Beruflich Dokumente

Kultur Dokumente

Rigid Pavement Joint Design - 2020 - QRDC

Hochgeladen von

geoprabhatOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rigid Pavement Joint Design - 2020 - QRDC

Hochgeladen von

geoprabhatCopyright:

Verfügbare Formate

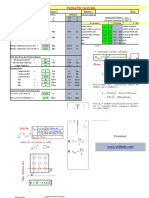

Traffic Calculation for design period

IRC 58:2015 Based Design

(Input in Red Cell only)

Design period , years 30

Annual rate of growth of commercial traffic (expre 0.065

Two-way commercial traffic volume per day (in the 2,000

% of traffic in predominant direction percent

0.50

(Lane Distribution Factor)

Traffic in predominant direction, commercial traffi 1,000

Average number of standard axles (steering/singl 2.5

Design Traffic in predominant direction, commercia78,817,063

Total day time traffic % of Total traffic in predomin 45.0%

Total day time Design Traffic 35,467,679

Total night time Design Traffic 43,349,385

Six hour day time traffic (10 AM - 4PM) @ 75% 26,600,759

Six hour night time traffic (0 AM - 6PM) 21,674,692

Design Traffic in predominant direction, commercial traffic

volume per day (For Fatigue Analysis) @ 25%

Design Traffic (for Bottom-up Cracking), K 6,650,190

Design Traffic (for Top-Down Cracking) , J 5,418,673

Analysis based on Load Spectrum Field Data No (Put YES / NO)

For Bottom-up For Top-Down

Ratio of

Axle category Cracking Analysis Cracking Analysis

total

(K x N) (J x N)

Front single axel (N1) 0.45 0 0

Rear single axle (N2) 0.15 997,528 812,801

Tandem axle (N3) 0.25 1,662,547 1,354,668

Tridem axle (N4) 0.15 997,528 812,801

Total 1.000 3,657,604 2,980,270

Front single (steering) Axles not considered

Understanding Temperature Difference Phenomenon

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Design Data IRC 58:2015 Based Design

(Input in Red Cell only)

175 micron

Effective modulus Plastic Sheet

of subgrade

reaction of

Effective modulus

CBR of Thickness of Dry combined

of DLC, MPa/m Poisson's Ratio of Radius of relative

compacted 8 Lean Concrete 100 250 foundation of 220 0.15 0.876

subgrade, % (Table 4/ IRC Concrete, Mu stiffness, m

subbase, mm subgrade +

58:2015)

granular sub-base

and DLC sub-

base , MPa/m 37

PQC 0

10

Load Transfer DLC

Effective modulus Efficiency 0

Max. day-time

of subgrade PQC : 28-day 28-day Flexural Factor for TDC

Effective CBR of Temperature

reaction of Comprehensive strength of analysis, Beta

compacted 8 50 Differential in slab, 19 40 4.4 0.66 Drainage Layer 15

subgrade, % foundation, strength of cement cement concrete, = 0.66 for

0

C (for bottom-up 0

MPa/m (Table 2/ concrete, MPa MPa dowel Joints,

cracking) 0.90 for joints

IRC 58:2015)

without dowels 15

GSB as Separation Layer

0

Night-time

Effective modulus

Temperature 500mm of Sungrade with

Thickness of of Untreated Elastic Modulus of Trial Thickness of min. CBR >8%

Differential in slab, Unit weight of

Granular Subbase, 150 Subbase, MPa/m 70 6 Concrete, Ec 30000 25 Concrete Slab, h, 0.370

0

C (for top-down Concrete, kN/m3

mm (Table 3/ IRC (MPa) m

cracking) = day-

58:2015)

time diff/2 + 5

Designed Pavement Section

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Axle Load Spectrum and Detials

Rear Single Axle Rear Tandem Axle Rear Tridem Axle

Frequency (%) Frequency (%) BUC _ TDC_ Frequency (%) BUC _ TDC_

Mid-Point of BUC _ TDC_ Mid-Point of Mid-Point of

Load Group Frequency (%) (If no Survey Load Group Frequency (%) (If no Survey Expected Expected Load Group Frequency (%) (If no Survey Expected Expected

Load Group Expected Expected Load Group Load Group

(kN) (From Survey) Data (kN) (From Survey) Data Repetitions Repetitions (kN) (From Survey) Data Repetitions Repetitions

(kN) Repetitions (ni) Repetitions (ni) (kN) (kN)

available)# available)# (ni) (ni) available)# (ni) (ni)

