Beruflich Dokumente

Kultur Dokumente

IMECE2018-86589: General Correlation For Heat Transfer During Two-Component Gas-Liquid Flow in Horizontal Pipes

Hochgeladen von

mostafa shahrabiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

IMECE2018-86589: General Correlation For Heat Transfer During Two-Component Gas-Liquid Flow in Horizontal Pipes

Hochgeladen von

mostafa shahrabiCopyright:

Verfügbare Formate

Proceedings of the ASME 2018

International Mechanical Engineering Congress and Exposition

IMECE2018

November 9-15, 2018, Pittsburgh, PA, USA

IMECE2018-86589

GENERAL CORRELATION FOR HEAT TRANSFER DURING TWO-COMPONENT

GAS-LIQUID FLOW IN HORIZONTAL PIPES

Mirza M. Shah

Engineering Research Associates

10 Dahlia Lane, Redding, CT 06896, USA

Mshah.erc@gmail.com

ABSTRACT which covered a wider range of parameters. Some modifications

Heat transfer to two-component gas-liquid mixtures is were made to improve agreement with data. The final correlation

needed in many industries but there is lack of a well-verified had mean absolute deviation of 19.2 % with 946 data points from

predictive method. A correlation is presented for heat transfer 18 studies covering a very wide range of parameters.

during flow of gas-liquid non-boiling mixtures in horizontal In the following, previous research by others is discussed, the

tubes. It has been verified with a wide range of data that includes: development of the new correlation is described, comparison of

tube diameters 4.3 to 57 mm, pressures from 1 to 4.1 bar, the present and other correlations with data is presented, and the

temperatures from 12 to 62 oC, gravity < 0.1 % to 100 % earth results are discussed.

gravity, liquid Reynolds number from 9 to 1.2E5, and ratio of gas

and liquid velocities from 0.24 to 9298. The 946 data points from .NOMENCLATURE

18 sources are predicted with mean absolute deviation of 19.2 %.

The same data were compared to several other correlations; they AVD Average deviation, defined by Eq. (17), (-)

had much larger deviations. D Inside diameter of tube, m

Ffp Flow pattern factor in present correlation, (-)

1. INTRODUCTION

Heat transfer to mixtures of permanent gases with liquid Fg Correction factor for effect of gravity, (-)

flowing in tubes/pipes is frequently encountered in petroleum, Fp Flow pattern factor, (-)

nuclear power, chemical, food, and pharmaceutical industries. FrL Liquid Froude number, = uLS2(ge D)-1, (-)

Injection of gas into liquid is also used for enhancing heat G Mass flux, kg m-2s-1

transfer. Due to its practical importance, many experimental g Acceleration due to gravity, m s-2

studies on such heat transfer have been done and many predictive

ge Acceleration due to gravity at earth, m s-2

techniques theoretical and empirical have been proposed. The

present author, Shah [1] had given general correlations for heat h Heat transfer coefficient, W m-2 oC-1

transfer in both horizontal and vertical tubes. This paper is hL Heat transfer coefficient of liquid phase, W m-2 oC-1

concerned only with horizontal tubes. Several researchers have hLS Heat transfer coefficient assuming liquid phase

reported good agreement of this correlation with their test data. flowing alone in the tube, Wm-2 oC-1

The correlation is in graphical form which makes it difficult to hTP Two-phase heat transfer coefficient, W m-2 oC-1

use it for computerized calculations. The author therefore

k Thermal conductivity, W m-1 oC-1

decided to convert it to equation form and to verify/improve it

by comparison with additional data. L Length of tube, m

The graphical correlation for horizontal tubes was converted MAD Mean absolute deviation, defined by Eq. (16), (-)

to equation form and then compared to the original database as N Number of data points

well as additional data for macro channels (diameter > 3 mm) P Pressure of mixture, bar

1 Copyright © 2018 ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 02/22/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Pr Prandtl number, (-) Koviri et al. [13] in a 12.5 mm ID tube. Measurements on larger

RL Liquid holdup = (1 – α), (-) tubes from 50 to 57 mm ID have been done by Noville and

Bannawart [14], Ruppert [6], and Deshpande et al. [15]. Most of

ReGS Reynolds number of gas flowing alone in tube, =

these studies include observation of flow patterns. Special

GGDμG-1, (-)

mention may be made of the study by Witte et al. [16] which was

ReLS Reynolds number assuming liquid phase flowing done at gravity level less than 0.1 % of earth gravity. Note that

alone, = GLDμL-1 , (-) boiling did not occur in any of these studies though evaporation

ReL Reynolds number of liquid at in-situ velocity, of water into air occurred in tests with air-water mixtures.

defined by Eq. (9), (-) The experimental studies generally show that at a fixed liquid

S Fraction of surface of tube in contact with liquid, (-) flow rate, heat transfer coefficient increases with increasing gas

T Temperature of mixture, oC flow rate, reaches a maximum, and then falls. The increase in

uLS Superficial velocity of liquid phase, ms-1 heat transfer coefficient is due to the increase in liquid velocity

caused by the increase of void fraction with increasing gas flow.

uGS Superficial velocity of gas phase, ms-1

The decrease following a maximum is attributable to partial or

ur Ratio of superficial velocities of gas and liquid, full dryout of the tube surface caused by the tearing away of

defined by Eq. (11), (-) liquid film by gas shear and effect of gravity which pushes the

ur,tr Value of ur at transition, (-) liquid (being heavier than vapor) towards the bottom of tube.

ured Reduced velocity, defined by Eq. (10), (-)

W Mass flow rate, kg s-1 2.2 Predictive Techniques

WeG Weber number, = GG2 D ρG-1 σ-1, (-) Many predictive techniques, empirical and analytical, have

been proposed. Many of these are exclusively for slug flow.

x Quality, WG . (WG + WL)-1, (-) Examples are Franca et al. [8], Deshpande et al. [15], and

Greek Shoham et al. [17]. Kim and Ghajar [18] presented correlations

α Void fraction (-) specific to each flow pattern with flow patterns identified by their

μ Dynamic viscosity, Pa. s own correlation. The problem in using such correlations is that

ρ Density, kg m-3 accurate prediction of flow patterns is difficult. The definitions

of flow patterns vary considerably and large differences are often

ΦL = (Mixture pressure drop/liquid pressure drop) 0.5, (-)

seen between the predictions of various flow pattern maps. For

Ψ = hTP . hLS-1 , (-) example, Kim [12] found large differences between his own flow

Subscripts pattern observation and the predictions of the Taitel and Dukler

L liquid [19] map. Correlations applicable to all flow patterns are

G gas discussed in the following.

tr at transition Some correlations which have been applied to heat transfer

in horizontal tubes are listed in Table 1.

w at wall temperature

In the Kim and Ghajar correlation, void fraction is obtained

by the Chisolm [24] correlation which is:

2. PREVIOUS WORK

−1

𝜌𝐿 0.5 1−𝑥 𝜌

Numerous experimental studies have been done and 𝛼 = [1 + (1 − 𝑥 + ) ( ) ( 𝐺 )] (1)

𝜌𝐺 𝑥 𝜌𝐿

many predictive techniques have been proposed for heat transfer

during flow of two-component gas-liquid mixtures in horizontal

tubes. These are briefly discussed in the following. In the Tang and Ghajar correlation, void fraction is calculated by

the Woldesemayat and Ghajar [25] correlation. In these two

2.1 Experimental Studies correlations, hL is calculated for liquid flowing at the in-situ

There have been numerous studies on mini channels (D ≤ 3 velocity with Reynolds number defined as:

mm) in recent years. Those are not discussed here as this paper 4𝑊𝐿

is exclusively for macro size tubes. Further, orientations other 𝑅𝑒𝐿 = (2)

𝜋(1−𝛼)0.5 𝜇𝐿𝐷

than horizontal are excluded.

Pioneering experimental studies on horizontal tubes include In the correlations listed in Table 1, transition from laminar to

those by Johnson and Abousabe [2], King [3], Fried [4], Pletcher turbulent flow is specified to occur when ReL or ReLS exceeds

and MacMannus [5], Ruppert [6], and Oliver and Wright [7]. 2100; hL and hLS are calculated using single phase heat transfer

Among other experimental studies are those of Franca et al. [8], equations appropriate for the regime.

