Beruflich Dokumente

Kultur Dokumente

Grupo Alvica: Control Valve

Hochgeladen von

Hernan YanezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Grupo Alvica: Control Valve

Hochgeladen von

Hernan YanezCopyright:

Verfügbare Formate

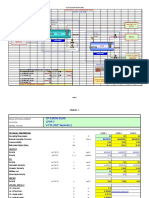

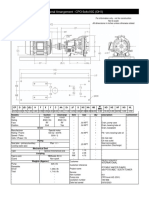

Contract: 04477000

CONTROL VALVE Data Sheet No.: 15-01.04.03 Rev 12

SPECIFICATIONS SHEET

Grupo Alvica

Unit: Hydroprocessing Support Unit

TAG No. 15-HV-016 P.O. No.: 477040-7-0115-C1

Piping Valve No V - 900F4 11 Instr. Engr. E. Terrible

Client: Petrolera Ameriven, S.A Process Engr. ProcData Rev Date

Plant: Hamaca Crude Upgrade

Site: Jose, Venezuela Page No. 1 of 1

Unless otherwise noted below all items shall comply with general specification sheets: SP-421300-70-1M & SP-421300-70-1101

1 Fluid Hydrocarbon Liquid Service: Stripper Btms to Emergency Isolation 11 Crit Press, Pc (PSIA) P&ID No. 15-A1-0100

Units Maximum Flow Normal Flow Minimum Flow Other Shut-off

2 Flow Rate ---

SERVICE / CONDITIONS

3 Inlet Pressure psig 150 11 175 psi

4 Outlet Pressure psig ---

5 Inlet Temperature °F 440 ---

6 Density / Spec Grav / Mol Wt lb/ft³ / - / - ---

7 Viscosity / Spec Heats Ratio cP ---

8 Vapor Pressure, Pv psia ---

9 Required Cv ---

10 Travel % 0

11 Allowable | Predicted SPL dBA <85 --- ---

12 Compressibility Factor, Z

13 Pipe Size In 16"-Sch. XS 53 NEC Class I Div 2 Group B, C, D

LINE

14 & Schedule Out 16"-Sch. XS 54 Type Double Acting Piston

15 Pipe Line Spec & Insulation J31D-Ih 55 Manufacturer & Model No. ROTORK # RP-240-485 B/D1 11

16 Type B-1 Type : Butterfly-Double Flange11 56 Size 240 12 Effective Area

17 Size 16" 57 On / Off n Modulating d

18 Max Press/Temp 175 psig 491 °F 58 Failure Position Open c Close d Last p

19 Manufacturer & Model No. (Series 30000-QTF)VANESSA # AA0111 59 Air Pressure Unit Yes,

VALVE / BODY / BONNET

20 Body / Bonnet Matl Steel, ASTM A216 WCB 60 Max Allowable Press. 60 psig Min. Required Press. 36 psig

21 Liner Material / ID None 61 Avail Air Supply Press. Max 100 psig Min 60 psig

ACTUATOR

22 End Connection In 16 " 300# Out 16" 300# 11 62 Bench Range N/A

23 Flg Face Finish RF 63 Valve Stem/Act.Orientation Horizontal/Horizontal( Parallel to Pipe

12

24 End Ext / Matl None 64 Handwheel None 11

25 Flow Direction Not Applicable 65 Air Failure Valve N/A Set at

26 Type of Bonnet Integral 66 Response Time 30 Seconds 12

27 Lub & Iso Valve None 67 Min, / Max Act'r. Output Torque: 1861/3550 ft-lb 11

28 Packing Material Graphite 68 Actuator Lock: No 11

29 Packing Type Standard 69 Manual Override: No 11

30 Rating CLASS 300# 70 Shear Fin Required: No 11

31 Type Disc 11 71 Quick Exhaust: No 12

32 Size Full 11 72 Valve Fire Safety Category: 1 11

33 Characteristic Equal % 11 73 Valve Emergency Position: Close 11

34 Balanced c Unbalanced d 74 Type Proximity Quantity 4 12

SWITCHES

TRIM

35 Rated Cv 6820 11 75 Manufacturer & Model No. Proximity Controls, 14RDO 12

36 Disk / Seal Material CARBON STEEL / DUPLEX 11 76 Contacts & Rating SPDT, 3 Amps @ 115 VAC 12

37 Seat Material Stellite GR 21 (Weld Overlay F31611 77 Actuation Points 98% Open & 98% Closed 12

38 Cage/Guide/Stack Mat'l. 304 SS HF 11 78 Tag No. Open 15-ZSO-016 & Closed 15-ZSC-016

39 Stem Material A182 GR F6A 11 79 Airset Mfr & Model No. Yes, Set Pr. 60 psig

ACC.

40 80 Solenoid Mfr & Model No.

41 Pressure Test Note 8 81 Solenoid Voltage Tag No.

TEST

42 Leakage Class ANSI Class V 82 Position Indicator yes (Visible after fireproofing 11

43 Pos. Material Identification 83 Outline Dimensions Certified Dimensions Outline Required

44 1. See data sheet 15-11.01.01 for hand switch, status light, control panel and volume tank requiremen

45 2. All electrical items shall meet specified electrical area classificatio

46 3. Control valve (metal to metal type) and actuator shall bFIRESAFE . 11

47 4. All electrical items shall be tropicalized

NOTES

48 5. For Testing: Vendor to provide a travel stop to stroke the valvefrom 100% open to 90% open and return to normal posi 11

49 6. Steam out @ -7.5 psig & 50 psig @ 300 deg F

50 7. Air Line Size and Est. Length (Remote between Local Panel and Actuator- By Others) : 1/2 " Tubing and 320 fe 11

51 8. Minimum hydrostatic shell pressure test shall be 1125 psig and seat closure test shall be 740 ps 12

52

REVISION LOG

REV. ISSUE STATUS DATE BY CHK'D APP'D

10 Approved for Design and RFQ 09-Oct-00 BM ER TS

11 Issued for Purchase 21-Aug-01 ET BM ER

12 Issued for Purchase 06-jun-02 BM ER ER

Notice: This document has not been published and is the sole property of the Fluor Corporation, and is lent to the borrower for his confidential use only: and in consideration of the loan of this drawing, the borrower promises and

agrees to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically furnished.