185-195 190 0.0 5.0 49876 40640 380 - 400 390 0.0 2.5 41564 33867 530-560 545 0.0 2.5 24938 20320

175-185 180 0.0 5.0 49876 40640 360 - 380 370 0.0 2.5 41564 33867 500-530 515 0.0 2.5 24938 20320

165-175 170 2.0 5.0 49876 40640 340 - 360 350 0.0 5.0 83127 67733 470-500 485 0.0 2.5 24938 20320

155-165 160 3.0 5.0 49876 40640 320 - 340 330 0.0 5.0 83127 67733 440-470 455 0.0 5.0 49876 40640

145-155 150 10.0 5.0 49876 40640 300 - 320 310 0.0 5.0 83127 67733 410-440 425 0.0 5.0 49876 40640

135-145 140 12.0 5.0 49876 40640 280 - 300 290 1.0 5.0 83127 67733 380-410 395 1.0 5.0 49876 40640

125-135 130 10.0 10.0 99753 81280 260 - 280 270 6.0 5.0 83127 67733 350-380 365 4.0 10.0 99753 81280

115-125 120 20.0 15.0 149629 121920 240 - 260 250 10.0 10.0 166255 135467 320-350 335 5.0 10.0 99753 81280

105-115 110 16.0 20.0 199506 162560 220 - 240 230 28.0 15.0 249382 203200 290-320 305 26.0 15.0 149629 121920

95-105 100 10.0 20.0 199506 162560 200 - 220 210 25.0 15.0 249382 203200 260-290 275 30.0 15.0 149629 121920

85-95 90 7.0 5.0 49876 40640 180 - 200 190 18.0 25.0 415637 338667 230-260 245 16.0 25.0 249382 203200

< 85 80 10.0 0.0 0 0 < 180 170 12.0 5.0 83127 67733 < 230 215 18.0 2.5 24938 20320

# Author Recommendation to include Overlaod Case too

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Fatigue Anaysis (BUC)

Rear Single Axle Rear Tandem Axle Rear Tridem Axle

Mid-Point of BUC _ Allowable Mid-Point of BUC _ Allowable Fatigue Mid-Point of BUC _ Allowable Fatigue

Flex Stress Stress Ratio Fatigue Flex Stress Stress Ratio Flex Stress Stress Ratio

Load Group Expected Repetitions Load Group Expected Repetitions Damage Load Group Expected Repetitions Damage

MPa (SR) Damage (ni/Ni) MPa (SR) MPa (SR)

(kN) Repetitions (ni) (Ni) (kN) Repetitions (ni) (Ni) (ni/Ni) (kN) Repetitions (ni) (Ni) (ni/Ni)

190 49876 2.32 0.52 273556 0.18 390 41564 1.64 0.37 Infinity 0.00 545 24938 2.43 0.55 125203 0.20

180 49876 2.25 0.51 499665 0.10 370 41564 1.60 0.36 Infinity 0.00 515 24938 2.35 0.53 220669 0.11

170 49876 2.19 0.49 1046390 0.05 350 83127 1.56 0.35 Infinity 0.00 485 24938 2.27 0.51 438220 0.06

160 49876 2.12 0.48 2724021 0.02 330 83127 1.52 0.34 Infinity 0.00 455 49876 2.19 0.49 1045398 0.05

150 49876 2.05 0.46 10597957 0.00 310 83127 1.48 0.33 Infinity 0.00 425 49876 2.10 0.48 3429666 0.01

140 49876 1.98 0.45 Infinity 0.00 290 83127 1.43 0.32 Infinity 0.00 395 49876 2.02 0.46 22603375 0.00

130 99753 1.91 0.43 Infinity 0.00 270 83127 1.39 0.31 Infinity 0.00 365 99753 1.94 0.44 Infinity 0.00

120 149629 1.84 0.42 Infinity 0.00 250 166255 1.35 0.31 Infinity 0.00 335 99753 1.86 0.42 Infinity 0.00

110 199506 1.77 0.40 Infinity 0.00 230 249382 1.31 0.30 Infinity 0.00 305 149629 1.77 0.40 Infinity 0.00

100 199506 1.70 0.38 Infinity 0.00 210 249382 1.27 0.29 Infinity 0.00 275 149629 1.69 0.38 Infinity 0.00

90 49876 1.64 0.37 Infinity 0.00 190 415637 1.23 0.28 Infinity 0.00 245 249382 1.61 0.36 Infinity 0.00

