Beruflich Dokumente

Kultur Dokumente

NWFA Wood Species

Hochgeladen von

Jason BaileyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

NWFA Wood Species

Hochgeladen von

Jason BaileyCopyright:

Verfügbare Formate

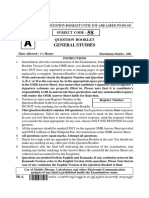

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No.

A200

Price: $30

WOOD

SPECIES

USED IN WOOD FLOORING

Revised Edition

APPEARANCE

PHYSICAL PROPERTIES

WORKABILITY

RELATIVE COST

AVAILABILITY

© 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

CONTENTS WOOD SPECIES USED IN WOOD FLOORING

3 INTRODUCTION: AN OVERVIEW OF WOOD PROPERTIES

6 RELATIVE AVAILABILITY OF SELECTED WOOD FLOORING SPECIES

7 RELATIVE HARDNESS OF SELECTED WOOD FLOORING SPECIES

8 RELATIVE STABILITY OF SELECTED WOOD FLOORING SPECIES

COLOR CHANGES IN WOOD FLOORING

9 PROPERTIES OF 13 DOMESTIC WOOD SPECIES

9 Ash, White 16 Mesquite

10 Beech 17 Oak, Red

11 Birch 18 Oak, White

12 Cherry, Black 19 Pine, Antique Heart

13 Douglas Fir 20 Pine, Southern Yellow

14 Hickory/Pecan 21 Walnut, American Black

15 Maple, Sugar/Hard

22 PROPERTIES OF 20 IMPORTED WOOD SPECIES

22

23

Bamboo

Bubinga

32

33

Maple, Brazilian

Merbau

24 Cherry, Brazilian 34 Oak, Tasmanian

25 Cork 35 Padauk

26 Cypress, Australian 36 Purpleheart

27 Gum, Spotted 37 Sapele

28 Gum, Sydney Blue 38 Teak, Brazilian

29 Iroko 39 Teak, Thai/Burmese

30 Jarrah 40 Walnut, Brazilian

31 Mahogany, Santos 41 Wenge

41 RESOURCES AND CREDITS

NO GUARANTEE OR WARRANTY

The information contained in this publication represents generally accepted descriptions of wood species and their properties. However,

wood is a natural material subject to numerous variations in grain, color, hardness and dimensional stability, and no description is able

to encompass all possible variations. The National Wood Flooring Association accepts no risk or liability for application of the information

contained in this publication.

2 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

WOOD SPECIES

USED IN WOOD FLOORING

Introduction: An Overview of Wood Properties

W

ood is a dynamic medium. Like all and natural warmth. A beautiful wood floor can

organic materials, it has character and enliven a drab room, enhance any architectural

quirks, responds to its environment, and style, complement furniture and design schemes,

changes over time. Because of its “personality,” wood and add value to any home or building.

should be treated with understanding and a certain A combination of qualities should be considered

amount of care. For wood flooring professionals, when selecting a species for flooring: appearance-

knowing about the properties of wood in general, as related attributes such as texture, grain and color;

well as those of individual wood species, is critical to as well as mechanical properties such as dimen-

proper installation. For consumers, it’s important to sional stability, durability, machinability and ease in

have realistic expectations about how wood will per- finishing; and finally, availability and cost.

form. Most wood used for flooring is essentially a

byproduct of more expensive wood-consuming Properties affecting appearance

industries (furniture manufacture, for example), so it Many different factors, from the nature of the living

is usually not the highest grade of lumber. However, tree to the way the lumber is sawed, affect the way

it is quite economical in comparison. the finished floor will look.

This publication provides an overview of the

HEARTWOOD, SAPWOOD: Heartwood is the older,

mechanical and physical properties of wood, followed

harder, central portion of a tree. It usually contains

by more detailed information on several species used

deposits of various materials that frequently give it a

in flooring. In selecting the species described, the

darker color than sapwood. It is denser, less permeable

aim has been to offer a fair sampling of some of

and more durable than the surrounding sapwood.

today’s most popular woods. Other species may be

Sapwood is the softer, younger, outer portion of a

included in later editions of this publication.

tree that lies between the cambium (formative layer

Note: The samples chosen to illustrate each

just under the bark) and the heartwood. It is more

species were selected to be as representative as

permeable, less durable and usually lighter in color

possible. However, there are many variations

than the heartwood.

within each species, and the methods used in

The relative amounts of heartwood and sapwood

sanding and finishing also affect the final appear-

in a flooring batch may affect the way it accepts

ance of a given species. Also, the samples were

stain and finish and, therefore, the finished appear-

photographed only a few days after being sanded

ance of the floor. In general, quartersawn and rift-

and finished. Some species, such as domestic

sawn flooring will contain less sapwood than

cherry, will change color significantly over time

plainsawn flooring (see “Types of saw cut,” next

(see page 8). Therefore, the appearance of any

page), and will tend to have a straighter grain and

installation may vary from the samples shown in

more uniform appearance. Heartwood also is more

this publication.

dimensionally stable than sapwood, so flooring with

a high percentage of heartwood will shrink and swell

The character of wood less than flooring that is mostly sapwood.

As a flooring material, wood is superior to vinyl or WOOD GRAIN AND TEXTURE: “Grain” and “texture”

carpet, both practically and aesthetically. A solid are loosely used to describe similar properties of

wood floor is more than a covering; it adds strength wood. Grain is often used in reference to annual

and stability to the floor system. A one-inch thick- growth rings, as in “fine” or “coarse” grain; it also is

ness of wood has the same insulating value as 15 used to indicate the direction of fibers, as in straight,

inches of concrete. Wood is durable and long-lasting spiral and curly grain. The direction of the grain, as

— occasional sanding and refinishing essentially well as the amount of figuring in the wood, can affect

results in a brand-new floor. Wood floors don’t retain the way it is sanded and sawed.

mildew or absorb dust, simplifying cleaning. Grain also is described as being either “open” or

Perhaps the most appealing characteristics of “closed,” referring to the relative size of the pores, which

wood flooring, though, are its attractive appearance affects the way a wood accepts stain and finishes.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 3

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

Texture usually refers to the finer structure of the slope in a right-handed direction for several years, in

wood, rather than to the annual rings. It is some- a left-handed direction for several years, back to

times used to combine the concepts of density and right-handed, and so on. A high degree of interlocked

degree of contrast between spring wood and summer grain may make a wood difficult to machine.

wood in the annual growth rings. TYPES OF SAW CUT: Lumber is either plainsawn,

quartersawn or riftsawn.