FORM E-593 (REV. 1/98) Printed: 23-sep-15

camd\Escritorio\ALCANCES SEMANA 25\INSTRUMENTACION\IC-CONF-2014-0503\Data Sheet\[Copia de 15010403R12.xls

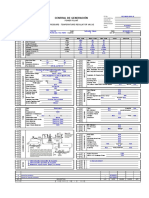

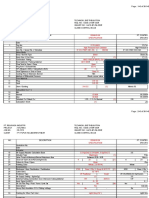

Contract: 04477000

CONTROL VALVE Data Sheet No.: 15-01.04.04 Rev 12

SPECIFICATIONS SHEET

Grupo Alvica

Unit: Hydroprocessing Support Unit

TAG No. 15-HV-041 P.O. No.: 477040-7-0115-C1

Piping Valve No V - 901E8 Instr. Engr. E. Terrible

Client: Petrolera Ameriven, S.A Process Engr. ProcData Rev Date

Plant: Hamaca Crude Upgrade

Site: Jose, Venezuela Page No. 1 of 1

Unless otherwise noted below all items shall comply with general specification sheets: SP-421300-70-1M & SP-421300-70-1101

1 Fluid Hydrocarbon Liquid Service: Stripper Ovrhd Liq to Emergency Isolation Crit Press, Pc (PSIA) P&ID No. 15-A1-0102

Units Maximum Flow Normal Flow Minimum Flow Other Shut-off

2 Flow Rate ---

SERVICE / CONDITIONS

3 Inlet Pressure psig 130 169 psi

4 Outlet Pressure psig ---

5 Inlet Temperature °F 100 ---

6 Density / Spec Grav / Mol Wt lb/ft³ / - / - ---

7 Viscosity / Spec Heats Ratio cP ---

8 Vapor Pressure, Pv psia ---

9 Required Cv ---

10 Travel % 0

11 Allowable | Predicted SPL dBA <85 --- ---

12 Compressibility Factor, Z

13 Pipe Size In 10"-Sch. 20 53 NEC Class I Div 2 Group B, C, D 11

LINE

14 & Schedule Out 10"-Sch. 20 54 Type Double Acting Piston

15 Pipe Line Spec & Insulation J14B 55 Manufacturer & Model No. ROTORK # RP-120-280 B/D1 11

16 Type B-1 Type : Butterfly-Double Flange11 56 Size 120 12 Effective Area

17 Size 10" 57 On / Off n Modulating d

18 Max Press/Temp 169 psig 300 °F 58 Failure Position Open c Close d Last p

19 Manufacturer & Model No. (Series 30000-QTF)VANESSA # AA0111 59 Air Pressure Unit Yes,

VALVE / BODY / BONNET

20 Body / Bonnet Matl Steel, ASTM A216 WCB 60 Max Allowable Press. 60 psig Min. Required Press. 36 psig

21 Liner Material / ID None 61 Avail Air Supply Press. Max 100 psig Min 60 psig

ACTUATOR

22 End Connection In 10" - 150# Out 10" - 150# 62 Bench Range N/A

23 Flg Face Finish RF 63 Valve Stem /Act.Orientation Horizontal/Horizontal (Parrell to Pipe12

24 End Ext / Matl None 64 Handwheel None 11

25 Flow Direction Not Applicable 65 Air Failure Valve N/A Set at

26 Type of Bonnet Integral 66 Response Time 30 Seconds 12

27 Lub & Iso Valve None 67 Min, / Max Act'r. Output Torque: 460/1675 ft-lb 12

28 Packing Material Graphite 68 Actuator Lock: No 11

29 Packing Type Standard 69 Manual Override: No 11

30 Rating CLASS 150# 70 Shear Fin Required: No 11

31 Type Disc 11 71 Quick Exhaust: No 12

32 Size Full 11 72 Valve Fire Safety Category: 1 11

33 Characteristic Equal % 11 73 Valve Emergency Position: Close 11

34 Balanced c Unbalanced d 74 Type Proximity Quantity 6 12

SWITCHES

TRIM

35 Rated Cv 2279 11 75 Manufacturer & Model No. Proximity Controls, 16RDO 12

36 Disk / Seal Material CARBON STEEL / DUPLEX 11 76 Contacts & Rating SPDT-3 Amps@ 115 VAC 12

37 Seat Material Stellite GR 21 (Weld Overlay F31611 77 Actuation Points 98% Open & 98% Closed 12

38 Cage/Guide/Stack Mat'l. 304 ss hf 11 78 Tag No. Open: See Note 9 & Closed: 15-ZSC-041 11

39 Stem Material A182 GR F6A 11 79 Airset Mfr & Model No. Yes, Set Pr. 60 psig

ACC.

40 80 Solenoid Mfr & Model No.

41 Pressure Test Note 8 11 81 Solenoid Voltage Tag No.

TEST

42 Leakage Class ANSI Class V 82 Position Indicator Yes (Visible after fireproofing 11

43 No

Pos. Material Identification 12 83 Outline Dimensions Certified Dimensions Outline Required

44 1. See data sheet 15-11.01.01 for hand switch, status light, control panel and volume tank requiremen

45 2. All electrical items shall meet specified electrical area classificatio

46 3. Control valve (metal to metal type) and actuator shall bFIRESAFE . 11

47 4. All electrical items shall be tropicalized

NOTES

48 5. For Testing: Vendor to provide a travel stop to stroke the valve from 100% open to 90% open and return to normal posi 11

49 6. Steam out @ -7.5 psig & 50 psig @ 300 deg F

50 7. Air Line Size and Est. Length (Remote between Local Panel and Actuator - By Others) 1/2" Tubing and 300 fe 11

51 8. Minimum hydrostatic shell pressure test shall be 450 psig and seat closure test shall be 285 ps 11

52 9. Limit Switches Tag No. for Open Status: 15-ZSO-041A; 15-ZSO-041B; 15-ZSO-041C 11

REVISION LOG

REV. ISSUE STATUS DATE BY CHK'D APP'D

10 Approved for Design and RFQ 24-Oct-00 ET ER TS

11 Issued for Purchase 21-Aug-01 ET BM ER

12 Issued for Purchase 06-jun-02 BM ER ER

Notice: This document has not been published and is the sole property of the Fluor Corporation, and is lent to the borrower for his confidential use only: and in consideration of the loan of this drawing, the borrower promises and

agrees to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically furnished.

FORM E-593 (REV. 1/98) Printed: 23-sep-15

camd\Escritorio\ALCANCES SEMANA 25\INSTRUMENTACION\IC-CONF-2014-0503\Data Sheet\[Copia de 15010404R12.xls

Contract: 04477000

CONTROL VALVE Data Sheet No.: 15-01.04.05 Rev 12

SPECIFICATIONS SHEET

Grupo Alvica

Unit: Hydroprocessing Support Unit

TAG No. 15-HV-042 P.O. No.: 477040-7-0115-C1

Piping Valve No V - 900F4 11 Instr. Engr. E. Terrible

Client: Petrolera Ameriven, S.A Process Engr. ProcData Rev Date

Plant: Hamaca Crude Upgrade

Site: Jose, Venezuela Page No. 1 of 1

Unless otherwise noted below all items shall comply with general specification sheets: SP-421300-70-1M & SP-421300-70-1101

