Beruflich Dokumente

Kultur Dokumente

Saudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 Inst

Hochgeladen von

nadeemOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Saudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 Inst

Hochgeladen von

nadeemCopyright:

Verfügbare Formate

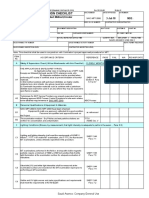

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 INST

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

TEST PROCEDURE ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

A General Conformance of Tests

Documented test procedures shall be submitted to Saudi Aramco for 34-SAMSS-820

A1

approval not less than thirty (30) days before commencement of test. Sec. 8

Review Factory Acceptance Test (FAT) documents detailing the set-up 34-SAMSS-820

A2

and procedures for the Functional Test to be provided. Sec. 8(a)

Verify that manufactured items have been inspected by the Saudi Aramco

34-SAMSS-820

A3 Inspection representative, per the Saudi Aramco Inspection Requirement

Sec. 8

175-343100 attached to the Purchase Order.

A certificate of compliance to the RFI requirements of IEC 61000-4-3,

Level 3. The certificate(s) shall be for either the entire cabinet or for all the

electronic equipment installed within the cabinet.

EMI/RFI Interference (Radiated Susceptibility):

The cabinet electronic equipment shall perform within the normal limits

without loss of function or degradation of performance when subjected to

34-SAMSS-820

A4 radiated electromagnetic fields in accordance with IEC 61000-4-3, Level

Sec. 8(b)

3, (at a 10 V/m power level), with cabinet doors open.

If certificates are not available, the equipment in the cabinet shall function

within the normal limit when tested with a 5 watt radio transceivers

operating at 5 Watts within the frequency ranges, 50-174 MHz, 406-

470MHz, and 800-870 MHz and held at a distance of 1.0 meter from the

cabinet, with cabinet doors open.

Service Personnel Qualifications and Experience: Service personnel

SAES-B-014 Sec.

A5 shall be qualified and experienced in the inspection, testing, and

3.2

maintenance of fire alarm systems. (NFPA 72-2010 Sec. 10.4.3.1)

Inspection: Visual inspections shall be performed in accordance with the

SAES-B-014 Sec.

A6 schedules in Table 14.3.1 or more often if required by the authority having

3.2

jurisdiction. (NFPA 72 Sec. 14.3.1)

Test Methods: Systems and associated equipment shall be tested

SAES-B-014 Sec.

A7 according to Table 14.4.2.2 and figure 10.6.2.3. (Attachment 2-5).

3.2

[NFPA 72 Sec. 14.4.2.2]

The Vendor is responsible for providing all test equipment required to

Schedule G

perform the tests described in this section. In addition, he shall perform

Sec. 2.5

A8 full functional tests and confirm that any problems have been resolved

SAES-B-014

prior to inviting Buyer's representative for the Buyer-witnessed functional

Sec. 7.9

test.

Specific tools and equipment shall be identified to make and perform tests Schedule Q

A9

in the field with instructions for their use, calibration and storage. Att. IV Sec. 7.1

Saudi Aramco: Company General Use

The CONTRACTOR shall identify, maintain, control, adjust and calibrate

Schedule Q

A10 all tools, gauges, instruments and other measuring and testing devices

Att. IV Sec. 7.1

used for controlling quality.

Calibration shall be performed at established periods as specified in

the most stringent of SAUDI ARAMCO standards, other applicable Schedule Q

A11

standards or manufacturer recommendations; if no standards apply, Att. IV Sec. 7.1

the calibration cycle shall not exceed six months.

CONTRACTOR shall provide backup equipment when the primary Schedule Q

A12

equipment is being calibrated or tested. Att. IV Sec. 7.1

CONTRACTOR personnel performing test and calibrations shall be Schedule Q

A13

trained per applicable international or manufacturer requirements. Att. IV Sec. 7.3

B Test Procedure / Methods for Control Equipment

Functions: At a minimum, control equipment shall be tested to verify

correct receipt of alarm, supervisory and trouble signals (inputs),

operation of evacuation signals and auxiliary functions (outputs), circuit

SAES-B-014

B1 supervision including detection of open circuits and ground faults, and

Sec. 3.2

power supply supervision for detection of loss of ac power and

disconnection of secondary batteries.

[NFPA 72-2013 Table14.4.3.2 Sec.2.(a)]

Fuses: The rating and supervision shall be verified. SAES-B-014

B2

[NFPA 72-2013 Table14.4.3.2 Sec.2.(b)] Sec. 3.2

Interfaced Equipment: Integrity of single or multiple circuits providing

interface between two or more control units shall be verified. Interfaced

equipment connections shall be tested by operating or simulating SAES-B-014

B3

operation of the equipment being supervised. Signals required to be Sec. 3.2

transmitted shall be verified at the control unit.

