a

special condition called a “lifting of a band termination after a tuck” or “lifted fiber.” In this case, do

not attempt to lift or cut the fiber to measure the damage.

All Level 2b damage must be inspected by Agility Fuel Solutions cylinder group to

determine if the condition is repairable. Contact Customer Care for assistance.

If the lifted fiber can be repaired, proceed using this procedure:

Rework instructions for lifted fiber:

1. Clean with water and mild detergent.

2. Wipe down with alcohol.

3. Apply quick setting epoxy.

4. After the epoxy is fully cured, the surface can be painted with polyurethane paint if the

cylinder is painted. No paint is needed if the cylinder is unpainted.

5. Venting (Defueling) and Refueling Cylinders

Things to know when defueling and refueling Agility CNG cylinders:

1. There are no flow restrictions during venting (defueling) an Agility cylinder that affects its

performance or suitability for service.

2. Rapid venting of natural gas normally causes a significant temperature reduction inside

natural gas vehicle fuel cylinders. Internal temperatures lower than -100°F (-73C) have

been measured.

3. CNG should be vented slowly to avoid freezing plumbing components which may decrease

flow.

4. The residual gas in the container after initial venting expands as the cylinder warms to its

surrounding temperature. This causes a buildup of pressure if the cylinder is not allowed to

vent throughout the defuel process.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 26 of 33

a. Keep the manual cylinder valve open during this warming stage to ensure the cylinder is

defueled as completely as possible.

b. Since the liner in the Agility Type 4 cylinder can get very cold during the defuel process,

it is important to wait 4 hours after venting before re-pressurizing the cylinder to prevent

liner damage.

5. Do not allow a vacuum to form in the cylinder at any time. If a vacuum occurs, the cylinder

should be opened to atmosphere and conditioned at a temperature above 60F (16C) for 8

hours before being pressurized.

5.1. Refueling Defueled or New Cylinders

There are no fill flow restrictions for Agility cylinders when:

1. The ambient temperature is greater than 10F (-12C), or

2. The cylinder is in natural gas vehicle service with a residual pressure greater than 100 psi

(649 kPa / 7 bar), or

3. The cylinder has been conditioned, see below.

5.2. Conditioning Cold Cylinders: A Special Condition

Agility fuel cylinders at less than 100 psi (649 kPa / 7 bar) and at an ambient temperature of 10F

(-12C) or less are called “cold cylinders.”

This condition could occur after maintenance work is performed on the fuel system, or during the

installation of new cylinders in cold climates.

There are no restrictions when time (slow) filling a cold cylinder.

After a cylinder is in service and a minimum pressure of 100 psi (649 kPa / 7 bar) is maintained,

the liner is seated and there is no restriction regardless of fill rate or temperature.

These procedures can be applied to any Type 4 cylinder, regardless of manufacturer.

A. No Type 4 CNG fuel cylinder (regardless of manufacturer) is compatible with

liquid methane. Liquid methane can form at the filling station from an

extremely cold, high pressure cascade.

B. Procedures for filling a cold cylinder must prevent damage to the plastic liner

by filling at a slow rate to a pressure that seats the liner.

If a cold cylinder is to be transit (fast) filled, the steps below should be performed.

1. Partially fill the cylinder, wait for a few minutes, and then re-fuel as follows:

2. Fill to 450 psi ± 50 psi (3103 kPa ± 345 kPa, 31 bar ± 3 bar) directly from a compressor (not

from a cascade or compressor-less transfer station).

3. Wait 1 hour.

4. Re-fuel normally.

Remember, after a cold cylinder is in service and a minimum pressure of 100 psi (649 kPa / 7

bar) is maintained, the liner is seated and there is no restriction regardless of fill rate or

temperature.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 27 of 33

6. Cylinder Decommissioning and Destruction

A. Residual gas remains in the cylinder after depressurization and must be

removed before destruction. Vent all pressure from the cylinder and displace

residual fumes with compressed nitrogen. If compressed nitrogen is not

available, flushing the cylinder with water will displace residual fumes.

B. NEVER use compressed air to purge the cylinder.

C. Wait at least 10 minutes to ensure no gas remains before drilling holes.

Before condemning a cylinder, the cylinder owner must be notified. Condemned cylinders must

be clearly marked “CONDEMNED” at the time of inspection. The marking shall be affixed to the

manufacturer’s label and the duplicate manufacturer’s label, if used.