1 Fluid Hydrocarbon Liquid Service: Debutanizer Ovrhd Liq to Emerg. Isolation Crit Press, Pc (PSIA) P&ID No. 15-A1-0105

Units Maximum Flow Normal Flow Minimum Flow Other Shut-off

2 Flow Rate ---

SERVICE / CONDITIONS

3 Inlet Pressure psig 269 345 psi

4 Outlet Pressure psig ---

5 Inlet Temperature °F 100 ---

6 Density / Spec Grav / Mol Wt lb/ft³ / - / - ---

7 Viscosity / Spec Heats Ratio cP ---

8 Vapor Pressure, Pv psia ---

9 Required Cv ---

10 Travel % 0

11 Allowable | Predicted SPL dBA <85 --- ---

12 Compressibility Factor, Z

13 Pipe Size In 8"-Sch. Std. Wt. 53 NEC Class I Div 2 Group B, C, D 11

LINE

14 & Schedule Out 8"-Sch. Std. Wt. 54 Type Double Acting Piston

15 Pipe Line Spec & Insulation J31D 55 Manufacturer & Model No. ROTORK # RP-240-280 B/D1 11

16 Type B-1 Type : Butterfly-Double Flange11 56 Size 240 12 Effective Area

17 Size 8" 57 On / Off n Modulating d

18 Max Press/Temp 345 psig 300 °F 58 Failure Position Open c Close d Last p

19 Manufacturer & Model No. (Series 30000-QTF)VANESSA # AA0111 59 Air Pressure Unit Yes

VALVE / BODY / BONNET

20 Body / Bonnet Matl Steel, ASTM A216 WCB 60 Max Allowable Press. 60 psig Min. Required Press. 36 psig

21 Liner Material / ID None 61 Avail Air Supply Press. Max 100 psig Min 60 psig

ACTUATOR

22 End Connection In 8" - 300 # Out 8" - 300 # 62 Bench Range N/A

23 Flg Face Finish RF 63 Valve Stem /Act.Orientation Horizontal/Horizontal (Parrell to Pipe 12

24 End Ext / Matl None 64 Handwheel None 11

25 Flow Direction Not Applicablle 65 Air Failure Valve N/A Set at

26 Type of Bonnet Integral 66 Response Time 30 Seconds 12

27 Lub & Iso Valve None 67 Min, / Max Act'r. Output Thrust: 620/2258 ft-lb 12

28 Packing Material Graphite 68 Actuator Lock: No 11

29 Packing Type Standard 69 Manual Override: No 11

30 Rating CLASS 300# 70 Shear Fin Required: No 11

31 Type Disc 11 71 Quick Exhaust: No 12

32 Size Full 11 72 Valve Fire Safety Category: 1 11

33 Characteristic Equal % 11 73 Valve Emergency Position: Close 11

34 Balanced c Unbalanced o 74 Type Proximity Quantity: 6 12

SWITCHES

TRIM

35 Rated Cv 1472 11 75 Manufacturer & Model No. Proximity Controls, 16RDO 12

36 Disk / Seal Material CARBON STEEL / DUPLEX 11 76 Contacts & Rating SPDT-3 Amps@ 115 VAC 12

37 Seat Material Stellite GR 21 (Weld Overlay F31611 77 Actuation Points 98% Open & 98% Closed 12

38 Cage/Guide/Stack Mat'l. 304 SS HF 11 78 Tag No. Open: See Note 9 & Closed: 15-ZSC-042 11

39 Stem Material A182 GR F6A 11 79 Airset Mfr & Model No. Yes, Set Pr. 60 psig

ACC.

40 80 Solenoid Mfr & Model No.

41 Pressure Test Note 8 11 81 Solenoid Voltage Tag No.

TEST

42 Leakage Class ANSI Class V 82 Position Indicator Yes (Visible after Fireproofing 11

43 No

Pos. Material Identification 12 83 Outline Dimensions Certified Dimensions Outline Required

44 1. See data sheet 15-11.01.01 for hand switch, status light, control panel and volume tank requiremen

45 2. All electrical items shall meet specified electrical area classificatio

46 3. Control valve (metal to metal type) and actuator shall bFIRESAFE . 11

47 4. All electrical items shall be tropicalized

NOTES

48 5. For Testing: Vendor to provide a travel stop to stroke the valvefrom 100% open to 90% open and return to normal posi 11

49 6. Steam out @ -7.5 psig & 50 psig @ 300 deg F

50 7. Air Line Size and Est. Length (Remote between Local Panel and Actuator - By Others) : 1/2" Tubing and 250 fe 11

51 8. Minimum hydroatatic shell pressure test shall be 450 psig and seat closure test shall be 285 ps 11

52 9. Limit Switch Tag No. for Open Status: 15-ZSO-042A; 15-ZSO-042B; 15-ZSO-042C 11

REVISION LOG

REV. ISSUE STATUS DATE BY CHK'D APP'D

10 Approved for Design and RFQ 24-Oct-00 ET ER TS

11 Issued for Purchase 21-Aug-01 ET BM ER

12 Issued for Purchase 06-jun-02 BM ER ER

Notice: This document has not been published and is the sole property of the Fluor Corporation, and is lent to the borrower for his confidential use only: and in consideration of the loan of this drawing, the borrower promises and

agrees to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically furnished.

FORM E-593 (REV. 1/98) Printed: 23-sep-15

camd\Escritorio\ALCANCES SEMANA 25\INSTRUMENTACION\IC-CONF-2014-0503\Data Sheet\[Copia de 15010405R12.xls

Contract: 04477000

CONTROL VALVE Data Sheet No.: 15-01.04.06 Rev 12

SPECIFICATIONS SHEET

Grupo Alvica

Unit: Hydroprocessing Support Unit

TAG No. 15-HV-043 P.O. No.: 477040-7-0115-C1

Piping Valve No V - 900F4 11 Instr. Engr. E. Terrible

Client: Petrolera Ameriven, S.A Process Engr. ProcData Rev Date

Plant: Hamaca Crude Upgrade

Site: Jose, Venezuela Page No. 1 of 1

Unless otherwise noted below all items shall comply with general specification sheets: SP-421300-70-1M & SP-421300-70-1101