80 0 1.57 0.35 Infinity 0.00 170 83127 1.18 0.27 Infinity 0.00 215 24938 1.52 0.34 Infinity 0.00

Total BUC 0.35 0.00 0.43

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Fatigue Anaysis (TUC)

Rear Single Axle Rear Tandem Axle Rear Tridem Axle

Mid-Point of Allowable Mid-Point of Allowable Fatigue Mid-Point of Allowable Fatigue

TDC_ Expected Flex Stress Stress Ratio Fatigue TDC_ Expected Flex Stress Stress Ratio TDC_ Expected Flex Stress Stress Ratio

Load Group Repetitions Load Group Repetitions Damage Load Group Repetitions Damage

Repetitions (ni) MPa (SR) Damage (ni/Ni) Repetitions (ni) MPa (SR) Repetitions (ni) MPa (SR)

(kN) (Ni) (kN) (Ni) (ni/Ni) (kN) (Ni) (ni/Ni)

190 40640 1.17 0.27 Infinity 0.00 390 33867 1.19 0.27 Infinity 0.00 545 20320 1.14 0.26 Infinity 0.00

180 40640 1.14 0.26 Infinity 0.00 370 33867 1.16 0.26 Infinity 0.00 515 20320 1.11 0.25 Infinity 0.00

170 40640 1.11 0.25 Infinity 0.00 350 67733 1.13 0.25 Infinity 0.00 485 20320 1.08 0.24 Infinity 0.00

160 40640 1.08 0.24 Infinity 0.00 330 67733 1.10 0.25 Infinity 0.00 455 40640 1.05 0.24 Infinity 0.00

150 40640 1.05 0.24 Infinity 0.00 310 67733 1.06 0.24 Infinity 0.00 425 40640 1.02 0.23 Infinity 0.00

140 40640 1.02 0.23 Infinity 0.00 290 67733 1.03 0.23 Infinity 0.00 395 40640 0.99 0.22 Infinity 0.00

130 81280 0.98 0.22 Infinity 0.00 270 67733 1.00 0.23 Infinity 0.00 365 81280 0.95 0.22 Infinity 0.00

120 121920 0.95 0.22 Infinity 0.00 250 135467 0.97 0.22 Infinity 0.00 335 81280 0.92 0.21 Infinity 0.00

110 162560 0.92 0.21 Infinity 0.00 230 203200 0.94 0.21 Infinity 0.00 305 121920 0.89 0.20 Infinity 0.00

100 162560 0.89 0.20 Infinity 0.00 210 203200 0.90 0.20 Infinity 0.00 275 121920 0.86 0.19 Infinity 0.00

90 40640 0.86 0.19 Infinity 0.00 190 338667 0.87 0.20 Infinity 0.00 245 203200 0.83 0.19 Infinity 0.00

80 0 0.83 0.19 Infinity 0.00 170 67733 0.84 0.19 Infinity 0.00 215 20320 0.80 0.18 Infinity 0.00

Total BUC 0.00 0.00 0.00

Cummulative Datigue Damage (Sum of above) 0.79

Safe Design

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Design of Panel Size

IRC 58:2015 Based Design

(Input in Red Cell only)

Input Data

Concrete Strength, fck 40 MPa

Tensile Strength of Concrete, σ at 0.08 MPa

Coefficient of Friction, f 1.5

Density of Concrete 25 KN/m3

Slab Thickness, h 370 mm

Width of Panel 3.5 m <4.5m, Safe

Required Length of Panel 4.3 m

Adopted Length of Panel 4.5 m <4.5m, Safe

Skematic Drawing

4.5 m

3.5 m

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Design of Dowel Bar

IRC 58:2015 Based Design

(Input in Red Cell only)

Input Data

Slab Thickness, h 370 mm

Joint width, z 20 mm (For expansion Joint)

(5mm for Contraction Joint/Construction Joint)

Modulus of Subgrade Reaction, k 220 MPa/m

Modulus of Elasticity of Bar, E 200000 MPa

Modulus of Dowel Support, k mds 415000 MPa/m

Poisson's Ratio 0.15

Radius of Relative Stiffness, l 876 mm (Calculated)

Maximum Single Axle Load 190 KN

Maximum Single Wheel Load 95 KN

Load Transfer % at Terminal Stage 0 (30% for Tied Shoulder, otherwize, ZERO)

Wheel Load for Dowel Design 95 KN

% of Load Transfer through the Dovel Bar 50 ( 50 for 100% Joint Efficiency)