[NFPA 72-2013 Table14.4.3.2 Sec.2.(c)]

Lamps and LEDs: Lamps and LEDs shall be illuminated. SAES-B-014

B4

[NFPA 72-2013 Table 14.4.3.2 Sec.2.(d)] Sec. 3.2

Primary (Main) Power Supply: All secondary (standby) power shall be

disconnected and tested under maximum load, including all alarm

appliances requiring simultaneous operation. All secondary (standby) SAES-B-014

B5

power shall be reconnected at end of test. For redundant power supplies, Sec. 3.2

each shall be tested separately.

[NFPA72-2013 Table10.4.3.2 Sec.2(e)]

Secondary (Standby) Power Supply: Disconnect all primary (main)

power supplies and verify the occurrence of required trouble indication for

loss of primary power. Measure or verify the system’s standby and alarm

current demand and verify the ability of batteries to meet standby and

SAES-B-014

B6 alarm requirements using manufacturer’s data. Operate general alarm

Sec. 3.2

systems a minimum of 5 minutes and emergency voice communications

systems for a minimum of 15 minutes.Reconnect primary (main) power

supply at end of test.

(NFPA 72-2013 Table14.4.3.2 Sec.7)

Uninterrupted Power Supply (UPS): If a UPS system dedicated to the

fire alarm system is used as a required power source, operation of the

SAES-B-014

B7 UPS system shall be verified by the building owner in accordance with

Sec. 3.2

NFPA 111, Standard on stored Electrical Energy Emergency and Standby

Power Systems. (NFPA 72-2013Table14.4.3.2 Sec.8)

C Batteries - General Tests

General Tests: Prior to conducting any battery testing, the person

conducting the test shall ensure that all system software stored in volatile SAES-B-014

C1

memory is protected from loss. Sec. 3.2

(NFPA 72-2013 Table14.4.2.2 Sec.9)

Saudi Aramco: Company General Use

Visual Inspection: Batteries shall be inspected for corrosion or leakage.

Tightness of connections shall be checked and ensured. If necessary,

SAES-B-014

C2 battery terminals or connections shall be cleaned and coated. Electrolyte

Sec. 3.2

level in lead-acid batteries shall be visually inspected. [NFPA 72-2010

Table14.4.2.2 Sec.5.(a)]

Battery Replacement: Batteries shall be replaced in accordance with the

recommendations of the alarm equipment manufacturer or when the SAES-B-014

C3

recharged battery voltage or current falls below the manufacturer’s Sec. 3.2

recommendations. [NFPA 72-2010 Table14.4.2.2 Sec.5(b)]

Charger Test: Operation of battery charger shall be checked in

SAES-B-014

C4 accordance with charger test for the specific type of battery.

Sec. 3.2

[NFPA 72-2010 Table14.4.2.2 Sec.5(c)]

Discharge Test: With the battery charger disconnected, load test the

batteries following the manufacturer’s recommendations. Verify the

voltage level does not fall below the levels specified. Load testing can be SAES-B-014

C5

by means of an artificial load equal to the full fire alarm load connected to Sec. 3.2

the battery.

[NFPA 72-2013 Table14.4.3.2 Sec.9(a)(3)]

Load Voltage Test: With the battery charger disconnected, the terminal

voltage shall be measured while supplying the maximum load required by

its application. The voltage level shall not fall below the levels specified for

the specific type of battery. If the voltage falls below the level specified, SAES-B-014

C6

corrective action shall be taken and the batteries shall be retested. Sec. 3.2

Exception: An artificial load equal to the full fire alarm load connected to

the battery shall be permitted to be used in conducting this test.

[NFPA 72-2013 Table14.4.3.2 Sec.9(a)(4)]

Battery - Tests (Specific Types)

Primary Battery Load Voltage Test: The maximum load for a No. 6

primary battery shall not be more than 2 amperes per cell. An individual

(1.5-volt) cell shall be replaced when a load of 1 ohm reduces the voltage SAES-B-014

C7

below 1 volt. A 6-volt assembly shall be replaced when a test load of 4 Sec. 3.2

ohms reduces the voltage below 4 volts.

[NFPA 72-2013 Table14.4.3.2 Sec.9]

Lead-Acid Type; Charger Test: With the batteries fully charged and

connected to the charger, the voltage across the batteries shall be

SAES-B-014

C8 measured with a voltmeter. The voltage shall be 2.30 volts per cell +0.02

Sec. 3.2

volts at 25°C (77°F) or as specified by the equipment manufacturer.