1 Fluid Hydrocarbon Liquid Service: Debutanizer Emergency Depressuring 11 Crit Press, Pc (PSIA) P&ID No. 15-A1-0106

Units Maximum Flow Normal Flow Minimum Flow Other Shut-off

2 Flow Rate ---

SERVICE / CONDITIONS

3 Inlet Pressure psig 282 320 psi

4 Outlet Pressure psig ---

5 Inlet Temperature °F 180 ---

6 Density / Spec Grav / Mol Wt lb/ft³ / - / - ---

7 Viscosity / Spec Heats Ratio cP ---

8 Vapor Pressure, Pv psia ---

9 Required Cv ---

10 Travel % 0

11 Allowable | Predicted SPL dBA <85 --- ---

12 Compressibility Factor, Z

13 Pipe Size In 8"-Sch. XS 53 NEC Class I Div 2 Group B, C, D 11

LINE

14 & Schedule Out 8"-Sch. XS 54 Type Double Acting Piston

15 Pipe Line Spec & Insulation J3007 55 Manufacturer & Model No. ROTORK # RP-120-300 B/D1 11

16 Type B-2 Type : Butterfly-Double Flange11 56 Size 120 12 Effective Area

17 Size 8" 57 On / Off n Modulating d

18 Max Press/Temp (Note 5) 11 320 psig 472 °F 58 Failure Position Open c Close d Last p

19 Manufacturer & Model No. (Series 30000-QTF)VANESSA # AA0111 59 Air Pressure Unit Yes

VALVE / BODY / BONNET

20 Body / Bonnet Matl Steel, ASTM A216 WCB 60 Max Allowable Press. 60 psig Min. Required Press. 36 psig

21 Liner Material / ID None 61 Avail Air Supply Press. Max 100 psig Min 60 psig

ACTUATOR

22 End Connection In 8" - 300 # Out 8" - 300 # 62 Bench Range N/A

23 Flg Face Finish RF 63 Valve Stem /Act.Orientation Horizontal/Horizontal (Parrell to Pipe12

24 End Ext / Matl None 64 Handwheel None 11

25 Flow Direction Not Applicable 65 Air Failure Valve N/A Set at

26 Type of Bonnet Integral 66 Response Time 30 Seconds 12

27 Lub & Iso Valve None 67 Min, / Max Act'r. Output Torque: 528/1919 ft-lb 12

28 Packing Material Graphite 68 Actuator Lock: No 11

29 Packing Type Standard 69 Manual Override: No 11

30 Rating CLASS 300# 70 Shear Fin Required: No 11

31 Type Disc 11 71 Quick Exhaust: No 12

32 Size Full 11 72 Valve Fire Safety Category: 1 11

33 Characteristic Equal % 11 73 Valve Emergency Position: Close 11

34 Balanced c Unbalanced o 74 Type Proximity Quantity 4 12

SWITCHES

TRIM

35 Rated Cv 1220 11 75 Manufacturer & Model No. Proximity Controls, 14RDO 12

36 Disk / Seal Material CARBON STEEL / DUPLEX 11 76 Contacts & Rating SPDT, 3 Amps @ 115 VAC 12

37 Seat Material Stellite GR 21 (Weld Overlay F31611 77 Actuation Points 98% Open & 98% Closed 12

38 Cage/Guide/Stack Mat'l. 304 SS HF 11 78 Tag No. Open 15-ZSO-043 & Closed 15-ZSC-043

39 Stem Material A182 GR F6A 11 79 Airset Mfr & Model No. Yes, Set Pr. 60 psig

Solenoid Mfr & Model No. VERSA Series V AA

ACC.

40 80 12

41 Pressure Test Note 8 11 81 Solenoid Voltage 24 VDC Low Pow Tag No. 15-HY-043 A/B 11

TEST

42 Leakage Class ANSI Class V 82 Position Indicator Yes (Visible after Fireproofing 11

43 No

Pos. Material Identification 12 83 Outline Dimensions Certified Dimensions Outline Required

44 1. See data sheet 15-11.01.01 for hand switch, status light, control panel and volume tank requiremen

45 2. All electrical items shall meet specified electrical area classificatio

46 3. Control valve (metal to metal type) and actuator shall bFIRESAFE . 11

47 4. All electrical items shall be tropicalized

NOTES

48 5. Minimum design metal temperature is -20 deg. F 11

49 6. All wetted parts shall comply withNACE MR-01-75. 11

50 7. Steam out @ -7.5 psig & 50 psig @ 300 deg F

51 8. Air Line Size and Est. Length (Remote between Local Panel and Actuator - By Others) : 1/2" Tubing and 225 fe 11

52 9. Minimum hydrostatic shell pressure test shall be 1125 psig and seat closure test shall be 740 ps 12

REVISION LOG

REV. ISSUE STATUS DATE BY CHK'D APP'D

10 Approved for Design and RFQ 24-Oct-00 ET ER TS

11 Issued for Purchase 21-Aug-01 ET BM ER

12 Issued for Purchase 06-jun-02 BM ER ER

Notice: This document has not been published and is the sole property of the Fluor Corporation, and is lent to the borrower for his confidential use only: and in consideration of the loan of this drawing, the borrower promises and

agrees to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically furnished.

FORM E-593 (REV. 1/98) Printed: 23-sep-15

camd\Escritorio\ALCANCES SEMANA 25\INSTRUMENTACION\IC-CONF-2014-0503\Data Sheet\[Copia de 15010406R12.xls

Contract: 04477000

CONTROL VALVE Data Sheet No.: 15-01.04.08 Rev 12

SPECIFICATIONS SHEET

Grupo Alvica

Unit: Hydroprocessing Support Unit

TAG No. 15-HV-045 P.O. No.: 477040-7-0115-C1

Piping Valve No V - 900F4 11 Instr. Engr. E. Terrible

Client: Petrolera Ameriven, S.A Process Engr. ProcData Rev Date

Plant: Hamaca Crude Upgrade

Site: Jose, Venezuela Page No. 1 of 1

Unless otherwise noted below all items shall comply with general specification sheets: SP-421300-70-1M & SP-421300-70-1101

1 Fluid Hydrocarbon Liquid Service: Deethanizer Accmlt'r Liq to Emerg Isolat'n Crit Press, Pc (PSIA) P&ID No. 15-A1-0112

Units Maximum Flow Normal Flow Minimum Flow Other Shut-off

2 Flow Rate ---

SERVICE / CONDITIONS

3 Inlet Pressure psig 402 472 psi

4 Outlet Pressure psig ---

5 Inlet Temperature °F 100 ---

6 Density / Spec Grav / Mol Wt lb/ft³ / - / - ---

7 Viscosity / Spec Heats Ratio cP ---

8 Vapor Pressure, Pv psia ---

9 Required Cv 11 ---

10 Travel % 0

11 Allowable | Predicted SPL dBA <85 --- ---

12 Compressibility Factor, Z

13 Pipe Size In 3"-Sch. Std. Wt. 53 NEC Class I Div 2 Group B, C, D 11

LINE

14 & Schedule Out 3"-Sch. Std. Wt. 54 Type Double Acting Piston

15 Pipe Line Spec & Insulation J31D 55 Manufacturer & Model No. ROTORK # RP-015-200 B/D1 11

16 Type B-1 Type : Butterfly-Double Flange11 56 Size 015 12 Effective Area

17 Size 3" 57 On / Off n Modulating d

18 Max Press/Temp (Note 9) 472 psig 300 11 °F 58 Failure Position Open c Close d Last p

19 Manufacturer & Model No. (Series 30000-QTF)VAANESSA # AA01 59 Air Pressure Unit Yes,

VALVE / BODY / BONNET

11

20 Body / Bonnet Matl Steel, ASTM A216 WCB 60 Max Allowable Press. 60 psig Min. Required Press. 36 psig

21 Liner Material / ID None 61 Avail Air Supply Press. Max 100 psig Min 60 psig

ACTUATOR

22 End Connection In 3" - 300 # Out 3" - 300 # 62 Bench Range N/A

23 Flg Face Finish RF 63 Valve Stem/Act.Orientation Horizontal/Horizontal(Parrell to Pipe 12

24 End Ext / Matl None 64 Handwheel None 11

25 Flow Direction Not Applicable 65 Air Failure Valve N/A Set at

26 Type of Bonnet Integral 66 Response Time 30 Seconds 12

27 Lub & Iso Valve None 67 Min, / Max Act'r. Output Torque: 116/288 ft-lb 12

28 Packing Material Graphite 68 Actuator Lock: No 11

29 Packing Type Standard 69 Manual Override: No 11

30 Rating CLASS 300# 70 Shear Fin Required: No 11

31 Type Disc 11 71 Quick Exhaust: No 12

32 Size Full 11 72 Valve Fire Safety Category: 1 11

33 Characteristic Equal % 11 73 Valve Emergency Position: Close 11

34 Balanced c Unbalanced o 74 Type Proximity Quantity 4 12

SWITCHES

TRIM

35 Rated Cv 85 11 75 Manufacturer & Model No. Proximity Controls, 14RDO 12

36 Disk / Seal Material CARBON STEEL / DUPLEX 11 76 Contacts & Rating SPDT, 3 Amps @ 115 VAC 12

37 Seat Material Stellite GR 21 (Weld Overlay F31611 77 Actuation Points 98% Open & 98% Closed 12

38 Cage/Guide/Stack Mat'l. 304 SS HF 11 78 Tag No. Open 15-ZSO-045 & Closed 15-ZSC-045

39 Stem Material A182 GR -F6A 11 79 Airset Mfr & Model No. Yes, Set Pr. 60 psig

ACC.