Load to be transferred, P 47.5 KN (Load shared by the dowels within l distance)

Dia. of Dowel Bar 38 mm (Plane Bar only)

Length of Dowel Bar 500 mm

Spacing of Dowel Bar, s 200 mm

Placement of first dowel 150 mm (From Pavement Edge)

Concrete Strength, fck 40 MPa

Permissible Bearing Stress in Concrete, 26.71 MPa

Analysis

95

c

c

Pt = 17.48

150 200 200 200 76 (Symbolic Sketch only )

y2 y3

y1

1 y0 Dowel Bar No. Ordinate

1 y0 1.000

2 y1 0.772

3 y2 0.543

4 y3 0.315

5 y4 0.087

6 y5 0.000

7 y6 0.000

Sum 2.717

Pt 17.48 (Maximu Force on Bar 1)

Check for Bearing Stress

Moment of Inertia of Dowel Bar 102353.9 mm4

Relative Stiffness of Dowel Bar embedded in Concrete, β 0.021 mm-1

Bearing Stress in Dowel Bar , F bmax 23.31 Mpa

Assumed Dowel Bar Size and Spacing is Safe

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Skematic Drawing

500

Dia. of Dowel

Bar 38

500

Dia. of Dowel

Bar 38

155 155

105 105

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Design of Tie Bar

IRC 58:2015 Based Design

(Input in Red Cell only)

Input Data and Analysis

Slab Thickness, h 0.370 m

Lane Width, b 3.5 m

Coefficient of Friction, f 1.5

Density of Concrete 25 KN/m3

Allowable Tensile Stress 200 MPa (Deformed Bar, As per IRC 15:2011)

Allowable Bomd Stress 2.46 MPa (Deformed Bar))

Dia. of Tie Bar 12 mm

Bar Area, Ab 113 mm2

Area of Bar required per meter, As 243 mm2 / m

No. of Bar required 3.15

Spacing of Bar required 466 mm

Spacing of Tie Bar adopted, s 400 mm

Safe

Required Length of Tie Bar 487.8049 mm

Increase length by 100mm for Loss of Bond due to painting and another 50mm for tolerance in placement

Provided Length of Bar 650 mm

Skematic Drawing

Dia. of Tie

Bar 12 650

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Developed By: Er. Prabhat Kumar Jha, SDE/QRDC/DoR

Das könnte Ihnen auch gefallen

- Detailed Project Report Development of Industrial Area,: at Piparsewa, Dist - MorenaDokument44 SeitenDetailed Project Report Development of Industrial Area,: at Piparsewa, Dist - MorenaVIKASNoch keine Bewertungen

- Irc 58 2015 Excel Sheet PDFDokument3 SeitenIrc 58 2015 Excel Sheet PDFtally3tallyNoch keine Bewertungen

- Vas Design and Infrastructure Consultants PVT LTD: Concrete Cores Test Result of HaryanaDokument2 SeitenVas Design and Infrastructure Consultants PVT LTD: Concrete Cores Test Result of HaryanaPankaj SherwalNoch keine Bewertungen

- PM Awas DesignDokument6 SeitenPM Awas DesignRam Samujh SharmaNoch keine Bewertungen

- Unsafe Design TNHD - PaveDokument17 SeitenUnsafe Design TNHD - Pavek.shanmuganathanNoch keine Bewertungen

- Haryana TestDokument1 SeiteHaryana TestPankaj SherwalNoch keine Bewertungen

- Pavement Design RPTDokument10 SeitenPavement Design RPTDolabari to Jamuguri 4 Lane Road ProjectNoch keine Bewertungen

- Rigid-Pavement-Design-as-Per-IRC-58-2011-DesignDokument5 SeitenRigid-Pavement-Design-as-Per-IRC-58-2011-Designarvind sharma100% (1)

- Blending WMMDokument2 SeitenBlending WMMPrasanna S Kulkarni100% (1)

- Aizawal-Tuipang (NH-54) - PKG 6: Design Notes-Retaining WallDokument114 SeitenAizawal-Tuipang (NH-54) - PKG 6: Design Notes-Retaining Wallnikhilnagpal2121994Noch keine Bewertungen

- IitpaveDokument10 SeitenIitpaveKanishka SarkarNoch keine Bewertungen

- National Highways: Quality Control Division, Madurai Benkelman Beam Deflection TestDokument35 SeitenNational Highways: Quality Control Division, Madurai Benkelman Beam Deflection Testk.shanmuganathanNoch keine Bewertungen

