Beruflich Dokumente

Kultur Dokumente

Mastering The Pic16C7X A/D Converter: By: Jim Simons

Hochgeladen von

Sixto AgueroOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mastering The Pic16C7X A/D Converter: By: Jim Simons

Hochgeladen von

Sixto AgueroCopyright:

Verfügbare Formate

MASTERING

THE PIC16C7X A/D CONVERTER

By: Jim Simons

The analog to digital converter (A/D) is the primary tool that General

allows analog signals to be quantized into the world of

Even though we are converting to the ‘digital world’, we

digital electronics. Once the signal is digitally represented,

must remember that certain analog ‘laws’ still hold true.

it can be stored, analyzed and manipulated by a variety of

Specifically, the A/D is basically a capacitor which has to

logic devices. The PIC16C7X microcontrollers have an A/D

have time to charge/discharge to the analog level on the I/O

integrated onto the PIC16CXX core processor. Utilizing

pin before a conversion can be started. Source impedance

Microchip’s A/D requires only a basic level of understanding and internal impedances add up to give an effective

to get a result. However, maximizing the effectiveness of the resistance in series with the capacitor(s). This RC time

A/D for each specific application requires a higher level of constant determines the minimum amount of

thought and understanding. Typically a thorough charge/discharge time to achieve a desired accuracy. This

comprehension of a device is obtained through experience, time is the minimum tracking time (referred to as the

studying data sheets and studying application notes for a minimum sampling time in our data book). Once the

reasonable amount of time. This article addresses the main minimum time has been met, the voltage on the capacitor

technical considerations for an effective design to reduce will track the voltage on the I/O pin until a conversion is

your design time. started. Once the conversion has begun, the I/O pin is

When detailing how to maximize the effectiveness of any internally disconnected from the capacitor. The voltage on

design, we look at the weakest (and strongest) elements. the capacitor is held constant for the entire conversion

Please DO NOT misinterpret the statements detailing process. This type of sampling circuit is referred to as a

weaknesses to be below our specification. Our part "track and hold".

specifications are based upon the worst case. All Step by Step

suggestions should improve on the worst case

specifications. 1. In order to perform a conversion, you must enable

the A/D by setting the ADON bit (ADCON0 register).

We’ll start by covering the A/D Basics, then dive into the

2. Select the channel to be sampled by setting/clearing

other three general technical categories which are essential

the CHS2, CHS1, and CHS0 bits (ADCON0

for an effective design:

register). See the ADCON0 register’s bit descriptions

• Speed in the device’s data sheet for the actual bit

• Accuracy combinations for the selected channel(s).

• Power Usage 3. The default input setup of all analog I/O pins is

analog, not digital. For I/O pins set up as analog, the

BASICS digital input buffers are internally disconnected. This

is to keep analog voltages off of the CMOS input

Specifications buffer. If the input voltage on a digital I/O was 0.5VDD

Microchip’s A/D is a successive approximation A/D which for example, then both the PMOS and NMOS cells

uses a bank of internal capacitors totalling 51.2pF. The which make up the CMOS input buffer would be

maximum resolution of the A/D is 8-bits. The converter turned on. This causes the input buffer to draw

accuracy specification is ±1 bit, but that can be made better around 100 to 150µA.

or worse by your design. The analog channels are

multiplexed to the converter which means that only one If you are using an analog I/O as a digital input, load

analog channel can be sampled at a time. The conversion the register ADCON1 with the correct value to

time and maximum sampling frequency is application change the default from analog to digital. The I/O

specific. pin’s bit will always read as a 0 when configured as

an analog input (since it is disconnected from the

pin). See the ADCON1 register’s bit descriptions in

the device’s data sheet for the actual bit

combinations for the selected channel(s).

1996 Microchip Technology Inc. FACT002-page 1

This document was created with FrameMaker 4 0 4

Step by Step (cont’d) EXAMPLE 1:

4. Wait for at least the minimum tracking time. The VDD = VREF = 5V

tracking time is the time required to charge a 51.2pF RIC = 1 kΩ

capacitor (located internal of the PIC16C7X) to the RSS = 7 kΩ

voltage level of the selected channel. The tracking RS = 10 kΩ

time is made up of three components: Error = 8 bits ±1/2 = 29 = 512

• Amplifier Settling Time tCHARGE = - (1kΩ + 7kΩ + 10kΩ)(51.2pF) ln 1/512 = 5.75µs

• Holding Capacitor Charging Time

• Temperature Coefficient EXAMPLE 2:

Same values as Example 1, except we put a .01µF

TTRACKING = TAMP + TCHARGE + TTEMP decoupling capacitor on the I/O pin. This effectively

Given:TtAMP = 5µs reduces RS to the impedance of the capacitor.