40 80 Solenoid Mfr & Model No.

41 Pressure Test Note 8 11 81 Solenoid Voltage Tag No.

TEST

42 Leakage Class ANSI Class V 82 Position Indicator Yes (Visible after Fireproofing

43 No

Pos. Material Identification 12 83 Outline Dimensions Certified Dimensions Outline Required

44 1. See data sheet 15-11.01.01 for hand switch, status light, control panel and volume tank requiremen

45 2. All electrical items shall meet specified electrical area classificatio

46 3. Control valve (metal to metal type) and actuator shall bFIRESAFE . 11

47 4. All electrical items shall be tropicalized

NOTES

48 5. For Testing: Vendor to provide a travel stop to stroke the valve from 100% open to 90% open and return to normal posi 11

49 6. Steam out @ -7.5 psig & 50 psig @ 300 deg F

50 7. Air Line Size and Est. Length (Remote between Local Panel and Actuator - By Others) :1/2" Tubing and 160 fe 11

51 8. Minimum hydrostatic shell pressure test shall be 1125 psig and seat closure test shall be 740 ps 11

52 9. Minimum design metal temperature is -62 degrees F 11

REVISION LOG

REV. ISSUE STATUS DATE BY CHK'D APP'D

10 Approved for Design and RFQ 24-Oct-00 ET ER TS

11 Issued for Purchase 21-Aug-01 ET BM ER

12 Issued for Purchase 06-jun-02 BM ER ER

Notice: This document has not been published and is the sole property of the Fluor Corporation, and is lent to the borrower for his confidential use only: and in consideration of the loan of this drawing, the borrower promises and

agrees to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically furnished.

FORM E-593 (REV. 1/98) Printed: 23-sep-15

camd\Escritorio\ALCANCES SEMANA 25\INSTRUMENTACION\IC-CONF-2014-0503\Data Sheet\[Copia de 15010408R12.xls

Contract: 04477000

CONTROL VALVE Data Sheet No.: 15-01.04.09 Rev 12

SPECIFICATIONS SHEET

Grupo Alvica

Unit: Hydroprocessing Support Unit

TAG No. 15-HV-046 P.O. No.: 477040-7-0115-C1

Piping Valve No V - 901E8 11 Instr. Engr. E. Terrible

Client: Petrolera Ameriven, S.A Process Engr. ProcData Rev Date

Plant: Hamaca Crude Upgrade

Site: Jose, Venezuela Page No. 1 of 1

Unless otherwise noted below all items shall comply with general specification sheets: SP-421300-70-1M & SP-421300-70-1101

1 Fluid Hydrocarbon Liquid Service: Naphtha Splitter Bttms Emerg. Isolation Crit Press, Pc (PSIA) P&ID No. 15-A1-0114

Units Maximum Flow Normal Flow Minimum Flow Other Shut-off

2 Flow Rate ---

SERVICE / CONDITIONS

3 Inlet Pressure psig 28 75 psi 11

4 Outlet Pressure psig ---

5 Inlet Temperature °F 322 ---

6 Density / Spec Grav / Mol Wt lb/ft³ / - / - ---

7 Viscosity / Spec Heats Ratio cP ---

8 Vapor Pressure, Pv psia ---

9 Required Cv ---

10 Travel % 0

11 Allowable | Predicted SPL dBA <85 --- ---

12 Compressibility Factor, Z

13 Pipe Size In 4"-Sch. Std. Wt. 53 NEC Class I Div 2 Group B, C, D 11

LINE

14 & Schedule Out 4"-Sch. Std. Wt. 54 Type Double Acting Piston

15 Pipe Line Spec & Insulation J14B 55 Manufacturer & Model No. ROTORK # RP-015-180 B/D1 11

16 Type B-1 Type : Butterfly-Double Flange11 56 Size 015 12 Effective Area

17 Size 4" 57 On / Off n Modulating d

18 Max Press/Temp 75 11 psig 379 °F 58 Failure Position Open c Close d Last p

19 Manufacturer & Model No. (Series 30000-QTF)VANESSA # AA0111 59 Air Pressure Unit Yes

VALVE / BODY / BONNET

20 Body / Bonnet Matl Steel, ASTM A216 WCB 60 Max Allowable Press. 60 psig Min. Required Press. 36 psig

21 Liner Material / ID None 61 Avail Air Supply Press. Max 100 psig Min 60 psig

ACTUATOR

22 End Connection In 4" - 150 # Out 4" - 150 # 62 Bench Range N/A

23 Flg Face Finish RF 63 Valve Stem/Act.Orientation Horizontal/Horizontal (Parallel to Pipe12

24 End Ext / Matl None 64 Handwheel None 11

25 Flow Direction Not Applicable 65 Air Failure Valve N/A Set at

26 Type of Bonnet Integral 66 Response Time 30 Seconds 12

27 Lub & Iso Valve None 67 Min, / Max Act'r. Output Thrust: 94/288 12

28 Packing Material Graphite 68 Actuator Lock: No 11

29 Packing Type Standard 69 Manual Override: No 11

30 Rating CLASS 150# 70 Shear Fin Required: No 11

31 Type Disc 11 71 Quick Exhaust: No 12

32 Size Full 11 72 Valve Fire Safety Category: 1 11

33 Characteristic Equal % 11 73 Valve Emergency Position: Close 11

34 Balanced c Unbalanced o 74 Type Proximity Quantity 4 12

SWITCHES

TRIM

35 Rated Cv 180 11 75 Manufacturer & Model No. Proximity Controls 14RDO 12

36 Disk/Seal Material CARBON STEEL / DUPLEX 11 76 Contacts & Rating SPDT, 3 Amps @ 125 VAC 12

37 Seat Material Stellite GR 21 (Weld Overlay F31611 77 Actuation Points 98% Open & 98% Closed 12

38 Cage/Guide/Stack Mat'l. 304 SS HF 11 78 Tag No. Open 15-ZSO-046 & Closed 15-ZSC-046

39 Stem Material A182 Gr. F6A 11 79 Airset Mfr & Model No. Yes, Set Pr. 60 psig

ACC.

40 80 Solenoid Mfr & Model No.

41 Pressure Test Note 8 11 81 Solenoid Voltage Tag No.

TEST

42 Leakage Class ANSI Class V 82 Position Indicator Yes (Visible after Fireproofing

43 Pos. Material Identification 83 Outline Dimensions Certified Dimensions Outline Required

44 1. See data sheet 15-11.01.01 for hand switch, status light, control panel and volume tank requiremen

45 2. All electrical items shall meet specified electrical area classificatio

46 3. Control valve (metal to metal type) and actuator shall bFIRESAFE . 11

47 4. All electrical items shall be tropicalized

NOTES

48 5. For Testing: Vendor to provide a travel stop to stroke the valve from 100% open to 90% open and return to normal posi 11

49 6. Steam out @ -7.5 psig & 50 psig @ 300 deg F

50 7. Air Line Size and Est. Length (Remote between Local Panel and Actuator - By Others) : 1/2" Tubing and 110 fe 11

51 8. Minimum hydrostatic shell pressure test shall be 450 psig and seat closure test shall be 285 ps 11

52

REVISION LOG

REV. ISSUE STATUS DATE BY CHK'D APP'D

10 Approved for Design and RFQ 24-Oct-00 ET ER TS

11 Issued for Purchase 21-Aug-01 ET BM ER

12 Issued for Purchase 06-jun-02 BM ER ER

Notice: This document has not been published and is the sole property of the Fluor Corporation, and is lent to the borrower for his confidential use only: and in consideration of the loan of this drawing, the borrower promises and

agrees to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically furnished.