Wood grain terminology Plainsawing is the most common and least expen-

Annual rings: Most species grown in temperate cli- sive method of sawing; most wood flooring is cut this

mates produce visible annual growth rings that show way. Plainsawn lumber is obtained by making the

the difference in density and color between wood first saw cut on a tangent to the circumference of the

formed early and that formed late in the growing sea- log and remaining cuts

son. The inner part of the growth ring, formed first, is parallel to the first. This

called “spring wood”; the outer part, formed later in method is the most eco-

the season, is called “summer wood.” nomical, because it pro-

Spring wood is characterized by cells having rela- vides the widest boards

tively large cavities and thin walls. Summer wood and results in the least

cells have smaller cavities and thicker walls, and waste.

consequently are more dense than those in spring Since most of the lum-

wood. The growth rings, when exposed by conven- ber produced by plainsaw-

tional sawing methods, provide the grain or charac- ing is flat-grained, with

teristic pattern of the wood. The distinguishing some vertical-grained wood

features among the various species results in part included, plainsawn lumber

from differences in growth-ring formation. And will tend to contain more

within species, natural variations in growth ensure variation within and among

the unique character and boards than quartersawn

beauty of each piece of lumber, in which nearly all of the wood is vertical-

wood. grained. Also, since flat-grained wood is less dimen-

Figure: The pattern pro- sionally stable than vertical-grained, plainsawn lumber

duced in a wood surface will tend to expand and contract more across the width

by annual growth rings, of the boards than quartersawn lumber.

rays, knots and deviations Other physical differences to consider when choos-

from regular grain. ing plainsawn lumber rather than quartersawn:

Medullary Rays: Medullary • Figure patterns resulting from the annual rings

rays extend radially from and some other types of figures are usually brought

the core of the tree toward out more conspicuously by plainsawing.

the bark. They vary in • Shakes and pitch pockets, when present, extend

height from a few cells in through fewer boards.

some species, to four or In quartersawing, lumber is produced by first

more inches in the oaks; they’re responsible for the quartering the log and then sawing perpendicular to

flake effect common in quartersawn lumber in cer- the growth rings. Quartersawing produces relatively

tain species. narrow boards, nearly all vertical-grained, and cre-

Flat Grain: Easily recognized by its parabolic ates more waste, making quartersawn lumber more

(arched) effect. Lumber is considered “flat-grained” expensive than plainsawn. However, much quarter-

when the annual growth rings make an angle of less sawn wood is obtained by culling the vertical-grained

than 45 degrees with the wide surface of the board. wood that naturally results from plainsawing.

Vertical or Edge Grain: Generally more dimension- For reasons other than cost, most people prefer

ally stable than flat grain—that is, vertical-grain quartersawn wood, although some people favor the

boards are less likely to expand or contract in width greater variety in figuring produced in plainsawing.

with changes in moisture. Lumber is considered Other physical factors to keep in mind when

“vertical-grained” when the annual growth rings choosing quartersawn lumber over plainsawn:

make an angle of 45 to 90 degrees with the wide sur- • It twists and cups less.

face of the board. • It surface-checks and splits less during season-

(Note: In hardwoods, plainsawn lumber gener- ing and in use.

ally contains mostly flat-grained wood, while • Raised grain produced by separation in the

quartersawn lumber is nearly all vertical-grained. annual growth rings does not appear as pronounced.

In softwood lumber, the terms “flat-grained” and • It wears more evenly.

“vertical-grained” are used instead of the terms • Figuring due to pronounced rays, interlocked

“plainsawn” and “quartersawn,” respectively. See and wavy grain are brought out more conspicuously.

“Types of saw cut” below.) • Sapwood appears only at the edges, and is lim-

Interlocked Grain: Grain in which the fibers may ited to the width of the log’s sapwood.

4 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

Riftsawing is similar to quartersawing, with many include an indication of dimensional stability, from

of the same advantages and limitations. It accentu- “below average” to “excellent,” as well as a comparison

ates the vertical grain and minimizes the flake effect to red oak. For example, mesquite is rated as “excel-

common in quartersawn oak. The angle of the cut is lent,” with a notation that it is 63 percent more stable

changed slightly so that fewer saw cuts are parallel than red oak—that is, mesquite is likely to shrink or

to the medullary rays, which are responsible for the swell 63 percent less. The percentages noted are based

flake effect. Riftsawing creates more waste than on comparing the shrinkage values (tangential shrink-

quartersawing, making it generally more expensive. age from green to ovendry moisture content) of each

species. Red oak was chosen as the benchmark

Mechanical properties because of its widespread familiarity and use in the

MOISTURE CONTENT AND DIMENSIONAL STABILITY: flooring industry. For a comparison of the relative

Moisture plays a large part in how wood behaves, dimensional stability of several species refer to the

both during the machining process and after instal- chart on page 8. Keep in mind that the shrinkage val-

lation. Installers would do well to study moisture’s ues come from laboratory testing, and some woods

effect on wood in some detail; however, a brief dis- shown to be relatively stable in the lab have demon-

cussion is included here. (For more information, see strated significant movement on actual job sites.

the NWFA Technical Manual A100: Water and For wood flooring professionals, it’s important to

Wood.) inform end users about the normal behavior of wood

Moisture content is defined as the weight of water in relation to moisture. Most solid wood flooring will

in wood expressed as a percentage of the weight of contract during periods of low humidity (during the

oven-dry wood. Weight, shrinkage, strength and heating season, for example), sometimes leaving

other properties depend on the moisture content of noticeable cracks between boards. To minimize this

wood. In trees, moisture content may be as much as effect, users should stabilize the environment of the

200 percent of the weight of wood substance. After building through temperature and humidity control.

harvesting and milling, the wood will be dried to the HARDNESS AND DURABILITY: Probably the most

proper moisture content for its end use. important strength property for wood used in floor-