Vaze and Bannerji [9], Nada [10], and Wang et al. [11]. Many Vaze & Bannerji [9] and Nada [10] have given correlations

experimental studies on air-water mixtures have been done at the that agree with their own data which have very limited ranges.

Oklahoma State University in horizontal as well as many other The present author, Shah [1], gave the following correlation

inclinations. Examples are Kim [12] in a 27.7 mm ID tube and for horizontal tubes:

2 Copyright © 2018 ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 02/22/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

For ReL < 170, Further, for 28 < D < 50 mm, Ffp =1 for annular flow but is

unknown for other flow patterns.

ℎ 𝑇𝑃 = ℎ𝐿𝑆 (1 + 𝑢𝐺𝑆 ⁄𝑢𝐿𝑆 )0.25 (3) As the flow pattern factor Ffp was developed using the map of

Mandhane et al. and as definitions of flow patterns used and their

For ReLS > 170, the correlation is presented in the form of a predictions by other correlations may be different, only the

graph. It has the following functional form: Mandhane et al. correlation (version without fluid properties) is

to be used.

Ψ = ℎ 𝑇𝑃 ⁄ℎ𝐿𝑆 = 𝑓𝑢𝑛𝑐𝑡𝑖𝑜𝑛(𝑢𝐺𝑆 ⁄𝑢𝐿𝑆 , 𝐹𝑟𝐿 ) (4)

The gravity correction factor Fg = 1 except for annular flow

At any particular Froude number FrL, ψ increases with increasing where it is given by:

velocity ratio till a transition velocity ratio ur,tran is reached. At

velocity ratios higher than ur,tran , ψ decreases. Shah [1] verified 𝐹𝑔 = 1 + 0.5 (1 −

𝑔

) (13)

𝑔𝑒

this correlation with data from seven sources which included a

wide range of parameters. Good agreement of this correlation

with their own data has been reported by Wang et al. [11] for air- The flow pattern is to be determined by a map suitable for the

water and air-oil in a 26 mm diameter tube, and Noville & actual gravitational acceleration g.

Bannawart [14] for air-water in a 50 mm diameter tube. The single phase heat transfer coefficient for liquid hLS is

Some researchers have presented numerical simulation calculated by the following relations.

models for prediction of heat transfer. For example, Perea et al.

[26] developed a numerical model for heat transfer during slug ReLS < 170,

flow in horizontal tubes. They compared it to the data of Lima

[27] for air-water flow in a 52 mm diameter tube. Their model ℎ𝐿𝑆 = 1.86(𝑅𝑒𝐿𝑆 𝑃𝑟𝐿 𝐷/𝐿)1/3 (𝜇𝐿 ⁄𝜇𝑤 )0.14 𝑘𝐿 /𝐷 (14)

predicted the data within ±30%. The predictions of the Shah

correlation were within 15 % of the model predictions. No ReLS ≥ 170,

numerical model has been verified with a wide range of test data.

ℎ𝐿𝑆 = 0.023𝑅𝑒𝐿𝑆 0.8 𝑃𝑟𝐿 0.4 𝑘𝐿 /𝐷 (15)

3. THE NEW CORRELATION

The new correlation is as given below. Eq. (14) is the correlation of Sieder and Tate [30]. Eq. (15) is the

For ReLS < 170, all flow patterns, correlation of Dittus and Boelter [31].

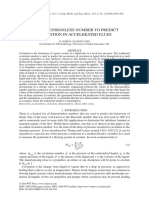

Figure 1 shows the correlation as given by the above

ℎ 𝑇𝑃 = ℎ𝐿𝑆 (1 + 𝑢𝐺𝑆 ⁄𝑢𝐿𝑆 )0.25 (5) equations for ReLS > 170 at earth gravity with Ffp =1

For ReLS ≥ 170, when ur ≤ ur,tr , 3.1 Development of the New correlation

Development of the new correlation is now briefly described.

(414+89.4𝑢𝑟0.49 ) Equations were fitted to the graphical correlation in [1]. These

Ψ = 𝐹𝑓𝑝 𝐹𝑔 (365+𝑢𝑟 0.49 )

(6) equations were then compared to the original database as well as

new data. The maximum diameter in the original data base was

For ReLS ≥ 170, when ur > ur,tr 25.4 mm. The new data included diameters up to 57 mm. The

data for the larger tubes showed influence of flow patterns as

Ψ = 𝐹𝑓𝑝 𝐹𝑔 Ψ𝑡𝑟 (1+0.15𝑢

(0.97+0.22𝑢𝑟𝑒𝑑 )

(7) determined by the map of Mandhane et al. [28]. This led to the

2

𝑟𝑒𝑑 +0.038𝑢𝑟𝑒𝑑 ) factor Ffp.

. Witte et al. [16] performed tests during parabolic flights in

𝑢𝑟,𝑡𝑟 = 58⁄𝐹𝑟𝐿 0.61 (8) aircraft with gravity less than 0.1 % of earth gravity. The paper

by Fore et al. [29] is also based on the same data. For all data

(414+89.4𝑢𝑟,𝑡𝑟 0.49 ) flow pattern observed by them was either annular or slug. When

Ψ𝑡𝑟 = (9)

(365+𝑢𝑟,𝑡𝑟 0.49 )

these data were compared to the present correlation without Fg,

it was found that all the data for slug flow were in satisfactory

𝑢𝑟𝑒𝑑 = 𝑢𝑟 ⁄𝑢𝑟,𝑡𝑟 (10) agreement but the data for annular flow were greatly

underpredicted. Most of these annular flow data were predicted

𝑢𝑟 = 𝑢𝐺𝑆 ⁄𝑢𝐿𝑆 (11) to be in the slug or wave flow regimes by the Mandhane et al.

map which is based on data at earth gravity. Thus the higher heat

The flow pattern factor Ffp = 1 except as follows: transfer coefficients at low gravity appear to be due to the change

For D ≥ 50 mm when flow pattern is stratified, slug, or wave, in flow pattern. In wave and slug flow, part or all of the tube

surface is in contact with gas which has low thermal conductivity

Ffp = 0.5 (12) while in annular flow, all the surface of the tube is in contact with

3 Copyright © 2018 ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 02/22/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

liquid which has high thermal conductivity. This results in heat Otherwise various other sources were used. Flow patterns used

transfer coefficient being higher with annular flow at low gravity for analyzing the data of Witte et al. [16] were as listed in their

data tables. They have given a flow pattern map based on Weber

number. For all their annular flow pattern data, WeG was greater

than 6. In fact for all except a few data point, We G was greater

than 10 for annular data points.

0.001

10

4.4 Results of Data Analysis

The results of data analysis are listed in Table 3. The

deviations listed therein are defined below.

ψ = hTP/hLS

0.01

Mean absolute deviation (MAD) is given by:

0.1

ABS ((h − hmeasured ) / hmeasured )

N

1

1 MAD = predicted

10 N 1 (16)

FrL = 100

1

0.1 1 10

uGS/uLS

100 1000 10000 Average deviation (AVD) of a data set is defined as:

((h − hmeasured ) / hmeasured )

N

Figure 1: The new correlation for Re LS > 170 1 (17)

AVD = predicted

N 1

when comparable flow rates at earth gravity produce slug or

wave flow. It is seen that the MAD of the present correlation with all 911

No other heat transfer data for horizontal tubes at low gravity data points is 19.7 % while the MAD of other correlations varies

were found. As the body force which produces flow asymmetry from 26.1 % to 95.1 %. Hence the present correlation is

decreases linearly with gravity, it was decided to assume a linear considerably more accurate than other correlations.

increase in heat transfer with decreasing gravity. The correction

factor for gravity Fg was developed accordingly. 5 DISCUSSION

.

