Beruflich Dokumente

Kultur Dokumente

House Specification Outline

Hochgeladen von

dante mortelOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

House Specification Outline

Hochgeladen von

dante mortelCopyright:

Verfügbare Formate

TECHNICAL SPECIFICATION

1.0 GENERAL TECHNICAL CONDITIONS

1.1 An actual examination of site shall be made prior to actual construction of the building.

1.2 There must be no discrepancies in the dimensions between the actual measurements of the lot and

those given in the plan.

In case of discrepancies among opinions regarding interpretation of the plans, and indicated

dimensions, the indicated dimensions shall govern and the Project Engineer and Inspector shall be

the final authority.

All necessary permits pertinent to the construction shall be secured and duly approved prior to work.

All works on any phase of construction shall conform to the existing ordinances and law of the

locality.

The owner’s representative duly assigned to inspect the works shall not be barred from entering the

premises and reserves further the right to approved or reject any work pertinent to the plans and

specifications.

All works shall be done by competent workers under an Engineer’s supervision and in strict

conformance with the plans and this specification.

2.0 SITE WORKS AND EXCAVATION:

The work covered this section includes all materials, equipments, labor services and other necessary

provisions for the completion of all earthworks.

All excavation shall be to the depths indicated, reckoned, either from the natural ground line or the

finished grade line, whichever is lower. The indicated depth is the minimum requirement for

excavation.

All excavations shall extend to a sufficient distance from walls and footings to allow for the

installation of service and for inspection.

3.0 CONCRETE AND REINFORCED CONCRETE WORKS:

All concrete mixture shall be ready mixed concrete delivered to the site by the transit mixer, or the

supervising engineer shall approve site mixed concrete.

All foundation slabs, foundation beams, girders, and columns, minimum compressive strength shall

be 3000 psi at 28 days.

Before any concrete slab pouring is to be executed, filling materials shall be alternatively tampered

and wetted sufficiently of the base.

Reinforcing bars shall be deformed bars of structural grade steel.

Coarse aggregates shall be gravel. Sand shall be clean, hard, uncoated, grains, free from deleterious

substance and shall range in size from coarse to fine as approved.

Cement shall be an approved brand of Portland cement or approved equal.

4.0 MASONRY WORKS:

Competent mason or masons shall do masonry works.

Forms shall be wood, hardboard or other approved materials that will not adversely affect the surface

of the concrete and that will produce correctly aligned concrete. Column forms shall be checked

for plumbness before concrete is deposited.

Exterior/interior concrete walls and column finishes shall be plain cement finish unless otherwise

indicated.

All materials to be used shall conform to the following specifications to be used whenever

indicated in the plans or noted in the schedule.

5.0 PLUMBING WORKS:

All materials to be used for all plumbing works shall be of their respective kind and quality.

All plumbing works shall conform to pertinent sanitary regulations and shall be done by a

competent plumber in accordance with the specified location of units shown in the plans.

Upon the completion of all the plumbing works, they shall be tested for any possible leaks or other

defects. It shall be done in the presence of project engineer/ or inspector.

6.0 PAINTING WORKS:

All paints to be shall be well grounded. It shall not settle badly or thicken in containers, shall

show good brushing properties. Standard specification of the Paint Manufacturer of the brand used

shall form part of these specifications.

7.0 ELECTRICAL WORKS:

All wiring connection, outlet, switches, control boxes, etc. shall be new and of best quality. All

wiring shall be concealed and properly insulated. Wiring installation shall be done in accordance

with the existing electrical laws by a duly licensed electrical engineer.

Concealed conduit work shall be installed during the construction of the building, all parts shall be

in place at such stages in the progress of the construction as to permit the cabinets and outlets to

mounted flushed and conduit to round the direct lines possible entirely concealed, use safety

switch ever brand with 60 amperes with 220 volts.

NOTE : NO REVISION SHALL BE MADE WITHOUT PRIOR NOTICE TO THE DESIGN

ENGINEER. ANY REVISIONS SHALL REQUIRE THE INITIAL OF SAID ENGINEER.

