Beruflich Dokumente

Kultur Dokumente

US2116806

Hochgeladen von

marlondiji0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten3 SeitenCopyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten3 SeitenUS2116806

Hochgeladen von

marlondijiCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

Patented May 10, 1938

2,116,806

UNITED STATES PATENT OFFICE

2,116,806

MXING, WALWE

Roy H. Zinkil, Oak Park, and Edward A. Fred

rickson, Chicago, El.., assignors to Crane Co.,

Chicago, Ill., a corporation of Illinois

Original application June 11, 1934, Serial No.

730,004, now Patent No. 2,094,288, dated Sep

tember 28, 1937. Divided and tilis applica

tion November 13, 1936, Serial No. 110,582

1 Claim. (CI. 277-18)

This invention relates to valves and more par 7. The valve chambers 2 have lateral inlets 8

ticularly to a valve constructed in a new manner and 9 adapted to be connected with the respec

and is a division of our co-pending application, tive cold and hot water Supply pipes (indicated

Serial No. 730,004, filed June 11, 1934, and now but not shown).

Patent No. 2,094,288, granted September 28, The upper ends of the valve chambers are 5

1937, for a mixing valve. closed by means of the plugs 0, which retain

Our invention relates to that type of pedal

Operated mixing valve in which hot and cold the springs 7, the plugs being preferably remov

water are brought together from each of their bers in able order to gain access to the valve men

and springs without necessitating discon

respective Supply pipes into a common chamber nection of the valve chamber from the floor it O

within the valve proper. self. The valve members 6 preferably seat

More particularly, the prinary purpose of against renewable

our invention is to provide for an accurate, con erably threadedly seat rings if, which are pref

attached to the casing .

Venient and more easily controlled mechanical

means for varying the temperature of the mixed byEach of the respective poppet valves is guided

the extension rods f2 and 2d which move ls

water.

Another important object is to provide for a the in reciprocating manner as journalled Within

Construction in which the adjustment of the re pose respective bores 3 of the caps 0, the pur

Spective hot and cold water valves is also readily prevent of the rods being to guide and to thereby

2) accessible after installation, comprising a re

a wobbling movement of the valve as

each returns to its seat 6 under the action of 20

movable or separable floor housing preferably the spring. The guide member 2, as previously

independent of the valve chamber proper. mentioned, is threaded to provide for the retain

Another important object is to obtain the ing means 3 for the renewable disc 4. In re

quick opening with a relatively small movement ferring to the valve shown in the right hand

5 of the actuating means of both valves with a portion of Fig. , the guide member 2 is pro 25

Smooth and uniform action, functioning by vided with a frustro-conical extension 2c against

means of a pivotable pedal.

Another object is to provide certain improve which theinpush rod 4 rests when the valve is

ments in mixing valves of this character afford installed its normal position. The member

2g is preferably threadedly attached to the

ing ease of installation upon the floor adjacent to guide means by Screwdriver slot 2b. This con 30

the fixture. struction applies to the valve controlling the sup

We attain these objects by mechanism similar. ply of hot water.

to that illustrated in the accompanying draw Referring to the left hand or cold water side

ing, in which of the Fig. 1 as designated by numeral 8, the

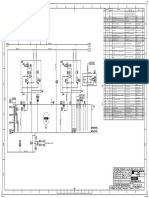

Fig. 1 is a front, vertical, sectional view of the guide 2d, therein is made to permit the tappet 3

internal relation of the valves and their control rod 4b to bear against the latter as at 4c.

ling parts within the respective valve chamber The reason for the difference in the construction

and housing and in which the mode of operation shown is to prevent the Wrongful positioning of

is obtained by means of a pivotable pedal action the respective valves. The tappet rod 4b, as in

for foot operation. dicated, is provided preferably integrally with an

Fig. 2 is a view partly in side elevation and enlargement thereon for the purpose of dinin 40

partly in side vertical section of the embodiment ishing the supply of cold water as the valve

shown in Fig. 1. approaches its maximum movement in opening,

Similar numerals refer to similar parts while the hot water under the Sane movement

throughout the views. and by reason of the same form of enlargement

Referring to Fig. 1, the body or housing of attached

the valve comprises a plurality of parallel posi its volumeto inthethe guide member 2 increases in

amount of Water entering

tioned valve chambers 2 at its upper portion, through the Seat opening as it is gradually

containing the valve members 3 consisting pref being opened. Briefly, so far as respective vol

erably of a disc retaining ring 3a for the pur

pose of retaining a composition disc 4 by means ume control is concerned, their action is re- :

ciprocal although this relationship as mentioned

of the threads 5. These valves more specifically may be materially changed by the positioning of

are guided for reciprocatory movement and are the threaded adjusting Screws hereinafter de

of a poppet type, seating downwardly against Scribed.

the valve seats 6 under the action of the Springs The elongated push rods or valve actuating 55

2 2,116,806

means 4 are each journalled within a spring theThus the temperature of the water and also

amount thereof entering the upper chamber

loaded stuffing box 5 extending through and Sc and discharging through the outlet 3d is

beyond the bushing 6 into the interior of the

lower housing, and are made of such length so conveniently controlled and handled.