[NFPA72-2013 Table14.4.3.2 Sec.9(a)(2)]

Lead-Acid Type: Load Voltage Test: Under load, the battery shall not SAES-B-014

C9

fall below 2.05 volts per cell. [NFPA 72-2013 Table14.4.3.2 Sec.9(a)(3)] Sec. 3.2

Lead-Acid Type: Specific Gravity: The specific gravity of the liquid in

the pilot cell or all of the cells shall be measured as required. The specific

gravity shall be within the range specified by the manufacturer. Although

the specified specific gravity varies from manufacturer to manufacturer, a

range of 1.205-1.220 is typical for regular lead-acid batteries, while 1.240- SAES-B-014

C10

1.260 is typical for high-performance batteries. A hydrometer that shows Sec. 3.2

only a pass or fail condition of the battery and does not indicate the

specific gravity shall not be used, because such a reading does not give a

true indication of the battery condition.

[NFPA 72-2013 Table14.4.3.2 Sec.9(a)(5)]

Saudi Aramco: Company General Use

Nickel-cadmium type: Charger test: With the batteries fully charged and

connected to the charger, an ampere meter shall be placed in series with

the battery under charge. The charging current shall be in accordance SAES-B-014

C11

with the manufacturer's recommendations for the type of battery used. In Sec. 3.2

the absence of specific information, 1/30 to 1/25 of the battery rating shall

be used. (NFPA 72 2013 Table14.4.3.2 Sec.9.(b).(2))

Nickel-Cadmium Type: Load Voltage Test: Under load, the float voltage

for the entire battery shall be 1.42 volts per cell, nominal. If possible, cells SAES-B-014

C12

shall be measured individually. Sec. 3.2

[NFPA 72-2013 Table14.4.3.2 Sec.9(b)(4)]

Sealed Lead-Acid Type: Charger Test: With the batteries fully charged

and connected to the charger, the voltage across the batteries shall be

SAES-B-014

C13 measured with a voltmeter. The voltage shall be 2.30 volts per cell +0.02

Sec. 3.2

volts at 25°C (77°F) or as specified by the equipment manufacturer.

[NFPA 72-2013 Table14.4.3.2 Sec.9(c)(2)]

Sealed Lead-Acid Type: Load Voltage Test: Under load, the battery

SAES-B-014

C14 shall perform in accordance with the battery manufacturer's specifications.

Sec. 3.2

[NFPA 72-2013 Table14.4.3.2 Sec.9(c)(4)]

D Transient Suppressors, Control Unit Trouble Signals & Annunciator

Transient Suppressors: Lightning protection equipment shall be

inspected and maintained per the manufacturer's published instructions. SAES-B-014

D1

Additional inspections shall be required after any lightning strikes. Sec. 3.2

(NFPA 72-2013 )

Audible and visual: Operation of control unit trouble signals shall be

verified as well as ring-back feature for systems using a trouble-silencing SAES-B-014

D2

switch that requires resetting. Sec. 3.2

[NFPA 72-2013 Table14.4.3.2 Sec.3(a)]

Disconnect Switches: If control unit has disconnect or isolating switches,

verify performance of intended function of each switch. Verify receipt of SAES-B-014

D3

trouble signal when a supervised function is disconnected Sec. 3.2

[NFPA 72-2013 Table14.4.3.2 Sec.3(b)]

Ground-Fault Monitoring Circuit: If the system has a ground detection

feature, the occurrence of ground-fault indication shall be verified SAES-B-014

D4

whenever any installation conductor is grounded. Sec. 3.2

[NFPA 72-2013 Table14.4.3.2 Sec.3(c)]

Transmission of Signals to Off-Premises Location: An initiating device

shall be actuated and receipt of alarm signal at the off-premises location

shall be verified. A trouble condition shall be created and receipt of a

trouble signal at the off-premises location shall be verified. A supervisory

device shall be actuated and receipt of a supervisory signal at the off-

SAES-B-014

D5 premises location shall be verified. If a transmission carrier is capable of

Sec. 3.2

operation under a single- or multiple-fault condition, an initiating device

shall be activated during such fault condition and receipt of a trouble

signal at the off-premises location shall be verified, in addition to the alarm

signal.

[NFPA 72-2013 Table14.4.3.2 Sec.3(d)]

Remote Annunciator: The correct operation and identification of

annunciator shall be verified. If provided, the correct operation of SAES-B-014

D6

annunciator under a fault condition shall be verified. Sec. 3.2

(NFPA 72-2013 Table14.4.3.2 Sec.11)

E Conductors - Metallic

Stray Voltage: All installation conductors shall be tested with a

volt/ohmmeter to verify that there are no stray (unwanted) voltages

between installation conductors or between installation conductors and

SAES-B-014

E1 ground. Unless a different threshold is specified in the published

Sec. 3.2

manufacturer's instructions for the installed equipment, the maximum

allowable stray voltage shall not exceed 1 volt ac/dc.