To prevent unauthorized pressurization, the cylinder must be destroyed by drilling two or more

holes one-half inch or greater completely through the cylinder wall and internal liner.

Figure 17. Condemned cylinders must be properly prepared and destroyed to prevent

use.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 28 of 33

7. False Indications of a Cylinder Leak

Type 4 gas cylinders consist of a flexible plastic liner that is overwrapped with composite

reinforcement. The internal liner provides the containment barrier for storing compressed gas,

while the composite resists the forces of internal pressure. The specific design manufactured by

Agility Fuel Solutions purposefully does not bond the liner to the composite.

First Fill

When the cylinder is filled for the first time, some amount of air will be present in the space

between the liner and composite. Depending on how the liner expands inside, this air may become

trapped.

With time and pressure cycling, trapped air will work its way out. However, if a bubble leak check

is performed during this time, the escaping air can generate bubbles around the metal end boss

or on the surface of the composite. This can be misinterpreted as a leak. The amount of bubbles

and how long it takes to dissipate depends on the size of the cylinder and variation in porosity of

the composite. Normally, trapped air escapes within 24 hours.

If bubbles are observed during the first fill, no action is necessary to confirm that the cylinder is

not leaking unless there is a strong smell of gas. Each cylinder manufactured by Agility Fuel

Solutions undergoes a gas leak check before it leaves the factory. This leak check can detect

extremely small amounts of gas and is more accurate than any possible leak check done in the

field or at the installer. No cylinder leaves the factory without a passing leak test.

In-Service Inspection or Maintenance

A similar condition can occur if a cylinder is at low pressure or defueled. In this case, permeated

gas evolving from the liner can collect and mix with the air. When filled again, a handheld

electronic leak detector may have the sensitivity to pick up low concentrations of gas. While gas

is present, the source is not a leak. Like the first fill scenario, trapped gas normally escapes within

24 hours.

If bubbles are observed during an inspection or maintenance period, no action is recommended

to confirm that the cylinder is not leaking unless there is a strong smell of gas.

If the smell of natural gas is present, it is recommended that the cylinder be pressurized to service

pressure and held for 24 hours in a well-ventilated area (preferably outdoors).

After the 24 hour waiting period, repeat the bubble leak check.

If the formation of bubbles is still present, reduce the pressure to 500 psi (3.44 MPa) and hold for

an additional 24 hours.

If the formation of bubbles is still being observed after the 24-hour hold at 500 psi, (3.44 MPa)

contact Agility Fuel Solutions Customer Care.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 29 of 33

8. CNG Cylinder and System Inspection Regulations, Codes

and Guidelines

This is not a comprehensive list. Other local, state or province regulations may apply. Check with

your authority having jurisdiction (AHJ), usually the fire department, for more information.

1. Federal Motor Vehicle Safety Standards (FMVSS) Standard 304, “Compressed Natural

Gas Fuel Container Integrity”

2. ANSI/IAS NGV2, “Basic Requirements for Compressed Natural Gas Vehicle Fuel

Containers”

3. ANSI NGV2-PRD-1, “Pressure Relief Devices for Natural Gas Vehicle (NGV) Fuel

Containers

4. ANSI NGV 3.1/CSA 12.3, “Fuel System Components for Compressed Natural Gas

Powered Vehicles”

5. Compressed Gas Association (CGA) Pamphlet CGA C-6.4, “Methods for External Visual

Inspection of Natural Gas Vehicle Fuel Containers and Their Installations”

6. National Fire Protection Association (NFPA) 52, “Vehicular Gaseous Fuel Systems

Code”

7. State of California Vehicle Code 2402.6, “Regulations and Standards: Compressed or

Liquefied Gas and Liquefied Petroleum Gas” and 270909, “Transporting Liquefied

Petroleum or Natural Gas”

8. Cylinder manufacturer guidelines

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 30 of 33

9. Glossary

Abrasion damage: Damage to composite caused by wearing, grinding or rubbing away of

composite material by friction.

All-composite (Type 4): A fuel cylinder made primarily from non-metallic materials such as

plastic and high strength fiber reinforced composites. May incorporate metal ports for valves

and other plumbing devices.

Boss (see “Ports”): The aluminum fittings at the ends of the tank, which contain the ports for

installation of valves, pressure relief devices and blank plugs.

Blank plug (see “Solid plug”): A threaded plug with O-ring seal.

Carbon fiber: One type of reinforcement fiber used in fuel cylinder composite overwrap.

