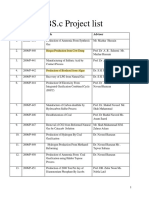

Beruflich Dokumente

Kultur Dokumente

Niosh 2554 PDF

Hochgeladen von

MICROLABORATORIO S.A de C.VOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Niosh 2554 PDF

Hochgeladen von

MICROLABORATORIO S.A de C.VCopyright:

Verfügbare Formate

GLYCOL ETHERS 2554

(1) CH3 OCH2 CHOHCH3 MW: 90.1 CAS: 107-98-2 RTECS: UB7700000

(2) CH3 OC3 H6 OC3 H6 OH 148.2 34590-94-8 JM1575000

(3) CH3 OCH2 CH(CH3 )COOCH3 132.16 108-65-6 AI8925000

METHOD: 2554 EVALUATION: PARTIAL Issue 1: 15 March 2003

OSHA : See Table I PROPERTIES: See Table I

NIOSH: See Table I

ACGIH: See Table I

SYNONYMS: (1) propylene glycol monomethyl ether, 1-methoxy-2-propanol, 2-methoxy-1-methylethanol, propylene glycol

methyl ether

(2) dipropylene glycol monomethyl ether

(3) propylene glycol monomethyl ether acetate, propylene glycol methyl ether acetate, 1-methoxy-2-propyl

acetate

SAMPLING MEASUREMENT

SAMPLER: SOLID SORBENT TUBE TECHNIQUE: GAS CHROMATOGRAPHY, FID

(Anasorb® 747, 140 mg/70 mg)

ANALYTE: See Table I

FLOW RATE: 0.1 to 0.2 L/min

DESORPTION: 1 mL of methylene chloride/methanol

VOL-MIN: 3L (85:15) for 30 minutes in ultrasonic bath

-MAX: 25 L (at lower flow rates) INJECTION

VOLUME: 1 :L

SHIPMENT: Keep cold, pack securely for shipping

TEMPERATURE

SAMPLE -INJECTION: 195°C

STABILITY: 14 days @ 5°C for analytes 1 and 3; -DETECTOR: 240°C

7 days @ 5°C for analyte 2 -COLUMN: 90°C (1 min) to 200°C (10°C/min)

BLANKS: 2 to 10 field blanks per set CARRIER GAS: Helium, 2.8 mL/min

COLUMN: Capillary, fused silica, 30 m x 0.32-mm

ACCURACY ID; 100% PEG-DA, Stabilwax or

equivalent

RANGE STUDIED: Not determined.

CALIBRATION: Solutions of analytes in desorption

BIAS: Not determined. solvent

OVERALL PRECISION (Ö r T ): Not determined. RANGE: (1) 1.5 to 369 :g[3]

(2) 3.0 to 375 :g[3]

ACCURACY: Not determined (3) 1.5 to 369 :g[3]

ESTIMATED LOD: (1) 0.5 :g[3]

(2) 1.0 :g[3]

(3) 0.5 :g[3]

PRECISION ( þ r ): (1) 0.013[3]

(2) 0.031[3]

(3) 0.016[3]

APPLICABILITY: The working range for propylene glycol monomethyl ether was 0.041 to 10.0 ppm (0.154 to 36.9 mg/m3 ), for

dipropylene glycol monomethyl ether was 0.050 to 6.19 ppm (0.305 to 37.5 mg/m3 ), and propylene glycol monomethyl ether

acetate was 0.030 to 6.83 ppm (0.151 to 36.9 mg/m3 ) for a 10 L sample . Other methods used for the collection of these

analytes used a different solid sorbent and were evaluated at higher analyte concentrations [1,2]. Collection and DE recovery at

levels greater than the working range listed should be equal or better than those achieved using charcoal sorbent tubes.

INTERFERENCES: No specific interferences were identified. However, any compound with a similar retention time as the

analytes of interest may interfere.

OTHER METHODS: OSHA method 99 [1] and OSHA method 101 [2] can also be used for sampling glycol ethers at or above

the REL and PEL. NIOSH Method S69, from the 2nd edition of the NIOSH Manual of Analytical Methods, was used previously

for the collection and analysis of dipropylene glycol monomethyl ether and had acceptable recovery at a concentrations at or

above the REL/PEL [4].