RS ≈ 50Ω

Given: TTEMP= (Temp - 25°C)(0.05µs/°C), if > 25°C

TTEMP= 0, if ≤ 25°C TCHARGE = - (1kΩ + 7kΩ + 50Ω)(51.2pF) ln 1/512 = 2.57µs

5. Choosing the A/D clock source (TAD) determines the

TCHARGE Equation Derivation: time required for the conversion of each bit. There

are four choices for the clock source: FOSC/2,

Basic Capacitor Charge Equation

FOSC/8, FOSC/32 and FRC. Bits ADCS1 & ADCS0

–T

--------- (ADCON0 register) determine the clock source.

RC

V C A P = V F I N A L – ( V F I N A L – V I N I T I A L) e

Table 1 will help you to choose the clock source according

or as it applies to your oscillator frequency.

– T C H ARG E TABLE 1: DEVICE OSCILLATOR

---------------------------

RC H O L D

V H O L D C A P = V R E F – ( V R E F – 0) e FREQUENCY BY CLOCK SOURCE

Where: R = RIC + RSS + RS FOSC/2 FOSC/8 FOSC/32 FRC

RS = Source Impedance

RIC = Internal Interconnect Impedance PIC16C71 ≤1MHz ≤4MHz ≤16MHz any F

RSS = Internal Sampling Switch Impedance PIC16C70/71A/72/73/74 ≤1.25MHz ≤5MHz ≤20MHz any F

(see PIC16/17 Data Book, Section 13.1 for values)

Note: FRC assigns TAD to an internal RC oscillator

C H O L D = 51.2pF which is typically 4µs (min = 2µs, max = 6µs).

VREF To calculate the precise tAD period you have chosen:

V H O L D C A P = V R E F – --------------

error x

T AD = --------------- where x = either 2, 8 or 32.

F OSC

Therefore:

6. After setting up the A/D and waiting the minimum

– T C H ARG E

----------------------------------------------------------------- tracking time, set the GO/DONE bit (ADCON0

V R E F – -------------

VREF ( R I C + R S S + R S) C H O L D

= VREF – VREF e

error register) to start the conversion.

– T C H ARG E 7. Either poll for the GO/DONE bit to be cleared, poll for

------------------------------------------------------------------

( R I C + R S S + R S) C H O L D

1

V 1 – -------------- = V 1–e

the ADIF to be set, or enable interrupts and wait for

ref error ref the interrupt to happen. When any one of these

events occurs, the conversion is finished and the

– T C H ARG E result is located in the ADRES register.

------------------------------------------------------------------

1 ( R I C + R S S + R S) C H O L D

-------------- = e 8. The A/D will begin tracking the analog signal again 2

error

TAD (TRESET) after the conversion has completed.

T C H ARG E = – ( R I C + R S S + R S ) C H O L D ( In --------- )

1

error 9. The time necessary to take an analog to digital

sample is the total of tracking time plus conversion

Reducing this time can significantly reduce the accuracy of time. For repetitive samples, TRESET is added to the

the result. total time. Use this equation to calculate the max.

repetitive sampling rate (FSAMPLING).

1/FSAMPLING

= TSAMPLE

= TTRACKING + TCONVERSION + TRESET

FACT002-page 2 1996 Microchip Technology Inc.

SPEED written to ADRES until the entire 8 bits have been

converted (regardless of the accuracy of each bit).