CNG: Compressed natural gas

Condemned cylinder: A fuel container that has been damaged beyond repair and must be

removed from service and rendered unusable. See “Destroyed.”

Cylinder: Preferred term for “tank” in CNG applications and systems.

Delamination: An induced separation between composite layers. This type of damage occurs

from localized impact or resin burn out.

Destroyed: Alteration of a fuel cylinder to make it unusable.

Drop-N-Go™: Agility Fuel Solutions side- or rail-mounted systems featuring mounting brackets

that simplify installation.

Factory inspection: An inspection and evaluation performed at an approved Agility Fuel

Solutions facility, utilizing comprehensive testing techniques that are not available in field

inspection.

Field inspection: Inspection performed at a location other than an Agility Fuel Solutions facility.

Impact damage: Cylinder damage caused by dropping or by a blow from another object.

Impact damage may be at the surface, internal to the structure or both.

Level 1 Damage: Minor damage that is considered inconsequential to safe cylinder operation.

Level 2 Damage: Damage which is more severe than Level 1. Additional evaluation and/or

rework may allow the cylinder to be returned to service.

Level 3 Damage: Damage that is not repairable and renders a tank unfit for continued service.

Cylinders with Level 3 damage must be condemned and destroyed.

Liner: An internal component of a Type 4 cylinder that serves as a permeation barrier,

preventing gas leakage through the composite structure.

Manufacturer’s Label: The label or labels containing the official markings required by the U.S.

DOT, FMVSS304, ANSI/CSA NGV2, ISO 11439, CSA B51-Part 2 (Canada), and/ or other

applicable standards. The label markings shall include a “CNG Only” designation,

manufacturer’s symbol or trademark, manufacturer’s model number, type designation, serial

number, month and year of manufacture, service pressure, the inspector’s symbol or trademark

and the date when the service life expires.

Maximum Fill Pressure: The fill pressure allowed to obtain the settled service pressure at 70°F

(21°C). For all tanks, maximum fill pressure under ANSI/ CSA NGV2 is 125% of the rated

service pressure.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 31 of 33

NGV: Natural gas vehicle.

Normal duty: Vehicle application typically for long haul, over the road with infrequent stops.

See severe duty.

Pressure relief device (PRD): A device installed in direct contact with internal pressure in the

cylinder that will release the contained gas in specific emergency conditions. Excessive

temperature, excessive internal pressure or both may activate the device depending on the

PRD design. Thermally activated pressure relief devices are required in all installations.

Resin: Epoxy material in the composite overwrap filling the space and transfers the load

between individual reinforcing fibers.

Severe duty: Vehicle application characterized by operation on extremely poor roads or off-

roads/highways, frequent short-distance or stop and go travel, such as refuse vehicles or transit

buses, construction site operation. See normal duty.

Solenoid valve: A valve which is turned on or off electrically.

Tank: Usually refers to liquefied natural gas (LNG) storage vessels. For compressed natural

gas (CNG), use the term “cylinder.”

TUFFSHELL®: Agility Fuel Solutions registered trademark for hybrid Type 4 cylinders. Includes

protective features such as foam inserts on the ends and a glass overwrap to absorb impact

and abrasion damage.

TUFFSHELL® ACF: Agility Fuel Solutions registered trademark for all-Carbon Fiber reinforced

in an epoxy resin. The all-carbon fiber cylinders may or may not have an external coating

(paint).

Vent line: A high-pressure line used to conduct gas away from a pressure relief device to a

location outside of the vehicle.

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 32 of 33

10. Natural Gas Vehicle Cylinder Inspection Record

Inspector Name

Inspection Date

Serial No.

Model No.

Expiration Date

Mounting Location

Vehicle Identification Number (VIN)

Vehicle Mileage

Examination Comments

Accept Reject

Features (Include damage level if applicable)

Cylinder and

brackets cleaned

prior to inspection

Cylinder

installation

1/2-in. (12.7mm)

clearance around

cylinder when

mounted

Cylinder bracket

and mounting

condition

Mounting

pads/isolators in

good condition

Labels in place

Cylinders not

expired

Cylinder service

pressure meets or

exceeds vehicle

service pressure

Valve condition

PRD condition

Plug condition

Fuel lines secure

Vent lines secure

Vent lines free of

debris or moisture

Interfaces free of

leaks

Cylinder condition

Cylinder dome with

valve condition

Cylinder dome no

valve condition

ENP-558 Rev. F (Downloaded Copy is Not Controlled) 33 of 33

Das könnte Ihnen auch gefallen

- Spanish Standard: UNE-EN 12245:2009+A1Dokument54 SeitenSpanish Standard: UNE-EN 12245:2009+A1Pablo Alcázar100% (1)