[NFPA 72-2013 Table10.4.3.2 Sec.15(a)]

Saudi Aramco: Company General Use

Ground Faults: All installation conductors other than those intentionally

and permanently grounded shall be tested for isolation from ground per SAES-B-014

E2

the installed equipment manufacturer's published instructions. Sec. 3.2

[NFPA 72-2013 Table 14.4.3.2 Sec.15(b)]

Short-Circuit Faults: All installation conductors other than those

intentionally connected together shall be tested for conductor-to-conductor

SAES-B-014

E3 isolation per the published manufacturer's instructions for the installed

Sec. 3.2

equipment. These same circuits also shall be tested conductor-to-ground.

[NFPA 72-2013 Table14.4.3.2 Sec.15(c)]

Loop Resistance: With each initiating and indicating circuit installation

conductor pair short-circuited at the far end, the resistance of each circuit

shall be measured and recorded. It shall be verified that the loop SAES-B-014

E4

resistance does not exceed the limits specified in the published Sec. 3.2

manufacturer's instructions for the installed equpment.

[NFPA 72-2013 Table14.4.3.2 Sec.15(d)]

Circuit integrity: Introduction of a fault in any circuit monitored for

integrity shall result in a trouble indication at the fire alarm control unit.

One connection shall be opened at not less than 10 percent of the SAES-B-014

E5

initiating devices, notification appliances and controlled devices on every Sec. 3.2

initiating device circuit, notification appliance circuit, and signaling line

circuit. [NFPA 72-2013 Table14.4.3.2 Sec.15(e)]

Conductors - Non Metallic

Circuit Integrity: Each initiating device, notification appliances, and

controlled devices on every initiating device circuit, notification appliance

SAES-B-014

E6 circuit, and signaling line circuit. Confirm all circuits perform as indicated

Sec. 3.2

in Sections 23.5,23.6, and 23.7

[NFPA 72-2013 Table14.4.3.2 Sec.16(b)]

Fiber Optics: The fiber-optic transmission line shall be tested in

accordance with the manufacturer’s instructions by the use of an optical

power meter or by an optical time domain reflectometer used to measure

the relative power loss of the line. This relative figure for each fiber-optic

line shall be recorded in the fire alarm control panel. If the power level

SAES-B-014

E7 drops 2 percent or more from the value recorded during the initial

Sec. 3.2

acceptance test, the transmission line, section thereof, or connectors shall

be repaired or replaced by a qualified technician to bring the line back into

compliance with the accepted transmission level per the manufacturer’s

recommendations.

[NFPA 72-2013 Table14.4.3.2 Sec.16(b)]

Supervision: Introduction of a fault in any supervised circuit shall result in

a trouble indication at the control unit. One connection shall be opened at

not less than 10 percent of the initiating device, notification appliance, and

signaling line circuit. Each initiating device, notification appliance, and SAES-B-014

E8

signaling line circuit shall be tested for correct indication at the control Sec. 3.2

unit. All circuits shall perform as indicated in Table 6.5, Table 6.6.1, or

Table 6.7. (Attachment 2)

[NFPA 72-2013 Table14.4.3.2 Sec.13(6)]

Saudi Aramco: Company General Use

Shop Drawings: Control unit wiring diagrams should be provided for all

control equipment (i.e., equipment listed as either a control unit or control

unit accessory), power supplies, battery chargers and annunciators and

should include the following information:

(1) Identification of the control equipment depicted

(2) Location(s)

(3) All field wiring terminals and terminal identifications

(4) All circuits connected to field wiring terminals, and circuit

SAES-B-014

E9 identifications

Sec. 3.2

(5) All indicators and manual controls, including the full text of all

labels

(6) All field connections to supervising station signaling equipment,

releasing equipment, and fire safety control interfaces.

Typical wiring diagrams should be provided for all initiating devices,

notification appliances, remote alarm light emitting diodes (LEDs), remote

test stations, and end-of-line and power supervisory devices. (NFPA 72-

2013 Section 7.4.7)

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract)

2. Schedule Q - Quality Requirements (Pro Forma Contract), Project Specific

3. SAES-B-014 - Safety Requirements for Plant and Operations Support Buildings,2 January 2018

4. 34-SAMSS-820 - Instrument Control Cabinets - Indoor, 13 July 2016

5. 34-SAMSS-831 - Instrumentation for Packaged Units,14 May 2018

6. NFPA 70 - National Electrical Code (NEC), 2017 Edition

7. NFPA 72 - National Fire Alarm Code, 2013 Edition

ATTACHMENTS:

1. Attachment 1: NFPA 72 Table 14.3.1 - Visual Inspection Frequencies

2. Attachment 2: NFPA 72 Tables A.12.3(a), A.12.3(b), A.12.3©

3. Attachment 3: Functional Test of Fire Alarm Panel (as one system) Page 1 of 3

4. Attachment 4: Functional Test of Fire Alarm Panel (as one system) Page 2 of 3

5. Attachment 5: Functional Test of Fire Alarm Panel (as one system) Page 3 of 3

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Name, Title, Department,

Name, Initials and Date:

Company, Initials and Date:

QC Inspector PID Representative

Saudi Aramco: Company General Use

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 INST

Attachment 1: NFPA 72, 2013 Table 14.3.1 - Visual Inspection Frequencies

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 INST

Attachment 2: NFPA 72 Tables A.12.3(a), A.12.3(b), A.12.3(c)

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 INST

Attachment 3: Functional Test of Fire Alarm Panel (as one system) Page 1 of 3

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Panel or Enclosure Tag No: EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

Ref. Mfr. Instruction Manual REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

Visual Inspection of Cabinet done Yes / No All loops continuity check done Yes / No

SYSTEM PREPARATION AND PRELIMINARY CHECKS

Internal wiring Cold Test done Yes / No Grounding Systems connected & Checked Yes / No

Internal Components Cold check : Yes / No Cabinet Segregation from Field Signals done Yes / No

Type of Transmission: Service:

Multiplex Reverse Priority Weekly Monthly

Digital RF Quarterly Semi-annually

Other (Specify) Annually Others (specify)

Control Unit Manufacturer:……………………………………………………………Model No………………………………….

Circuits Styles:…………………………………… Number of Circuits:…………………………………………………………..

Software Rev:……………………………Last Date System Had Any Service Performed:…………………………………….

SYSTEM ENERGISATION

Last Date that any Software or Configuration was Revised:......................................................

Power Supplies Input Check: Yes / No Power Supplies on…………………………………………………..

Switching System Check :…………………….. Warm up Check …………………………………………….

Back-up Battery Check :…………………….. Others (Specify) …………………………………………….

ALARM-INITIATING DEVICES AND CIRCUIT INFORMATION

Quantity Circuit Style

Manual Fire Alarm Boxes

Ion Detectors

Photo Detectors

Duct Detectors

Heat Detectors

Water flow Switches

Others (Specify) …………………………………………….

Alarm verification feature is disabled ------------------- enabled-------------

(NFPA Inspection and Testing , 1 of 4)

ALARM-NOTIFICATION APPLIANCES AND CIRCUIT INFORMATION

Quantity Circuit Style

Bells

Horns

Chimes

Strobes

Speakers

Others (Specify) …………………………………………….

No of alarm notification appliance circuits:------------------------------------

Are Circuits monitored for integrity? Yes / No

(NFPA Inspection and Testing , 2 of 4)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 INST

Attachment 4: Functional Test of Fire Alarm Panel (as one system) Page 2 of 3

SUPERVISORY SIGNAL-INITIATING DEVICES AND CIRCUIT INFORMATION

Quantity Circuit Style

Building Temp.

Site Water Temp.

Site water Level

Fire Pump Power

Fire Pump Running

Fire Pump Auto Position

Fire Pump or Pump Controller Trouble

Fire Pump Running

Generator In Auto Position

Generator or Controller Trouble

Switch Transfer

Generator Engine Running

Others (Specify) …………………………………………….

SIGNALING LINE CIRCUITS:

Quantity and style of signaling line circuits connected to system ( NFPA 72, Table 6.6.1)

Quantity …………………………………………….. Style (s)……………………………………………………...

SYSTEM POWER SUPPLIES:

(a) Primary (Main): Nominal Voltage……………...…………………………Amps……………………………………………...

Overcurrent Protection : Type…………………………………………..Amps……………………………………….………

Location(of Primary Supply Panelboard)………………………………………………………………………….................

Disconnecting Means Location:........................................................................................................................

(b) Secondary (Standby):

..............................................................Storage Battery : Amp-Hr Rating.............................................................

Calculated capacity to operate sytem, in hours:...........................24...........................60...................................

......................................Engine-driven generator dedicated to fire alarm System:

Location of fuel storage:.................................................................................................................................

TYPE BATTERY

Dry Cell------------------------------- Nickle- Cadmium ............................ Sealed Lead- Acid............................................

Other (Specify)

(c) Emergency or standby system used as a backup to primary power supply, instead of using a secondary power supply:

.......................................Emergency System described in NFPA 70, Article 700

.......................................legally required standby described in NFPA 70, Article 701

.......................................Optional standby system described in NFPA 70, Article 702, which also meets the performance requirements of Article 700 or

701.