-------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------

PROJECT TITLE : PROPOSED BUNGALOW-TYPE RESIDENCE

LOCATION :

OWNER :

-------------------------------------------------------------------------------------------------------------------------------

------------------------------------------

CERTIFIED BY:

Civil Engineer

REG. NO. :

PTR NO. :

TIN NO. :

ISSUED ON :

ISSUED AT :

-------------------------------------------------------------------------------------------------------------------------------

------------------------------------------

Das könnte Ihnen auch gefallen

- Plumbing Technical SpecificationsDokument10 SeitenPlumbing Technical SpecificationsMarilou BasalloNoch keine Bewertungen

- Project: 4 Storey Commercial and Residential Bldg. Subject: SpecificationDokument5 SeitenProject: 4 Storey Commercial and Residential Bldg. Subject: SpecificationKURONoch keine Bewertungen

- Specifications: Project: Owner:: LocationDokument6 SeitenSpecifications: Project: Owner:: LocationMaria Theresa AlarconNoch keine Bewertungen

- Structural Specifications Items General: City Building and Architecture OfficeDokument11 SeitenStructural Specifications Items General: City Building and Architecture OfficeEd AnchetaNoch keine Bewertungen

- Construction Specifications in The PhilippinesDokument4 SeitenConstruction Specifications in The Philippinessunny sunflowerNoch keine Bewertungen

- BT4 SpecificationsDokument8 SeitenBT4 SpecificationsJet BlackNoch keine Bewertungen

- Sample Project Specs 10 STOREY COMMERCIALDokument3 SeitenSample Project Specs 10 STOREY COMMERCIALBernie RomeroNoch keine Bewertungen

- Layouting StakingDokument2 SeitenLayouting StakingMarsheil BawaanNoch keine Bewertungen

- Specifications: Project: Proposed Two (2) Storey Residential Location: OwnerDokument4 SeitenSpecifications: Project: Proposed Two (2) Storey Residential Location: OwnerJ.P.Almera ArDesignNoch keine Bewertungen

- A5 - Sections, Gutter Blow Up DetailDokument1 SeiteA5 - Sections, Gutter Blow Up DetailArjelyNoch keine Bewertungen

- Rule 20 NBCPDokument20 SeitenRule 20 NBCPDonna MelgarNoch keine Bewertungen

- Technical Specifications: A. General ConditionsDokument4 SeitenTechnical Specifications: A. General ConditionsKurein ReotutarNoch keine Bewertungen

- Arch 530 - BT4 Technical SpecificationsDokument13 SeitenArch 530 - BT4 Technical SpecificationsAlyanna PanganibanNoch keine Bewertungen

- Building Laws PDFDokument5 SeitenBuilding Laws PDFNikki Angela Lirio BercillaNoch keine Bewertungen

- Marces Osmeña General SpecificationsDokument5 SeitenMarces Osmeña General SpecificationsAlexander Osmeña IINoch keine Bewertungen

- 1 Specification WritingDokument31 Seiten1 Specification Writingprince vargasNoch keine Bewertungen

- Specification Nov. 25, 2013Dokument4 SeitenSpecification Nov. 25, 2013Mary Ann LictaoaNoch keine Bewertungen

- Proposed Two Specification WritingDokument4 SeitenProposed Two Specification WritingKelly Santiago100% (1)

- Rule 4 - Types of Construction (Book Format)Dokument2 SeitenRule 4 - Types of Construction (Book Format)Thea AbelardoNoch keine Bewertungen

- Division 2 SiteworkDokument3 SeitenDivision 2 SiteworkMa Monica M. MuncadaNoch keine Bewertungen

- The National Building Code of The Philippines (P.D. 1096) " and Shall Be Referred To As The "IRR"Dokument14 SeitenThe National Building Code of The Philippines (P.D. 1096) " and Shall Be Referred To As The "IRR"Averie Rhone PavonNoch keine Bewertungen

- BSD LongDokument11 SeitenBSD LongkkkNoch keine Bewertungen

- Civil Code Provisions Pertinent To Practice of Architecture Part IDokument27 SeitenCivil Code Provisions Pertinent To Practice of Architecture Part Ilucerocatapanggwen.03Noch keine Bewertungen

- Project:2 Bedroom Bungalow Residence: I. GeneralDokument4 SeitenProject:2 Bedroom Bungalow Residence: I. Generalpauly mari refuerzoNoch keine Bewertungen

- NSCP Reviewer 1 PDFDokument78 SeitenNSCP Reviewer 1 PDFanon_716820639Noch keine Bewertungen

- SpecificationsDokument6 SeitenSpecificationsRomeo Atienza100% (1)