- Iso TR 11364-2012-12Dokument34 SeitenIso TR 11364-2012-12DanielVegaNeira100% (1)

- Pfi Es-48Dokument7 SeitenPfi Es-48Ecruz Cruz LNoch keine Bewertungen

- D.09 - Vehicle Entry Permit FormDokument1 SeiteD.09 - Vehicle Entry Permit FormBenedito Cossa FelicianoNoch keine Bewertungen

- Iecex Ine 13.0078XDokument11 SeitenIecex Ine 13.0078XFrancesco_CNoch keine Bewertungen

- Written Schemes of Examinations Example Template - Course DownloadDokument9 SeitenWritten Schemes of Examinations Example Template - Course Downloadgamil2Noch keine Bewertungen

- TUVME Profile 05 2014Dokument142 SeitenTUVME Profile 05 2014Илгар НахматовNoch keine Bewertungen

- Maintenance InstructionDokument134 SeitenMaintenance Instructionrknaidu100% (3)

- BA 4722 Marketing Strategy SyllabusDokument6 SeitenBA 4722 Marketing Strategy SyllabusSri GunawanNoch keine Bewertungen

- Roland Fantom s88Dokument51 SeitenRoland Fantom s88harryoliff2672100% (1)

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingDokument14 SeitenMobile Offshore Drilling Units 2008: Rules For Building and ClassingmfazioliNoch keine Bewertungen

- ASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsDokument31 SeitenASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsSamsudin AhmadNoch keine Bewertungen

- Dot - 3A (Hse) : Specification For Seamless SteelDokument17 SeitenDot - 3A (Hse) : Specification For Seamless SteelantonironiNoch keine Bewertungen

- 13480-5 - 2017 - EN-Inspection and TestingDokument34 Seiten13480-5 - 2017 - EN-Inspection and TestingPaulo VidasinhaNoch keine Bewertungen

- OTS60PBDokument4 SeitenOTS60PBLiza Taguines VillegasNoch keine Bewertungen

- Hydrostatic Test 3.1Dokument1 SeiteHydrostatic Test 3.1yogitatanavadeNoch keine Bewertungen

- Tank Lorry Safety & Security Check-Step 1Dokument3 SeitenTank Lorry Safety & Security Check-Step 1fawad haider100% (1)

- THIELE Grade80 A5 EnglishDokument52 SeitenTHIELE Grade80 A5 EnglishalpNoch keine Bewertungen

- (Other Than Fast Rescue Boats) Refresher Training 1/2 Day Route 1Dokument4 Seiten(Other Than Fast Rescue Boats) Refresher Training 1/2 Day Route 1Bright OkunkpolorNoch keine Bewertungen

- CNG Cylinders Type I: Material & ProductionDokument16 SeitenCNG Cylinders Type I: Material & Productionawrche020676100% (2)

- Iso 1005-9Dokument12 SeitenIso 1005-9jayalakshmivinothNoch keine Bewertungen

- Method of Statement PDFDokument7 SeitenMethod of Statement PDFSakib AyubNoch keine Bewertungen

- En 10204Dokument9 SeitenEn 10204Uthayan SPNoch keine Bewertungen

- PT - Aditya Tangguh Perkasa: Flare Stack Inspection & Test Plan (Itp)Dokument3 SeitenPT - Aditya Tangguh Perkasa: Flare Stack Inspection & Test Plan (Itp)lailatul kodriNoch keine Bewertungen

- Iso 14692 4 2017Dokument15 SeitenIso 14692 4 2017Mayara AlvesNoch keine Bewertungen

- G8s-5034-02-Bubble Leak TestDokument4 SeitenG8s-5034-02-Bubble Leak TestmaheshNoch keine Bewertungen

- D3230 19 PDFDokument7 SeitenD3230 19 PDFalexanderNoch keine Bewertungen

- Pds Hempel's Urethane 5595u En-UsDokument2 SeitenPds Hempel's Urethane 5595u En-UsFreddy Carl FredricksenNoch keine Bewertungen

- (En) SHC107-84 PART B (Ver.7.3)Dokument8 Seiten(En) SHC107-84 PART B (Ver.7.3)Minh BảoNoch keine Bewertungen