It is apparent that our invention is capable of 5

as to permit the necessary clearance between the numerous modifications falling within its spirit

adjusting screw 7 and the end of the respec and we desire, therefore, to be limited only to

tive rod 4a. A crosshead member 8 supports the extent of the appended claim.

the adjusting Screws 7 in locked or non-rotat We claim:

able engagement by means of the locknuts f 9 In a mixing valve comprising a casing having 10

0 and is attached to the central operating means hot and cold fluid inlets thereto and a fluid

by a nut and Washer, respectively designated as Outlet or outlets therefron, a housing adjacent

2 and 22, and also held in non-rotatable posi to the Said casing and having a forward, Verti

tion, as indicated. The upper end of the cally extending Wall, Simultaneously operable

broached head 23 has the thread member 25 valves for the control of fluids through said in 5

5 preferably made for guidance within the hollow lets, a crosshead reciprocably movable and jour

guide 26. nally guided within the interior lower portion

It is apparent that the respective valve rods 4 of the said housing, the said crosshead being ac

being operated by depressing the foot pedal des tuated by a Single pivotable pedal operable ex

ignated as 34, which is hingedly attached to the teriorly of Said housing the said pedal being 20

20 housing 32 as shown at 35, thereby engages the

slidable assembly 36 by means of the slotted con limited to downward movement and mounted

nection 3 which assembly consists of the slot upon said Vertically extending wall, the Said

CrOSShead having independently adjustable

and the complementary lever extension 38. The means cooperating with the Said pedal for ac

spring 39 tends to keep the extension 36 bearing complishing the time of movement and regulat 25

25 against the shoulder 4 and by depressing the

pedal 34 the respective extension stems are lift ing the travel of the said valves, the latter hav

ed axially until Such time as the valves 3 are ing extending portions projecting within said

raised from the seats, thus admitting the de housing, the said extending portions serving as

sired amount of hot and cold Water respectively. means for contacting with the said adjustable

means of the crosshead. 30

30 It is obvious that the amount of depression of

the respective valves is easily controllable by ROY H. ZINKL,

neans Of the fine adjustment permissible on the

adjusting screws 7 mounted upon the cross EDWARD A, FREDRICKSON.

head 8.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- ZZZZZ& : April 15, 1958Dokument5 SeitenZZZZZ& : April 15, 1958marlondijiNoch keine Bewertungen

- Budynas SM ch03Dokument56 SeitenBudynas SM ch03Na2ryNoch keine Bewertungen

- Performance Evaluation of Utilization of Waste Polyethylene Terephthalate (PET) in Stone Mastic AsphaltDokument6 SeitenPerformance Evaluation of Utilization of Waste Polyethylene Terephthalate (PET) in Stone Mastic AsphaltAgustina ManurungNoch keine Bewertungen

- Filed July 30, 1923: Pedal of Erator For Flush ValvesDokument3 SeitenFiled July 30, 1923: Pedal of Erator For Flush ValvesmarlondijiNoch keine Bewertungen

- United States Patent (19) : Woltz Et Al. (45) Date of Patent: Jul. 27, 1993Dokument7 SeitenUnited States Patent (19) : Woltz Et Al. (45) Date of Patent: Jul. 27, 1993marlondijiNoch keine Bewertungen

- 1,176,784. Patented Mar, 28, 1916.: Walwe Operating Mechanism For LawatoresDokument5 Seiten1,176,784. Patented Mar, 28, 1916.: Walwe Operating Mechanism For LawatoresmarlondijiNoch keine Bewertungen

- March 8, 1932. L. W. Beebe 1,848,456: 2észz72/7zezsDokument6 SeitenMarch 8, 1932. L. W. Beebe 1,848,456: 2észz72/7zezsmarlondijiNoch keine Bewertungen

- United States Patent (19) : Gilbert, Sr. (45) Date of Patent: Feb. 7, 1995Dokument13 SeitenUnited States Patent (19) : Gilbert, Sr. (45) Date of Patent: Feb. 7, 1995marlondijiNoch keine Bewertungen

- Iiihiii: United States PatentDokument9 SeitenIiihiii: United States PatentmarlondijiNoch keine Bewertungen

- Mapa Conceptual Normas Del Mantenimiento PDFDokument3 SeitenMapa Conceptual Normas Del Mantenimiento PDFmarlondijiNoch keine Bewertungen