If your design will require an A/D sample time less than 60µs Figure 1 illustrates the timing required to determine

then you will want to consider the following factors: tracking each bit. Since the A/D operates synchronously with

time, conversion time, and minimum acceptable precision. respect to the internal instruction cycle (4/FOSC), we

When choosing the clock source to get the fastest can accurately determine when to select a faster tAD

conversion time, we want to get a TAD as close to (but not (FOSC/2). The least significant bits determined after

less than) 2µs for a PIC16C71 and 1.6µs for a PIC16C70, the conversion has been accelerated will be

PIC16C71A, PIC16C72, PIC16C73 or PIC16C74. unreliable and most likely inaccurate. The following

1. What is the minimum precision your design requires calculation determines the minimum amount of time

(i.e., 4-bit, 6-bit or 8-bit)? This is an important before you can change the tAD clock select bits for

question, since we can accelerate the conversion the resolution required.

after the desired accuracy has been achieved. We

cannot interrupt or abort the conversion after TCONVERSION = 1.5 • Tad + N • Tad + (8 - N)(2 • Tosc)

achieving the desired accuracy since the result is not (where N = Number of bits of resolution)

FIGURE 1: A/D CONVERSION TIMING

BSF ADCON0, GO

(TOSC/2) *

131

Q4

130

A/D CLK

A/D DATA 7 6 5 4 3 2 1 0

ADRES OLD_DATA NEW_DATA

ADIF

GO DONE

TRACKING TIME TRACKING STOPPED

132

* If the A/D clock source is selected as RC, a time of TCY is added before the A/D clock starts.

This allows the sleep instruction to be executed.

1996 Microchip Technology Inc. FACT002-page 3

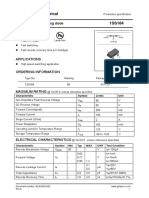

TABLE 2: A/D CONVERSION REQUIREMENTS*

Parameter # Sym. Characteristic Min. Typ.† Max. Units Conditions

130 TAD A/D clock period 1.6 — µs VREF≥3.0V

2.0 — µs VREF full range

130 TAD A/D Internal RC ADCS1,0 = 11

Oscillator source (RC oscillator source)

3.0 6.0 9.0 µs PIC16LC74

2.0 4.0 6.0 µs PIC16C74

131 TCNV Conversion time (not — 9.5TAD — —

including S/H

time)(Note 1)

132†† TSMP Sampling time 5 — — µs The minimum time is the amplifier settling

time. This may be used if the “new” input

voltage has not changed by more than 1LSb

(i.e., 20mV @ 5.12V) from the last sampled

voltage (as stated on CHOLD).

* These parameters are characterized but not tested.

† Data in “Typ” column is at 5.0V, 25°C unless otherwise stated. These parameters are for design guidance only and are

not tested.

Note 1: ADRES register may be read on the following TCY cycle.

†† TTRACK = TSMP. Parameter #132 is TSMP Sampling Time.

EXAMPLE 3: A STANDARD 8 BIT (±1 LSb) FAST CONVERSION

Processor = PIC16C74

Oscillator = 20MHz

Max possible TAD = 1.6µs

TAD clock source = FOSC/32 ∴ TAD = 1.6µs

TTRACKING = (5µs + 0µs + 2.57µs) = 7.65µs [from Example 2]

tCONVERSIOn = 1.5•1.6µs + 8•1.6µs + (8 - 8)(2•50ns) = 15.2µs

TAD_SAMPLE = 15.2µs + 7.6µs + 2•1.6µs = 26µs

FMAX_A/D_SAMPLING_RATE = 38.4kHz

EXAMPLE 4: A 4 BIT (±1/32 LSb) FAST CONVERSION

Processor = PIC16C71

Oscillator = 16MHz

Max possible TAD = 2.0µs

TAD clock source = FOSC/32 ∴ TAD = 2.0µs

TTRACKING = (5µs + 0µs + 2.57µs) = 7.65µs [from Example 2]

TCONVERSION = 1.5•2.0µs + 4•2.0µs + (8 - 4)(2•62.5ns) = 11.5µs

TAD_SAMPLE = 11.5µs + 7.6µs + 2•2.0µs= 23.1µs

FMAX_A/D_SAMPLING_RATE = 43.3kHz

2. Executing a few instructions while the previous result. (The GO bit is cleared at that time.) In order to

conversion is still running will allow ‘overhead’ code ensure that the sampling time is started as quickly as

to be executed during the tracking time and possible, set up the A/D channel for the next

conversion time. Don’t worry about using the data conversion (ADCON1) after the current tracking has

from the A/D immediately after the GO bit has been stopped and before the current conversion is done

cleared. The ADRES register will contain the (this will not affect the current conversion).

previous A/D result until it is updated with the new

FACT002-page 4 1996 Microchip Technology Inc.