- Report of Ultrasonic Flaw Detection Test of Weld JointDokument1 SeiteReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- ASTM D6392-12 Det The Integrity of Nonreinforced Geomembrane Seams Using Thermo-Fusion MethodsDokument6 SeitenASTM D6392-12 Det The Integrity of Nonreinforced Geomembrane Seams Using Thermo-Fusion MethodsMoeketsi KhubeluNoch keine Bewertungen

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Dokument2 SeitenWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiNoch keine Bewertungen

- NR 26 Safety SignallingDokument6 SeitenNR 26 Safety SignallingMarcia Rezende AntonioNoch keine Bewertungen

- Mordec-Catalogue 2011 MayDokument83 SeitenMordec-Catalogue 2011 Maykiiru88100% (1)

- 800D SeriesDokument3 Seiten800D Seriesvkeie0206Noch keine Bewertungen

- Carbon Arc Cutting PDFDokument44 SeitenCarbon Arc Cutting PDFMark InnesNoch keine Bewertungen

- NDT Training Syllabus PDFDokument8 SeitenNDT Training Syllabus PDFNkwor AndersonNoch keine Bewertungen

- Techsonic EZ III Rev 4 092010 PDFDokument70 SeitenTechsonic EZ III Rev 4 092010 PDFandresgomez10Noch keine Bewertungen

- Is 8451Dokument30 SeitenIs 8451Ramakrishnan AmbiSubbiahNoch keine Bewertungen

- Interseal 670HDokument2 SeitenInterseal 670Hmadmax_mfpNoch keine Bewertungen

- ASME V Art 27 LT PDFDokument12 SeitenASME V Art 27 LT PDFAgniva DuttaNoch keine Bewertungen

- Saep 1102Dokument6 SeitenSaep 1102Francis ReyesNoch keine Bewertungen

- Iso 7800 - 2012Dokument12 SeitenIso 7800 - 2012Institute of Marketing & Training ALGERIANoch keine Bewertungen

- A Comparison of BS en 287 Part 1 and ISO 9606Dokument3 SeitenA Comparison of BS en 287 Part 1 and ISO 9606Joe ClarkeNoch keine Bewertungen

- DBB CatalogueDokument28 SeitenDBB CatalogueHeri SetyantoNoch keine Bewertungen

- Iso 4624 2016Dokument9 SeitenIso 4624 2016Luis CarneroNoch keine Bewertungen

- AIGA 030 - 06 - Storage of Cryogenic Air Gases at Users' PremiseDokument25 SeitenAIGA 030 - 06 - Storage of Cryogenic Air Gases at Users' PremiseseetoyeeNoch keine Bewertungen

- Quality Assurance & Standards in Lifting Equipment Inspection, Examination & TestingDokument21 SeitenQuality Assurance & Standards in Lifting Equipment Inspection, Examination & TestingikponmwonsaNoch keine Bewertungen

- BilcoFlex (R) ENG BrochureDokument20 SeitenBilcoFlex (R) ENG BrochureArseniko ArsNoch keine Bewertungen

- ISO Index Welding Standards - 1Dokument1 SeiteISO Index Welding Standards - 1Waqas WaqasNoch keine Bewertungen

- 002-Method of Statement of Row PreparationDokument11 Seiten002-Method of Statement of Row Preparationahmed08839494Noch keine Bewertungen

- I Safety ProfileDokument6 SeitenI Safety ProfileMohammed Rizwan AhmedNoch keine Bewertungen

- BS 2452 (1954)Dokument30 SeitenBS 2452 (1954)siswou100% (1)

- ABS Rules & Guides PDFDokument6 SeitenABS Rules & Guides PDFJorge Adrian Rojo UbedaNoch keine Bewertungen

- Rupk 78Dokument39 SeitenRupk 78puccio78Noch keine Bewertungen

- Vc-Api 650 PDFDokument6 SeitenVc-Api 650 PDFShinta ShowiantariNoch keine Bewertungen

- Traffic Collision and Vehicle Fire ResponseDokument5 SeitenTraffic Collision and Vehicle Fire ResponseepraetorianNoch keine Bewertungen

- Fuel Handlers Study GuideDokument27 SeitenFuel Handlers Study Guidekamaleshaiah100% (6)

- Vehicle Extrication OperationsDokument6 SeitenVehicle Extrication OperationsepraetorianNoch keine Bewertungen

