Beruflich Dokumente

Kultur Dokumente

Internal Memo: Hazrds and Unsafe Working Conditions

Hochgeladen von

Asad AwanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Internal Memo: Hazrds and Unsafe Working Conditions

Hochgeladen von

Asad AwanCopyright:

Verfügbare Formate

INTERNAL MEMO

Date: July 8, 2020

To: Management

Thro: Technical Manager

From: Hse Officer

Subject: REPORT ON HAZARDS ANALYSIS AND CONTROL FOR THE OMAR JIBRAN

ENGINEERING PLANT LAHORE.

Sir, in view of the safety concerns of the company, a detailed safety audit was

carried out at the Omar Jibran Plant. The purpose is to identify, analyze and adopt

control measures for hazards associated with the job.

The safety audit is also meant to assess the present state of company’s Health

Safety and Environment (HSE)-Management system in order to bring about

improvements.

HAZRDS AND UNSAFE WORKING CONDITIONS

During the audit exercise, we identified number of hazards and unsafe working

conditions associated with the plants are stated below.

1. Incomplete personal protective equipment’s (PPE’s): Most of the workers

are seen working without personal protective equipment’s because they

were not given. The absence of these protective equipments is of great risk

because some injuries which would have ordinarily been prevented are left

unguarded due to the absence of these equipments. The most essential

required personal protective equipments (PPE’s) for the jobs at plant:

REQUIRED PPE’s

Safety Shoes with protective toecaps

Hand Gloves with a cuff

Safety Glasses

Surgical Masks

Apron

Insulated gloves

Industrial Safety Helmets

Ear plugs, Ear muffs

2. Absence of fire Alarms, flash point detectors and other fire safety aids

around the plant premises other than fire extinguishers

3. Occupational Health hazards to the workers resulting to their exposure to

adverse weather condition

The direct effect of the sun rays (Heat Stroke) on the loaders.

The plant lacks a bathroom facility as per need, hence workers

(polish shop) take advantage of any available space within a plant for

taking shower. This is very unhygienic.

4. . Some of very essential working equipments/tools are defective and in

some cases absent. This has left the workers with no option but to resort

to unsafe actions.

Absence of scaffolds and ladder for maintenance work at height.

There are no facilities available for maintenance workers for lifting heavy

equipments; hence workers resort to manually carrying even without

PPE’s

Electric cables at polish& nickel shop are old, defective and potential

sources of electrical leakage/shock.

5. General lack of awareness to safety, good housekeeping and contingency

management.

HAZARDS ASSESMENT AND CONSEQUENCE

Having identified some of the hazards and unsafe conditions associated with the

jobs inside plant, we also need to analyze the consequences in order to under to

understand and avert the impending contingencies that might arise.

When we place the frequency level of hazards and unsafe conditions around the

work area, against the ISO 14001 risk assessment matrix, there is a very high

probability of an impending undesired occurrence (accident).The potential

damage that might result to life ,assets, environment and reputation of the

company is such that cannot be over looked. The situation is one that calls for

immediate response by management top ensure that appropriate measures are

taken to control the above risk factors to “as law as reasonably practicable”

RECOMMENDATION FOR HAZARDS ANALYSIS AND CONTROL

In an effort to minimize the safety concerns analyzed above, it will be highly

productive for management to consider review and implement the following

recommendations below.

1. Pre-Task Planning: - There should be a health and safety and environment

(HSE) management System In place to ensure every task to be performed is

carefully planned and all the hazards associated with it, clearly identified.

This involve the following processes.

All the personnel to perform the task should be identified and their

competence assured

The various tools and equipment to be used for the job should also

be identified and tested. Any noticed short falls in performance

rectified and made ready for use.

The hazards associated with the task are fully discussed with all

concerned.

All the personal protective equipments required should be identified,

provided and the understanding of the usage is explained.