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

GLY CO L ET HER S: ME TH OD 2554, Issue 1, dated 1 5Ma rch 2003 - Page 2 of 4

REAGENTS: EQUIPMENT:

1. Propylene glycol m ono m ethyl ethe r, reag ent 1. Sam pler: glass tube, 7 cm long, 6-mm OD, 4-

grad e.* mm ID, flame-sealed ends, containing two

2. Dipropylene glycol monomethyl ether, reagent sections of Anasorb® 747 (140mg/70 mg)

grad e.* sep arate d by a 2 -m m ureth ane foam plug. A

3. Propylene glycol monomethyl ether acetate, silylated glass wool plug precedes the front

reag ent grade .* section. A urethane foam plug follows the

4. Me thylene chloride, chrom atographic gra de.* back sectio n. T ubes are com m ercially

5. Me than ol, chrom atog raph ic grade.* available from SKC, Inc.

6. Desorbing solution, 15% m ethanol in 85% 2. Personal sampling pump, 0.1 to 0.2 L/min,

m ethylene chloride (V/V). connected with flexible tubing.

7. Propylene glycol monomethyl ether calibration 3. Gas chrom atograph, FID, integrator, and 30-m

stock solution, 46.2 mg/m L. Dilute 0.5 mL Stabilwax-DA or equivalent capillary column

analyte to 10 mL with desorbing solution. (page 255 4-1).

8. Dipropylene glycol monomethyl ether calibration 4. Vials, autosampler, with PTFE-lined caps.

stock solution, 47.5 mg/m L. Dilute 0.5 mL 5. Syringes, 10-:L, 25-:L, and 1-mL.

analyte to 10 mL with desorbing solution. 6. Volumetric flasks, 10-mL.

9. Propylene glycol m ono m ethyl ethe r ace tate 7. Refrigerant packs for shipping.

calibra tion sto ck solution, 48.5 m g/m L. Dilute

0.5 mL nitrobenzene to 10 mL with desorbing

solution.

10. Air, compressed, purified, and filtered.

11. Helium, purified and filtered.

12. Hydrogen, filtered.

* See SPECIAL PRECAUTIONS

SPECIAL PRECAUTIONS: Methylene chloride is a carcinogen [3]. Methanol is very flamm able and

toxic. Glycol ethers are irritants and hazardous compounds. W ear appropriate protective clothing and

work with these compounds in a well-ventilated hood.

SAMPLING:

1. Ca librate each pers ona l sam pling pum p with a represe ntative sam pler in line.

2. Break the ends of the sampler imm ediately prior to sampling. Attach sampler to personal sampling

pump with flexible tubing.

3. Sam ple at an accurately known flow rate between 0.1 and 0.2 L/min for a total sample size of 10 L.

4. Cap the samplers with plastic (not rubber) caps and pack securely for shipment. Samples should be

kept cold.

SAMPLE PREPARATION:

5. Place the front and back sorbent sections of the sampler tube in separate vials. Place the glass wool

preceding the front section into the vial containing the front section. Discard the remaining foam

plugs.

6. Ad d 1.0 m L of the desorbing solution into each vial. Attach crim p caps to each vial.

7. Plac e the sam ple vials in an u ltrasonic ba th for 3 0 m inutes .

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

GLY CO L ET HER S: ME TH OD 2554, Issue 1, dated 1 5Ma rch 2003 - Page 3 of 4

CALIBRATION AND QUALITY CONTRO L:

8. Calibrate daily with at least s ix workin g stan dards to cover the analytica l ran ge. If necessary,

additional standards may be added to extend the calibration curve.

a. Add known amounts of analytes to solvent solution in 10-mL volumetric flasks and dilute to the

m ark. Mix well.

b. Analyze together with samp les and blanks (steps 11 and 12).

c. Prepare calibration graph (peak area versus :g an alyte).

9. Dete rm ine desorption efficiency (DE) at least once for each lot of Anasorb 747 used fo r sam pling in

the calibration ranges (step 8).

a. Prepare three tubes at each of five levels plus three media blanks.

b. Inject a known amount of calibration stock solution directly onto the front sorbent section of each

Anasorb 747 tube with a microliter syringe.

c. Allow the tub es to air equ ilibrate for several m inutes , then cap the ends of ea ch tube a nd a llow to

stan d overnight.

d. Deso rb (steps 5-7) and a nalyze together with standards and blanks (steps 11 and 12).

e. Prepare a graph of DE versus :g analyte recovered.