- CTB Tyre Pressure Fig 12.38Dokument5 SeitenCTB Tyre Pressure Fig 12.38Ravinder kumarNoch keine Bewertungen

- 408010745-Rigid-Pavement-xls CopiedDokument17 Seiten408010745-Rigid-Pavement-xls CopiedrajNoch keine Bewertungen

- Pavement Design WMM Stablized Iit Pave1Dokument25 SeitenPavement Design WMM Stablized Iit Pave1mineNoch keine Bewertungen

- Rigid Pavement Design - Speacial Case Studies1Dokument6 SeitenRigid Pavement Design - Speacial Case Studies1Srujhana RaoNoch keine Bewertungen

- White Topping of Concrete: Department of Civil Engineering Jce, BelgaumDokument20 SeitenWhite Topping of Concrete: Department of Civil Engineering Jce, BelgaumSohan MeharwadeNoch keine Bewertungen

- Pile Cap Design Calculations With CSI SAFEDokument6 SeitenPile Cap Design Calculations With CSI SAFEroshanNoch keine Bewertungen

- Flexible Pavement Design - NH-219 Existing RoadDokument12 SeitenFlexible Pavement Design - NH-219 Existing Roadabhijeet kumarNoch keine Bewertungen

- 2 - Axle Load PDFDokument17 Seiten2 - Axle Load PDFDebanjan MukherjeeNoch keine Bewertungen

- U SOR DPR Tech@ Jalgaon To Bhramhanwadi RoadDokument275 SeitenU SOR DPR Tech@ Jalgaon To Bhramhanwadi RoadEr.Tushar KakadeNoch keine Bewertungen

- IRC-58-2015-for Pakhdeva Kokha MargDokument9 SeitenIRC-58-2015-for Pakhdeva Kokha MargRam Samujh SharmaNoch keine Bewertungen

- Full Height Vs Partial Height Re Wall: Overall Rate Difference #N/A #N/ADokument2 SeitenFull Height Vs Partial Height Re Wall: Overall Rate Difference #N/A #N/ANaresh SharmaNoch keine Bewertungen

- Design With Irc 72Dokument5 SeitenDesign With Irc 72vijay chouhanNoch keine Bewertungen

- TRANSLINK - Company Profile PDFDokument39 SeitenTRANSLINK - Company Profile PDFKaran DaveNoch keine Bewertungen

- Bituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Dokument4 SeitenBituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Mozibur RahmanNoch keine Bewertungen

- Design of Concrete Pavement Name of The WorkDokument10 SeitenDesign of Concrete Pavement Name of The WorkDurga Rama Swamy KalvakolanuNoch keine Bewertungen

- 36 MTR SpanDokument13 Seiten36 MTR SpanAnonymous sfkedkymNoch keine Bewertungen

- Technology Data's For PMGSYDokument20 SeitenTechnology Data's For PMGSYmagbool100% (1)

- Highway Lab Report (Full) PDFDokument84 SeitenHighway Lab Report (Full) PDFWai KiatNoch keine Bewertungen

- Aor Cantilever 6m SignDokument6 SeitenAor Cantilever 6m SignDaljit624Noch keine Bewertungen

- Dual Carriageway Roads 4 Lane Carriageway: Click On The Type of PavementDokument18 SeitenDual Carriageway Roads 4 Lane Carriageway: Click On The Type of PavementTarunNoch keine Bewertungen

- GSB Mix Design Summary-1Dokument3 SeitenGSB Mix Design Summary-1Dontha SrikanthNoch keine Bewertungen

- Short Reinforcement Long Reinforcement: +ive in Span Due ToDokument14 SeitenShort Reinforcement Long Reinforcement: +ive in Span Due ToshivamomshantiNoch keine Bewertungen

- HPC & Slab PDFDokument3 SeitenHPC & Slab PDFAbhijeet SahuNoch keine Bewertungen

- SoilTest ProjectDokument115 SeitenSoilTest ProjectMd Shahimul HaqueNoch keine Bewertungen

- Sarda Rikhe Pier Found FinalDokument9 SeitenSarda Rikhe Pier Found FinalHimal KafleNoch keine Bewertungen

- ROHIT Barmer Gudamalani Gadesara Loonawa 1Dokument529 SeitenROHIT Barmer Gudamalani Gadesara Loonawa 1Roopesh ChaudharyNoch keine Bewertungen