- Assignment Specifications - DelacruzDokument9 SeitenAssignment Specifications - DelacruzShyra Dela CruzNoch keine Bewertungen

- BT LecturesDokument22 SeitenBT LecturesNoel Christian VelascoNoch keine Bewertungen

- Specifications: (6 Storey Office-Commercial Building With Roof Deck & Basement)Dokument14 SeitenSpecifications: (6 Storey Office-Commercial Building With Roof Deck & Basement)Doroty Castro100% (2)

- Technical Specifications: Name of Project Location OwnerDokument2 SeitenTechnical Specifications: Name of Project Location OwnerLerie Lou R. PenarroyoNoch keine Bewertungen

- General Specification - Proposed Two Storey Residential HouseDokument9 SeitenGeneral Specification - Proposed Two Storey Residential HouseMark RamirezNoch keine Bewertungen

- Assignment 3 CEPM1 - SanchezRobertDokument11 SeitenAssignment 3 CEPM1 - SanchezRobertRjohn SanchezNoch keine Bewertungen

- Item 1009Dokument3 SeitenItem 1009Ester Marian100% (1)

- Sample Specs 4Dokument5 SeitenSample Specs 4Julian Castro100% (1)

- Lighting InstallationDokument27 SeitenLighting Installationangel deanNoch keine Bewertungen

- Until The Architects or Engineers Judgment, A Goo Level Is Reached For Foundations, EtcDokument5 SeitenUntil The Architects or Engineers Judgment, A Goo Level Is Reached For Foundations, EtcJillian Flaire VillarNoch keine Bewertungen

- Specification For General Construction FroilanDokument6 SeitenSpecification For General Construction FroilanRafael Luis So100% (1)

- SPP 205Dokument2 SeitenSPP 205Jadine ParambitaNoch keine Bewertungen

- Electrical and Mechanical RegulationsDokument25 SeitenElectrical and Mechanical RegulationsDayanski B-m0% (1)

- APAYAO HouseDokument9 SeitenAPAYAO HouseKritz CimaraNoch keine Bewertungen

- Technical Specfications - Elsa AbenojaDokument7 SeitenTechnical Specfications - Elsa AbenojaCattleya PenalosaNoch keine Bewertungen

- Reflected Ceiling Plan 2 PDFDokument1 SeiteReflected Ceiling Plan 2 PDFjohn mark magno100% (1)

- General Construction SpecificationsDokument6 SeitenGeneral Construction SpecificationsCOMPASS LanguageAndskillsTrainingNoch keine Bewertungen

- Architectural SpecificationDokument5 SeitenArchitectural SpecificationJustine Alexis IngresoNoch keine Bewertungen

- Specifications For General ConstructionDokument3 SeitenSpecifications For General ConstructionBLUE BUILD CONSTRUCTION SERVICESNoch keine Bewertungen

- The Implementing Rules and Regulations (Irr) of Republic Act No. 9266Dokument39 SeitenThe Implementing Rules and Regulations (Irr) of Republic Act No. 9266Gen Lamsis AlmoraNoch keine Bewertungen

- TS - Rough Carpentry (Interior Fit - Out) PDFDokument4 SeitenTS - Rough Carpentry (Interior Fit - Out) PDFJo BompatNoch keine Bewertungen

- Tabon Cave 2. Lean-To: Katalogo NG Arkitekturang FilipinoDokument23 SeitenTabon Cave 2. Lean-To: Katalogo NG Arkitekturang FilipinoSadrach CruzNoch keine Bewertungen

- NSCP Definition of TermsDokument22 SeitenNSCP Definition of Termsstuckinyournightmare stories100% (1)

- Domestic AirportDokument46 SeitenDomestic AirportZenitsu ChanNoch keine Bewertungen

- The Architect S Code of EthicsDokument7 SeitenThe Architect S Code of EthicsRon Gerald RicaNoch keine Bewertungen

- Reyes - BT4 - Specification Writing SeatworkDokument11 SeitenReyes - BT4 - Specification Writing SeatworkCameron ReyesNoch keine Bewertungen

- General Notes FinalsDokument1 SeiteGeneral Notes FinalsAubrey Rose Dela Peña - Magluyan100% (1)

- BT4 Specifications Sample (ETEEAP)Dokument43 SeitenBT4 Specifications Sample (ETEEAP)Freeli BerameNoch keine Bewertungen