ACCURACY 5. Increasing the tracking time (TTRACKING) >5µs pro-

duces a measurable increase in accuracy. 20µs is

Every designer should understand what effects the generally a good length of tracking time before start-

accuracy of the A/D. The following techniques may improve ing a conversion.

your designs. A meticulous and careful design can achieve 6. Increase TAD to about 4µs. This allows the internal

approximately ±1 LSb. comparator response time to increase with less

1. A critical factor in our A/D’s accuracy is the power overdrive error. Notice that TRC is typically 4µs.

supply to the PIC16C7X. Noise or ripple on VDD can 7. Operate at room temperature (25°C) since a high

adversely affect the conversion’s accuracy (the temperature increases leakage from the sample

degree to which the accuracy is affected is depen- capacitor and low temperatures shift threshold

dent upon the amplitude of the noise). To improve the levels. If you know that high temperature operation is

supply, use common filtering techniques, such as possible, keep tAD as close to the minimum

decoupling capacitors for various frequencies. as possible.

Note: Remember that capacitors are not ideal and are 8. Do not change the value on any I/O pins which are

really band-pass, not low-pass, filters (i.e., more configured as output while a conversion is in

than one of different values may be necessary). progress (regardless of the port). The high

source/sink capability of the pins could directly inject

2. VREF can pull up to 1mA for 8 to 20ns when a

noise onto VDD.

conversion is started. The VREF source (either RA3

or VDD) doesn’t change the current draw. Make sure 9. The A/D is capable of finishing a conversion while the

your design can source this current (and be able to part is sleeping. Putting the part to sleep helps

do it very fast). Capacitors on VREF will act as a accuracy since this mode eliminates the internal

source for this current draw. switching noise of the processor core.

3. VDD is a better VREF source than RA3 because if Note: You can do this with any oscillator mode, but you

noise is present on VDD it is absolutely coupled, NOT will have to allow for the osc wake-up time when

linearly coupled. using LP, XT or HS modes. RC mode has no

start-up timer and starts up instantly.

EXAMPLE 5: If you put the processor to sleep, consider clearing all

20mV of noise when VDD = 5.0V = VREF is ±1 LSb interrupt enable bits (including the GIE bit), except for the

ADIE. This will cause the processor to wake up from sleep

20mV of noise when RA3 = 3.0 = VREF is ±1 LSb when the conversion is complete and resume executing

4. Noise on the A/D input channel during tracking will code with the instruction following the sleep instruction. This

add error to the desired result. A properly sized filter method helps simplify your interrupt service routine for

capacitor on the input pin will help correct this. other peripherals.

Note: On the PIC16C71 and PIC16C70, RA0 is right

next to OSC1 and cannot help but pick up some EXAMPLE 6: (PIC16C71 AND PIC16C70)

noise. If possible, make this pin an output to help CLRF INTCON

isolate the noise from getting to RA1. BSF INTCON,ADIE

BSF ADCON0,GO

SLEEP

MOVF ADRES,0

1996 Microchip Technology Inc. FACT002-page 5

POWER USAGE Keeping the A/D Usage Simple

• Put a decoupling capacitor on VDD.

The following simple, straight-forward pointers can help any

application meet its power requirements. • Put a .01µF capacitor on the analog input source.

• Select which pins are digital and which pins are analog

1. Keeping the A/D turned off until you are ready to start

(register ADCON1).

tracking will reduce approximately 180µA of current

draw from your system. The ADON (ADCON0) bit • Using the internal RC oscillator to determine the tAD

turns the A/D on or off. provides a relatively fast and accurate conversion for

most applications (bits ADCS1, ADCS0 = 1,1 in

2. Configure all analog inputs to be analog since this

register ADCON1). If you are using RC mode for the

will disconnect the CMOS digital input buffer. If you

core’s oscillator, then you should put the part to sleep

do not, and the signal on the pin is 0.5VDD, both

during the conversion (see PIC16C71 Rev B errata) or

transistors in the CMOS input buffer will be turned

choose an appropriate tAD source other than RC.

on, causing the maximum current draw of the

input buffer. • Select which channel is to be sampled (bits CHS2,

CHS1 and CHS0 in register ADCON0).