4. DATA ANALYSIS 5.1 Accuracy of the Present and Other Correlation

In addition to the data analyzed in Shah [1], more data were

obtained through literature search. The complete range of data As seen in Table 3, the MAD of the present correlation is 19.7

analyzed is given in Table 2. So that the performance of the % for the 911 data points from 18 sources. These cover a very

present correlation be viewed in perspective, some other wide range of parameters that includes tube diameters 4.3 to 57

correlations were evaluated together with the present correlation. mm, pressures from 0.48 to 4.1 bar, temperatures from 12 to 62

All the correlations listed in Table 1 were evaluated. Another o

C, gravity < 0.1 to 1 g, ReLS from 9 to 1.2E5, ReGS 6 to 4.7E5,

correlation evaluated is a modified form of the Shah [1] and uGS/uLS from 0.24 to 9298.

correlation in which its formula for Re LS < 170, Eq. (5), is also The correlation with the next lowest deviation is the modified

used at higher Reynolds number with hLS calculated with Shah correlation with MAD of 26.7 %. The MAD of other

turbulent heat transfer correlation. This modified Shah correlations varies from 33.2 to 92.8 %. These correlations show

correlation was compared by several authors to a wide range of good agreement with some data sets but large deviations with

data with good results. These authors include Koviri et al. [13], other data sets. Hence none of these can be considered suitable

Kim and Ghajar [18], Hossainy [33], and Kalapatapu [34]. for general use.

For several data sets, pressure and/or temperature were not

explicitly stated in the papers. In such cases, these were 5.2 Recommendations for Use

estimated from related information such as test setup description, The present correlation can be used with confidence for macro

given values of parameters such as Prandtl number, etc. In tubes up to 28 mm diameter at earth gravity as there were 14 data

calculations with the correlations of Johnson & Abousabe and sets in this range. There were only three data sets for larger

Kaminsky, void fraction was calculated by the Chisolm diameters; these were in the range 50 to 57 mm. Hence it has to

correlation, Eq. (1), and ΦL was calculated with the Lockhart be used cautiously for diameters greater than 28 mm. Extreme

Martinelli [35] correlation. Properties of gases and water were caution is needed for use at low gravity conditions as the data for

calculated with REFPROP 9.1, Lemmon et al. [36] except as low gravity analyzed were only from one source.

noted in the following. Properties of glycerol solution were taken To what extent this correlation can be used for mini channels

from Vargaftik [37]. If properties of other liquids were given in (D ≤ 3 mm) is unknown. The limit of applicability needs to be

the papers from which the test data were taken, they were used.

4 Copyright © 2018 ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 02/22/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

determined through data analysis. Until this limit is known, this [9] Vaze, M.J., and Banerjee, J. “A Modified Heat Transfer

correlation should not be used for minichannels. Correlation for Two-Phase Flow,” J. Heat Mass Transfer, Vol. 47

(2011): pp. 1159- 1165.

6. CONCLUSIONS [10] Nada, S. A. “Experimental Investigation and Empirical

1. A correlation has been presented which shows good Correlations of Heat Transfer in Different Regimes of Air–Water

agreement with a wide range of data for heat transfer to Two-Phase Flow in a Horizontal Tube,” J. Thermal Science and

permanent gas-liquid mixtures flowing in horizontal tubes. The Engineering Applications, Vol. 9 (2017): pp. 021004-1 to

data include tube diameters from 4.3 mm to 57 mm and a very 021004-9.

wide range of flow rates, gas and liquid Reynolds number, [11] Wang, X., Wang, Z., Zhang, X., and Limin, H. E. “Heat

pressures, temperatures, and extremely low gravity to normal Transfer of Oil-Gas Slug Flow in Horizontal Pipe,” CISE

gravity. The MAD for 946 data points from 18 studies is 19.2 %. Journal, Vol. 68, No. 6 (2017): pp. 2306-2314.

2. The same database was also compared to six other [12] Kim, D. “An Experimental and Empirical Investigation of

correlations. Their MAD ranged from 26.7 % to 92.8 %. Hence Convective Heat Transfer for Gas–Liquid Two-Phase Flow In

the present correlation is much more reliable than others. Vertical and Horizontal Pipes, Ph.D. Thesis, School of

3. Further verification with data for tubes of large diameters is Mechanics and Aerospace Engineering, Oklahoma State

desirable as the amount of such data was limited. It is also University, Stillwater, OK (2000).

desirable to compare it with data for small diameter tubes in the [13] Koviri, R. N. K., Bhagwat, S. M., and Ghajar, A. J. “Heat

mini range to find its limit of applicability. Transfer Measurements and Correlations Assessment for

4. Comparison with additional data at very low gravity is Upward Inclined Gas-Liquid Two Phase Flow,” Proceedings of

needed. Such data for horizontal tubes is presently not available. the 1st Thermal and Fluid Engineering Summer Conference,

TFESC, August 9-12 (2015), New York City, NY.

FUNDING [14] Noville, I., and Bannwart, A. C. “Experimental Study of

This work did not receive any funding from any source. Heat Transfer in Horizontal Gas-Liquid Intermittent Flow,”

Proc. 14th Int. Heat Transfer Conf., Washington, DC, USA

REFERENCES (2010)..

[15] Deshpande, S., Bishop, A., and Karandikar, B. “Heat

[1] Shah, M.M. “Generalized Prediction of Heat Transfer During Transfer to Air-Water Plug-Slug Flow in Horizontal Pipes,”

Two Component Gas-Liquid Flow in Tubes and Other Industrial & Engineering Chemistry Research, Vol 30, No. 9

Channels,” AIChE Symp. Series, Vol. 77, No. 208 (19810: pp. (1991): pp. 2172- 2180.

40-151. [16] Witte, L. C., Bousman, W. S., and Fore, L. B., 1996,

[2] Johnson, H. A., and Abou-Sabe, A. H. “Heat Transfer and “Studies of Two-Phase Flow Dynamics and Heat Transfer at

Pressure Drop for Turbulent Flow of Air-Water Mixtures In a Reduced Gravity Conditions,” NASA Contractor Report

Horizontal Pipe,” Trans. ASME, Vol. 74 (1952): pp. 977-987. 198459, NASA Lewis Research Center, Cleveland, Ohio (1996).

[3] King, C. D. G. “Heat Transfer and Pressure Drop for an Air- [17] Shoham, 0., Dukler, A. E., and Taitel, Y. 1982, “Heat

Water Mixture Flowing In a 0.737 Inch I.D. Horizontal Tube,” Transfer During Intermittent/Slug Flow in Horizontal Tubes,”

M.S. thesis, University of California, Berkeley, California Ind. Eng. Chem. Fundam., Vol. 21 (1982): pp. 312-319.

(1952).. [18] Kim, D., and Ghajar, A. J. “Heat Transfer Measurements

[4] Fried, L. “Pressure Drop and Heat Transfer for Two-Phase, and Correlations for Air-Water Flow of Different Flow Patterns

Two-Component Flow,” Chem. Eng. Prog. Svmp. Series, Vol. 50, in a Horizontal Pipe,” Experimental Thermal and Fluid Science,

No. 9 (1954): pp. 47 - 51. Vol. 25 (2002): pp. 659–676.

[5] Pletcher, R. H., and McManus, H. N. “Heat Transfer and [19] Taitel, Y. and Dukler, A. E. “A Model for Predicting Flow

Pressure Drop in Horizontal Annular Two-Phase, Two- Regime Transitions in Horizontal and Near Horizontal Gas-

Component Flow,” International Journal of Heat and Mass Liquid Flow,” AIChE Journal, Vol. 22, No. 1 (1976): pp. 47-54.

Transfer, Vol. 11, No. 7 (1968): pp. 1087-1104. [20] Knott, R. F., Anderson, R. N., Acrivos, A., and Petersen, E.

[6] Ruppert, K. A. “Druckverlust und Warmeubergang bei der E., 1959, “An Experimental Study of Heat Transfer to Nitrogen-

Verdampfung in durchstromten glatten und Rauhen Rohren in Oil Mixtures,” Industrial and Engineering Chemistry, Vol. 51,

Gegenwart von Inertgassen,” Dr. Ing. Dissertation, Karlsruhe No. 11 (1959): pp.1369-1372. (Data tables obtained from

University, Germany (1975). National Technical Information Service, Washington, DC.)