- Dowel Bar-Tie Bar-IRC-58-2015Dokument3 SeitenDowel Bar-Tie Bar-IRC-58-2015SONU SINGHNoch keine Bewertungen

- Low Volume Road Traffic DesignDokument3 SeitenLow Volume Road Traffic DesignSatish BhairanattiNoch keine Bewertungen

- Locked DESIGN SHEET FINAL ARUN-SATYENDRA 11.06.2019Dokument5 SeitenLocked DESIGN SHEET FINAL ARUN-SATYENDRA 11.06.2019ajay_430Noch keine Bewertungen

- (PDF) IRC-58 2015 Excel SheetDokument3 Seiten(PDF) IRC-58 2015 Excel SheetPratik JoshiNoch keine Bewertungen

- Thulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Dokument4 SeitenThulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Himal KafleNoch keine Bewertungen

- Irc HighwayDokument23 SeitenIrc HighwaysrikanthNoch keine Bewertungen

- Sr-380 Gtifr Pc-04 38bhs Rev2Dokument608 SeitenSr-380 Gtifr Pc-04 38bhs Rev2Amit RawatNoch keine Bewertungen

- Practice BBS As Per MOST&HDokument1 SeitePractice BBS As Per MOST&HHegdeVenugopalNoch keine Bewertungen

- Mastic Asphalt Design (Without Ca)Dokument30 SeitenMastic Asphalt Design (Without Ca)Soundar PachiappanNoch keine Bewertungen

- Steel Girder 60m and RDSO Span QtyDokument2 SeitenSteel Girder 60m and RDSO Span Qtyabhishek pathakNoch keine Bewertungen

- Design of Flexible PavementsDokument19 SeitenDesign of Flexible PavementsshivamomshantiNoch keine Bewertungen

- Pavement Design IRC 37Dokument2 SeitenPavement Design IRC 37Subhransu Sekhar SwainNoch keine Bewertungen

- Crash Barrier + Friction Slab Qty PDFDokument1 SeiteCrash Barrier + Friction Slab Qty PDFNeeraj DuaNoch keine Bewertungen

- Soil GSB WMM by Sand Replacement MethodDokument1 SeiteSoil GSB WMM by Sand Replacement MethodBrahammanand BairwaNoch keine Bewertungen

- Part 1 Hydraulic Design Calculation 473Dokument13 SeitenPart 1 Hydraulic Design Calculation 473shashi rajhansNoch keine Bewertungen

- Elastomeric Bearings: 6 (1) Design Load On BearingsDokument8 SeitenElastomeric Bearings: 6 (1) Design Load On BearingsCivil MexNoch keine Bewertungen

- General Arrangement Drawing: Sanction of Crs To Be Taken Before Execution of WorkDokument1 SeiteGeneral Arrangement Drawing: Sanction of Crs To Be Taken Before Execution of Workmrinal kayalNoch keine Bewertungen

- 6.1 Bio Reactor Roof WalkwayDokument6 Seiten6.1 Bio Reactor Roof WalkwayRey GonzalesNoch keine Bewertungen

- CC Design forDLC 100 MMDokument14 SeitenCC Design forDLC 100 MMamit singhNoch keine Bewertungen

- ETABS Composite Column Design: ETABS 18.0.2 License # 1PJPHBGNRCE4GAWDokument2 SeitenETABS Composite Column Design: ETABS 18.0.2 License # 1PJPHBGNRCE4GAWIvan PorrasNoch keine Bewertungen

- 20171120-I6079-Interaction Dia CH 13720 Max WTDokument7 Seiten20171120-I6079-Interaction Dia CH 13720 Max WTDEBASIS BARMANNoch keine Bewertungen

- StarLAN Technology ReportVon EverandStarLAN Technology ReportBewertung: 3 von 5 Sternen3/5 (1)

- Norms-Cabinet-Final Print - DoR PDFDokument309 SeitenNorms-Cabinet-Final Print - DoR PDFBinod ThapaNoch keine Bewertungen

- Heavy Equipment Division Itahari Equipment Hire Rate 2019Dokument6 SeitenHeavy Equipment Division Itahari Equipment Hire Rate 2019santosh sah100% (1)

- Heavy Equipment Division Itahari Equipment Hire Rate 2019Dokument6 SeitenHeavy Equipment Division Itahari Equipment Hire Rate 2019santosh sah100% (1)

- Standard Specifications For Road and Bridge Works - 2073Dokument708 SeitenStandard Specifications For Road and Bridge Works - 2073Mohit Kohli67% (3)