3. You may want to put the controller to sleep during the

conversion. There are several factors to consider for • Turn on the A/D by setting the ADON bit (reg

this decision, here are a few: ADCON0).

• The Frc move must be selected for A/D • Wait 20µs (tracking time).

conversion clock. • Set the GO bit (reg ADCON0) to start the conversion.

• Do you have any timers running that cannot be • Poll either the ADIF or the GO bit to determine when

stopped? the conversion has completed.

• Is the wake-up from sleep time longer than the • Utilize the result located in the ADRES register.

conversion time? • Clear the ADIF bit.

• Can you afford to lose the processing time while

sleeping & waking up from sleep?

EXAMPLE 7:

BSF STATUS,RP0

MOVLW 0xFE ;MAKE RA0 AN OUTPUT

;AND RA1 AN INPUT

MOVWF TRISA

CLRF ADCON1 ;MAKE ANALOG INPUTS

BCF STATUS,RP0

MOVLW 0C9h ;RC OSC, RA1, ADON

MOVF ADCON0,W

CALL 20US_DELAY

GIE_OFF BCF INTCON,GIE ;

BTFSC INTCON,GIE ;MAKE SURE BCF WAS NOT INTERRUPTED

GOTO GIE_OFF ;

BSF ADCON0,G0

AD_GOING BTFSC ADCON0,GO

GOTO AD_GOING

;Result is located in ADRES

FACT002-page 6 1996 Microchip Technology Inc.

Das könnte Ihnen auch gefallen

- Mastering The PIC16C7X A/D ConverterDokument8 SeitenMastering The PIC16C7X A/D ConverterGuillermo Hernandez100% (1)

- ADC On A PICDokument4 SeitenADC On A PICDurgesh Kumar Singh100% (1)

- CoE115 1s1920 Lab4Dokument3 SeitenCoE115 1s1920 Lab4Ingrid EstoyaNoch keine Bewertungen

- Title: Design of A Flash Analog To Digital ConverterDokument4 SeitenTitle: Design of A Flash Analog To Digital Converteranon_776365175Noch keine Bewertungen

- Construction of Microcontroller Based Digital Voltmeter: Md. Imran Hossain Jony, Md. Moshiur RahmanDokument4 SeitenConstruction of Microcontroller Based Digital Voltmeter: Md. Imran Hossain Jony, Md. Moshiur Rahmanshiva kumarNoch keine Bewertungen

- E 03 B 035Dokument1 SeiteE 03 B 035Tariq Zuhluf100% (1)

- 21 Adc2Dokument9 Seiten21 Adc2vishnuksNoch keine Bewertungen

- Laboratory 5 - ADC ManualDokument18 SeitenLaboratory 5 - ADC ManualSravan KumarNoch keine Bewertungen

- Experiment No. 4 ADC PDFDokument16 SeitenExperiment No. 4 ADC PDFRia Cordova0% (1)

- Finnal Diploma ME 111 Control ProjectDokument18 SeitenFinnal Diploma ME 111 Control ProjectSharif AwadNoch keine Bewertungen

- DLC LAB - 10 - Student - ManualDokument8 SeitenDLC LAB - 10 - Student - ManualImtiaj SajinNoch keine Bewertungen

- DPScope SE Design Description PDFDokument11 SeitenDPScope SE Design Description PDFingenierognvNoch keine Bewertungen

- CHAPTER 5 Hardware InterfacingDokument51 SeitenCHAPTER 5 Hardware InterfacingCheng Ching HaoNoch keine Bewertungen

- CLG BellDokument24 SeitenCLG BellNikhil Kumar SinghNoch keine Bewertungen

- Project Using Microcontroller-Atmega16: Pushparaj Mani PathakDokument34 SeitenProject Using Microcontroller-Atmega16: Pushparaj Mani PathakKARTHIK S SNoch keine Bewertungen

- Dec Exp 7 Student ManualDokument4 SeitenDec Exp 7 Student ManualAntarldNoch keine Bewertungen