Das könnte Ihnen auch gefallen

- The Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsVon EverandThe Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsNoch keine Bewertungen

- The Construction Safety Guide: Injury and Illness Prevention through DesignVon EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignBewertung: 4 von 5 Sternen4/5 (6)

- Safety Officer ReportDokument7 SeitenSafety Officer Reportpekunalexander94% (47)

- INSPECTION REPORT - Group CDokument8 SeitenINSPECTION REPORT - Group C205695 Onyeukwu Stephen Gift IndustrialNoch keine Bewertungen

- Engineering Health and SafetyDokument24 SeitenEngineering Health and SafetyKobby BrineNoch keine Bewertungen

- 3 Lecture 2 N 3-1 Fundamentals of SafetyDokument29 Seiten3 Lecture 2 N 3-1 Fundamentals of SafetyArjan GhoshNoch keine Bewertungen

- No. Matrikulasi: No. Kad Pengnealan: No. Telefon: E-MelDokument12 SeitenNo. Matrikulasi: No. Kad Pengnealan: No. Telefon: E-MelNaru TosNoch keine Bewertungen

- Matrix Number Muhammad Amir Aiman Bin Hamimi Muhammad Faris Bin AzmanDokument10 SeitenMatrix Number Muhammad Amir Aiman Bin Hamimi Muhammad Faris Bin AzmanM.farisNoch keine Bewertungen

- CHEA 512 Safety in Process-Hazard ClassificationDokument26 SeitenCHEA 512 Safety in Process-Hazard ClassificationroxetteNoch keine Bewertungen

- JOB CERT 2 Information Sheet Plumbing 2024Dokument66 SeitenJOB CERT 2 Information Sheet Plumbing 2024wallendelroyNoch keine Bewertungen

- Unit - 2Dokument6 SeitenUnit - 2محمد محمدNoch keine Bewertungen

- Control of Industrial HazardsDokument19 SeitenControl of Industrial Hazardsnickokinyunyu11Noch keine Bewertungen

- WPP ModuleDokument93 SeitenWPP Modulejoehardy329Noch keine Bewertungen

- Good Morning Class! February 10, 2021: Tle-CarpentryDokument57 SeitenGood Morning Class! February 10, 2021: Tle-CarpentryGlenn Fortades SalandananNoch keine Bewertungen

- And Injury by Management of The WorkDokument3 SeitenAnd Injury by Management of The WorkAntonette CaparaNoch keine Bewertungen

- Why engineers must study Basic Occupation Safety and Health (BOSHDokument8 SeitenWhy engineers must study Basic Occupation Safety and Health (BOSHCarl Vincent TaboadaNoch keine Bewertungen

- Inspecting Technical Quality of WorkDokument3 SeitenInspecting Technical Quality of Workkhurvy keishaNoch keine Bewertungen

- SAFE DESIGN AND PPEDokument7 SeitenSAFE DESIGN AND PPEAlfie Delos Reyes100% (1)

- Industrial Safety and Hazard ManagementDokument89 SeitenIndustrial Safety and Hazard ManagementRoshanNoch keine Bewertungen

- Safety PDFDokument7 SeitenSafety PDFPratik SudraNoch keine Bewertungen

- Chemical Engineering Safety PrinciplesDokument106 SeitenChemical Engineering Safety PrinciplesAFEC AGIRONoch keine Bewertungen

- 3-HAZARD IDENTIFICATIONxyzDokument80 Seiten3-HAZARD IDENTIFICATIONxyzazozinlcNoch keine Bewertungen

- Occupational Safety and Health SeminarDokument207 SeitenOccupational Safety and Health SeminarFernandez JainardNoch keine Bewertungen

- Practicing Occupational Health and Safety ProcedureDokument20 SeitenPracticing Occupational Health and Safety ProcedureKEN RolloqueNoch keine Bewertungen

- IMS Checklist 5 - Mod 4Dokument9 SeitenIMS Checklist 5 - Mod 4Febin C.S.Noch keine Bewertungen