10. Analyze three quality control blind spikes and three analyst spikes to ensure that the calibration graph

and D E graph are in control.

MEASUREMENT:

11. Set gas chromatograph according to manufacturer’s recomm endations and to conditions given on

page 2554-1. Inject a 1-:L sample aliquot manually using the solvent flush technique or with an

autosam pler.

NOTE: If pea k area is abo ve the linear ra nge of the working standard s, dilute w ith solve nt,

reanalyze and apply the appropriate dilution factor in the calculations.

12. Measure peak areas.

CALCULATIONS:

13. De term ine the m ass , :g (corrected for D E) of analyte found in the sam ple front (W f) and back (W b)

sorbent sec tions, and in the average m edia blank front (B f) and back (B b) sorbent sections.

NOTE: If W b > W f/10, report b reak throu gh a nd p oss ible sam ple loss.

14. Calculate conce ntration, C, of analyte in the air volume sam pled, V(L):

NO TE : :g/L = m g/m 3

EVALUATION OF METHOD:

In order to obtain improved analyte collection and recove ry results, several procedures were incorporated in

the m etho d de velop m ent. These included the use of a s tain less stee l inlet liner in the injection port to reduce

the possibility of degradation of analytes, lower injection port and detector temperatures to prevent thermal

decomposition of a nalytes, and the use of Anasorb 747 solid sorbent tubes to reduce the possibility of the

hydrolysis of the analytes.

This m eth od was developed in support of a fie ld survey to iden tify and quan titate glycol ether vapors emitted

from heat-cured solder mask paints. This method is applicable when levels below the REL/PEL are expected.

The average desorption efficiency (DE) recovery for propylene glycol monomethyl ether was 100.6% (RSD

= 1.6), for dipropylene glycol monomethyl ether, was 102.4% (RSD = 1.8), and for propylene glycol

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

GLY CO L ET HER S: ME TH OD 2554, Issue 1, dated 1 5Ma rch 2003 - Page 4 of 4

mon om ethyl ether acetate was 102.0% (RSD = 1.7). The average 14-day storage stability recovery at

approxim ate ly 75x the LOQ for propylene glycol monom ethyl ether was 103.1% (RSD = 2.1), for dipropylene

glycol monom ethyl ether was 77.7% (RSD = 2.3), and propylene glycol m onom eth yl ether acetate was 95.4%

(RSD = 3.7). Samples containing dipropylene glycol monomethyl ether should be analyzed soon after

collection to minimize sample loss during storage.

REFERENCES:

[1] OSHA [1993]. Propylene Glycol Monomethyl Ethers/Acetate, Method 99. Organic Methods

Evaluation Branch, OSHA A nalytical Methods Manual. Salt Lake City, UT: U.S. Department of

Labor, O ccupa tional Safety and He alth Adm inistration, OSH A Salt Lake T echnical Cen ter.

[2] OSHA [1993]. Dipropylene Glycol Methyl Ether, Method 101. Organic Methods Evaluation Branch,

OSHA Analytical Methods Manual. Salt Lake City, UT: U.S. Department of Labor, Occupational

Safety and He alth Adm inistration, OSH A Salt Lake T echnical Cen ter.

[3] Pendergrass SM [1998]. Backup data report for glycol ethers. Unpublished report. NIOSH/DPSE.

[4] NIOSH [1977]. Docum entation of the NIOSH Validation Tests, S69, U.S. Department of Health,

Educa tion, and W elfare; Publ. (NIOSH ) 77-185 (197 7).

[5] NIOSH Recom mendations for Occupational Safety and Health, U.S. Department of Health and

Hum an Services, (NIO SH) P ubl. 92-100 (Janua ry 1992).

METHOD WRITTEN BY: Stephanie M. Pendergrass, NIOSH/DPSE

TABLE 1. EXPOSURE LIMITS AND PHYSICAL PROPERTIES

Analyte OSHA NIOSH ACG IH mg/m 3 = Physical Properties

PEL REL TLV 1 ppm

(p pm ) (p pm ) (ppm ) @ NTP

Propylene glycol None 100 100 3.75 Liquid; d 0.9234 g/mL @ 20 °C, BP

monom ethyl ether 120.1 °C, VP 1.6 kPa (12 mm Hg)

@ 20°C

Dipropylene glycol 100 100 100 6.16 Liquid; d 0.9500 g/mL @ 20 °C, BP

monom ethyl ether 189.6 °C, VP 0.05 kPa (0.5 mm Hg)