Wood is dimensionally stable when the moisture ing applications is its side hardness, also known as

content is above the fiber saturation point (usually Janka hardness. Side hardness represents the resis-

about 30 percent moisture content). Below that, wood tance of wood to wear, denting and marring. It is

changes dimension when it gains or loses moisture. measured by the load required to embed a 0.444-

The ideal moisture content for flooring installation inch steel ball to one-half its diameter in the wood.

can vary from an extreme of 4 to 18 percent, Janka hardness ratings are generally based on an

depending on the wood species, the geographic loca- average of tests on both tangential and radial (plain-

tion of the end product and the time of year. Most sawn and quartersawn) samples. A comparison

oak flooring, for example, is milled at 6 to 9 percent. chart of the Janka hardness ratings for each of the

Before installation, solid wood flooring should be species described in this chapter appears on page 7.

acclimated to the area in which it is to be used, then Also, the individual species descriptions include a

tested with a moisture meter to ensure the proper percentage comparison to indicate each species

moisture content. hardness relative to Northern red oak.

(Note: Engineered flooring tends to be more INSTALLATION AND NAILING: When nailing some of

dimensionally stable than solid flooring and may not the denser woods with hand or air nailers, installers

require acclimation prior to installation—check with may encounter splitting tongues, as well as failure to

the manufacturer of the flooring for that product’s secure the fastener even after repeated attempts. This

recommendations.) can sometimes be corrected by changing the angle of

Different woods exhibit dif- the nail’s point of entry. On certain exceptionally

ferent moisture stability dense species, pilot holes may have to be drilled to

factors, but they generally ease nailing. Blunting the ends of fasteners may also

shrink and swell the most help prevent splitting. With pneumatic nailers, the air

in the direction of the pressure may need to be adjusted to reduce splinter-

annual growth rings (tan- ing or tongue breakage.

gentially), about half as Though dense, heavy woods normally offer higher

much across the rings nail-withdrawal resistance, less dense species allow

(radially) and only slightly the use of more and larger-diameter fasteners to

along the grain (longitudi- compensate for their lower holding ability. When nail-

nally). This means that ing imported species, check with the supplier for the

plainsawn flooring will tend recommended fastener.

to shrink and swell more in Consider wearing gloves while working with some

width than quartersawn flooring, and that most floor- woods, especially exotic species. Splinters should be

ing will not shrink or swell much in length. removed immediately, as some species have been

The individual species descriptions that follow known to cause an adverse reaction in some people.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 5

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

SANDING: Some wood species are highly resinous lation and also check with the finish manufacturer.

and tend to clog sandpaper. When working with such For more information on finishing, see the NWFA

species, it may be necessary to use a coarser grit of Technical Manual B200: Sanding and Finishing of

sandpaper than normal, or to change the sandpaper Hardwood Floors.

more often than with other species.

Also, the wood dust created by sanding some Availability

species tends to cause an allergic reaction in some Just as every individual wood species is dynamic and

people. This is more likely to occur with imported prone to change in response to its environment, so

species than with domestic. However, even North too is the market for all wood flooring species. Avail-

American oak has been known to cause a skin rash ability estimates were obtained through interviews

or respiratory difficulties in some people. Where with industry sources and reflect market conditions

applicable, known tendencies to cause allergic reac- during 2003.

tions are noted.

EASILY AVAILABLE:

As a precaution, flooring mechanics should wear

Brazilian cherry (jatoba)

long sleeves, gloves, repirators (with a rating of at least

Hard maple

N95/NIOSH-approved) and eye protection when sand-

Red oak

ing. To test for possible allergic reaction to a species,

Southern yellow pine

perform a skin-patch test by placing a small amount

White oak

of wood dust under a round adhesive bandage on the

inside of the forearm. If serious skin irritation is pre- READILY AVAILABLE:

sent when the bandage is removed after 24 hours, Ash

consider not working with that species. Australian cypress

For more information on sanding, see the NWFA Bamboo

Technical Manual B200: Sanding and Finishing of Black cherry

Hardwood Floors. Brazilian walnut (ipé)

Cork

FINISHING: Many finish formulations are undergoing Douglas fir

continual change as their manufacturers move to com- Hickory/pecan

ply with evolving environmental regulations, making Santos mahogany

hard-and-fast finishing rules difficult to come by. Teak, Thai/Burmese

Some woods, especially imports, contain oils and

MODERATELY AVAILABLE:

chemical compounds that may adversely react with

Beech

certain types of finishes to inhibit drying, dramatically

Black walnut, American

change the color of the wood, or both. Some imported

Birch

species may weep natural oils for an extended period of

Brazilian maple

time, possibly causing finish problems at a later date.

Brazilian teak (cumaru)

It is recommended that such floors be sealed or coated

Iroko

immediately after the final sanding cut.

Jarrah

Water-based urethane finishes are quick-drying and Merbau

increasingly durable. Some flooring professionals also Padauk

believe they tend to inhibit the color change certain Sapele

woods undergo over time, which may be desirable. Spotted gum

These finishes tend to leave wood lighter in color. Non- Sydney blue gum

ambering urethanes are often recommended for finish- Tasmanian oak

ing white, stenciled or pastel floors. Water-based

LIMITED AVAILABILITY:

finishes tend to adhere well to most woods, including

Antique heart pine

exotics, whereas some solvent-based finishes have

Bubinga

adhesion, drying or color change problems with

Mesquite

woods such as teak, Brazilian walnut, purpleheart,

Purpleheart

padauk and wenge.

Wenge

For floors that are to be stained to alter the natural

color of the wood, flooring professionals should be

aware that some species (hard maple, pine and fir, for

example) do not accept stain as readily or as evenly

as other species.

A grain filler is sometimes used for wood species

with large pores, such as oak and walnut, if a smooth

finish is desired.

When working with a new species for the first

time, installers should test stains and finishes on a

small sample of flooring before attempting an instal-

6 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

RELATIVE HARDNESS OF SELECTED

WOOD FLOORING SPECIES

(Ranked by Janka hardness rating)

The Janka (or side) hardness test mea-

sures the force required to embed a Walnut, Brazilian 3680

.444-inch steel ball to half its diameter Teak, Brazilian 3540

in wood. It is one of the best measures

of the ability of a wood species to with-

Purpleheart 2890

stand denting and wear. By the same Cherry, Brazilian (jatoba) 2820

token, it also is a good indicator of how Bubinga 2690

hard or easy a species is to saw or nail.