[7] Oliver D. R., and Wright, S. J. “Pressure Drop and Heat [21] Kaminsky, R. D. “Estimation of Two-Phase Flow Heat

Transfer in Gas-Liquid Slug Flow in Horizontal Tubes,” British Transfer in Pipes,” J. Energy Resour. Technol, Vol. 121, No. 2

Chemical Engineering, Vol. 9, No. 9 (1964): pp. 590-596. (1999): pp. 75-80.

[8] Franca, F. A., Bannwart, A. C., Ricardo M. T., Camargo, R. [22] Kim, J. and Ghajar, A. “A General Heat Transfer Correlation

M., and Gonçalves, M. A. L. “Mechanistic Modeling of the for Non-Boiling Gas-Liquid Flow with Different Flow Patterns

Convective Heat Transfer Coefficient in Gas-Liquid Intermittent in Horizontal Pipes,” International Journal of Multiphase Flow,

Flows,” Heat Transfer Engineering,” Vol 29, No. 9 (2008): pp. Vol. 32 (2006): pp. 447-465.

984-998.

5 Copyright © 2018 ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 02/22/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

[23] Tang, C. C., and Ghajar, A. J. “Validation of a General Heat Flow,” MS Thesis, Oklahoma State University, School of

Transfer Correlation for Non-Boiling Two-Phase Flow with Mechanics and Aerospace Engineering, Oklahoma State

Different Flow Patterns and Pipe Inclination Angles,” University, Stillwater, OK (2014).

Proceedings of the 2005 ASME-JSME Thermal Engineering [34] Kalapatapu, S. B. “Non-Boiling Heat Transfer in Horizontal

Heat Transfer Conference, Vancouver, Canada, July 8-12 ( and Near Horizontal Upward Inclined Gas-Liquid Two Phase

2007). Quoted in Hossainy [33]. Flow,” MS Thesis, Oklahoma State University, School of

[24] D. Chisholm, 1973, “Void Fraction During Two-Phase Mechanics and Aerospace Engineering, Oklahoma State

Flow,” Journal of Mechanical Engineering Science, Vol. 15 University, Stillwater, OK (2014}.

(1973): pp. 235-236. Quoted in Kim and Ghajar [22]. [35] Lockhart, R. and Martinelli, R. C. “Proposed Correlation of

[25] Woldesemayat, M. A. and Ghajar, A. J. “Comparison of Data for Isothermal Two-Phase, Two-Component Flow In

Void Fraction Correlations for Different Flow Patterns in Pipes,” Chem. Eng. Prog., Vol. 45, No. 1 (1949): pp. 39-48.

Horizontal and Upward Inclined Pipes,” International Journal of [36] Lemmon, E. W., Huber, M. L., and McLinden, M. O. “NIST

Multiphase Flow, Vol. 33 (2007): pp. 347-370. Reference Fluid Thermodynamic and Transport Properties,”

[26] Perea, C. D., Bassani, C. L., Cozin, C., Juquueira, and REFPROP version 9.1, NIST, Gaithersburg, MD (2013).

Morales, R. E. M. “Numerical Simulation of Heat Transfer in [37] Vargaftik, N. B. Tables on the Thermophysical Properties of

Two-Phase Slug Flow Using a Slug Tracking Method, 14th Liquids and Gases, 2nd edition. Hemisphere Publishing,

Brazilian Congress of Thermal Sciences and Engineering, Washington, DC, (1975).

November 18-22 (2012), Rio de Janeiro, RJ, Brazil. [38] Ghajar, A. J. and Tang, C.C. “Heat Transfer Measurements,

[27] Lima, I. N. R. C. “Estudo Experimental da Transferência de Flow Pattern Maps, and Flow Visualization for Non-Boiling

Calor No Escoamento Bifásico Intermitente Horizontal,” MS Two-Phase Flow in Horizontal and Slightly Inclined Pipe,” Heat

Thesis, Universidade Estadual de Campinas, Sau Paulo, Brazil Transfer Engineering, Vol. 28, No. 6 (2007): pp. 525–540,

(2009). Quoted in Perea et al. [26]. [39] Kosorotov, M. A. 1974, “Heat Transfer to Water/Air Flow

[28] Mandhane, J. M., Gregory, G. A., and Aziz, K. “A Flow with Low Air Content,” Teploenergetica, Vol. 21, No. 9 (1974):

Pattern Map for Gas-Liquid Flow in Horizontal Pipes,” pp. 29-31.

International Journal of Multiphase Flow, Vol. 1 (1974): pp. [40] Wright, S. J. PhD Thesis, University of Birmingham, UK

537-553. (1962). Quoted in Oliver and Wright [7]. Data tables from the

[29] Fore, L. B., Witte, L. C., and McQuillen, J. B. “Heat thesis kindly provided by D. R. Oliver.

Transfer to Two-Phase Slug Flows Under Reduced-Gravity [41] Johnson, H. A. “Heat Transfer and Pressure Drop for

Conditions,” Int. J. Multiphase Flow, Vol. 23, No. 2 (1997): pp. Viscous-Turbulent Flow of Oil-Air Mixtures in a Horizontal

301-311. Pipe," ASME Trans., Vol. 77 (1955): pp. 1257-1264.

[30] Sieder, E. N. and Tate, G. E. “Heat Transfer and Pressure [42] Pletcher, R. H. “An Experimental and Analytical Study of

Drop of Liquids In Tubes,” Industrial & Engineering Chemistry, Heat Transfer and Pressure Drop in Horizontal Annular Two-

Vol. 28 (1936): pp.1429-1435. Phase Two-Component Flow,” PhD Thesis, Cornell Univ.,

[31] Dittus, F.W. and Boelter, L.M.K. “Heat Transfer in (1966).

Automobile Radiators of the Tubular Type,” University of [43] Durant, W. B. “Heat Transfer Measurement of Annular Two-

California Publications in Engineering, Vol. 2 (1930): pp. 443- Phase Flow in Horizontal and a Slightly Upward Inclined Tube,”

461. M.S. Thesis, Oklahoma State University, Stillwater, Oklahoma

[32] Nino, E and Ruocco, G. “Experimental Investigation of The (2003).

Heat Exchange to a Compartmentalized Plug

Flow,” International Journal of Thermal Sciences, Vol. 38, No.

11: pp. 955-959.

[33] Hossainy, T. A. “Non-Boiling Heat Transfer in Horizontal

and Near Horizontal Downward Inclined Gas-Liquid Two Phase

6 Copyright © 2018 ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 02/22/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Table 1: Some correlations that have been used for heat transfer in horizontal channels.

Author Correlation Basis

Johnson & Abou- ℎ𝐿𝑆 (1−∝)−0.5 ∅𝐿 0.33 Own air-water data for

Sabe [2] ℎ 𝑇𝑃 = horizontal tube

1 + 0.006𝑅𝑒𝐺𝑆 0.5

Knott et al. [20] ℎ 𝑇𝑃 = ℎ𝐿𝑆 (1 + 𝑢𝐺𝑆 ⁄𝑢𝐿𝑆 )1/3 Own data for nitrogen-oil

in vertical upflow in

tubes, also verified with

horizontal tube data.

Kaminsky [21] For turbulent flow, Data for horizontal and

ℎ 𝑇𝑃 = ℎ𝐿𝑆 ∅𝐿 𝑆 0.5 vertical pipes from

For laminar flow, several sources.