@ 20°C

Propylene glycol None None None 5.40 Liquid; d 0.9700 g/mL @ 20 °C, BP

monom ethyl ether 145.8 °C, VP 0.5 @ 20°C KPa

ace tate

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

Das könnte Ihnen auch gefallen

- Application of IC-MS and IC-ICP-MS in Environmental ResearchVon EverandApplication of IC-MS and IC-ICP-MS in Environmental ResearchRajmund MichalskiNoch keine Bewertungen

- (CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Dokument3 Seiten(CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Patricia RoaNoch keine Bewertungen

- Niosh 1403Dokument5 SeitenNiosh 1403MICROLABORATORIO S.A de C.VNoch keine Bewertungen

- Formulas: Table 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 2553Dokument4 SeitenFormulas: Table 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 2553Nicolas ZeballosNoch keine Bewertungen

- Niosh 2555Dokument5 SeitenNiosh 2555KayceePortsNoch keine Bewertungen

- Niosh 1405Dokument6 SeitenNiosh 1405MICROLABORATORIO S.A de C.VNoch keine Bewertungen

- Niosh 2500 Metil Etil Cetona (Mek)Dokument4 SeitenNiosh 2500 Metil Etil Cetona (Mek)EverChumpisucaAlvarezNoch keine Bewertungen

- Niosh Methanol 2000Dokument4 SeitenNiosh Methanol 2000Endang MilahNoch keine Bewertungen

- Table 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Alcohols I 1400Dokument4 SeitenTable 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Alcohols I 1400Cristian Gutiérrez PeñaNoch keine Bewertungen

- NISOH 1401 ButanolDokument4 SeitenNISOH 1401 Butanolluis norabuenaNoch keine Bewertungen

- 1,1,1,2-TETRACHLORO-2,2-DIFLUOROETHANE and 1016 (2) 1,1,2,2-TETRACHLORO-1,2-DIFLUOROETHANEDokument4 Seiten1,1,1,2-TETRACHLORO-2,2-DIFLUOROETHANE and 1016 (2) 1,1,2,2-TETRACHLORO-1,2-DIFLUOROETHANEPatricia RoaNoch keine Bewertungen

- Table 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Amines, Aromatic 2002Dokument6 SeitenTable 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Amines, Aromatic 2002Huy MinhNoch keine Bewertungen

- CH Oc (CH) MW: 88.15 CAS: 1634-04-4 RTECS: KN5250000: Methyl Tert-Butyl Ether 1615Dokument4 SeitenCH Oc (CH) MW: 88.15 CAS: 1634-04-4 RTECS: KN5250000: Methyl Tert-Butyl Ether 1615MICROLABORATORIO S.A de C.VNoch keine Bewertungen

- NIOSH 1457-1994 Ethyl Acetate Udara Lingker GC FIDDokument4 SeitenNIOSH 1457-1994 Ethyl Acetate Udara Lingker GC FIDFakhri MuflihNoch keine Bewertungen

- CH CHCH CL MW: 76.53 CAS: 107-05-1 RTECS: UC7350000: Allyl Chloride 1000Dokument3 SeitenCH CHCH CL MW: 76.53 CAS: 107-05-1 RTECS: UC7350000: Allyl Chloride 1000Cristian Gutiérrez PeñaNoch keine Bewertungen

- Methyl AcetateDokument3 SeitenMethyl AcetatetranhungNoch keine Bewertungen

- TOLUENE (Diffusive Sampler) 4000: C H CH MW: 92.14 CAS: 108-88-3 RTECS: XS5250000Dokument4 SeitenTOLUENE (Diffusive Sampler) 4000: C H CH MW: 92.14 CAS: 108-88-3 RTECS: XS5250000VaninaNoch keine Bewertungen

- Table 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 1301Dokument5 SeitenTable 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 1301Nicolas ZeballosNoch keine Bewertungen

- Niosh Naftas 1550Dokument6 SeitenNiosh Naftas 1550Enrique Alejandro OvandoNoch keine Bewertungen

- Cloruro de MetilenoDokument4 SeitenCloruro de MetilenoLuisa MinaNoch keine Bewertungen

- CH CHCLCH CL MW: 112.99 CAS: 78-87-5 RTECS: TX9625000: Propylene Dichloride 1013Dokument4 SeitenCH CHCLCH CL MW: 112.99 CAS: 78-87-5 RTECS: TX9625000: Propylene Dichloride 1013Patricia RoaNoch keine Bewertungen