Northern red oak, for example, has a Gum, spotted 2473

Janka hardness rating of 1290. Spot- Mesquite 2345

ted gum, with a rating of 2473, is

nearly twice as hard. If you’re accus- Mahogany, santos 2200

tomed to working with red oak and Gum, Sydney blue 2023

decide to tackle a job with spotted

gum, you can expect it to be much

Merbau 1925

harder to cut and nail. Jarrah 1910

A rating is not included for bamboo, Hickory/pecan 1820

as bamboo flooring varies greatly

between different manufacturers’ prod- Padauk 1725

ucts and between vertical and horizon- Wenge 1630

tal construction. Likewise, a rating is

not included for cork flooring. Maple, Brazilian 1500

• Source: Hardness ratings for most species taken

Sapele 1500

from the U.S. Dept. of Agriculture, Forest Service,

Forest Products Laboratory, Center for Wood

Maple, hard 1450

Anatomy Research Web site

www2.fpl.fs.fed.us/TechSheets/techmenu.html. Bub-

Cypress, Australian 1375

inga value taken from Wood Handbook: Wood as

an Engineering Material (Forest Products Society,

Oak, white 1360

1999). Padauk and Brazilian maple

values were provided by Wood Flooring Interna-

Oak, Tasmanian 1350

tional. Spotted gum,

Sydney blue gum and Tasmanian oak values were

Ash, white 1320

provided by Boral Timber. The heart pine rating Beech 1300

was provided by Mountain Lumber. The mesquite

rating was provided by Mesquite Products of Texas. Oak, Northern red 1290

• Douglas fir rating is an average of ratings for

Coast, Interior West and Interior North species. Birch 1260

• Values for Brazilian cherry, purpleheart and

Thai/Burmese teak represent average values. Iroko 1260

Pine, heart (antique) 1225

Teak, Thai/Burmese 1078

1010 Walnut, American black

Cherry, black 950

870 Pine, Southern yellow (longleaf)

690 Pine, Southern yellow (loblolly/shortleaf)

Douglas fir 660

0While 500

While Janka 1000 give

Janka values

values 1500

give 2000

aa general

general 2500

sense

sense of 3000 many

of hardness,

hardness, 3500other

many 4000

other

ffactors also contribute to a wood floor’s durability, including the type

of cut (i.e. plainsawn, quartersawn), denseness of cell structure, and

finish used.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 7

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

RELATIVE STABILITY OF SELECTED Beech 11.9

WOOD FLOORING SPECIES Jarrah 11.0

(Ranked by percentage of tangential shrinkage from Oak, white 10.5

green to ovendry moisture content) Maple, hard 9.9

The numbers in the chart reflect the percentage of tangential

Birch (yellow) 9.5

shrinkage from green to ovendry moisture content for the vari-

ous species. Tangential change values normally will reflect Hickory/pecan 8.9

changes in plainsawn wood. Quartersawn wood usually will Maple, Brazilian/pau marfim 8.8

be more dimensionally stable than plainsawn. Oak, Northern red 8.6

These percentages are listed only as a means of comparison Cherry, Brazilian (jatoba) 8.5

of stability between the species. As these values represent Bubinga 8.4

change from green to ovendry, actual percentage change on

job sites will be drastically less. Walnut, Brazilian/ipé 8.0

Although some tropical woods such as Australian cypress, Ash, white 7.8

merbau and wenge appear in this chart to have excellent mois- Walnut, American black 7.8

ture stability compared to domestic oak, actual installations of Teak, Brazilian/cumaru 7.6

many of these woods have demonstrated significant movement Pine, Southern yellow 7.5

in use. To avoid problems later, extra care should be taken to

inform potential users of these tendencies prior to purchase.

Sapele 7.4

Several species listed in this book are not included in the Douglas fir 7.3

chart. This data currently is not available for Tasmanian oak, Cherry, black 7.1

Sydney blue gum and spotted gum. Due to its composited con- Mahogany, santos 6.2

struction, cork is not included, and due to its engineered con- Purpleheart 6.1

struction, bamboo is not included. Also, due to the many

different species and ages of the wood classified as antique

Teak, Thai/Burmese 5.8

heart pine, that wood is not listed. Wenge 5.8

Padauk 5.2

• Source: Stability ratings taken from the U.S. Dept. of Agriculture, Forest Ser-

vice, Forest Products Laboratory, Center for Wood Anatomy Research Web site Merbau 4.6

www2.fpl.fs.fed.us/TechSheets/techmenu.html

• Douglas fir rating is an average of ratings for Coast, Interior West and Interior Iroko 3.8

North species. Mesquite 3.2

• Pine rating is an average of ratings for loblolly, longleaf, shortleaf and slash

species. 2.8 Cypress, Australian

0 2 4 6 8 10 12

COLOR CHANGES IN WOOD FLOORING

Whether finished or unfinished, wood changes color over time due to oxidation and exposure to light. Some species

darken in color over time, while others lighten. There is no set value for “color fastness” of a species, so contractors

and their customers need to be aware of how much change they should expect from the species they choose. Cer-

tain species, including American cherry, Brazilian cherry and many imported species, are especially notorious for

their tendency to change in color. A demonstration of this change is shown below. The panels on the left for each

species show how the wood had aged since originally being sanded and finished for this publication in 1994. The

panels on the right are the same panels as they appear now after being freshly sanded and finished in 2004. It is

important to note that all panels shown on the following pages are shown freshly sanded and finished. Some color

change is to be expected for all species, and a drastic change can be expected for some.

American cherry Brazilian cherry

water-based finish water-based finish

water-based finish water-based finish

oil-based finish oil-based finish

Aged panel Aged panel

oil-based finish oil-based finish

Same panel freshly sanded Same panel freshly sanded

8 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

ASH, WHITE

Fraxinus americana

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 50 at a 7 to 15 degree angle to the grain

COLOR: Heartwood is light tan to dark brown; sapwood

Second Cut: 60 or 80 straight with the grain

is creamy white. Similar in appearance to white oak,

Third Cut: 80 or 100

but frequently more yellow.