PRIOR TO ANY TESTING

NOTIFICATIONS ARE MADE Yes No Who Time

Monitoring Entity Yes No ………….. ………………

Building Occupants Yes No ………….. ………………

Building Management Yes No ………….. ………………

Other (Specify) Yes No ………….. ………………

Authorities Having Jurdiction Notified

of any Impairments Yes No ………….. ………………

SYSTEM TESTS AND INSPECTIONS

TYPE Visual Functional Comments

Control Unit

Interface Equipment

Lamps / LEDs

Fuses

Primary Power Supply

Trouble Signals

Saudi Aramco: Company General Use

Disconnect Switches

Ground-Fault Monitoring

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 INST

Attachment 5: Functional Test of Fire Alarm Panel (as one system) Page 3 of 3

SYSTEM TESTS AND INSPECTIONS

Secondary Power Type Visual Functional Comments

Battery Condition

Load Voltage N/A

Discharge Test N/A

Charger Test N/A

Specific Gravity N/A

TRANSIENT SUPPRESSORS N/A

REMOTE ANNUNCIATOR

NOTIFICATIONS APPLIANCES

Audible

Visible

Speakers

Voice Clarity N/A

INITIATING AND SUPERVISORY DEVICE TESTS AND INSPECTIONS

Loc. & S/N Device Type Visual Check Functional Test Factory Setting Measured Setting Pass Fail

Comments:

Emergency Communication Equipt. Visual Functional Comments

Phone Set

Phone Jacks

Off-Hook Indicator

Amplifier (s)

Tone Generator (s)

Call-in Signal

System Performance

INTERFACE EQUIPMENT Visual Device Operation Simulated Operation

(Specify)

(Specify)

(Specify)

SPECIAL HAZARD SYSTEMS Visual Device Operation Simulated Operation

(Specify)

(Specify)

(Specify)

Special Procedures:

Comments:

SUPERVISING STATION MONITORING

Yes No Time Comments

Alarm Signal Yes No ………….. ………………

Alarm Restoration Yes No ………….. ………………

Trouble Signal Yes No ………….. ………………

Supervisory Signal Yes No ………….. ………………

Supervisory Restoration Yes No ………….. ………………

The following did not operate correctly:

Comments:

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Das könnte Ihnen auch gefallen

- En 15259 Air Quality MeasurementDokument82 SeitenEn 15259 Air Quality MeasurementJose Ortuño Martín100% (1)

- ASTM D2137 11 - Standard Test Methods For Rubber Property-Brittleness Point of Flexible Polymers and Coated FabricsDokument7 SeitenASTM D2137 11 - Standard Test Methods For Rubber Property-Brittleness Point of Flexible Polymers and Coated FabricsAndre SpirimNoch keine Bewertungen

- Sae 442Dokument8 SeitenSae 442miguelyzrNoch keine Bewertungen

- Vernier CaliperDokument2 SeitenVernier CaliperMechtek LabNoch keine Bewertungen

- Saudi Aramco Test ReportDokument7 SeitenSaudi Aramco Test Reportkarthi51289Noch keine Bewertungen

- Tank Calibration ReportDokument5 SeitenTank Calibration ReportSadia Hasan100% (1)

- Button Pull Test Machine SOPDokument1 SeiteButton Pull Test Machine SOPTaufiq Ahmed100% (2)

- Saudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDokument2 SeitenSaudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestJagdishNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDokument13 SeitenSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument20 SeitenSaudi Aramco Inspection Checklistnisha_khanNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument10 SeitenSaudi Aramco Inspection Checklistnisha_khanNoch keine Bewertungen

- Saudi Aramco Test Report: SATR-B-6103 30-Oct-17 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestDokument9 SeitenSaudi Aramco Test Report: SATR-B-6103 30-Oct-17 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestJagdishNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument12 SeitenSaudi Aramco Inspection Checklistnisha_khanNoch keine Bewertungen

- Saudi Aramco Test ReportDokument2 SeitenSaudi Aramco Test ReportSino hydroNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument6 SeitenSaudi Aramco Inspection Checklistnisha_khanNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 InstDokument18 SeitenSaudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 Instnisha_khanNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDokument4 SeitenSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNoch keine Bewertungen

- Saudi Aramco Test Report: SATR-B-6103 10-Jun-19 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestDokument5 SeitenSaudi Aramco Test Report: SATR-B-6103 10-Jun-19 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestSino hydroNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Dokument6 SeitenSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNoch keine Bewertungen

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDokument2 SeitenSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroNoch keine Bewertungen

- Saudi Aramco Test ReportDokument2 SeitenSaudi Aramco Test ReportJagdishNoch keine Bewertungen

- Satr J 6104Dokument5 SeitenSatr J 6104Shahzad HussainNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDokument4 SeitenSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNoch keine Bewertungen

- SAIC-A-2005 Rev 8Dokument4 SeitenSAIC-A-2005 Rev 8Syed ImranNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDokument8 SeitenSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Dokument6 SeitenSaudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Ma.socorro SaballaNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: In-Process Inspection 0f Direct Contact Method (Circular Magnetization Technique)Dokument8 SeitenSaudi Aramco Inspection Checklist: In-Process Inspection 0f Direct Contact Method (Circular Magnetization Technique)karthi51289Noch keine Bewertungen