ℎ 𝑇𝑃 = ℎ𝐿𝑆 (2 − 𝑅𝐿 )/𝑅𝐿 2/3

𝑅𝐿 = 𝑆 − 𝑆 𝑙𝑛(2𝜋𝑆)/2𝜋

0.08 1−𝐹 0.39 𝑃𝑟 0.03 0.01

Kim & Ghajar ℎ 𝑇𝑃 = 𝐹𝑃 ℎ𝐿 {1 + 0.82 [(

𝑥

) ( 𝑃

)𝐺

( )

𝜇

( 𝐿) ]} Data for horizontal and

[22] 1−𝑥 𝐹𝑃 𝑃𝑟𝐿 𝜇𝐺 vertical flow from several

sources

Tang & Ghajar ℎ 𝑇𝑃 = 𝐹𝑃 ℎ𝐿 {1 + 0.55 [(

𝑥

)

0.1 1−𝐹 0.4 𝑃𝑟 0.25

( 𝑃

) 𝐺

( )

𝜇

( 𝐿)

0.25

(𝐼)0.25 ]} Data for horizontal and

[23] 1−𝑥 𝐹𝑃 𝑃𝑟𝐿 𝜇𝐺 vertical flow from several

sources

Table 2: Range of data with which the present correlation was verified.

Range

Mixtures Air-water, N2-88% glycerine, air-oil

Tube diameter (L/D) 4.3 to 57.0 (20 to 244)

Heat transfer method Cooling by liquid, heating by liquid/steam/electricity

Mixture pressure, bar 0.48 to 4.1

Mixture temperature, oC 12 to 62

Gravity < 0.1 % earth gravity to earth gravity

ReLS 9 to 1.23E5

ReGS 6 to 4.7E5

FrL 0.0001 to 49

uGS/uLS 0.24 to 9298

Number of sources 18

7 Copyright © 2018 ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 02/22/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Table 3: Comparison of test data with the present and other correlations

Source D, mm Heating Mixtur P T ReLS ReGS FrL uGS/uL N Deviation, %

oC

(L/D) or e Bar S Mean Absolute/Average

Cooling Kim Tang Knot Johns Kami Shah Present

Method & & t et on & nsky Mod.

Ghaja Ghaja al. Abou

r r sabe

Nino & 4.3 Liquid Air + 1 26 857 20 0.87 0.19 7 39.9 47.1 49.8 47.7 36.6 25.1 13.9

Ruocco [32] (46.5) cooled water 1926 4.4 0.42 -39.9 -47.1 -49.8 -47.7 -36.6 -25.1 -11.1

Kosorotov 6 Electric Air- 1 40 1566 6 0.10 0.50 41 25.8 28.5 239.5 27.7 28.3 17.0 13.6

et al. [39] (167) Heat water 1.2 4110 2060 49.2 3.5 -17.8 -28.5 230.6 13.6 -6.9 -5.7 4.5

Wright [40] 6.3 Liquid N2 + 1* 20 14 5290 0.77 0.41 21 25.1 46.0 3.9 3.5 82.4 6.6 6.6

(144) heated 88% 35 51 27100 13.0 8.8 -20.3 -46.0 2.2 2.0 82.4 -6.5 -6.5

Liquid glycerol 10 9 5470 2.2 0.48 9 17.8 24.1 26.3 29.1 138.0 15.6 15.6

cooled 21 35 27300 47 51 6.8 -22.5 26.3 29.1 138.0 15.6 15.6

Kalapatitu 12.5 Electric Air + 1.1* 30* 1874 300 0.12 0.46 27 20.7 30.1 118.3 20.2 24.8 12.5 12.1

[34] (80) heating Water 10642 20000 4.9 197 -20.0 -30.1 109.9 12.2 4.3 -3.2 4.8

Hossainy 12.5 Electric Air + 1.1* 30* 2606 300 0.23 0.56 15 29.9 34.1 38.5 32.1 32.1 22.2 21.0

[33] (110) heating Water 9834 20000 3.2 1142 -27.3 -34.1 29.4 23.2 10.5 4.7 11.0

King [3] 18.7 Stem Air + 1.1 53 25232 1573 2.3 0.48 21 40.0 40.3 29.5 26.5 36.0 23.8 18.4

(256) heated water 3.7 62 1.18E5 2.6E5 49 52 -12.9 -25.6 13.5 -17.6 7.0 5.1 -1.1

Johnson 18.7 Steam Air + 1.02 52 322 1888 0.91 1.1 39 29.6 28.6 421.6 21.3 23.4 25.8 21.2

[41] (244) heated oil 4.1 62 2224 1.2E5 37 127 -5.2 -24.2 418.7 -10.3 -2.3 -19.3 -5.9

Fried [4] 18.7 Steam Air + 1.3 53 17297 3227 1.2 0.29 30 22.6 25.2 20.1 25.6 23.3 14.1 13.3

(256) Heated water 3.7 85 2.96E5 87291 208 88 -5.5 -22.4 8.6 -25.1 4.2 -7.8 -1.3

Johnson & 22.1 Steam Air + 1.08 48 12470 1618 0.49 0.32 24 28.7 28.7 23.4 10.8 25.5 11.2 14.2

Abousabe (216) Heated water 3.7 55 1.23E5 74801 42 101 -12.6 -24.5 22.4 -9.5 13.1 1.5 7.8

[2]

Nada [10] 24.5 Steam Air + 1 50* 3488 1034 0.023 2.1 41 63.3 59.9 20.2 15.4 18.1 13.1 12.4

(40) heated water 15603 15530 0.47 136 -63.3 -59.9 17.0 7.8 0.1 -9.6 -6.2

Pletcher 25.4 Electric Air + 1.1* 19 1726 35809 0.016 72 48 77.0 32.4 389.5 39.7 161.0 38.3 23.4

[42] (60) heated water 38 11402 3.2E5 0.47 3019 70.3 12.3 389.5 36.3 161.0 34.1 21.6

Witte et al. 25.4 Electric Air + 1.0 17 620 297 0.003 0.33 68 52.6 54.6 16.6 23.0 24.9 28.9 14.2

[16] (22) heated water 1.6 38 17874 36818 1.4 183 -50.7 -54.6 -15.5 -22.0 -21.6 -28.7 -7.0

Air + 50 1.04 24 194 643 0.004 0.21 35 57.6 63.4 - 29.8 39.4 34.0 42.0 25.0

% 2.05 31 3520 58112 1.4 716 -55.0 63.4 -29.8 -39.4 -5.7 -42.0 -22.6

glycerol

Ghajar & 26.6 Electric Air + 1.1* 25* 7026 796 0.21 0.49 15 10.8 10.1 89.2 48.2 62.3 53.4 62.8

Tang [38] (99) heated water 26210 39975 2.9 91 5.8 -4.3 89.2 48.2 60.9 53.4 62.8

Ruppert [6] 26.0 Electric Air + 1.01 20 160 9795 0.001 49 99 29.3 44.0 529.7 30.9 244.8 45.8 20.4

(15.4) heat water 1.38 62 13950 5.0E5 0.56 9298 -11.7 -44.0 527.8 11.5 241.6 -7.2 -7.5

8 Copyright © 2018 ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 02/22/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Kim [12] 27.9 Electric Air + 1.04 12 628 527 0.002 0.47 164 23.3 55.1 68.0 25.9 17.7 24.9 23.3

(100) heated water 2.2 34 30714 19200 3.6 196 -14.7 -55.0 57.1 -14.5 -12.5 -20.0 -14.7

Durant [43] 27.9 Electric Air + 1* 25* 2836 27263 0.030 62 30 44.1 48.7 36.6 5.1 36.6 8.6 7.0

(95) heated water 8044 37177 0.25 195 -44.1 -48.7 36.6 -0.6 -36.6 6.0 -1.0

Deshpande 28.0 Electric Air + 1.1* 30* 10889 564 0.35 1 3 13.0 15.2 23.8 23.7 5.8 13.1 26.4

et al. [15] (61) heated water 1791 3 -7.6 -15.2 23.8 23.7 1.6 13.1 26.4

57.0 21247 1144 0.16 1.0 12 21.7 28.8 10.8 11.8 17.7 10.6 7.0

(30) 35504 2861 0.44 3.5 -21.7 -28.8 -0.1 -7.8 -17.7 -8.0 3.5

Ruppert [6] 50.0 Electric Air + 1 14 274 11316 0.0001 49 181 31.7 41.7 353.2 30.7 212.1 34.9 18.8

(12.2) heated water 1.3 20 24907 4.7E5 0.63 9298 -17.0 -41.6 352.3 8.8 211.1 -0.9 9.8