Hard Plate: 100

GRAIN: Bold, straight, moderately open grain with

Screen: 80 or 100

occasional wavy figuring. Can have strong contrast

FINISHING: May be difficult to stain.

in grain in plainsawn boards.

VARIATIONS WITHIN SPECIES AND GRADES:

Sometimes confused with hickory; the zone of large Origin

pores is more distinctive in ash, similar to that of North America.

red oak.

Availability

Readily available.

Properties

HARDNESS/JANKA: 1320 (2% harder than Northern

red oak).

DIMENSIONAL STABILITY: Above average (7.8; 9%

more stable than Northern red oak).

Workability

SAWING/MACHINING: Good machining qualities.

NAILING: No known problems.

SANDING: Sands satisfactorily if the correct sanding

sequence is followed.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 9

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

BEECH

Fagus grandifolia

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 50 or 60 at a 7 to 15 degree angle to the

COLOR: Heartwood is mostly reddish brown; sap-

grain

wood is generally pale white.

Second Cut: 60 or 80 straight with the grain

GRAIN: Mostly closed, straight grain; fine, uniform

Third Cut: 80 or 100

texture. Coarser than European beech.

Hard Plate: Not recommended

VARIATIONS WITHIN SPECIES AND GRADES: Only

First Screen: 80 or 100

one species is native to the United States. Moderate

Second Screen: 120 or 150

to high color variation between boards.

FINISHING: May be difficult to stain.

Properties Origin

HARDNESS (JANKA): 1300 (1% harder than

North America.

Northern red oak).

DIMENSIONAL STABILITY: Below average (11.9; 38% Availability

less stable than Northern red oak). Moderately available.

Workability

SAWING/MACHINING: Difficult to work with hand

tools, but good machining qualities.

NAILING: Has a tendency to split the tongues.

SANDING: Sands satisfactorily if correct sanding

sequence is followed.

10 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

BIRCH

Betula spp.

water-based finish

oil-based finish

Appearance Workability:

COLOR: In yellow birch (B. alleghaniensis), sapwood is SAWING/MACHINING: Difficult to work with hand

creamy yellow or pale white; heartwood is light red- tools, but good machining qualities.

dish brown tinged with red. In sweet birch (B. lenta), NAILING: No known problems.

sapwood is light colored and heartwood is dark brown SANDING: Sands satisfactorily if the correct sanding

tinged with red. sequence is followed.

GRAIN: Medium figuring, straight, closed grain, even Suggested Sequence

texture. Occasional curly grain or wavy figure in First Cut: 50 at a 7 to 15 degree angle to the grain

some boards. Second Cut: 80 straight with the grain

VARIATIONS WITHIN SPECIES AND GRADES: Yellow Third Cut: 120

birch, sweet birch, paper birch. Paper birch (B. Hard Plate: 100 or 120

papyrifera) is softer and lower in weight and strength First Screen: 100

than yellow or sweet birch. However, yellow birch is Second Screen: 100

most commonly used for flooring. Boards can vary FINISHING: May be difficult to stain.

greatly in grain and color.

Origin

Properties North America.

SIDE HARDNESS/JANKA: Yellow: 1260 (2% softer

than Northern red oak). Availability

DIMENSIONAL STABILITY: Average (Yellow: 9.5; 10% Moderately available.

less stable than Northern red oak).

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 11

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

CHERRY, BLACK

Prunus serotina

water-based finish

oil-based finish

Appearance sequence is followed.

Suggested Sequence

COLOR: Heartwood is light to dark reddish brown,

First Cut: 60 at a 7-15 degree angle with the grain

lustrous; sapwood is light brown to pale with a light Second Cut: 80 straight with the grain

pinkish tone. Some flooring manufacturers steam lum- Third Cut: 100

ber to bleed the darker heartwood color into the sap- Hard Plate: Not recommended

wood, resulting in a more uniform color. Color darkens Screen: 80 or 100

significantly with age. FINISHING: No known problems.

GRAIN: Fine, frequently wavy, uniform texture. Dis-

tinctive flake pattern on true quartersawn surfaces.

Texture is satiny, with some gum pockets.

Origin

VARIATIONS WITHIN SPECIES AND GRADES: Signifi- North America.

cant color variation between boards.

Availability

Properties Readily available.

HARDNESS (JANKA): 950 (26% softer than Northern

red oak).

DIMENSIONAL STABILITY: Above average (7.1; 17%

more stable than Northern red oak).

Workability

SAWING/MACHINING: Good machining qualities.

NAILING: No known problems.

SANDING: Sands satisfactorily if the correct sanding

12 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

DOUGLAS FIR

Pseudotsuga menziesii

water-based finish

oil-based finish

Appearance NAILING: No known problems.

SANDING: Sands satisfactorily if the correct sanding

COLOR: Heartwood is yellowish tan to light brown.

sequence is followed.

Sapwood is tan to white. Heartwood may be confused

Suggested Sequence

with that of Southern yellow pine. Radical color change

First Cut: 60 at a 7-15 degree angle with the grain

upon exposure to sunlight.

Second Cut: 80 straight with the grain

GRAIN: Normally straight, with occasional wavy or

Third Cut: 100 or 120

spiral texture. Nearly all fir flooring is vertical-grain

Hard Plate: Not recommended

or riftsawn clear-grade material.

Screen: 100 or 120

VARIATIONS WITHIN SPECIES AND GRADES: Wood

FINISHING: Some boards develop a slight pinkish to

varies greatly in weight and strength. Young trees of

bright salmon color when finished with some products.

moderate to rapid growth have reddish heartwood and

Because of tendency toward color change, care must

are called red fir. The narrow-ringed wood of old trees

be taken to avoid oversanding when refinishing an

may be yellowish-brown and is known as yellow fir.

existing floor. May be difficult to stain.

COMMENTS: Sometimes milled as vertical end-grain

Properties block, which is significantly harder than plainsawn.

HARDNESS (JANKA): 660 (49% softer than Northern

red oak). Origin

DIMENSIONAL STABILITY: Above average (7.3; 15%

North America.

more stable than Northern red oak).

Workability Availability

Readily available.