- 22509 Management Chapter 4 Study MaterialDokument26 Seiten22509 Management Chapter 4 Study MaterialVirendra PatilNoch keine Bewertungen

- TVL-CapsLET - ANI - Week2b (OHS) - Palis, MaryGayDokument15 SeitenTVL-CapsLET - ANI - Week2b (OHS) - Palis, MaryGayArthur ManaloNoch keine Bewertungen

- Occupational Health & Safety (OHS)Dokument36 SeitenOccupational Health & Safety (OHS)MmeraKi100% (1)

- VNM - MEGA - Site Minimum H&S Standard Concept-EngDokument18 SeitenVNM - MEGA - Site Minimum H&S Standard Concept-EngTN QwertyNoch keine Bewertungen

- OSH Brief No. 1Dokument4 SeitenOSH Brief No. 1Anime ListNoch keine Bewertungen

- Reviewer in BoshDokument8 SeitenReviewer in BoshAlban Ronel D.Noch keine Bewertungen

- Safety in Chemical Process PlantsDokument5 SeitenSafety in Chemical Process PlantsSrinivasan .MNoch keine Bewertungen

- MESH TrainingDokument54 SeitenMESH TrainingKarl Gerard TyNoch keine Bewertungen

- Lec 3. Inspection & Prevention (CM-112)Dokument30 SeitenLec 3. Inspection & Prevention (CM-112)Naveed AhmadNoch keine Bewertungen

- Group 1 Safety EngineeringDokument103 SeitenGroup 1 Safety EngineeringErnielle Rae Dela CruzNoch keine Bewertungen

- Accident Prevention in Industry: BY Suresh PatilDokument50 SeitenAccident Prevention in Industry: BY Suresh PatilgohelgohelNoch keine Bewertungen

- Occupational Health and Safety: Safety Must Be Addressed in Every Workplace. by and Large, The DefinitionDokument10 SeitenOccupational Health and Safety: Safety Must Be Addressed in Every Workplace. by and Large, The DefinitionQah AcNoch keine Bewertungen

- Accident Prevention Plan - Manglore Port TrustDokument19 SeitenAccident Prevention Plan - Manglore Port TrustRahul ShandilyaNoch keine Bewertungen

- Over View of The Industrial Fabrication YardDokument6 SeitenOver View of The Industrial Fabrication Yardzam110100% (1)

- Accident Prevention TechniquesDokument8 SeitenAccident Prevention TechniquesvsrslmNoch keine Bewertungen

- Unit 3 - Major Accident Hazard Control.Dokument50 SeitenUnit 3 - Major Accident Hazard Control.Madhan MNoch keine Bewertungen

- A Safe Workplace Is Created When Everyone Takes A Role in Managing Health and Safety IssuesDokument6 SeitenA Safe Workplace Is Created When Everyone Takes A Role in Managing Health and Safety IssuesCharles Dhanniel BawasNoch keine Bewertungen

- Construction Safety Management Lessons on Concrete, Cranes, and ForkliftsDokument22 SeitenConstruction Safety Management Lessons on Concrete, Cranes, and ForkliftsM Zohaib Mudabber KhanNoch keine Bewertungen

- Environmental Health and Safety: Group 7Dokument12 SeitenEnvironmental Health and Safety: Group 7Luis ArcillNoch keine Bewertungen

- Protecting Employees Who Work On Homeland Security and Critical Infrastructure ProjectsDokument11 SeitenProtecting Employees Who Work On Homeland Security and Critical Infrastructure ProjectsAjendra SinghNoch keine Bewertungen

- HSE 2014 Unit I & IIDokument71 SeitenHSE 2014 Unit I & IIBaby ChickooNoch keine Bewertungen

- Hand Out Maintenance Course For EngineersDokument109 SeitenHand Out Maintenance Course For EngineersGauravNoch keine Bewertungen

- Employee Safety ManagementDokument119 SeitenEmployee Safety ManagementT S Kumar Kumar100% (1)