- NIOSH 0500-1994 (Total Dust As Inhalable Dust)Dokument4 SeitenNIOSH 0500-1994 (Total Dust As Inhalable Dust)apriliandiniNoch keine Bewertungen

- Niosh 1610Dokument3 SeitenNiosh 1610tio dameroNoch keine Bewertungen

- Acetona Niosh 1300 PDFDokument5 SeitenAcetona Niosh 1300 PDFOscar Garcia GutierrezNoch keine Bewertungen

- Table 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Alcohols I 1400Dokument4 SeitenTable 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Alcohols I 1400cerbero36Noch keine Bewertungen

- Descripcion MetodoDokument4 SeitenDescripcion MetodoAaron HernandezNoch keine Bewertungen

- NIOSH Manual of Analytical Methods - 1501Dokument7 SeitenNIOSH Manual of Analytical Methods - 1501Eng Wanders MillerNoch keine Bewertungen

- CH C H Oh MW: 108.14 Cas: 1319-77-3 Rtecs: Go5950000 C H Oh 94.11 108-95-2 SJ3325000Dokument4 SeitenCH C H Oh MW: 108.14 Cas: 1319-77-3 Rtecs: Go5950000 C H Oh 94.11 108-95-2 SJ3325000HectorNoch keine Bewertungen

- Niosh 1501Dokument7 SeitenNiosh 1501Lucas OliveiraNoch keine Bewertungen

- Volatile Organic Compounds, C1 To C10, Canister Method: Formula: Table 1 MW: Table 1 CAS: Table 1 RTECS: Table 1Dokument14 SeitenVolatile Organic Compounds, C1 To C10, Canister Method: Formula: Table 1 MW: Table 1 CAS: Table 1 RTECS: Table 1Karly RodriguezNoch keine Bewertungen

- Yodo - NIOSH 6005Dokument4 SeitenYodo - NIOSH 6005Mario LagosNoch keine Bewertungen

- Niosh 1610Dokument4 SeitenNiosh 1610MICROLABORATORIO S.A de C.VNoch keine Bewertungen

- Niosh 1450Dokument6 SeitenNiosh 1450MICROLABORATORIO S.A de C.VNoch keine Bewertungen

- CH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Dokument4 SeitenCH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Haryo SaputroNoch keine Bewertungen

- Hidroxipropilmetil Celulosa SIN 464Dokument7 SeitenHidroxipropilmetil Celulosa SIN 464Andrea Sanchez AbarcaNoch keine Bewertungen

- IMPCA MethanolDokument13 SeitenIMPCA MethanolHito Jimenez SalinasNoch keine Bewertungen

- CH (CH) NH MW: 73.16 CAS: 109-73-9 RTECS: EO2975000: N-Butylamine 2012Dokument4 SeitenCH (CH) NH MW: 73.16 CAS: 109-73-9 RTECS: EO2975000: N-Butylamine 2012Jayesh PanjabiNoch keine Bewertungen

- Niosh 6009 PDFDokument5 SeitenNiosh 6009 PDFCaleb ConnerNoch keine Bewertungen

- Plastificanti Come DOPDokument5 SeitenPlastificanti Come DOPMarco CorrengiaNoch keine Bewertungen

- Hydrogen Peroxide Determination: by Redox TitrationDokument6 SeitenHydrogen Peroxide Determination: by Redox Titrationdaniel_12Noch keine Bewertungen

- Hydrocarbons, Halogenated 1003: Table 1 MW: Table 2 Cas: Table 1 Rtecs: Table 1Dokument7 SeitenHydrocarbons, Halogenated 1003: Table 1 MW: Table 2 Cas: Table 1 Rtecs: Table 1api-3728640Noch keine Bewertungen

- (CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Dokument4 Seiten(CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Fauzan FebriyantoNoch keine Bewertungen

- CH CHCN MW: 53.06 CAS: 107-13-1 RTECS: AT5250000: Acrylonitrile 1604Dokument4 SeitenCH CHCN MW: 53.06 CAS: 107-13-1 RTECS: AT5250000: Acrylonitrile 1604Huy MinhNoch keine Bewertungen