SAWING/MACHINING: Harder to work with hand

tools than the soft pines.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 13

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

HICKORY/PECAN

Carya spp.

water-based finish

oil-based finish

Appearance Workability

COLOR: Pecan heartwood is reddish brown with dark SAWING/MACHINING: Hickory’s density makes it dif-

brown stripes; sapwood is white or creamy white with ficult to machine and work with hand tools.

pinkish tones. Hickory heartwood is tan or reddish; NAILING: Has a tendency to split the tongues.

sapwood is white to cream, with fine brown lines. SANDING: Difficult to sand because of density, and

GRAIN: Pecan is open, occasionally wavy or irregular. because light color makes sander marks show more

Hickory is closed, with moderate definition; somewhat than on darker woods.

rough-textured. Suggested Sequence

VARIATIONS WITHIN SPECIES AND GRADES: In both First Cut: 40 or 50 at a 7-15 degree angle with the

hickory and pecan, there are often pronounced differ- grain

entiations in color between spring wood and summer Second Cut: 50 or 60 straight with the grain

wood. In pecan, sapwood is usually graded higher than Third Cut: 80 or 100

darker heartwood. Pecan and hickory are traditionally Hard Plate: 100

mixed by flooring mills. Screen: 80 or 100

FINISHING: May be difficult to stain.

Properties

HARDNESS (JANKA): 1820 (41% harder than Northern Origin

red oak). Pecan is slightly softer than true hickories. North America.

DIMENSIONAL STABILITY: Average (8.9; 3% less stable

than Northern red oak). Availability

Readily available.

14 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

MAPLE, SUGAR/HARD

Acer saccharum

water-based finish

oil-based finish

Appearance are more obvious due to maple’s density and light

color. The species also burnishes, dulling fine paper

COLOR: Heartwood is creamy white to light reddish

and screens and making it difficult to cut out previ-

brown; sapwood is pale to creamy white. ous scratches.

GRAIN: Closed, subdued grain, with medium figuring

Suggested Sequence

and uniform texture. Occasionally shows quilted, fid- First Cut: 50 at a 7 to 15 degree angle to the grain

dleback, curly or bird’s-eye figuring. Figured boards Second Cut: 80 straight with the grain

often culled during grading and sold at a premium. Third Cut: 120

VARIATIONS WITHIN SPECIES AND GRADES: Black

Hard Plate: 100 or 120

maple (B. nigrum) is also hard; other species are clas- First Screen: 100

sified as soft. Second Screen: 100

FINISHING: Takes neutral finish well. May be diffi-

Properties cult to stain.

HARDNESS (JANKA): 1450 (12% harder than North-

ern red oak). Origin

DIMENSIONAL STABILITY: Average (9.9; 15% less sta-

North America.

ble than red oak).

Workability Availability

Easily available. Figured grains have limited avail-

SAWING/MACHINING: Density makes machining

ability.

difficult.

NAILING: No known problems.

SANDING: Extra care must be taken during sand-

ing and finishing, as sanding marks and finish lines

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 15

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

MESQUITE

Prosopis glandulosa

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 40 or 50 at a 7-15 degree angle with the

COLOR: Light brown to dark reddish brown.

grain

GRAIN: High in character, with ingrown bark and

Second Cut: 60 or 80 straight with the grain

mineral streaks. Most commonly used in flooring as

Third Cut: 80 or 100

end-grain block, which has small irregular cracks

Hard Plate: 100

radiating across the grain.

First Screen: 80 or 100

VARIATIONS WITHIN SPECIES AND GRADES: One

Second Screen: 120

grade; moderate color variations.

FINISHING: No known problems.

COMMENTS: End-grain block usage results in a hard,

Properties high-wear surface. Produces only shorter-length

HARDNESS (JANKA): 2345 (82% harder than boards.

Northern red oak).

DIMENSIONAL STABILITY: Excellent (3.2; 63% more

stable than Northern red oak).

Origin

North America.

Workability Availability

SAWING/MACHINING: Very good machining qualities.

Limited availability.

NAILING: Splits tongues easily.

SANDING: Plainsawn can be sanded to a smooth sur-

face. End-grain requires a coarser abrasive to flatten; it

is recommended that it be flattened by sanding at a

45-degree angle to the grain.

16 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

OAK, RED

Quercus spp.

water-based finish

oil-based finish

Appearance Northern red oak).

COLOR: Heartwood and sapwood are similar, with

sapwood lighter in color; most pieces have a reddish

Workability

tone. Slightly redder than white oak. SAWING/MACHINING: Above average in all machining

GRAIN: Open, slightly coarser (more porous) than operations.

white oak. Plainsawn boards have a plumed or flared NAILING: No known problems.

grain appearance; riftsawn has a tighter grain pattern, SANDING: Sands satisfactorily if the correct sanding

low figuring; quartersawn has a flake pattern, some- sequence is followed.

times called tiger rays or butterflies. Suggested Sequence

VARIATIONS WITHIN SPECIES AND GRADES: More than First Cut: 50 at a 7-15 degree angle with the grain

200 subspecies in North America; great variation in Second Cut: 80 straight with the grain

color and grain, depending on the origin of the wood Third Cut: 100

and differences in growing seasons. Northern, Southern Hard Plate: 100

and Appalachian red oak all can be divided into upland Screen: 100 or 120

and lowland species. Because they grow more slowly, FINISHING: Stains well and demonstrates strong stain

upland species have a more uniform grain pattern than contrast. Red oak generally works better than white

lowland species, with more growth rings per inch. oak for bleached floors because it is more porous, and

because tannins in white oak can discolor the floor.

Properties

HARDNESS (JANKA): Northern: 1290 (benchmark). Origin

Southern: below average (1060; 18% softer than North America.

Northern red oak).

DIMENSIONAL STABILITY: Northern: average (8.6). Availability

Southern: below average (11.3; 31% less stable than Easily available.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 17

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

OAK, WHITE

Quercus spp.

water-based finish

oil-based finish

Appearance SANDING: Sands satisfactorily if the correct sanding

sequence is followed.