- Micro Converter (Analog Device) 12-Bit Adcs and Dacs With Embedded High Speed 62-Kb Flash McuDokument20 SeitenMicro Converter (Analog Device) 12-Bit Adcs and Dacs With Embedded High Speed 62-Kb Flash McushaileshNoch keine Bewertungen

- Developing Islanding Arrangement Automatically For Grid On Sensing Bad Voltage or FrequencyDokument29 SeitenDeveloping Islanding Arrangement Automatically For Grid On Sensing Bad Voltage or FrequencyNitin AdamNoch keine Bewertungen

- Part 1Dokument31 SeitenPart 1SarthakGuptaNoch keine Bewertungen

- AVR MicrocontrollerDokument51 SeitenAVR MicrocontrollerOsama Tahir100% (1)

- Communication Between ADC0804 and 8051Dokument12 SeitenCommunication Between ADC0804 and 805121070106 Nguyễn Xuân ThếNoch keine Bewertungen

- Virtex Analog To Digital Converter: Application NoteDokument8 SeitenVirtex Analog To Digital Converter: Application NoteTulasi RadhikaNoch keine Bewertungen

- Circuit Logic User GuideDokument59 SeitenCircuit Logic User Guideঅন্তরআত্মারসন্ধানে100% (1)

- UntitledDokument23 SeitenUntitlednurul damiaNoch keine Bewertungen

- Eeprom BL24C32 BL24C64Dokument13 SeitenEeprom BL24C32 BL24C64Hugo PerezNoch keine Bewertungen

- RPM Measurement (Tachometer)Dokument10 SeitenRPM Measurement (Tachometer)19E45A0229 SDESEEENoch keine Bewertungen

- Chapter 1. OverviewDokument58 SeitenChapter 1. OverviewmgitecetechNoch keine Bewertungen

- PIC16/PIC18 ADC Technical Brief: 2018 Microchip Technology Inc. 90003194a-Page 1Dokument27 SeitenPIC16/PIC18 ADC Technical Brief: 2018 Microchip Technology Inc. 90003194a-Page 1Java Papa DoqNoch keine Bewertungen

- 2 Input Output PortsDokument29 Seiten2 Input Output PortsUmair AhmadhNoch keine Bewertungen

- Dec Exp 6 Student ManualDokument5 SeitenDec Exp 6 Student ManualSakib MahmudNoch keine Bewertungen

- MAX22530 Isolated ADCDokument37 SeitenMAX22530 Isolated ADCRoy ChaiNoch keine Bewertungen

- Module 2 AVR ATMega32 ArchitectureDokument44 SeitenModule 2 AVR ATMega32 ArchitectureehsanNoch keine Bewertungen

- AVR ATMEGA16/32: Your Best Friend in Autonomous Robotics !!!Dokument25 SeitenAVR ATMEGA16/32: Your Best Friend in Autonomous Robotics !!!sidraiz26Noch keine Bewertungen

- Osmeoisis 2022-09-06 15-33-19PIC - Enh - A - 10Dokument20 SeitenOsmeoisis 2022-09-06 15-33-19PIC - Enh - A - 10Tomás BurónNoch keine Bewertungen

- MM Lab ManualDokument53 SeitenMM Lab ManualDev SejvaniNoch keine Bewertungen

- Icp IccDokument6 SeitenIcp IccGiovani ScarpatiNoch keine Bewertungen

- PIC18f452: Course: ContactDokument13 SeitenPIC18f452: Course: ContactMalik Adil FarooqNoch keine Bewertungen

- Gas Leakage Alerting System in IndustriesDokument44 SeitenGas Leakage Alerting System in IndustriesGanesan S BENoch keine Bewertungen

- Digital IC-Tester PDFDokument9 SeitenDigital IC-Tester PDFSatyajit Dhar100% (1)

- Member of The Ams Group: Cambridge CMOS SensorsDokument25 SeitenMember of The Ams Group: Cambridge CMOS SensorsMd. Masrur SaqibNoch keine Bewertungen

- BL24C32Dokument15 SeitenBL24C32no188Noch keine Bewertungen

- Analog To Digital Converter With Two-Digit Seven Segment DisplayDokument26 SeitenAnalog To Digital Converter With Two-Digit Seven Segment DisplayChristian Mauricio Aldás SolísNoch keine Bewertungen