- 1600 PDFDokument4 Seiten1600 PDFHarold Alonso CFNoch keine Bewertungen

- HydrazineDokument3 SeitenHydrazineSylab InstrumentsNoch keine Bewertungen

- CH CH BR MW: 108.97 CAS: 74-96-4 RTECS: KH6475000: Ethyl Bromide 1011Dokument4 SeitenCH CH BR MW: 108.97 CAS: 74-96-4 RTECS: KH6475000: Ethyl Bromide 1011Patricia RoaNoch keine Bewertungen

- WS2 ChlorideDokument6 SeitenWS2 ChlorideAnish KarthikeyanNoch keine Bewertungen

- Ca MW: Table 1 CAS: Table 1 RTECS: Table 1: CALCIUM and Compounds, As Ca 7020Dokument4 SeitenCa MW: Table 1 CAS: Table 1 RTECS: Table 1: CALCIUM and Compounds, As Ca 7020Harold Alonso CFNoch keine Bewertungen

- Allyl Chloride 1000: CH CHCH CL MW: 76.53 CAS: 107-05-1 RTECS: UC7350000Dokument3 SeitenAllyl Chloride 1000: CH CHCH CL MW: 76.53 CAS: 107-05-1 RTECS: UC7350000Luis TrejoNoch keine Bewertungen

- Niosh 5522Dokument6 SeitenNiosh 5522JAVIER MARTINEZNoch keine Bewertungen

- 6014-1 (NO y NO2)Dokument5 Seiten6014-1 (NO y NO2)Pablo Isaai Bracamonte CurielNoch keine Bewertungen

- AOAC 994.10 - GC - Cholesterol in Foods PDFDokument2 SeitenAOAC 994.10 - GC - Cholesterol in Foods PDFdennisaberliani100% (1)

- 5990 3285en PDFDokument16 Seiten5990 3285en PDFLutfi CiludNoch keine Bewertungen

- CH Oc (CH) MW: 88.15 CAS: 1634-04-4 RTECS: KN5250000: Methyl Tert-Butyl Ether 1615Dokument4 SeitenCH Oc (CH) MW: 88.15 CAS: 1634-04-4 RTECS: KN5250000: Methyl Tert-Butyl Ether 1615Nick WangNoch keine Bewertungen

- 2542 Metil Merkaptan Metil SulideDokument4 Seiten2542 Metil Merkaptan Metil SulideEndang WahyulNoch keine Bewertungen

- Hardness: DR 900 Analytical ProcedureDokument4 SeitenHardness: DR 900 Analytical Procedurewulalan wulan100% (1)

- NIOSH 3502-1993 (Phenol)Dokument3 SeitenNIOSH 3502-1993 (Phenol)apriliandiniNoch keine Bewertungen

- Section 10 - Medicines & Biological AnalysisDokument43 SeitenSection 10 - Medicines & Biological AnalysisNguyễn Mai Thanh LộcNoch keine Bewertungen

- Cloruro de Zinc PDFDokument3 SeitenCloruro de Zinc PDFPaola RiveraNoch keine Bewertungen

- Niosh 1501Dokument7 SeitenNiosh 1501Claudio Nunes0% (1)

- CH Oc (CH) MW: 88.15 CAS: 1634-04-4 RTECS: KN5250000: Methyl Tert-Butyl Ether 1615Dokument4 SeitenCH Oc (CH) MW: 88.15 CAS: 1634-04-4 RTECS: KN5250000: Methyl Tert-Butyl Ether 1615MICROLABORATORIO S.A de C.VNoch keine Bewertungen

- Niosh 1450Dokument6 SeitenNiosh 1450MICROLABORATORIO S.A de C.VNoch keine Bewertungen

- Osha 5001Dokument61 SeitenOsha 5001MICROLABORATORIO S.A de C.VNoch keine Bewertungen

- Niosh 1610Dokument4 SeitenNiosh 1610MICROLABORATORIO S.A de C.VNoch keine Bewertungen

- AIR PRODUCTS Cleaning Formulary BrochureDokument56 SeitenAIR PRODUCTS Cleaning Formulary BrochureZoltán Király100% (6)

- FMDS0281 Fire Protection System Inspection, Testing and MaintenanceDokument52 SeitenFMDS0281 Fire Protection System Inspection, Testing and Maintenancejulioagricola35Noch keine Bewertungen

- Pu-2013-Color-fixing Polyester and Preparatio1Dokument4 SeitenPu-2013-Color-fixing Polyester and Preparatio1Syed Tawab ShahNoch keine Bewertungen