FORM E-593 (REV. 1/98) Printed: 23-sep-15

camd\Escritorio\ALCANCES SEMANA 25\INSTRUMENTACION\IC-CONF-2014-0503\Data Sheet\[Copia de 15010409R12.xls

Contract: 04477000

CONTROL VALVE Data Sheet No.: 15-01.04.10 Rev 12

SPECIFICATIONS SHEET

Grupo Alvica

Unit: Hydroprocessing Support Unit

TAG No. 15-HV-047 P.O. No.: 477040-7-0115-C1

Piping Valve No V - 901E8 11 Instr. Engr. E. Terrible

Client: Petrolera Ameriven, S.A Process Engr. ProcData Rev Date

Plant: Hamaca Crude Upgrade

Site: Jose, Venezuela Page No. 1 of 1

Unless otherwise noted below all items shall comply with general specification sheets: SP-421300-70-1M & SP-421300-70-1101

1 Fluid Hydrocarbon Liquid Service: Naphtha Splt'r Accmlt'r Liq Emerg Isolat'n Crit Press, Pc (PSIA) P&ID No. 15-A1-0115

Units Maximum Flow Normal Flow Minimum Flow Other Shut-off

2 Flow Rate ---

SERVICE / CONDITIONS

3 Inlet Pressure psig 20 65 psi 11

4 Outlet Pressure psig ---

5 Inlet Temperature °F 173 ---

6 Density / Spec Grav / Mol Wt lb/ft³ / - / - ---

7 Viscosity / Spec Heats Ratio cP ---

8 Vapor Pressure, Pv psia ---

9 Required Cv ---

10 Travel % 0

11 Allowable | Predicted SPL dBA <85 --- ---

12 Compressibility Factor, Z

13 Pipe Size In 8"-Sch. 20 53 NEC Class I Div 2 Group B, C, D 11

LINE

14 & Schedule Out 8"-Sch. 20 54 Type Double Acting Piston

15 Pipe Line Spec & Insulation J14B 55 Manufacturer & Model No. ROTORK # RP-060-200 B/D1 11

16 Type B-1 Type : Butterfly-Double Flange11 56 Size 060 12 Effective Area

17 Size 8" 57 On / Off n Modulating d

18 Max Press/Temp 65 11 psig 300 °F 58 Failure Position Open c Close d Last p

19 Manufacturer & Model No. (Series 30000-QTF)VANESSA # AA0111 59 Air Pressure Unit Yes

VALVE / BODY / BONNET

20 Body / Bonnet Matl Steel, ASTM A216 WCB 60 Max Allowable Press. 60 psig Min. Required Press. 36 psig

21 Liner Material / ID None 61 Avail Air Supply Press. Max 100 psig Min 60 psig

ACTUATOR

22 End Connection In 8" - 150 # Out 8" - 150 # 62 Bench Range N/A

23 Flg Face Finish RF 63 Valve Stem /Act.Orientation Horizontal/Horizontal (Parrell to Pipe12

24 End Ext / Matl None 64 Handwheel None

25 Flow Direction Not Applicable 65 Air Failure Valve N/A Set at

26 Type of Bonnet Integral 66 Response Time 30 Seconds 12

27 Lub & Iso Valve None 67 Min, / Max Act'r. Output Torque: 196/712 ft-lb 12

28 Packing Material Graphite 68 Actuator Lock: No 11

29 Packing Type Standard 69 Manual Override: No 11

30 Rating CLASS 150# 70 Shear Fin Required: No 11

31 Type Disc 11 71 Quick Exhaust: No 12

32 Size Full 11 72 Valve Fire Safety Category: 1 11

33 Characteristic Equal % 11 73 Valve Emergency Position: Close 11

34 Balanced c Unbalanced o 74 Type Proximity Quantity 4 12

SWITCHES

TRIM

35 Rated Cv 1220 11 75 Manufacturer & Model No. Proximity Controls, 14RDO 12

36 Disk/Seal Material CARBON STEEL / DUPLEX 11 76 Contacts & Rating SPDT, 3 Amps @ 125 VAC 12

37 Seat Material Stellite GR 21 (Weld Overlay F31611 77 Actuation Points 98% Open & 98% Closed 12

38 Cage/Guide/Stack Mat'l. 304 SS HF 11 78 Tag No. Open 15-ZSO-047 & Closed 15-ZSC-047

39 Stem Material A182 -Gr. F6A 11 79 Airset Mfr & Model No. Yes, Set Pr. 60 psig

ACC.

40 80 Solenoid Mfr & Model No.

41 Pressure Test Note 8 11 81 Solenoid Voltage Tag No.

TEST

42 Leakage Class ANSI Class V 82 Position Indicator Yes (Visible after Fireproofing 11

43 Pos. Material Identification 83 Outline Dimensions Certified Dimensions Outline Required

44 1. See data sheet 15-11.01.01 for hand switch, status light, control panel and volume tank requiremen

45 2. All electrical items shall meet specified electrical area classificatio

46 3. Control valve (metal to metal type) and actuator shall bFIRESAFE . 11

47 4. All electrical items shall be tropicalized

NOTES

48 5. For Testing: Vendor to provide a travel stop to stroke the valve from 100% open to 90% open and return to normal posi 11

49 6. Steam out @ -15 psig & 300 deg F

50 7. Air Line Size and Est. Length (Remote between Local Panel and Actuator - By Others) : 1/2" Tubing and 95 fe 11

51 8. Minimum hydrostatic shell pressure test shall be 450 psig and seat closure test shall be 285 ps 11

52

REVISION LOG

REV. ISSUE STATUS DATE BY CHK'D APP'D

10 Approved for Design and RFQ 24-Oct-00 ET ER TS

11 Issued for Purchase 21-Aug-01 ET BM ER

12 Issued for Purchase 06-jun-02 BM ER ER

Notice: This document has not been published and is the sole property of the Fluor Corporation, and is lent to the borrower for his confidential use only: and in consideration of the loan of this drawing, the borrower promises and

agrees to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically furnished.