COLOR: Heartwood is light brown; some boards may

Suggested Sequence

have a pinkish tint or a slight grayish cast. Sapwood

First Cut: 50 or 60 at a 7-15 degree angle with the

is white to cream.

grain

GRAIN: Open, with longer rays than red oak. Occa-

Second Cut: 60 or 80 straight with the grain

sional crotches, swirls and burls. Plainsawn boards

Third Cut: 80 or 100

have a plumed or flared grain appearance; riftsawn

Hard Plate: 100

has a tighter grain pattern, low figuring; quarter-

Screen: 80 or 100

sawn has a flake pattern, sometimes called tiger

FINISHING: During the finishing process, tannins at

rays or butterflies.

the surface can react with some liquids to turn the

VARIATIONS WITHIN SPECIES AND GRADES: Consid-

wood green or brown. This effect tends to be more

erable variation among boards in color and grain tex-

pronounced with products that have a high water

ture, but variations not as pronounced as in red oak.

content, such as wood bleach and water-based fin-

ishes. Stains very well and accepts stain evenly.

Properties

HARDNESS (JANKA): 1210 (6% softer than Origin

Northern red oak).

North America.

DIMENSIONAL STABILITY: Average (10.5; 22% less sta-

ble than red oak).

Availability

Easily available.

Workability

SAWING/MACHINING: Excellent machining qualities.

NAILING: No known problems.

18 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

PINE, ANTIQUE HEART

Pinus spp.

water-based finish

oil-based finish

Appearance quently during sanding. Beginning with a coarse

grade is recommended.

COLOR: Heartwood is yellow after cutting and turns

Suggested Sequence

deep pinkish tan to warm reddish brown within First Cut: 40 at a 7-15 degree angle with the grain

weeks due to high resin content. Sapwood remains Second Cut: 50 straight with the grain

yellow, with occasional blue-black sap stain. Third Cut: 80

GRAIN: Dense, with high figuring. Plainsawn is

Hard Plate: Not recommended

swirled; rift- or quartersawn is primarily pinstriped. Screen: 80

Curly or burl grain is rare. FINISHING: May be difficult to stain. To reduce the

VARIATIONS WITHIN SPECIES AND GRADES: Moderate

wood’s tendency to repel finish coats, surface resins

color variation. may be removed with a 100 percent pure (not recy-

cled) solvent that is compatible with the finish to be

Properties used (do not use water).

HARDNESS (JANKA): 1225 (5% softer than Northern

red oak). Origin

DIMENSIONAL STABILITY: Values can vary greatly

North America. Often recovered from structural tim-

due to the variety of species and ages used. bers in pre-1900 warehouses and factories, or as

sunken logs from river bottoms.

Workability

SAWING/MACHINING: Good machining and hand- Availability

tooling qualities. Limited.

NAILING: No known problems.

SANDING: Tendency to clog paper due to high resin

content. Abrasives will need to be changed fre-

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 19

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

PINE, SOUTHERN YELLOW

Pinus spp.

water-based finish

oil-based finish

Appearance SANDING: Resin in wood tends to clog abrasives; fre-

quent sandpaper changes are required.

COLOR: Heartwood varies from light yellow/orange

Suggested Sequence

to reddish brown or yellowish brown; sapwood is

First Cut: 50 at a 7-15 degree angle with the grain

light tan to yellowish white.

Second Cut: 60 or 80 straight with the grain

GRAIN: Closed, with high figuring; patterns range

Third Cut: 80 or 100

from clear to knotty.

Hard Plate: Not recommended

VARIATIONS WITHIN SPECIES AND GRADES: Longleaf

Screen: 80 or 100

pine (P. palustris), shortleaf pine (P. echinata), loblolly

FINISHING: May be difficult to stain. To reduce the

pine (P. taeda), slash pine (P. elliottii). All have many of

wood’s tendency to repel finish coats, surface resins

the same characteristics as Douglas fir. Old-growth

may be removed with a 100 percent pure (not recy-

lumber in these varieties has substantially higher den-

cled) solvent that is compatible with the finish to be

sity and is more stable than second-growth material.

used (do not use water).

COMMENTS: Generally manufactured for flooring

Properties with no end-match; sometimes flooring is “distressed”

HARDNESS (JANKA): Loblolly and shortleaf 690, to create an antique look.

(47% softer than Northern red oak); longleaf 870

(33% softer than Northern red oak). Origin

DIMENSIONAL STABILITY: Above average (7.5; 13%

North America.

more stable than Northern red oak).

Workability Availability

Easily available.

SAWING/MACHINING: Good machining qualities.

NAILING: No known problems.

20 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

WALNUT, AMERICAN BLACK

Juglans nigra

water-based finish

oil-based finish

Appearance Workability

COLOR: Heartwood ranges from a deep, rich dark SAWING/MACHINING: Excellent machining qualities.

brown to a purplish black. Sapwood is nearly white to NAILING: No known problems.

tan. Difference between heartwood and sapwood color SANDING: Sands satisfactorily.

is great; some flooring manufacturers steam lumber to Suggested Sequence

bleed the darker heartwood color into the sapwood, First Cut: 60 at a 7-15 degree angle with the grain

resulting in a more uniform color. Second Cut: 80 straight with the grain

GRAIN: Mostly straight and open, but some boards Third Cut: 100

have burled or curly grain. Arrangement of pores is Hard Plate: Not recommended

similar to hickories and persimmon, but pores are First Screen: 80 or 100

smaller in size. Second Screen: 100 or 120

VARIATIONS WITHIN SPECIES AND GRADES: Great FINISHING: No known finishing problems.

variety of color and figure within species, as well as COMMENTS: Frequently used as a highlight material

variation in color among boards, especially in lower for borders or other inlay techniques.

grades and from material that isn’t steamed prior to

kiln-drying. Origin

North America.

Properties

HARDNESS (JANKA): 1010 (22% softer than Northern Availability

red oak). Moderately available.

DIMENSIONAL STABILITY: Average (7.8; 9% more sta-

ble than Northern red oak).

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 21

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

BAMBOO

Phyllostachys spp.

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 60 at a 7-15 degree angle with the grain

COLOR: Typically available in light (manila/yellow

Second Cut: 80 straight with the grain

tones) or dark (tannish brown) shades. Colors vary

Third Cut: 100 or 120

between manufacturers.