- EVT (Sop)Dokument21 SeitenEVT (Sop)Farvin FleetNoch keine Bewertungen

- Pakistan Railways Carriage Factory, IslamabadDokument10 SeitenPakistan Railways Carriage Factory, IslamabadFarhan EdwinNoch keine Bewertungen

- Project Report: Personal Protective EquipmentDokument89 SeitenProject Report: Personal Protective EquipmentVivace SystmNoch keine Bewertungen

- Behavior-Based Safety OmctDokument123 SeitenBehavior-Based Safety OmctariftaskeenadvocateNoch keine Bewertungen

- Lecture Safety InspectionDokument43 SeitenLecture Safety InspectionRose Mica AngelesNoch keine Bewertungen

- Risk Assessment: Julia WaygoodDokument30 SeitenRisk Assessment: Julia WaygoodOana PNoch keine Bewertungen

- OSH BasicsDokument8 SeitenOSH BasicsPiotr KnapikNoch keine Bewertungen

- 0 Tips To Prevent Workplace InjuriesDokument4 Seiten0 Tips To Prevent Workplace InjuriesDon Johnnedel Basa OsitaNoch keine Bewertungen

- Basic Safety Procedure in High Risk Activities and IndustriesDokument10 SeitenBasic Safety Procedure in High Risk Activities and IndustriesKent Daniel DinopolNoch keine Bewertungen

- Prevention and Hazard ControlDokument21 SeitenPrevention and Hazard ControlKladees WorldNoch keine Bewertungen

- Unit - I Industrial SafetyDokument27 SeitenUnit - I Industrial SafetyKanda SamyNoch keine Bewertungen

- Site Inspection 1Dokument24 SeitenSite Inspection 1Dan ValleroNoch keine Bewertungen

- HSE Dashboard: NKM Heights NKM Pearl NKM RoyalsDokument4 SeitenHSE Dashboard: NKM Heights NKM Pearl NKM RoyalsAsad Awan75% (4)

- Root Cause Analysis Tool Cs Version 2Dokument6 SeitenRoot Cause Analysis Tool Cs Version 2Asad AwanNoch keine Bewertungen

- Butt Weld PipesDokument6 SeitenButt Weld PipesAsad AwanNoch keine Bewertungen

- Introduction Aand Exective Summary 2Dokument4 SeitenIntroduction Aand Exective Summary 2Asad AwanNoch keine Bewertungen

- Preventing Fires During Hot Work OperationsDokument8 SeitenPreventing Fires During Hot Work OperationsMuhammad YounasNoch keine Bewertungen

- ABBREVATIONDokument5 SeitenABBREVATIONAsad AwanNoch keine Bewertungen

- GC3 - The Health and Safety Practical Application: Khurram RasheedDokument1 SeiteGC3 - The Health and Safety Practical Application: Khurram RasheedAsad AwanNoch keine Bewertungen

- Daily Performance of SsoDokument636 SeitenDaily Performance of SsoAsad AwanNoch keine Bewertungen

- 1404 Pak Safety Solution 00431763 Khurram RasheedDokument2 Seiten1404 Pak Safety Solution 00431763 Khurram RasheedAsad AwanNoch keine Bewertungen

- Nebosh Legislation Quiz AnswersDokument1 SeiteNebosh Legislation Quiz AnswersAsad AwanNoch keine Bewertungen

- Project: Installing New Bathrooms: Try HANDS HQ and Complete A Risk Assessment in MinutesDokument2 SeitenProject: Installing New Bathrooms: Try HANDS HQ and Complete A Risk Assessment in MinutesAsad AwanNoch keine Bewertungen

- Workplace Safety Checklist: General Y N N/A CommentsDokument1 SeiteWorkplace Safety Checklist: General Y N N/A CommentsAsad AwanNoch keine Bewertungen

- Fire Safety Training RequirementsDokument2 SeitenFire Safety Training RequirementsAsad AwanNoch keine Bewertungen

- Incident Reporting FlowchartDokument2 SeitenIncident Reporting FlowchartAsad AwanNoch keine Bewertungen