- Rover 75 Owners ManualDokument293 SeitenRover 75 Owners ManualYarg Nitram100% (2)

- 05Dokument17 Seiten05Andreas StathatosNoch keine Bewertungen

- RevlonDokument13 SeitenRevlonSarosh AtaNoch keine Bewertungen

- Heirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseDokument2 SeitenHeirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseAlvin Dela CruzNoch keine Bewertungen

- Arithmetic-Progressions - MDDokument8 SeitenArithmetic-Progressions - MDJay Jay GwizaNoch keine Bewertungen

- Functions PW DPPDokument4 SeitenFunctions PW DPPDebmalyaNoch keine Bewertungen

- Carpentry Grade 8 Week 1 2Dokument20 SeitenCarpentry Grade 8 Week 1 2SANTIAGO ALVISNoch keine Bewertungen

- Cosmic Handbook PreviewDokument9 SeitenCosmic Handbook PreviewnkjkjkjNoch keine Bewertungen

- EDB Postgres Failover Manager Guide v2.1Dokument86 SeitenEDB Postgres Failover Manager Guide v2.1Anggia MauritianaNoch keine Bewertungen

- Waswere Going To Waswere Supposed ToDokument2 SeitenWaswere Going To Waswere Supposed ToMilena MilacicNoch keine Bewertungen

- Durability of Prestressed Concrete StructuresDokument12 SeitenDurability of Prestressed Concrete StructuresMadura JobsNoch keine Bewertungen

- Case No. Class Action Complaint Jury Trial DemandedDokument43 SeitenCase No. Class Action Complaint Jury Trial DemandedPolygondotcom50% (2)

- Empanelled Hospitals List Updated - 06-12-2022 - 1670482933145Dokument19 SeitenEmpanelled Hospitals List Updated - 06-12-2022 - 1670482933145mechmaster4uNoch keine Bewertungen

- LSL Education Center Final Exam 30 Minutes Full Name - Phone NumberDokument2 SeitenLSL Education Center Final Exam 30 Minutes Full Name - Phone NumberDilzoda Boytumanova.Noch keine Bewertungen

- Current Surgical Therapy 13th EditionDokument61 SeitenCurrent Surgical Therapy 13th Editiongreg.vasquez490100% (41)

- Tourbier Renewal NoticeDokument5 SeitenTourbier Renewal NoticeCristina Marie DongalloNoch keine Bewertungen

- Shaker ScreenDokument2 SeitenShaker ScreenRiaz EbrahimNoch keine Bewertungen

- Needle BasicsDokument31 SeitenNeedle BasicsARYAN RATHORENoch keine Bewertungen

- Gmail - ICICI BANK I PROCESS HIRING FOR BACKEND - OPERATION PDFDokument2 SeitenGmail - ICICI BANK I PROCESS HIRING FOR BACKEND - OPERATION PDFDeepankar ChoudhuryNoch keine Bewertungen

- Atom SDDokument5 SeitenAtom SDatomsa shiferaNoch keine Bewertungen

- DLI Watchman®: Vibration Screening Tool BenefitsDokument2 SeitenDLI Watchman®: Vibration Screening Tool Benefitssinner86Noch keine Bewertungen

- Generator ControllerDokument21 SeitenGenerator ControllerBrianHazeNoch keine Bewertungen

- SRS Document Battle Royale Origins - V2Dokument36 SeitenSRS Document Battle Royale Origins - V2Talha SajjadNoch keine Bewertungen

- 2001 Ford F150 ManualDokument296 Seiten2001 Ford F150 Manualerjenkins1100% (2)

- D. Das and S. Doniach - Existence of A Bose Metal at T 0Dokument15 SeitenD. Das and S. Doniach - Existence of A Bose Metal at T 0ImaxSWNoch keine Bewertungen

- Universal and Commercial Banks in The PhilippinesDokument1 SeiteUniversal and Commercial Banks in The Philippinesjohngo888Noch keine Bewertungen

- Switching Lab-05b Configuring InterVLAN RoutingDokument2 SeitenSwitching Lab-05b Configuring InterVLAN RoutingHernan E. SalvatoriNoch keine Bewertungen

- Lotus Exige Technical InformationDokument2 SeitenLotus Exige Technical InformationDave LeyNoch keine Bewertungen

- Thermodynamic c106Dokument120 SeitenThermodynamic c106Драгослав БјелицаNoch keine Bewertungen

- ProbDokument10 SeitenProbKashif JawaidNoch keine Bewertungen