FORM E-593 (REV. 1/98) Printed: 23-sep-15

camd\Escritorio\ALCANCES SEMANA 25\INSTRUMENTACION\IC-CONF-2014-0503\Data Sheet\[Copia de 15010410R12.xls

Das könnte Ihnen auch gefallen

- Classe de Matériel Tuyauterie 150CP11: 6117-XH-SL-STC-2/3Dokument17 SeitenClasse de Matériel Tuyauterie 150CP11: 6117-XH-SL-STC-2/3Guillaume de PluviéNoch keine Bewertungen

- PCV Data Sheet PDFDokument5 SeitenPCV Data Sheet PDFveenaNoch keine Bewertungen

- Datasheet For Control Valve - IfbDokument34 SeitenDatasheet For Control Valve - Ifbfathan fathullahNoch keine Bewertungen

- Client:: Magnetic Flow Transmitter Data SheetDokument13 SeitenClient:: Magnetic Flow Transmitter Data SheetCristian RománNoch keine Bewertungen

- Test Manifold Package No:: Client Saudi Aramco Oil CoDokument7 SeitenTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNoch keine Bewertungen

- Classe de Matériel Tuyauterie 100CP11: 6117-XH-SL-STC-2/3Dokument17 SeitenClasse de Matériel Tuyauterie 100CP11: 6117-XH-SL-STC-2/3Guillaume de PluviéNoch keine Bewertungen

- RELOAD - 0025M - 12418 - MEIP Rev.3Dokument2 SeitenRELOAD - 0025M - 12418 - MEIP Rev.3Claudio AmoneNoch keine Bewertungen

- Control Valve Data SheetDokument1 SeiteControl Valve Data SheetKelly Perez LopezNoch keine Bewertungen

- Classe de Matériel Tuyauterie 20SP11: 6117-XH-SL-STC-2/3Dokument12 SeitenClasse de Matériel Tuyauterie 20SP11: 6117-XH-SL-STC-2/3Guillaume de PluviéNoch keine Bewertungen

- 104 13479 Mob02918 DSH 420 J 0018 - 1Dokument3 Seiten104 13479 Mob02918 DSH 420 J 0018 - 1Roberto Capcha SernaNoch keine Bewertungen

- 3K8x6-14ARV M3 ST - Bombas Existentes P-2556 ABC - P-2557ADokument6 Seiten3K8x6-14ARV M3 ST - Bombas Existentes P-2556 ABC - P-2557AeduinNoch keine Bewertungen

- Ingenieria de Detalle para La Ampliación Y Optimización de Las Facilidades de Tratamiento de Fluidos Campo Rio SaldañaDokument1 SeiteIngenieria de Detalle para La Ampliación Y Optimización de Las Facilidades de Tratamiento de Fluidos Campo Rio Saldañajuan carlos suaNoch keine Bewertungen

- Data Sheet & Sizing SheetDokument3 SeitenData Sheet & Sizing SheetazitaggNoch keine Bewertungen

- Hoja de Datos - Transmisor de Nivel: GeneralDokument1 SeiteHoja de Datos - Transmisor de Nivel: GeneralPatricio AlarconNoch keine Bewertungen

- I S Ument D Ta Sheet: N TR ADokument1 SeiteI S Ument D Ta Sheet: N TR Adilip matalNoch keine Bewertungen

- Control Valves Modulating: Customer: Contractor: Plant: LocationDokument64 SeitenControl Valves Modulating: Customer: Contractor: Plant: LocationJorge GonzalezNoch keine Bewertungen

- Float Level Switch Specification - AFC-1 (ALL)Dokument8 SeitenFloat Level Switch Specification - AFC-1 (ALL)Phạm Tấn PhướcNoch keine Bewertungen

- A11627SE-04 - CVDS Rev C Technical Specification 840GDokument2 SeitenA11627SE-04 - CVDS Rev C Technical Specification 840GMichael Adu-boahenNoch keine Bewertungen

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEDokument1 SeitePlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEAnthony InostrozaNoch keine Bewertungen

- PI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Dokument1 SeitePI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Annie De WildeNoch keine Bewertungen

- Datasheet Rev 1Dokument7 SeitenDatasheet Rev 1Tauasi TauasisNoch keine Bewertungen

- CL04-GPNT-PRO-LST-0001-01 Line List - RADokument4 SeitenCL04-GPNT-PRO-LST-0001-01 Line List - RAperdana kusumaNoch keine Bewertungen

- PVSV 1340 1341Dokument1 SeitePVSV 1340 1341Nelson NavaNoch keine Bewertungen

- Coil Inspection ReportDokument3 SeitenCoil Inspection ReportVINAYNoch keine Bewertungen

- MEC-JTB-SF-M-DTS-900-00028 - 0 - 5-Datasheet - Wet-Instrument-Air-Receiver - (440-D-9001) - Commented.1-SA-MC (Code 2)Dokument5 SeitenMEC-JTB-SF-M-DTS-900-00028 - 0 - 5-Datasheet - Wet-Instrument-Air-Receiver - (440-D-9001) - Commented.1-SA-MC (Code 2)Yusri FakhrizalNoch keine Bewertungen

- 18CO5009-10-It2-D03-1 Data Sheets (Pumps) - FLOWSERVE FormatDokument4 Seiten18CO5009-10-It2-D03-1 Data Sheets (Pumps) - FLOWSERVE FormatGerencia Rigar Colombia SASNoch keine Bewertungen

- V-710 CPRP-7Dokument22 SeitenV-710 CPRP-7balajikrishnanNoch keine Bewertungen

- MAT-p eDokument4 SeitenMAT-p eedark2009Noch keine Bewertungen

- CCV 308Dokument8 SeitenCCV 308francisco abarcaNoch keine Bewertungen

- A11627SE-08 - CVDS Rev B Technical Specification 840GDokument2 SeitenA11627SE-08 - CVDS Rev B Technical Specification 840GMichael Adu-boahenNoch keine Bewertungen

- Hoja de Datos XV-5025Dokument1 SeiteHoja de Datos XV-5025dgii.oftec.car2Noch keine Bewertungen

- 2061-MIX-001 Rev1Dokument2 Seiten2061-MIX-001 Rev1Emmanuel Ber SNoch keine Bewertungen

- Central de Generación: Power Plant Pressure - Temperature Regulator ValveDokument1 SeiteCentral de Generación: Power Plant Pressure - Temperature Regulator Valvejuan carlos suaNoch keine Bewertungen

- Data SHEET SEPARADOR 3Dokument1 SeiteData SHEET SEPARADOR 3Diego RuanoNoch keine Bewertungen

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-012 KNIFE VALVEDokument1 SeitePlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-012 KNIFE VALVEAnthony InostrozaNoch keine Bewertungen

- PROYECTO: 13479 Epc - Sistema de Bombeo de Relaves Lineas Norte Y Sur - Elevación 4165 Etapa: Ingeniería de Detalle - 104Dokument2 SeitenPROYECTO: 13479 Epc - Sistema de Bombeo de Relaves Lineas Norte Y Sur - Elevación 4165 Etapa: Ingeniería de Detalle - 104Luis Orlando Gil BancallanNoch keine Bewertungen

- ANEXO 3.1 - Hoja de Datos PSV-110A - Version 2 - Rta 6Dokument1 SeiteANEXO 3.1 - Hoja de Datos PSV-110A - Version 2 - Rta 6Annie De WildeNoch keine Bewertungen

- VF003 - Level Gauge (ALL) PDFDokument21 SeitenVF003 - Level Gauge (ALL) PDFPhạm Tấn PhướcNoch keine Bewertungen

- RDFALWN-CAM S Full en Us LetterDokument5 SeitenRDFALWN-CAM S Full en Us LetterJustinNoch keine Bewertungen

- 315020-DOC-7015 - (Instrument Datasheet - Pressure Regulator Valve) - RevADokument3 Seiten315020-DOC-7015 - (Instrument Datasheet - Pressure Regulator Valve) - RevAanwar sadatNoch keine Bewertungen

- Manifold Layout With ColorsDokument1 SeiteManifold Layout With ColorshectdgNoch keine Bewertungen