- RACI Matrix: Roles and ResponsibilitiesDokument3 SeitenRACI Matrix: Roles and ResponsibilitiesAsad AwanNoch keine Bewertungen

- Workplace Housekeeping: Training Slides OnDokument42 SeitenWorkplace Housekeeping: Training Slides OnAsad AwanNoch keine Bewertungen

- BIN AND HOPPER SAFETY GUIDELINESDokument23 SeitenBIN AND HOPPER SAFETY GUIDELINESvishnusankarNoch keine Bewertungen

- (Sample) : Employees. at A Minimum, Employees Must Know The General Safety and Health Rules of The Worksite, Specific SiteDokument7 Seiten(Sample) : Employees. at A Minimum, Employees Must Know The General Safety and Health Rules of The Worksite, Specific SiteeastNoch keine Bewertungen

- Anemometer ReadingDokument9 SeitenAnemometer ReadingAsad AwanNoch keine Bewertungen

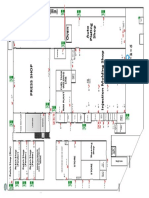

- Safety Layout UpdatedDokument2 SeitenSafety Layout UpdatedAsad AwanNoch keine Bewertungen

- File PDFDokument158 SeitenFile PDFAsad AwanNoch keine Bewertungen

- COVID-19 Safety Plan for Omar Jibran Engineering PlantDokument17 SeitenCOVID-19 Safety Plan for Omar Jibran Engineering PlantAsad AwanNoch keine Bewertungen

- Consolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.17 DateDokument1 SeiteConsolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.17 DateradhouaneNoch keine Bewertungen

- Safety Layout FinalDokument1 SeiteSafety Layout FinalAsad AwanNoch keine Bewertungen

- FactoryDokument8 SeitenFactoryJonathan D'limaNoch keine Bewertungen

- Compressed Gas Safety EssentialsDokument15 SeitenCompressed Gas Safety EssentialsAsad AwanNoch keine Bewertungen

- Motor vehicle repair risk assessmentDokument7 SeitenMotor vehicle repair risk assessmentAsad AwanNoch keine Bewertungen

- OHS Workplace ChecklistDokument5 SeitenOHS Workplace ChecklistAsad AwanNoch keine Bewertungen

- Accident Report FormDokument2 SeitenAccident Report FormAF Dowell MirinNoch keine Bewertungen

- DACReq 06 I3 R1Dokument25 SeitenDACReq 06 I3 R1Chiheb KaanicheNoch keine Bewertungen

- HP Steam Superheater 2 Intermediate Tube Sheets Repair JSADokument1 SeiteHP Steam Superheater 2 Intermediate Tube Sheets Repair JSAVIctor OdususiNoch keine Bewertungen

- Hazop Surface Gas and Mud Handling Systems During Drilling OperationsDokument14 SeitenHazop Surface Gas and Mud Handling Systems During Drilling OperationsTee Shi FengNoch keine Bewertungen

- Carbon Dioxide Solid MSDSDokument11 SeitenCarbon Dioxide Solid MSDSDolfin YohanesNoch keine Bewertungen

- Critical Systems Validation: ©ian Sommerville 2004Dokument45 SeitenCritical Systems Validation: ©ian Sommerville 2004Cecep Kurnia SastradiprajaNoch keine Bewertungen

- Fire Code Summary Me LawDokument6 SeitenFire Code Summary Me LawMarc Danielle G Josue IINoch keine Bewertungen

- Unilap 100 E: Installation TesterDokument4 SeitenUnilap 100 E: Installation Testerchoban19840% (1)

- CERAN WR 2 MsdsDokument13 SeitenCERAN WR 2 MsdsKyrylo TerokhinNoch keine Bewertungen

- RAMS For Pressure TestingDokument21 SeitenRAMS For Pressure TestingAnandu AshokanNoch keine Bewertungen