- Saic A 2005Dokument10 SeitenSaic A 2005karthi51289Noch keine Bewertungen

- Saudi Aramco Test ReportDokument3 SeitenSaudi Aramco Test ReportMa.socorro SaballaNoch keine Bewertungen

- Saudi Aramco Test ReportDokument8 SeitenSaudi Aramco Test ReportMa.socorro SaballaNoch keine Bewertungen

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDokument6 SeitenSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNoch keine Bewertungen

- Saic P 3002Dokument1 SeiteSaic P 3002aneeshjokay0% (1)

- SAIC-A-2009 Rev 7Dokument4 SeitenSAIC-A-2009 Rev 7sajidazmi.amuNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDokument4 SeitenSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection Checklistnisha_khanNoch keine Bewertungen

- Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ElectDokument8 SeitenSaudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Electkarthi51289Noch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument9 SeitenSaudi Aramco Inspection Checklistnisha_khanNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDokument6 SeitenSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNoch keine Bewertungen

- Section 7 - Examination and Inspection ProgramDokument4 SeitenSection 7 - Examination and Inspection ProgramYasser Hammad MohamedNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument8 SeitenSaudi Aramco Inspection Checklistnisha_khanNoch keine Bewertungen

- SAIC-A-2009 Rev 6 Test EquipmentDokument5 SeitenSAIC-A-2009 Rev 6 Test Equipmentpookkoya thangalNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument4 SeitenSaudi Aramco Inspection Checklistnisha_khanNoch keine Bewertungen

- SAIC-P-3003 Rev 7 FinalDokument7 SeitenSAIC-P-3003 Rev 7 FinalEnginerShahzadGhaffarNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstDokument2 SeitenSaudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstAdel KlkNoch keine Bewertungen

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDokument9 SeitenInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDokument7 SeitenSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNoch keine Bewertungen

- SAIC-A-2005 Rev 5 Leak TestDokument4 SeitenSAIC-A-2005 Rev 5 Leak Testpookkoya thangalNoch keine Bewertungen

- ARAMCO RT Inpection Check List - SAIC-RT-2001Dokument15 SeitenARAMCO RT Inpection Check List - SAIC-RT-2001Anonymous hBBam1nNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDokument16 SeitenSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNoch keine Bewertungen

- Saic-A-2001 Rev 62Dokument21 SeitenSaic-A-2001 Rev 62pradeepthalava97Noch keine Bewertungen

- SAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials ReceivingDokument2 SeitenSAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials Receivinghomsalwaled88Noch keine Bewertungen

- Saic-P-3003 Rev 0 PDFDokument4 SeitenSaic-P-3003 Rev 0 PDFHesham HelalNoch keine Bewertungen

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationDokument5 SeitenInspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationTariqMalikNoch keine Bewertungen

- Saic e 2008Dokument4 SeitenSaic e 2008usmanNoch keine Bewertungen

- Saudi Aramco Test ReportDokument5 SeitenSaudi Aramco Test ReportzhangNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection Checklistnisha_khanNoch keine Bewertungen

- Saudi Aramco Test ReportDokument5 SeitenSaudi Aramco Test Reportkarthi51289Noch keine Bewertungen

- Saudi Aramco Test ReportDokument5 SeitenSaudi Aramco Test Reportkarthi51289Noch keine Bewertungen

- SATR-J-6913 Rev 0 PDFDokument6 SeitenSATR-J-6913 Rev 0 PDFAdel KlkNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 MechDokument5 SeitenSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 Mechkarthi51289Noch keine Bewertungen

- Saudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 ElectDokument8 SeitenSaudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 Electkarthi51289Noch keine Bewertungen

- Saudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstDokument2 SeitenSaudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstAdel KlkNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument6 SeitenSaudi Aramco Inspection ChecklistMa.socorro SaballaNoch keine Bewertungen

- Saudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 ElectDokument6 SeitenSaudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 Electkarthi51289Noch keine Bewertungen

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BVon EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNoch keine Bewertungen

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbDokument2 SeitenSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbnadeemNoch keine Bewertungen

- Release Structure For Intumescent Fireproofing (FP) : Saudi Aramco Test ReportDokument2 SeitenRelease Structure For Intumescent Fireproofing (FP) : Saudi Aramco Test ReportnadeemNoch keine Bewertungen

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDokument17 SeitenSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListnadeemNoch keine Bewertungen

- In-Process Inspection Report For Fire Proofing: Saudi Aramco Test ReportDokument2 SeitenIn-Process Inspection Report For Fire Proofing: Saudi Aramco Test ReportnadeemNoch keine Bewertungen

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechDokument3 SeitenSaudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechnadeemNoch keine Bewertungen