Noville & 50 Liquid Air + 1* 40* 45541 861 0.72 0.24 20 13.1 22.9 16.7 21.8 26.8 17.9 13.9

Bannawart (120) cooled water 1.05E5 2060 4.0 7.2 -3.9 =22.6 -3.6 -21.6 -26.8 -16.5 -1.6

[14]

All sources 4.3 – 57 0.48 12 9 6 0.0001 0.24 946 41.6 45.2 41.2 33.2 92.8 26.7 19.2

(12.2 - 4.1 62 1.23E5 4.7E5 49 9298 -26.0 -42.1 21.1 -2.3 72.4 -9.7 -1.1

244)

*Estimated

9 Copyright © 2018 ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 02/22/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Das könnte Ihnen auch gefallen

- Friction Fatigue and Drivability Analysis of Open Ended Pipe Piles Based On Cone Penetration Testing Results Maghaddam Et Al. 2017Dokument13 SeitenFriction Fatigue and Drivability Analysis of Open Ended Pipe Piles Based On Cone Penetration Testing Results Maghaddam Et Al. 2017nsaifulNoch keine Bewertungen

- 00 Downhole Hydraulic KTC VersionDokument44 Seiten00 Downhole Hydraulic KTC VersionaungwinnaingNoch keine Bewertungen

- Dampers - A Configuration of Seismic Energy Dissipation System For Still StructuresDokument8 SeitenDampers - A Configuration of Seismic Energy Dissipation System For Still Structurespepess2010Noch keine Bewertungen

- Gas Flow HydraulicsDokument22 SeitenGas Flow HydraulicsGary JonesNoch keine Bewertungen

- Module 1 - Atomic StructureDokument19 SeitenModule 1 - Atomic Structureegramfive100% (1)

- UAE Government Approved Laboratories Dubai 24112020 Tcm8 161089Dokument1 SeiteUAE Government Approved Laboratories Dubai 24112020 Tcm8 161089Mohammed IqbalNoch keine Bewertungen

- CE199 2L 1Q1819 HGE 1st Take PDFDokument8 SeitenCE199 2L 1Q1819 HGE 1st Take PDFCristal Haze VictoriaNoch keine Bewertungen

- Effect of Time On Pipe RoughnessDokument11 SeitenEffect of Time On Pipe Roughnessmostafa shahrabiNoch keine Bewertungen

- Effect of Time On Pipe RoughnessDokument11 SeitenEffect of Time On Pipe Roughnessmostafa shahrabiNoch keine Bewertungen

- Effect of Time On Pipe RoughnessDokument11 SeitenEffect of Time On Pipe Roughnessmostafa shahrabiNoch keine Bewertungen

- November2017 Physics Paper 2 HL MarkschemeDokument15 SeitenNovember2017 Physics Paper 2 HL MarkschemeAnanya AggarwalNoch keine Bewertungen

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringVon EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNoch keine Bewertungen

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedVon EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNoch keine Bewertungen

- Model Validation For The Heat Transfer in Gasket Plate Heat Exchangers Working With Vegetable OilsDokument13 SeitenModel Validation For The Heat Transfer in Gasket Plate Heat Exchangers Working With Vegetable OilsCsaba AndrásNoch keine Bewertungen

- Steady-State Gas Flow in Pipes: Petroleum Science & EngineeringDokument22 SeitenSteady-State Gas Flow in Pipes: Petroleum Science & EngineeringnurudinsatharNoch keine Bewertungen

- Shape Optimization of Welded Plate Heat Exchangers Based On GreyDokument9 SeitenShape Optimization of Welded Plate Heat Exchangers Based On GreySandro Chuqui PorteroNoch keine Bewertungen

- 2010 Correlations of 2 Phase Frictional Drop and Void Fraction in Mini Channel - ZhangDokument13 Seiten2010 Correlations of 2 Phase Frictional Drop and Void Fraction in Mini Channel - ZhangBabita GuptaNoch keine Bewertungen

- Comparative AnalysisDokument17 SeitenComparative AnalysisrebolledojfNoch keine Bewertungen

- 2022 CondensationcorrelationDokument21 Seiten2022 CondensationcorrelationZouhir ZEROUALNoch keine Bewertungen

- Applied Thermal Engineering: Derong Duan, Peiqi Ge, Wenbo Bi, Jiadong JiDokument9 SeitenApplied Thermal Engineering: Derong Duan, Peiqi Ge, Wenbo Bi, Jiadong JicesarNoch keine Bewertungen

- Journal of Natural Gas Science and Engineering: Peng Wang, Bo Yu, Dongxu Han, Dongliang Sun, Yue XiangDokument9 SeitenJournal of Natural Gas Science and Engineering: Peng Wang, Bo Yu, Dongxu Han, Dongliang Sun, Yue XiangBakhytzhan AssilbekovNoch keine Bewertungen

- (2018) 1Dokument30 Seiten(2018) 1Christian Hernández RecabarrenNoch keine Bewertungen

- Article in Press: Analytical Methods To Calculate Water Content in Natural GasDokument15 SeitenArticle in Press: Analytical Methods To Calculate Water Content in Natural GasSamuel BatuboNoch keine Bewertungen

- CFD Simulation Analysis of Two-Dimensional Convergent-Divergent NozzleDokument12 SeitenCFD Simulation Analysis of Two-Dimensional Convergent-Divergent NozzlePett PeeveNoch keine Bewertungen

- 1 s2.0 S1359431116326680 Main PDFDokument11 Seiten1 s2.0 S1359431116326680 Main PDFArjunLohanNoch keine Bewertungen

- International Journal of Heat and Mass Transfer: Cheen Su An, Man-Hoe KimDokument6 SeitenInternational Journal of Heat and Mass Transfer: Cheen Su An, Man-Hoe KimnaveenNoch keine Bewertungen

- International Journal of Multiphase FlowDokument12 SeitenInternational Journal of Multiphase FlowakinhaciNoch keine Bewertungen

- Air Side Pressure Drop in Plate Finned Tube Heat Exchangers PDFDokument14 SeitenAir Side Pressure Drop in Plate Finned Tube Heat Exchangers PDFZeroRecoNoch keine Bewertungen

- Cuchau DatosDokument8 SeitenCuchau DatosgénesisNoch keine Bewertungen

- 2021 - Energy - Jouhara - Experimental and Theoretical Investigation of The Performance of An Air To Water Multi-Pass Heat Pipe-Based Heat ExchangerDokument17 Seiten2021 - Energy - Jouhara - Experimental and Theoretical Investigation of The Performance of An Air To Water Multi-Pass Heat Pipe-Based Heat ExchangerJoshep SeoNoch keine Bewertungen

- As 1Dokument17 SeitenAs 1Shanmugam DhinakaranNoch keine Bewertungen

- File ServeDokument18 SeitenFile Serverasyal iyanNoch keine Bewertungen

- 2018 - Hybrid CFD ModelDokument29 Seiten2018 - Hybrid CFD ModelSateesh kumar SNoch keine Bewertungen

- Steady Flow Analysis and Modeling of The Gas Distribution Network Using The Electrical AnalogyDokument8 SeitenSteady Flow Analysis and Modeling of The Gas Distribution Network Using The Electrical AnalogyMedeaNoch keine Bewertungen

- Numerical Analyses of High Reynolds Number Flow of High Pressure Fuel Gas Through Rough PipesDokument12 SeitenNumerical Analyses of High Reynolds Number Flow of High Pressure Fuel Gas Through Rough PipesJorge ManoelNoch keine Bewertungen

- Prediction of Two-Phase Pipe Flows Using Simple Closure Relations in A 2D Two-Fluid ModelDokument13 SeitenPrediction of Two-Phase Pipe Flows Using Simple Closure Relations in A 2D Two-Fluid Modelvivek9199Noch keine Bewertungen

- NASA - Convective Heat Transfer in The Reusable Solid Rocket Motor of The Space Transportation SystemDokument39 SeitenNASA - Convective Heat Transfer in The Reusable Solid Rocket Motor of The Space Transportation SystemUdil BalmogimNoch keine Bewertungen