- Training Manual EN PDFDokument140 SeitenTraining Manual EN PDFFabio SplendorNoch keine Bewertungen

- Risk Assessment - Chiller RoomDokument3 SeitenRisk Assessment - Chiller RoomPraveen0% (1)

- Reflection Paper - Powerplant and Transmission Line SafetyDokument3 SeitenReflection Paper - Powerplant and Transmission Line SafetyChristian Mark De JesusNoch keine Bewertungen

- Chemical Process Safety Prof. Shishir Sinha Department of Chemical Engineering, IIT Roorkee Risk Management & Hazardous Substance RulesDokument24 SeitenChemical Process Safety Prof. Shishir Sinha Department of Chemical Engineering, IIT Roorkee Risk Management & Hazardous Substance Ruless dNoch keine Bewertungen

- ULT.A3X2G5+BK23187-A 000000000030246042 SDS GEN US en 9-0Dokument11 SeitenULT.A3X2G5+BK23187-A 000000000030246042 SDS GEN US en 9-0mcincicNoch keine Bewertungen

- Low RDS(ON) N ch Trench Power MOSFETDokument9 SeitenLow RDS(ON) N ch Trench Power MOSFETytnateNoch keine Bewertungen

- R-30+B/R-30+B Mate/R-30+B Plus CONTROLLER OPERATOR'S MANUALDokument350 SeitenR-30+B/R-30+B Mate/R-30+B Plus CONTROLLER OPERATOR'S MANUALSTEPHANY VANESSA LOMBANA ROJAS100% (1)

- SDS UltraSnap US en 1 - 0Dokument14 SeitenSDS UltraSnap US en 1 - 0IG ChannelNoch keine Bewertungen

- Occidental Oil and Gas Corporation Mechanical Integrity StandardDokument7 SeitenOccidental Oil and Gas Corporation Mechanical Integrity StandardedwinsazzzNoch keine Bewertungen

- ACPO Protection Driver Manual 2009Dokument28 SeitenACPO Protection Driver Manual 2009German Eduardo Bogota Moreno100% (1)

- Fire Safety Measures Rule ExplainedDokument138 SeitenFire Safety Measures Rule ExplainedsubyNoch keine Bewertungen

- Process Safety & Personal Safety in Oil Well Drilling - 2017-06-01 - ISHNDokument4 SeitenProcess Safety & Personal Safety in Oil Well Drilling - 2017-06-01 - ISHNPimol SuriyaprasitNoch keine Bewertungen

- Nebosh: Management of Health and Safety Unit Ig1Dokument5 SeitenNebosh: Management of Health and Safety Unit Ig1Muhammad Talha0% (1)

- HSE Site Instruction For Contractor FormDokument1 SeiteHSE Site Instruction For Contractor FormAsif HussainNoch keine Bewertungen

- SDS SikaHyflex 250 Facade - EU - ENDokument9 SeitenSDS SikaHyflex 250 Facade - EU - ENFajar Reza LaksanaNoch keine Bewertungen

- Gcc-Works - 20130708 - 165943 General Conditions of ContractDokument57 SeitenGcc-Works - 20130708 - 165943 General Conditions of ContractDeepakNoch keine Bewertungen

- Aripelly NagarjunaDokument5 SeitenAripelly Nagarjunaaripally NagarjunaNoch keine Bewertungen

- Nanotechnology in Nutraceuticals and Functional Foods 2016Dokument10 SeitenNanotechnology in Nutraceuticals and Functional Foods 2016chandana s kNoch keine Bewertungen

- Code of Conduct: For Nippon Koei GroupDokument21 SeitenCode of Conduct: For Nippon Koei GroupDianNoch keine Bewertungen

- Martin Screw Conveyor-SecHDokument176 SeitenMartin Screw Conveyor-SecHcontact@coreeslNoch keine Bewertungen

- NAEMT AMLS AcknowledgmentsDokument4 SeitenNAEMT AMLS AcknowledgmentsJim ThorntonNoch keine Bewertungen