- Saudi Aramco Test Report: Water Chemistry Report SATR-A-2014 24-Jul-18 MechDokument2 SeitenSaudi Aramco Test Report: Water Chemistry Report SATR-A-2014 24-Jul-18 MechnadeemNoch keine Bewertungen

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDokument2 SeitenSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNoch keine Bewertungen

- Saudi Aramco Test ReportDokument8 SeitenSaudi Aramco Test ReportnadeemNoch keine Bewertungen

- Saudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Jul-18 MechDokument2 SeitenSaudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Jul-18 MechnadeemNoch keine Bewertungen

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechDokument2 SeitenSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechnadeemNoch keine Bewertungen

- Saes Z 004Dokument40 SeitenSaes Z 004nadeem100% (1)

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDokument2 SeitenSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Saudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechDokument2 SeitenSaudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechnadeemNoch keine Bewertungen

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechDokument2 SeitenSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechnadeemNoch keine Bewertungen

- Saudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechDokument2 SeitenSaudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechnadeemNoch keine Bewertungen

- Saes A 100Dokument6 SeitenSaes A 100nadeemNoch keine Bewertungen

- Precast Concrete Technician Study GuideDokument37 SeitenPrecast Concrete Technician Study Guidefree4bruceNoch keine Bewertungen

- Instructions For Use Trig: VITROS Chemistry Products TRIG SlidesDokument13 SeitenInstructions For Use Trig: VITROS Chemistry Products TRIG SlidesSaravnan RajendranNoch keine Bewertungen

- OQ Protocol Cleanroom Monitoring SystemDokument37 SeitenOQ Protocol Cleanroom Monitoring SystemThinaNoch keine Bewertungen

- Renishaw Goprobe Cycles For Contact Tool Setting: For Use With Makino ControlsDokument46 SeitenRenishaw Goprobe Cycles For Contact Tool Setting: For Use With Makino ControlsMax LitvinNoch keine Bewertungen

- Verka Complete Traning FilrDokument46 SeitenVerka Complete Traning FilrSaab Rana100% (1)

- CLD134 Manual EngDokument88 SeitenCLD134 Manual EngArsenio Dymas100% (1)

- AMS SNAP-ON Applications: Gani Prayuda Technical SupportDokument20 SeitenAMS SNAP-ON Applications: Gani Prayuda Technical Supportgani prayudaNoch keine Bewertungen

- InstrumentationDokument24 SeitenInstrumentationmuru0105100% (1)

- Drag Coefficients of ConesDokument54 SeitenDrag Coefficients of ConesLukasz OlszewskiNoch keine Bewertungen

- Non Conformance FormDokument1 SeiteNon Conformance FormResearcherNoch keine Bewertungen

- Caliper Xy MemoryDokument6 SeitenCaliper Xy MemoryA MuNoch keine Bewertungen

- Humboldt Catalog 14 - 2020 PDFDokument403 SeitenHumboldt Catalog 14 - 2020 PDFFaber VillaNoch keine Bewertungen

- Manual de Usuario PTW PDFDokument27 SeitenManual de Usuario PTW PDFJorge CifuentesNoch keine Bewertungen

- Example RM - 0204060810 - 2018Dokument3 SeitenExample RM - 0204060810 - 2018Filiberto Aguilar RamírezNoch keine Bewertungen

- Bluehill 3 Testing Software BrochureDokument20 SeitenBluehill 3 Testing Software Brochuremechmaster4uNoch keine Bewertungen

- 9100D Manual PDFDokument12 Seiten9100D Manual PDFluciano GarciaNoch keine Bewertungen

- MPP Manual - EngDokument23 SeitenMPP Manual - EngLý Chính ĐạoNoch keine Bewertungen

- ISATrainingCatalog 09-10Dokument32 SeitenISATrainingCatalog 09-10INTRAVEcom Industrial AutomationNoch keine Bewertungen

- AKM 345 Gen2: Instruction ManualDokument32 SeitenAKM 345 Gen2: Instruction ManualNicolás HuenufilNoch keine Bewertungen

- AWSD1 1 Procedure UtDokument19 SeitenAWSD1 1 Procedure UtGhilman0529Noch keine Bewertungen

- Amir Hussain Resume Instrument TechDokument3 SeitenAmir Hussain Resume Instrument TechTahirNoch keine Bewertungen

- 3000 Series T31P T31XW Indicator Quick Start Guide en 80253021Dokument4 Seiten3000 Series T31P T31XW Indicator Quick Start Guide en 80253021DaniloSripNoch keine Bewertungen

- Monitoring and MeasurementDokument5 SeitenMonitoring and MeasurementImtiyaz AkhtarNoch keine Bewertungen

- 1 s2.0 S0021967317304909 MainDokument5 Seiten1 s2.0 S0021967317304909 MaineducobainNoch keine Bewertungen