- Rule 7c - Classification & General Requirements of All Bldgs by Use or Occupancy - Part 3 - Revised2Dokument39 SeitenRule 7c - Classification & General Requirements of All Bldgs by Use or Occupancy - Part 3 - Revised2Thea AbelardoNoch keine Bewertungen

- RSW FN 01 PDFDokument70 SeitenRSW FN 01 PDFKennedy TuguinayNoch keine Bewertungen

- PROJECT, PROPOS-WPS OfficeDokument6 SeitenPROJECT, PROPOS-WPS OfficeEvangelin GuardamanoNoch keine Bewertungen

- Technical SpecificationDokument43 SeitenTechnical SpecificationGovinda RmNoch keine Bewertungen

- Tijaarat Developers Limited: Canyon Views Developments Defence Housing Authorities Phase Ii (Ext) Islamabad, PakistanDokument9 SeitenTijaarat Developers Limited: Canyon Views Developments Defence Housing Authorities Phase Ii (Ext) Islamabad, PakistanMuhammadIqbalMughalNoch keine Bewertungen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Second Floor Plan: Proposed Two (2) - Storey Commercial Building With RoofdeckDokument1 SeiteSecond Floor Plan: Proposed Two (2) - Storey Commercial Building With Roofdeckdante mortelNoch keine Bewertungen

- Basement Plan: Proposed Two (2) - Storey Commercial Building With RoofdeckDokument1 SeiteBasement Plan: Proposed Two (2) - Storey Commercial Building With Roofdeckdante mortelNoch keine Bewertungen

- Roofdeck Plan: Proposed Two (2) - Storey Commercial Building With RoofdeckDokument1 SeiteRoofdeck Plan: Proposed Two (2) - Storey Commercial Building With Roofdeckdante mortelNoch keine Bewertungen

- Ground Floor Plan: Proposed Two (2) - Storey Commercial Building With RoofdeckDokument1 SeiteGround Floor Plan: Proposed Two (2) - Storey Commercial Building With Roofdeckdante mortelNoch keine Bewertungen

- Site Development Plan: Proposed Two (2) - Storey Commercial Bldg. With RoofdeckDokument1 SeiteSite Development Plan: Proposed Two (2) - Storey Commercial Bldg. With Roofdeckdante mortelNoch keine Bewertungen

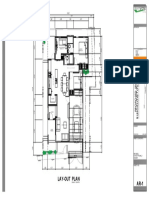

- AR-1 Lay-Out Plan: Master'S Bedroom Home Theater Bedrm. 3Dokument1 SeiteAR-1 Lay-Out Plan: Master'S Bedroom Home Theater Bedrm. 3dante mortelNoch keine Bewertungen

- Ground Floor Plan Second Floor Plan Roof Plan: Proposed Two (2) - Storey ResidenceDokument1 SeiteGround Floor Plan Second Floor Plan Roof Plan: Proposed Two (2) - Storey Residencedante mortelNoch keine Bewertungen

- Proposed Two (2) - Storey Residential Building Mr. Jeremy Edward A. SyDokument1 SeiteProposed Two (2) - Storey Residential Building Mr. Jeremy Edward A. Sydante mortelNoch keine Bewertungen

- The Site: Proposed Two (2) - Storey Residential BuildingDokument1 SeiteThe Site: Proposed Two (2) - Storey Residential Buildingdante mortelNoch keine Bewertungen

- Front Elevation Right Side Elevation: SCALE: 1: 150 MTS. SCALE: 1: 150 MTSDokument1 SeiteFront Elevation Right Side Elevation: SCALE: 1: 150 MTS. SCALE: 1: 150 MTSdante mortelNoch keine Bewertungen

- Steel Column Analysis-Code Check: Stress Code Check Per AISC 9th Edition Manual (ASD)Dokument1 SeiteSteel Column Analysis-Code Check: Stress Code Check Per AISC 9th Edition Manual (ASD)dante mortelNoch keine Bewertungen

- 24 - Article - $mbps Vs $MHZ Why Is This ImportantDokument2 Seiten24 - Article - $mbps Vs $MHZ Why Is This ImportantShiraz SiddiqNoch keine Bewertungen

- Física Práctica 1 MRUDokument5 SeitenFísica Práctica 1 MRUPolet BarrionuevoNoch keine Bewertungen