- Ds28e07 3122240Dokument24 SeitenDs28e07 3122240ManunoghiNoch keine Bewertungen

- Welcome To Turbofuture!: Internet Computers Cell Phones Consumer ElectronicsDokument26 SeitenWelcome To Turbofuture!: Internet Computers Cell Phones Consumer ElectronicsMoyukh MandalNoch keine Bewertungen

- AVRDokument20 SeitenAVRAhsan KhanNoch keine Bewertungen

- NE5034Dokument6 SeitenNE5034teguh.setionoNoch keine Bewertungen

- Osmeoisis 2022-09-06 15-33-19PIC - Enh - C - 8Dokument19 SeitenOsmeoisis 2022-09-06 15-33-19PIC - Enh - C - 8Tomás BurónNoch keine Bewertungen

- Embedded Control For 2.017/2.019: Notes Adapted From T.R. Consi 2003Dokument12 SeitenEmbedded Control For 2.017/2.019: Notes Adapted From T.R. Consi 2003Dr. Ir. R. Didin Kusdian, MT.Noch keine Bewertungen

- Multiple On and Off Time Programmed Industrial Load: Submitted byDokument24 SeitenMultiple On and Off Time Programmed Industrial Load: Submitted byakashNoch keine Bewertungen

- Mbed BK Ed2 CH 5Dokument20 SeitenMbed BK Ed2 CH 5NecNoch keine Bewertungen

- 07-Design and Implementation of Smart Energy MeterDokument59 Seiten07-Design and Implementation of Smart Energy MeterAvetri VigneshwaranNoch keine Bewertungen

- Contador 7217Dokument20 SeitenContador 7217boanergess2Noch keine Bewertungen

- Model Railroad DCC Command StationDokument12 SeitenModel Railroad DCC Command StationLoloNoch keine Bewertungen

- Under The Guidance ofDokument19 SeitenUnder The Guidance ofAnonymous ONQrF8nfQ4Noch keine Bewertungen

- No Touch Hand Washing Product DesignDokument14 SeitenNo Touch Hand Washing Product DesignalazarNoch keine Bewertungen

- Cop310 410 411Dokument20 SeitenCop310 410 411Riadalg RiadNoch keine Bewertungen

- Adc Sar Seq 2-40Dokument35 SeitenAdc Sar Seq 2-40Kauã AntunezNoch keine Bewertungen

- Layout Guidelines For ControllersDokument7 SeitenLayout Guidelines For Controllersnrupavesh nNoch keine Bewertungen

- Copeland Condensing Units Datasheet PDFDokument54 SeitenCopeland Condensing Units Datasheet PDFSixto AgueroNoch keine Bewertungen

- NF7FX R134a 115V 60Hz 07-03 Cg43x422Dokument2 SeitenNF7FX R134a 115V 60Hz 07-03 Cg43x422Sixto AgueroNoch keine Bewertungen

- PICkit 3 Poster 51792aDokument1 SeitePICkit 3 Poster 51792aEugenio Morocho CayamcelaNoch keine Bewertungen

- Remote Control and Security Systems Hybrids - Ver.2: TelecontrolliDokument37 SeitenRemote Control and Security Systems Hybrids - Ver.2: TelecontrolliSixto AgueroNoch keine Bewertungen

- DTQ-14Z5SC CH CN-001P PDFDokument35 SeitenDTQ-14Z5SC CH CN-001P PDFSixto AgueroNoch keine Bewertungen

- Icl 8211Dokument14 SeitenIcl 8211Sixto AgueroNoch keine Bewertungen

- APC Back UPS 250,400,600 - 1 PDFDokument1 SeiteAPC Back UPS 250,400,600 - 1 PDFSixto Aguero50% (2)

- GM 1067 AmplifierDokument12 SeitenGM 1067 AmplifierSixto AgueroNoch keine Bewertungen

- Lib 12F629Dokument18 SeitenLib 12F629Sixto AgueroNoch keine Bewertungen

- FISHER CA-520 AmplifierDokument14 SeitenFISHER CA-520 AmplifierSixto AgueroNoch keine Bewertungen

- Circuit Theory 2 - Online Questions 1112Dokument2 SeitenCircuit Theory 2 - Online Questions 1112daisybloomNoch keine Bewertungen