- MORTH StandardDataBook PDFDokument328 SeitenMORTH StandardDataBook PDFSrinivas PNoch keine Bewertungen

- Norms DUDBC PDFDokument60 SeitenNorms DUDBC PDFDebendra Dev Khanal84% (19)

- Fog Seal Treatment Guideline 2020Dokument21 SeitenFog Seal Treatment Guideline 2020geoprabhatNoch keine Bewertungen

- Arbitration ActDokument27 SeitenArbitration ActSajeev RanjitNoch keine Bewertungen

- Rigid Pavement Construction As Per IRC SP 62 2004Dokument113 SeitenRigid Pavement Construction As Per IRC SP 62 2004Vizag Roads98% (54)

- Rigid Pavement Joint Design - 2020 - QRDC (Less Than 450CVPD)Dokument9 SeitenRigid Pavement Joint Design - 2020 - QRDC (Less Than 450CVPD)geoprabhatNoch keine Bewertungen

- Advice FaramDokument5 SeitenAdvice FaramgeoprabhatNoch keine Bewertungen

- Pavement Less 2 MsaDokument2 SeitenPavement Less 2 MsageoprabhatNoch keine Bewertungen

- महालेखापरीक्षकको छपन्नौं वार्षिक प्रतिवेदन min PDFDokument598 Seitenमहालेखापरीक्षकको छपन्नौं वार्षिक प्रतिवेदन min PDFgeoprabhatNoch keine Bewertungen

- SLOPEWDokument4 SeitenSLOPEWBraian LlanosNoch keine Bewertungen

- Draft Specification For BearingsDokument7 SeitenDraft Specification For BearingsTan Nguyen CongNoch keine Bewertungen

- Standard Specifications For Road and Bridge Works - 2073Dokument708 SeitenStandard Specifications For Road and Bridge Works - 2073Mohit Kohli67% (3)

- Mid Term Review of Sector Wide Road Programme & Priority Investment Plan 1Dokument92 SeitenMid Term Review of Sector Wide Road Programme & Priority Investment Plan 1geoprabhatNoch keine Bewertungen

- Is 458 2003Dokument39 SeitenIs 458 2003somnathjoyNoch keine Bewertungen

- Geotechnical Laboratory: DIRECT SHEAR TESTINGDokument14 SeitenGeotechnical Laboratory: DIRECT SHEAR TESTINGLuca BrandiNoch keine Bewertungen

- Is 3502 2009 PDFDokument10 SeitenIs 3502 2009 PDFRajashekar.PNoch keine Bewertungen

- Guage Thickness in MM Weight Per Sq. Ft. Weight Per Pc. Kgs. Pc. IN M/TonDokument3 SeitenGuage Thickness in MM Weight Per Sq. Ft. Weight Per Pc. Kgs. Pc. IN M/TongeoprabhatNoch keine Bewertungen

- A5. Class Method To Procure Consultancy ServiceDokument57 SeitenA5. Class Method To Procure Consultancy ServicegeoprabhatNoch keine Bewertungen

- A 2. Class Preparation of Bidding Document For Works 2076Dokument126 SeitenA 2. Class Preparation of Bidding Document For Works 2076geoprabhatNoch keine Bewertungen

- A 4. Class Contract Management - Rev.Dokument40 SeitenA 4. Class Contract Management - Rev.geoprabhatNoch keine Bewertungen

- A 1. Class Specification, Rate Analysis & Cost Estimation Rev.Dokument65 SeitenA 1. Class Specification, Rate Analysis & Cost Estimation Rev.geoprabhatNoch keine Bewertungen

- QFT Irfu13Dokument70 SeitenQFT Irfu13cifarha venantNoch keine Bewertungen

- Heat and Mass Transfer: Fundamentals & Applications: Errata SheetDokument3 SeitenHeat and Mass Transfer: Fundamentals & Applications: Errata SheetYamaneko ShinNoch keine Bewertungen

- International Physics OlympiadsDokument468 SeitenInternational Physics OlympiadsJurandi Leão100% (1)

- Fall 2016 Lab Manual - CHEG455 (Sec 51 & 52) PDFDokument68 SeitenFall 2016 Lab Manual - CHEG455 (Sec 51 & 52) PDFMashaelNoch keine Bewertungen

- Fluent TutorialsDokument864 SeitenFluent Tutorialsnaru_saNoch keine Bewertungen