- Bombas Agua PotableDokument1 SeiteBombas Agua PotableRafael SalazarNoch keine Bewertungen

- HLJ072T4LC6 4517Dokument3 SeitenHLJ072T4LC6 45170kphNoch keine Bewertungen

- AnnexureDokument391 SeitenAnnexureTommy ArjanggiNoch keine Bewertungen

- Datasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)Dokument2 SeitenDatasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)usama666Noch keine Bewertungen

- Elom-35q-419 R4Dokument1 SeiteElom-35q-419 R4ariyakkannaa0% (1)

- Ds-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Dokument5 SeitenDs-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Panisa BanimaNoch keine Bewertungen

- Collar Cam Chain Guide Roller PdirDokument1 SeiteCollar Cam Chain Guide Roller PdirPreetam KumarNoch keine Bewertungen

- GBCPP PCV 2030Dokument1 SeiteGBCPP PCV 2030Firstyan Dhika AldaniNoch keine Bewertungen

- FA-For ReferenceDokument1 SeiteFA-For ReferenceUmer KhanNoch keine Bewertungen

- 15NO03 DS 60 008. Datasheet Temperature GaugeDokument4 Seiten15NO03 DS 60 008. Datasheet Temperature Gaugebagus handokoNoch keine Bewertungen

- Example Pump Selection: Equipment Data SheetDokument4 SeitenExample Pump Selection: Equipment Data SheetMohamed Yassine LahianiNoch keine Bewertungen

- Pt. Bayer Motor 3.7 KWDokument20 SeitenPt. Bayer Motor 3.7 KWhamzah naoreyNoch keine Bewertungen

- Example Pump Selection: Hoja de Datos de EquiposDokument2 SeitenExample Pump Selection: Hoja de Datos de EquiposAlonso DIAZNoch keine Bewertungen

- 000 in DTS 401Dokument6 Seiten000 in DTS 401zsmithNoch keine Bewertungen

- Mecánica Data Sheet For Walnut Shell Filter Feed Pumps Tag P-222051 A/B - Stap - Pia LlanitoDokument5 SeitenMecánica Data Sheet For Walnut Shell Filter Feed Pumps Tag P-222051 A/B - Stap - Pia LlanitoJavier Andres Barahona GarciaNoch keine Bewertungen

- 3827-E10-062 - Two Position Valve - DDokument4 Seiten3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNoch keine Bewertungen

- Interseal 670 HSDokument4 SeitenInterseal 670 HSFikru DdienNoch keine Bewertungen

- Interzinc 52 TDSDokument4 SeitenInterzinc 52 TDSDele TedNoch keine Bewertungen

- 6 Equipment Inventory Template ES1Dokument10 Seiten6 Equipment Inventory Template ES1Freddy AntonioNoch keine Bewertungen

- Grupo Alvica: Control ValveDokument2 SeitenGrupo Alvica: Control ValveHernan YanezNoch keine Bewertungen

- Grupo Alvica: Control ValveDokument7 SeitenGrupo Alvica: Control ValveHernan YanezNoch keine Bewertungen

- CHAPTER 6 - Incompressible Inviscid FlowDokument33 SeitenCHAPTER 6 - Incompressible Inviscid FlowRamadhanu SuwondoNoch keine Bewertungen

- Test Methods To Predict Moisture Sensitivity of Hot-Mix AsphaltDokument38 SeitenTest Methods To Predict Moisture Sensitivity of Hot-Mix AsphaltshyabedNoch keine Bewertungen

- Filter Vessel Calculations Per As Me Viii 1Dokument40 SeitenFilter Vessel Calculations Per As Me Viii 1Anonymous J1vjrU2Noch keine Bewertungen

- Grade 10 ActivityDokument52 SeitenGrade 10 Activityapi-340407914100% (1)

- Astm D2672 (1996)Dokument4 SeitenAstm D2672 (1996)hussein100% (1)

- Physics ProjectDokument3 SeitenPhysics ProjectTITISHA ROYNoch keine Bewertungen

- PVT Properies Correlations SLBDokument128 SeitenPVT Properies Correlations SLBginozky100% (2)

- Basic Pipe Network Unit Fluid Friction in Pipes Unit: FME23. AFT/PDokument1 SeiteBasic Pipe Network Unit Fluid Friction in Pipes Unit: FME23. AFT/PvrajendraupadhyayNoch keine Bewertungen

- Boyles LawDokument26 SeitenBoyles LawIking De LaraNoch keine Bewertungen

- International Journal of Heat and Mass TransferDokument12 SeitenInternational Journal of Heat and Mass TransferYomiraElisaSambonyNoch keine Bewertungen

- Chapter 2 Dry Gas Reservoir: Example 1Dokument8 SeitenChapter 2 Dry Gas Reservoir: Example 1Muhammad Nizam50% (2)

- Electrical Submersible PumpDokument119 SeitenElectrical Submersible PumpAnonymous iCFJ73OMpD100% (1)

- Well Pressure Profile BetaDokument3 SeitenWell Pressure Profile BetaDevito PradiptaNoch keine Bewertungen

- Mechanical Principles H2 Tutorial 4 Self Assessment Exercise No.1Dokument6 SeitenMechanical Principles H2 Tutorial 4 Self Assessment Exercise No.1layiro2Noch keine Bewertungen

- ChemistryDokument13 SeitenChemistryaman98mailNoch keine Bewertungen

- Kech 106Dokument47 SeitenKech 106Ashutosh PantNoch keine Bewertungen

- 12 16Dokument10 Seiten12 16Aboalmaail AlaminNoch keine Bewertungen

- Zaman of Chapter 2 - Fluid PressureDokument41 SeitenZaman of Chapter 2 - Fluid PressureFatin HazwaniNoch keine Bewertungen

- 03 SM6 - General Parameter IntroductionDokument12 Seiten03 SM6 - General Parameter IntroductionThức VõNoch keine Bewertungen

- Becker VT 4.10 - VT 4.40Dokument2 SeitenBecker VT 4.10 - VT 4.40binhNoch keine Bewertungen

- Introduction To Fiscal MeteringDokument24 SeitenIntroduction To Fiscal MeteringAliNoch keine Bewertungen

- Hydraulic Resevoir Design Criteria PDFDokument10 SeitenHydraulic Resevoir Design Criteria PDF2345421Noch keine Bewertungen

- ProgressiveDokument160 SeitenProgressiveLuisgarciaBerlangaNoch keine Bewertungen

- Attachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1Dokument1 SeiteAttachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1rohitkushNoch keine Bewertungen

- Secondary Physics 1 Student TextbookDokument276 SeitenSecondary Physics 1 Student TextbookʆʬʆØff SídeʆʬʆNoch keine Bewertungen

- WRTGRTBDokument1 SeiteWRTGRTB224883061Noch keine Bewertungen

- Ds Concrete Forming HBDokument108 SeitenDs Concrete Forming HBUpali KarunarathneNoch keine Bewertungen

- Q and A Problem Solving ReliefDokument3 SeitenQ and A Problem Solving ReliefCharlotte Bacani SamilinNoch keine Bewertungen

- Flash SteamDokument12 SeitenFlash SteamDuy Nguyen DucNoch keine Bewertungen

- Iso 11650 en PDFDokument8 SeitenIso 11650 en PDFLEANDRO AUGUSTONoch keine Bewertungen