- Westec Chemical Resistance Chart (ABC)Dokument5 SeitenWestec Chemical Resistance Chart (ABC)Feshir GutierrezNoch keine Bewertungen

- Ethylene Glycol Chemical Engineering Final Year ProjectDokument108 SeitenEthylene Glycol Chemical Engineering Final Year ProjectNatarajan Girish79% (14)

- Coolant and Your Engine SEBD0970!03!01-ALLDokument52 SeitenCoolant and Your Engine SEBD0970!03!01-ALLjaNoch keine Bewertungen

- BSC Project List (Last 10 Years)Dokument16 SeitenBSC Project List (Last 10 Years)ahmadNoch keine Bewertungen

- Propiedades Refrigerantes Secundarios PDFDokument13 SeitenPropiedades Refrigerantes Secundarios PDFBeatriz ReyesNoch keine Bewertungen

- Patent Application Publication (10) Pub. No.: US 2014/0100293 A1Dokument17 SeitenPatent Application Publication (10) Pub. No.: US 2014/0100293 A1JutonoNoch keine Bewertungen

- Flow AssuranceDokument29 SeitenFlow Assurancevelu2317Noch keine Bewertungen

- ClenAir by Nu-Calgon CatalogDokument12 SeitenClenAir by Nu-Calgon CatalogornotNoch keine Bewertungen

- BOA H DatabookletDokument14 SeitenBOA H DatabookletRicardo BarrosNoch keine Bewertungen

- Nptel: Chemical Process Industries - Web CourseDokument2 SeitenNptel: Chemical Process Industries - Web Coursejeas grejoy andrewsNoch keine Bewertungen

- 07 - GAS DEHYDRATION - Rev 8.3Dokument172 Seiten07 - GAS DEHYDRATION - Rev 8.3Fabricio Pedraza100% (1)

- US3242116A - Method of Making An Epoxy Grout Composition - Google PatentsDokument4 SeitenUS3242116A - Method of Making An Epoxy Grout Composition - Google Patentssreenath sreedharanNoch keine Bewertungen

- BRB Personal Care Cost Effictive Guide Formulation Edition 2019Dokument28 SeitenBRB Personal Care Cost Effictive Guide Formulation Edition 2019Abdulrahman HamdanNoch keine Bewertungen

- Dow HTM RangeDokument16 SeitenDow HTM RangeflashiitmNoch keine Bewertungen

- c7 Overheating TroubleshootingDokument124 Seitenc7 Overheating Troubleshootingali100% (2)

- Ethylene Oxide ProductionDokument22 SeitenEthylene Oxide Productionsaleem razaNoch keine Bewertungen

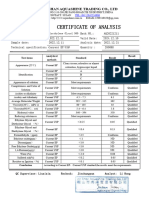

- Polyethylene Glycol 300 (PEG-300) COADokument1 SeitePolyethylene Glycol 300 (PEG-300) COAMariano CaligarisNoch keine Bewertungen

- EMG 2502 - Tutorial Sheet 4Dokument21 SeitenEMG 2502 - Tutorial Sheet 4Mogeni HenryNoch keine Bewertungen

- Ineos 1-Ethoxy-2-PropanolDokument15 SeitenIneos 1-Ethoxy-2-PropanolOmar Eduardo Davalillo MarínNoch keine Bewertungen

- Material Safety Data Sheet: 1. Product and Company IdentificationDokument5 SeitenMaterial Safety Data Sheet: 1. Product and Company IdentificationOrshanetzNoch keine Bewertungen

- York Ylaa 150.72-Icom6Dokument206 SeitenYork Ylaa 150.72-Icom6yair tovar100% (1)

- Chapter OneDokument61 SeitenChapter OneAbraham wisdom100% (1)

- US9309419 Blends in InkDokument10 SeitenUS9309419 Blends in InkIsabel MinuesaNoch keine Bewertungen

- MoviTec 50HzDokument72 SeitenMoviTec 50Hzavf86Noch keine Bewertungen

- Thermolator TW Ugh014 0100Dokument78 SeitenThermolator TW Ugh014 0100daniel menaNoch keine Bewertungen

- Pump MeterDokument52 SeitenPump MeterNiko LazićNoch keine Bewertungen

- Ethylene Glycol Production From Synthesis GasDokument2 SeitenEthylene Glycol Production From Synthesis Gaspre11111Noch keine Bewertungen