- Non - Rectangular Components: Prepared By: D.M.ODokument2 SeitenNon - Rectangular Components: Prepared By: D.M.OCiero John MarkNoch keine Bewertungen

- Change of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonaDokument13 SeitenChange of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonaEuphoria V KhosaNoch keine Bewertungen

- Determination of Absolute Permeability of Core Sample by Using Liquid Phase FluidDokument14 SeitenDetermination of Absolute Permeability of Core Sample by Using Liquid Phase FluidNurrahmisrNoch keine Bewertungen

- Energies: Investigation of Stratified Thermal Storage Tank Performance For Heating and Cooling ApplicationsDokument15 SeitenEnergies: Investigation of Stratified Thermal Storage Tank Performance For Heating and Cooling ApplicationsRicardo Chegwin HillembrandNoch keine Bewertungen

- 21CIV24 Module 3 QB - Centroid & Moment of InertiaDokument15 Seiten21CIV24 Module 3 QB - Centroid & Moment of InertiaSuman naidu RNoch keine Bewertungen

- MD Module 1 StressDokument5 SeitenMD Module 1 StressCllyan Reyes100% (1)

- AvcDokument18 SeitenAvcgulshanNoch keine Bewertungen

- GKR GKS GSS Gearboxes With MD MH AC Motors - v1-0 - ENDokument460 SeitenGKR GKS GSS Gearboxes With MD MH AC Motors - v1-0 - ENIndahNoch keine Bewertungen

- Journal of Philosophy, Inc. The Journal of PhilosophyDokument15 SeitenJournal of Philosophy, Inc. The Journal of Philosophycaruiz69Noch keine Bewertungen

- The High Strength Friction GripDokument10 SeitenThe High Strength Friction GripfiarNoch keine Bewertungen

- A New Hypothetical Solution To Gravitational Singularities: León, Spain, June 2019Dokument12 SeitenA New Hypothetical Solution To Gravitational Singularities: León, Spain, June 2019M,,,Noch keine Bewertungen

- Modeling of Low Voltage Switchgear and Controlgear Assemblies Using Computational Fluid Dynamics - 465-147668798701-06Dokument6 SeitenModeling of Low Voltage Switchgear and Controlgear Assemblies Using Computational Fluid Dynamics - 465-147668798701-06Bao LamNoch keine Bewertungen

- AISC - Verification Examples: 1 Bolted Flange Plate Moment Connection - LRFDDokument35 SeitenAISC - Verification Examples: 1 Bolted Flange Plate Moment Connection - LRFDPablo García Peña100% (1)

- CH 06Dokument147 SeitenCH 06Larissa Albunio SilvaNoch keine Bewertungen

- 2.3 Temperature Conversions: Chapter 2 Energy and MatterDokument18 Seiten2.3 Temperature Conversions: Chapter 2 Energy and MatterBeverly PamanNoch keine Bewertungen

- Advanced Survey MethodsDokument83 SeitenAdvanced Survey MethodsMaxine MukokiNoch keine Bewertungen

- HT Practice Problems PDFDokument2 SeitenHT Practice Problems PDFChinnarao PulapaNoch keine Bewertungen

- FLOCALC Calc DetailsDokument15 SeitenFLOCALC Calc DetailsLuanLTNoch keine Bewertungen

- Pile Group Analysis: A Study of Two Methods: by Harry G. Poulos, M. ASCE and Mark F. RandolphDokument18 SeitenPile Group Analysis: A Study of Two Methods: by Harry G. Poulos, M. ASCE and Mark F. Randolphkalyan rangadhamNoch keine Bewertungen

- Chapter 14Dokument23 SeitenChapter 14Alvaro Fernandez VillarNoch keine Bewertungen

- Analysis of Composite WingDokument260 SeitenAnalysis of Composite WingIr AyenNoch keine Bewertungen

- 2 Conduction Heat TransferDokument52 Seiten2 Conduction Heat Transferbirhanu kefieNoch keine Bewertungen

- Analysis and Design of Circular Sewerage Tank - 2023Dokument33 SeitenAnalysis and Design of Circular Sewerage Tank - 2023adnan-651358Noch keine Bewertungen

- Structural Analysis: Lecture SeriesDokument9 SeitenStructural Analysis: Lecture SeriesSourNoch keine Bewertungen

- A Vortex Model of The Darrieus Turbine: An Analytical and Experimental StudyDokument6 SeitenA Vortex Model of The Darrieus Turbine: An Analytical and Experimental Studyjohn arbuckleNoch keine Bewertungen