- EnsayoDokument4 SeitenEnsayomarlondijiNoch keine Bewertungen

- Marco ConceptualDokument2 SeitenMarco ConceptualmarlondijiNoch keine Bewertungen

- Parker VOAC F11-F12 Technical DocumentDokument44 SeitenParker VOAC F11-F12 Technical DocumentPablo Soto100% (1)

- Itt 04Dokument124 SeitenItt 04Edgar DominguezNoch keine Bewertungen

- Clutch and Operation System Repair ManualDokument22 SeitenClutch and Operation System Repair Manualsample nameNoch keine Bewertungen

- PRFD - Design ManualDokument2 SeitenPRFD - Design ManualSreepathy RangarajanNoch keine Bewertungen

- C15 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic SymbolsDokument2 SeitenC15 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic Symbolsminh le huu100% (2)

- Installation, Operation, and Maintenance Manual: 80 Series PumpDokument29 SeitenInstallation, Operation, and Maintenance Manual: 80 Series PumpFelipe Ignacio PaillavilNoch keine Bewertungen

- Info 241 enDokument58 SeitenInfo 241 enVratNoch keine Bewertungen

- CEBDokument2 SeitenCEBnehaNoch keine Bewertungen

- Draft SystemDokument5 SeitenDraft Systemmkchy12Noch keine Bewertungen

- 01 P & I Legend 1062M100s1rCDokument1 Seite01 P & I Legend 1062M100s1rCChihiya Fitria NurhayatiNoch keine Bewertungen

- Rifox Product Overview 3.2010Dokument16 SeitenRifox Product Overview 3.2010eyderortega1980Noch keine Bewertungen

- 6N330 (0CH10-M26102)Dokument343 Seiten6N330 (0CH10-M26102)Agung Hidayatullah100% (3)

- Hitachi Water Pump CatalogueDokument6 SeitenHitachi Water Pump CatalogueRicky al ikhsaniNoch keine Bewertungen

- B737 Pneumatic Sys T.SDokument4 SeitenB737 Pneumatic Sys T.SDavid ObiNoch keine Bewertungen

- Third Officer Second Officer: Maintaining Navigational Watch atDokument11 SeitenThird Officer Second Officer: Maintaining Navigational Watch atAchmad DahlanNoch keine Bewertungen

- Hydraulic FundamentalsDokument17 SeitenHydraulic FundamentalsRoyal Ritesh SharmaNoch keine Bewertungen

- Prosim Beta Manual-06!16!2011Dokument62 SeitenProsim Beta Manual-06!16!2011alvaro2005Noch keine Bewertungen

- AE115 Powerstar ManualDokument16 SeitenAE115 Powerstar ManualDayna Harrell-JohnsonNoch keine Bewertungen

- Ac20 135 PDFDokument18 SeitenAc20 135 PDFJawariNoch keine Bewertungen

- SL1168 Instruction ManualDokument51 SeitenSL1168 Instruction ManualBruno Diaz100% (1)

- SDB Series Blower Purge Desiccant Dryers 1200-12000 SCFMDokument4 SeitenSDB Series Blower Purge Desiccant Dryers 1200-12000 SCFMramiro alvarezNoch keine Bewertungen

- Saep 57 PDFDokument30 SeitenSaep 57 PDFRami ElloumiNoch keine Bewertungen

- RV Irv Series Steering GearDokument4 SeitenRV Irv Series Steering GearPop EhabbNoch keine Bewertungen

- Plumbing Code 2012 ICC IPC Full Text PDFDokument194 SeitenPlumbing Code 2012 ICC IPC Full Text PDFGabriel TorresNoch keine Bewertungen

- Tech Guide To Filling MachinesDokument12 SeitenTech Guide To Filling MachinesLatifani Ayu ChaerunnisaNoch keine Bewertungen

- 01 PP01024 B Hyd - CKTDokument1 Seite01 PP01024 B Hyd - CKTAvishek DasNoch keine Bewertungen

- Inspection of Boiling House EquipmentDokument7 SeitenInspection of Boiling House EquipmentAnonymous cw6ExKwpKNoch keine Bewertungen

- ASTM F 1508 2021, Standard Specification For Angle Style, PressureDokument15 SeitenASTM F 1508 2021, Standard Specification For Angle Style, PressurelaythNoch keine Bewertungen

- Manual Ingles Secadores Hhe HHL Hhs SeriesDokument68 SeitenManual Ingles Secadores Hhe HHL Hhs SeriesHoney18180% (1)

- Basics of Valves Interview Questions & Answers: Directional Control ValveDokument7 SeitenBasics of Valves Interview Questions & Answers: Directional Control ValveJêmš NavikNoch keine Bewertungen