- A Mechanistic Heat Transfer Correlation For Non-Boiling Two Phase Flow in Horizontal, Inclined and Vertical PipesDokument9 SeitenA Mechanistic Heat Transfer Correlation For Non-Boiling Two Phase Flow in Horizontal, Inclined and Vertical Pipesmostafa shahrabiNoch keine Bewertungen

- Numerical Investigations of The Convective Heat Transfer From Turbulent Flow Over Staggered Tube BankDokument11 SeitenNumerical Investigations of The Convective Heat Transfer From Turbulent Flow Over Staggered Tube BankYasser AlrifaiNoch keine Bewertungen

- Ijtpp 05 00020 v2Dokument32 SeitenIjtpp 05 00020 v2Jean Carlos Jimenez HuillcaNoch keine Bewertungen

- 2010 Comsol DimensionlessDokument9 Seiten2010 Comsol Dimensionlessfernando aguilarNoch keine Bewertungen

- The Effect of Tray Geometry On The Sieve Tray EfficiencyDokument9 SeitenThe Effect of Tray Geometry On The Sieve Tray EfficiencyDr Mohammed AzharNoch keine Bewertungen

- Prediction of Pressure Drop in Vertical Pneumatic ConveyorsDokument9 SeitenPrediction of Pressure Drop in Vertical Pneumatic ConveyorshendrobamaNoch keine Bewertungen

- Horizontal Tube Part 1Dokument10 SeitenHorizontal Tube Part 1Mudhafar MudhafarNoch keine Bewertungen

- Sahar Et Al. - 2017 - Effect of Hydraulic Diameter and Aspect Ratio On SDokument22 SeitenSahar Et Al. - 2017 - Effect of Hydraulic Diameter and Aspect Ratio On Smosab.backkupNoch keine Bewertungen

- Numerical Simulation of Nanofluid Turbulent Flow in A Double Pipe Heat Exchanger Equipped With Circular FinsDokument13 SeitenNumerical Simulation of Nanofluid Turbulent Flow in A Double Pipe Heat Exchanger Equipped With Circular FinsnabeelNoch keine Bewertungen

- Thermal Performance Investigation in A Novel Corrugated Plate Heat ExchangerDokument11 SeitenThermal Performance Investigation in A Novel Corrugated Plate Heat ExchangerFurkan YildirimNoch keine Bewertungen

- International Journal of Thermal Sciences: Katarina Kosutova, Twan Van Hoo FF, Bert BlockenDokument15 SeitenInternational Journal of Thermal Sciences: Katarina Kosutova, Twan Van Hoo FF, Bert BlockenNhat TrieuNoch keine Bewertungen

- Barakos (1994)Dokument25 SeitenBarakos (1994)Diego AlejandroNoch keine Bewertungen

- CFD Analysis of Turbulent Convective Heat Transfer in A Hydro-Generator Rotor-Stator SystemDokument12 SeitenCFD Analysis of Turbulent Convective Heat Transfer in A Hydro-Generator Rotor-Stator SystemMichel DangNoch keine Bewertungen

- Study On Heat Transfer Area of A Plate-Fin Heat Exchanger With Wavy SurfacesDokument15 SeitenStudy On Heat Transfer Area of A Plate-Fin Heat Exchanger With Wavy SurfacesJignesh RohitNoch keine Bewertungen

- Correlations Plate HeDokument13 SeitenCorrelations Plate HemattiturboNoch keine Bewertungen

- Identifying Heat and Mass Transfer Characteristics of Metal Hydride Reactor During Adsorption: Improved Formulation About Parameter AnalysisDokument10 SeitenIdentifying Heat and Mass Transfer Characteristics of Metal Hydride Reactor During Adsorption: Improved Formulation About Parameter AnalysisjehadyamNoch keine Bewertungen

- Zvonimir Jankovi C, Jaime Sieres, Fernando Cerdeira, Branimir Pavkovi CDokument10 SeitenZvonimir Jankovi C, Jaime Sieres, Fernando Cerdeira, Branimir Pavkovi CFrancisco OppsNoch keine Bewertungen

- An Optimization of Heat Transfer of Nanofluid Flow in A Helically Coiled Pipe Using Taguchi MethodDokument14 SeitenAn Optimization of Heat Transfer of Nanofluid Flow in A Helically Coiled Pipe Using Taguchi MethodM. SukarmanNoch keine Bewertungen

- Applied Thermal Engineering: S. Defaee Rad, A. Ashrafizadeh, M. NickaeenDokument12 SeitenApplied Thermal Engineering: S. Defaee Rad, A. Ashrafizadeh, M. NickaeenGuillermo TubillaNoch keine Bewertungen

- International Journal of Heat and Mass Transfer: R. Niroomand, M.H. Saidi, S.K. HannaniDokument22 SeitenInternational Journal of Heat and Mass Transfer: R. Niroomand, M.H. Saidi, S.K. HannaniAYUSH SINGH IET Lucknow StudentNoch keine Bewertungen

- Fully Developed Viscous-Flow Heat Transfer in Curved Circular Uniform Waii TemperatureDokument7 SeitenFully Developed Viscous-Flow Heat Transfer in Curved Circular Uniform Waii TemperatureGustavo Gabriel JimenezNoch keine Bewertungen

- Natural Convection Heat Transfer in Horizonal Cylindrical Cavities (ASME)Dokument4 SeitenNatural Convection Heat Transfer in Horizonal Cylindrical Cavities (ASME)jmpandolfiNoch keine Bewertungen

- Elsharkawy 2001Dokument13 SeitenElsharkawy 2001Mohamad Hasen japerNoch keine Bewertungen

- Application of RELAP5Mod33 - Fluent Coupling CodesDokument16 SeitenApplication of RELAP5Mod33 - Fluent Coupling CodesoscarcanalinNoch keine Bewertungen

- Correlations of Flow Boiling Heat Transfer of R-134a in Minichannels: Comparative StudyDokument16 SeitenCorrelations of Flow Boiling Heat Transfer of R-134a in Minichannels: Comparative StudySamittisak PlaikaewNoch keine Bewertungen

- Predicting HT During Flow Boilng in Mini Channels & Micro ChannelsDokument9 SeitenPredicting HT During Flow Boilng in Mini Channels & Micro ChannelsVivek ShuklaNoch keine Bewertungen

- An Efficient Method To Predict Compressibility Factor of Natural Gas StreamsDokument20 SeitenAn Efficient Method To Predict Compressibility Factor of Natural Gas StreamsJWC Sales & Services :Noch keine Bewertungen

- A New Correlation For Accurate Estimation of Natural Gases Water ContentDokument13 SeitenA New Correlation For Accurate Estimation of Natural Gases Water ContentWilder GanozaNoch keine Bewertungen

- 1 s2.0 S2451904920300032 MainDokument7 Seiten1 s2.0 S2451904920300032 MainABHIJITH K RNoch keine Bewertungen

- International Journal of Heat and Mass Transfer: Omran Abushammala, Rainier Hreiz, Cécile Lemaître, Éric FavreDokument15 SeitenInternational Journal of Heat and Mass Transfer: Omran Abushammala, Rainier Hreiz, Cécile Lemaître, Éric FavreTamires OishiNoch keine Bewertungen

- A Thermodynamic Consistency Test For ExpDokument6 SeitenA Thermodynamic Consistency Test For ExpMohamedNoch keine Bewertungen

- Energies 16 04209Dokument30 SeitenEnergies 16 04209lalluNoch keine Bewertungen

- Numerical Study On Flow and Heat Transfer Characteristics of Trapezoidal Printed Circuit Heat ExchangerDokument16 SeitenNumerical Study On Flow and Heat Transfer Characteristics of Trapezoidal Printed Circuit Heat ExchangerEng Saif MohanadNoch keine Bewertungen

- Example Letter To Send To EmbassyDokument2 SeitenExample Letter To Send To EmbassyEgi Defiska MulyaNoch keine Bewertungen

- A Notice: EZ Setup EZ SetupDokument1 SeiteA Notice: EZ Setup EZ SetupTheomas AbdiNoch keine Bewertungen