- B3 SMD Datasheet PDFDokument4 SeitenB3 SMD Datasheet PDFJayceemikelNoch keine Bewertungen

- Sulyok Et Al-2018-Energy Science & EngineeringDokument13 SeitenSulyok Et Al-2018-Energy Science & Engineeringpetar2001Noch keine Bewertungen

- STK402 240Dokument5 SeitenSTK402 240tyros5Noch keine Bewertungen

- API Eis Solutions Guide 2019Dokument8 SeitenAPI Eis Solutions Guide 2019Dimitra KatsiorchiNoch keine Bewertungen

- 01-RXM Plugin Relay PDFDokument8 Seiten01-RXM Plugin Relay PDFshaikhsajid242Noch keine Bewertungen

- Euler PathDokument10 SeitenEuler PathSopno GhuriNoch keine Bewertungen

- HCPL 314JDokument14 SeitenHCPL 314JonafetsNoch keine Bewertungen

- Analog Electronics Circuits (Semester V - EEE) : Important QuestionsDokument2 SeitenAnalog Electronics Circuits (Semester V - EEE) : Important QuestionsHadush KingNoch keine Bewertungen

- HBLDokument7 SeitenHBLUông TháiNoch keine Bewertungen

- IR Proximity SensorDokument22 SeitenIR Proximity SensorKhushiNoch keine Bewertungen

- Lecture Notes - Voltage ControlDokument12 SeitenLecture Notes - Voltage ControlNik Mohd Bazli100% (1)

- X Ray Machine Operation ManualDokument14 SeitenX Ray Machine Operation ManualMarcelino Navarrete EvaristoNoch keine Bewertungen

- CS5532Dokument50 SeitenCS5532Héctor LiendoNoch keine Bewertungen

- 2011 Nec Changes - Ieee - 1202Dokument46 Seiten2011 Nec Changes - Ieee - 1202fesaraNoch keine Bewertungen

- SEMICON-LAB SyllabusDokument6 SeitenSEMICON-LAB Syllabusnandithanarayanan349Noch keine Bewertungen

- Measuring CMOS Dynamic Input CapacitanceDokument118 SeitenMeasuring CMOS Dynamic Input CapacitanceDalton BentleyNoch keine Bewertungen

- Inductive Couple Plasma Reactive Ion Etching Characteristics of TiO2Dokument8 SeitenInductive Couple Plasma Reactive Ion Etching Characteristics of TiO2Rudy FalcaoNoch keine Bewertungen

- Three Phase Circuits PDFDokument31 SeitenThree Phase Circuits PDFveeraiahNoch keine Bewertungen

- Health and Medicine LawDokument18 SeitenHealth and Medicine LawThakur Astha SinghNoch keine Bewertungen

- Transistor Biasing and StabilisationDokument22 SeitenTransistor Biasing and Stabilisationsanjaysinghcoer100% (1)

- Lecture 1Dokument52 SeitenLecture 1Lokendra AgarwalNoch keine Bewertungen

- VACC VibrationInResearchSettingsDokument1 SeiteVACC VibrationInResearchSettingsrernitmcNoch keine Bewertungen

- SMPS Trouble Shoot GuideDokument55 SeitenSMPS Trouble Shoot Guidekingkhan97100% (2)

- PriceDokument3 SeitenPriceMohd Saifol IshakNoch keine Bewertungen

- Chapter 4 - Bipolar Junction Transistors (BJTS)Dokument77 SeitenChapter 4 - Bipolar Junction Transistors (BJTS)toswaroopNoch keine Bewertungen

- A Industrial Training Project Report ON: VHDL Coding For Decade Counter On Xilinx and Create Test Waveform"Dokument40 SeitenA Industrial Training Project Report ON: VHDL Coding For Decade Counter On Xilinx and Create Test Waveform"SHADAN khanNoch keine Bewertungen

- Motor Drive Solutions GuideDokument20 SeitenMotor Drive Solutions GuideAmy Price100% (1)

- 150W AmpDokument9 Seiten150W AmpRey SorianoNoch keine Bewertungen

- Ntroduction To Pintronics: Josh Schaefferkoetter February 27, 2007Dokument21 SeitenNtroduction To Pintronics: Josh Schaefferkoetter February 27, 2007irmaNoch keine Bewertungen