- Iso 6395 2008 en PDFDokument11 SeitenIso 6395 2008 en PDFjamesNoch keine Bewertungen

- TCP IP CompleteDokument167 SeitenTCP IP Completereddyhell99Noch keine Bewertungen

- Memristor Modeling in MATLAB®&SimulinkDokument6 SeitenMemristor Modeling in MATLAB®&Simulinkjoseamh69062247Noch keine Bewertungen

- 7 Basic Control ActionsDokument27 Seiten7 Basic Control ActionsAhmad ElsheemyNoch keine Bewertungen

- Menstruum and Rose Quartz TinctureDokument3 SeitenMenstruum and Rose Quartz Tincturetravellerfellow100% (2)

- Bicycle and Motorcycle DynamicsDokument36 SeitenBicycle and Motorcycle DynamicsChanakya ChNoch keine Bewertungen

- Paper: Theory/Week: Credits: Mobile Application Development Using Android Hours: IA: ExamDokument1 SeitePaper: Theory/Week: Credits: Mobile Application Development Using Android Hours: IA: ExamHaseeb MogralNoch keine Bewertungen

- M60 Main Battle TankDokument7 SeitenM60 Main Battle Tankbcline50% (2)

- Planning For Procurement of Construction ContractsDokument41 SeitenPlanning For Procurement of Construction ContractsJoel AlcantaraNoch keine Bewertungen

- Detailed Lesson Plan in IctDokument4 SeitenDetailed Lesson Plan in IctJai AidamusNoch keine Bewertungen

- Meritor Axle MT 40 143MA NDokument55 SeitenMeritor Axle MT 40 143MA Nford62bNoch keine Bewertungen

- Instruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 ADokument32 SeitenInstruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 AYunisNoch keine Bewertungen

- Codex 2017 enDokument713 SeitenCodex 2017 enJIgnacio123Noch keine Bewertungen

- Ahu-Ok CatalogueDokument6 SeitenAhu-Ok Catalogue-Tokusatsu Man-Noch keine Bewertungen

- Greenstar Cdi Installation ManualDokument60 SeitenGreenstar Cdi Installation Manualkb1856Noch keine Bewertungen

- Project 3 FinalDokument15 SeitenProject 3 Finalapi-285419046Noch keine Bewertungen

- lfb10 Call PointDokument1 Seitelfb10 Call PointOmar AhmedNoch keine Bewertungen

- ASTM E1417 Penetrant Testing - 9 PDFDokument11 SeitenASTM E1417 Penetrant Testing - 9 PDFbikaNoch keine Bewertungen

- Design of Earth-Quake Resistant Multi Storied RCC Building On A Sloping GroundDokument24 SeitenDesign of Earth-Quake Resistant Multi Storied RCC Building On A Sloping GroundKakula SasidharNoch keine Bewertungen

- Current Electricity All DerivationsDokument11 SeitenCurrent Electricity All DerivationsRonit VaskarNoch keine Bewertungen

- How To Use Volatility - v2Dokument65 SeitenHow To Use Volatility - v2John SedoskiNoch keine Bewertungen

- LG Rad 226B PDFDokument65 SeitenLG Rad 226B PDFFrancisReis0% (1)

- Benq mp510 Level1Dokument212 SeitenBenq mp510 Level1Juan Duarte Lopez100% (1)

- Welder and Welding Operator Qualification Test Record (Asme Ix Code)Dokument1 SeiteWelder and Welding Operator Qualification Test Record (Asme Ix Code)Neil TaneoNoch keine Bewertungen

- Operating & Installation Instructions NA-FS10V7 NA-FS95V7Dokument32 SeitenOperating & Installation Instructions NA-FS10V7 NA-FS95V7Kis NermalNoch keine Bewertungen

- Lhotse Manual E V1.2Dokument46 SeitenLhotse Manual E V1.2vpNoch keine Bewertungen

- Feslog - 1508161122 - Fiat Doblo' (Type 223) Cargo 1.3 Mjet 16vDokument19 SeitenFeslog - 1508161122 - Fiat Doblo' (Type 223) Cargo 1.3 Mjet 16vraulUTCNNoch keine Bewertungen

- OTN Training-Lv1-Fonst 3000 Equipment IntroductionDokument28 SeitenOTN Training-Lv1-Fonst 3000 Equipment IntroductionJenny Rodriguez Aguirre100% (1)