- Gas Pipeline Hydraulics: E. Shashi MenonDokument13 SeitenGas Pipeline Hydraulics: E. Shashi Menonmostafa shahrabiNoch keine Bewertungen

- (Paperhub - Ir) 10.1002 9781119083948.ch5Dokument140 Seiten(Paperhub - Ir) 10.1002 9781119083948.ch5mostafa shahrabiNoch keine Bewertungen

- Watson IEC 1943Dokument9 SeitenWatson IEC 1943mostafa shahrabiNoch keine Bewertungen

- New Dimensionless Number To Predict Cavitation in Accelerated FluidDokument9 SeitenNew Dimensionless Number To Predict Cavitation in Accelerated Fluidmostafa shahrabiNoch keine Bewertungen

- Author Manuscript: Reference Correlation For The Viscosity of Ammonia From The Triple Point To 725 K and Up To 50 Mpaa)Dokument27 SeitenAuthor Manuscript: Reference Correlation For The Viscosity of Ammonia From The Triple Point To 725 K and Up To 50 Mpaa)mostafa shahrabiNoch keine Bewertungen

- Visa Interview Questions: Personal InfoDokument5 SeitenVisa Interview Questions: Personal Infomostafa shahrabiNoch keine Bewertungen

- New Dimensionless Number To Predict Cavitation in Accelerated FluidDokument9 SeitenNew Dimensionless Number To Predict Cavitation in Accelerated Fluidmostafa shahrabiNoch keine Bewertungen

- 51 Successful Answers For Visa InterviewDokument4 Seiten51 Successful Answers For Visa Interviewmostafa shahrabiNoch keine Bewertungen

- Orifice Gas Flow Chart PDFDokument1 SeiteOrifice Gas Flow Chart PDFmostafa shahrabiNoch keine Bewertungen

- Viscosity Measurements of Ammonia, R32, and R134a. Vapor Buoyancy and Radial Acceleration in Capillary ViscometersDokument34 SeitenViscosity Measurements of Ammonia, R32, and R134a. Vapor Buoyancy and Radial Acceleration in Capillary Viscometersmostafa shahrabiNoch keine Bewertungen

- Computational Compliance Criteria in Water Hammer Modelling: E3S Web of Conferences September 2017Dokument9 SeitenComputational Compliance Criteria in Water Hammer Modelling: E3S Web of Conferences September 2017mostafa shahrabiNoch keine Bewertungen

- SN19.4-Matthews-Lessons Learned Express Pipeline ProjectDokument12 SeitenSN19.4-Matthews-Lessons Learned Express Pipeline Projectmostafa shahrabiNoch keine Bewertungen

- Solar: MCL CDokument37 SeitenSolar: MCL Cmostafa shahrabiNoch keine Bewertungen

- App 6Dokument2 SeitenApp 6mostafa shahrabiNoch keine Bewertungen

- Adibatic Bulk ModulusDokument2 SeitenAdibatic Bulk ModulusTechie HarryNoch keine Bewertungen

- A022003 Aci PDFDokument12 SeitenA022003 Aci PDFmostafa shahrabiNoch keine Bewertungen

- Eng BD Fta1181Dokument14 SeitenEng BD Fta1181mostafa shahrabiNoch keine Bewertungen

- Compressor Strategy 2012 - FINAL RedactedDokument43 SeitenCompressor Strategy 2012 - FINAL Redactedmostafa shahrabiNoch keine Bewertungen

- (Paperhub Ir) 10 1007@bf02917005Dokument11 Seiten(Paperhub Ir) 10 1007@bf02917005mostafa shahrabiNoch keine Bewertungen

- 10 1 1 678 1140 PDFDokument5 Seiten10 1 1 678 1140 PDFmostafa shahrabiNoch keine Bewertungen

- HidratosDokument6 SeitenHidratosLuis Joel Ramos RamosNoch keine Bewertungen

- Acs Iecr 9b03512Dokument26 SeitenAcs Iecr 9b03512mostafa shahrabiNoch keine Bewertungen

- Gas Hydrate Formation and Dissociation Numerical Modelling With Nitrogen and Carbon DioxideDokument30 SeitenGas Hydrate Formation and Dissociation Numerical Modelling With Nitrogen and Carbon Dioxidemostafa shahrabiNoch keine Bewertungen

- Acs Iecr 9b03512Dokument26 SeitenAcs Iecr 9b03512mostafa shahrabiNoch keine Bewertungen

- MacSTARS 2000 Reference Manual (Eng)Dokument23 SeitenMacSTARS 2000 Reference Manual (Eng)Jefferson Alves Freitas100% (1)

- Structural Mechanics PDFDokument2 SeitenStructural Mechanics PDFJOHN MAKOTONoch keine Bewertungen

- Tugas Kelompok B. InggrisDokument8 SeitenTugas Kelompok B. Inggrisolivia agathaNoch keine Bewertungen

- HW 5Dokument8 SeitenHW 5Anonymous AjrDxGNoch keine Bewertungen

- AC Through An InductorDokument2 SeitenAC Through An InductorLaiqa QamarNoch keine Bewertungen

- Thermo Physical Properties of NanofluidDokument20 SeitenThermo Physical Properties of Nanofluidvishnoi19Noch keine Bewertungen

- Effect of Yaw Angle Misalignment On BrakeDokument20 SeitenEffect of Yaw Angle Misalignment On BrakeakkkkNoch keine Bewertungen

- Concurrent ForcesDokument3 SeitenConcurrent ForcesroythomascNoch keine Bewertungen

- 1.15 The Slider-Crank Chain: Mechanisms and MachinesDokument8 Seiten1.15 The Slider-Crank Chain: Mechanisms and MachinesNAGU2009Noch keine Bewertungen

- FM 3e SI Chap09 LectureDokument111 SeitenFM 3e SI Chap09 LectureRuben SegarNoch keine Bewertungen

- 2-Axis Force Platform Force Platform: Typical ApplicationsDokument1 Seite2-Axis Force Platform Force Platform: Typical ApplicationsAlfian KamilNoch keine Bewertungen

- Phys2 Ch3 Firstlawthermo NewDokument54 SeitenPhys2 Ch3 Firstlawthermo NewQuỳnh NguyễnNoch keine Bewertungen

- Toolox 33, 40 and 44: Engineering & Tool SteelDokument2 SeitenToolox 33, 40 and 44: Engineering & Tool Steel146235Noch keine Bewertungen

- Summative Test 4Dokument13 SeitenSummative Test 4Ginielle Gem Atim BelarminoNoch keine Bewertungen

- Curie-Weiss Law Wiess Theory of ParamagnetismDokument11 SeitenCurie-Weiss Law Wiess Theory of ParamagnetismShashank SharmaNoch keine Bewertungen

- Lecture1# 115Dokument29 SeitenLecture1# 115Ahmed ElkomyNoch keine Bewertungen

- 8th MidDokument21 Seiten8th MidFALAK FATIMANoch keine Bewertungen

- Plastic Hinge Lengths of Normal and High-Strength Concrete in FlexureDokument7 SeitenPlastic Hinge Lengths of Normal and High-Strength Concrete in FlexureNikola JankovicNoch keine Bewertungen

- Turnitin Originality ReportDokument26 SeitenTurnitin Originality Reportrabia.malikNoch keine Bewertungen

- Lab 3 - Basic Trajectory Planning With MatlabDokument10 SeitenLab 3 - Basic Trajectory Planning With MatlabazrarajanNoch keine Bewertungen

- Mechanical Properties of High Strength S690 Steel Welded Sections Through Tensile Tests On Heat-Treated Coupons - ScienceDirectDokument41 SeitenMechanical Properties of High Strength S690 Steel Welded Sections Through Tensile Tests On Heat-Treated Coupons - ScienceDirectEhsan HaratiNoch keine Bewertungen

- FM-II CHP 13 CFDDokument41 SeitenFM-II CHP 13 CFDMALIK MUHAMMAD HAMZA FAROOQ MALIK MUHAMMAD FAROOQNoch keine Bewertungen