Hard Plate: Not recommended

GRAIN: Distinctive grain pattern shows nodes from

First Screen: 100 or 120

the bamboo stalks.

Second Screen: 150

VARIATIONS WITHIN GRADES: Available either hori-

FINISHING: All surface-type finishes have been used

zontally or vertically laminated. Horizontal construc-

successfully with bamboo. Darker colors may tend to

tion tends to show nodes more prominently.

show lap marks—moving quickly during application

and applying finish quickly around cut-in areas can

Properties minimize this effect. Filling is recommended.

HARDNESS (JANKA): Bamboo is a grass. Janka val- COMMENTS: Mostly available factory-finished.

ues vary widely between various manufacturers and Because the product is rigid, installers should pay

between horizontal and vertical construction. careful attention to the flatness of the subfloor.

DIMENSIONAL STABILITY: Engineered construction.

Origin

Workability Asia. The majority is made in China from the Phyl-

SAWING/MACHINING: Cuts easily with most tools. lostachys pubescens (common name: Moso) species;

NAILING: No known problems. however, some bamboo flooring is made from different

SANDING: Due to its unique, fibrous structure, bamboo species grown in countries such as Vietnam.

bamboo should not be sanded across the grain or at

a 45-degree angle to the grain. Its light color tends to

show swirl marks, other sanding marks and finish

Availability

Readily available.

imperfections, much as a light maple floor can.

22 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

BUBINGA

Guibourtia demeusei

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 50 at a 7-15 degree angle with the grain

COLOR: Pink, red or red/brown with purple streaks

Second Cut: 60 or 80 straight with the grain

or veins; changes from pinkish rose when freshly

Third Cut: 100

milled to burgundy red when aged.

Hard Plate: 100

GRAIN: Fine; straight or interlocked, can be highly

First Screen: 80

figured.

Second Screen: 100 or 120

VARIATIONS WITHIN SPECIES AND GRADES: Quar-

FINISHING: Test all products before using them on the

tered exhibits flame figure; flatsawn has rosewood

actual floor. Oil-modified finished will require a lengthy

graining.

dry time. (See finishing comments on page 6.)

COMMENTS: Dust has been known to cause contact

Properties dermatitis.

HARDNESS (JANKA): 2690 (109% harder than North-

ern red oak).

DIMENSIONAL STABILITY: Average (8.4; 2% more sta-

Origin

Africa.

ble than Northern red oak).

Workability Availability

Limited availability.

SAWING/MACHINING: Saws and planes well.

NAILING: Tends to split tongues. Pre-drilling and

hand-nailing may be preferred.

SANDING: Sands satisfactorily if correct sanding

sequence is followed.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 23

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

CHERRY, BRAZILIAN

Jatoba

Hymenaea courbaril

water-based finish

oil-based finish

Appearance angle of penetration be adjusted carefully. If using a

pneumatic nailer, the air pressure should be adjusted.

COLOR: Sapwood is gray-white; heartwood is salmon

SANDING: Scratches are easily seen—each sanding

red to orange-brown when fresh and becomes russet must carefully remove the scratches from the previ-

or reddish brown when seasoned; often marked with ous cut, or sanding marks will be visible in the finish.

dark streaks. Suggested Sequence

GRAIN: Mostly interlocked; texture is medium to

First Cut: 50 at a 7-15 degree angle with the grain

rather coarse. Second Cut: 60 or 80 straight with the grain

VARIATIONS WITHIN SPECIES AND GRADES: Moderate

Third Cut: 100

to high color variation. Hard Plate: 100

First Screen: 80

Properties Second Screen: 100 or 120

HARDNESS (JANKA): Average of 2820 (119% harder

FINISHING: Coating with oil-modified polyurethane

than Northern red oak). may occasionally cause white spots or specks, as

DIMENSIONAL STABILITY: Average (8.5; 1% more stable

well as white end joints, to appear. This may be

than Northern red oak). However, actual installations avoided by buffing in a clear oil sealer or neutral

have shown significant movement. Longer-than-normal stain, then buffing on satin polyurethane. (See fin-

acclimation time is recommended. ishing comments on page 6.)

Workability

SAWING/MACHINING: Sawing is difficult due to high

Origin

density; requires frequent resharpening of tools. Planing South America.

is difficult due to interlocked grain. Can be machined to

a smooth surface. Carbide tooling recommended.

Availability

NAILING: Due to hardness it is very important that the Easily available.

24 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

CORK

Quercus suber

water-based finish

oil-based finish

Appearance (100/120/150) should be backed with a maroon pad.

Small orbital sanders or hand-sanding are recom-

COLOR: Varies from light to dark; many colors avail-

mended for corners and wall lines, as hand-scrapers

able depending on manufacturer. may gouge the cork.

GRAIN: Distinctive look unlike wood—cork is actu-

Suggested Sequence

ally the bark of a type of oak. First Cut: 100

VARIATIONS WITHIN SPECIES AND GRADES: Many

Second Cut: 120

patterns available depending on manufacturer. Third Cut: Not recommended

Hard Plate: 120 or 150

Properties First Screen: 120

HARDNESS (JANKA): Varies. Second Screen: 120

DIMENSIONAL STABILITY: Cork reacts quickly, some- FINISHING: All surface-type finishes are successfully

times within hours, to changes in moisture. (Typical used on cork (choose a finish that will bend as the

dimensional stability measurements do not apply to cork compresses). Oil-and-wax also is used frequently.

cork’s composite construction.) COMMENTS: Pay particular attention to subfloor

preparation, as cork is very sensitive to moisture,

Workability and also transfers any imperfections in the subfloor

SAWING/MACHINING: Cork may be cut with a util- to the surface appearance.

ity knife.

NAILING: Cork is installed using adhesive. Origin

SANDING: Use the finest grit possible to flatten the Spain and Portugal.

floor. The following sequences are recommended for

use only with a multi-disc sander or a hardplate on a Availability

buffer. If the edger is used, fine sandpaper Readily available.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 25

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

CYPRESS, AUSTRALIAN

Callitris glauca

water-based finish

oil-based finish

Appearance mended as the final screening to minimize the

scratch pattern.

COLOR: Cream-colored sapwood; heartwood is

Suggested Sequence

honey-gold to brown with darker knots throughout. First Cut: 50 at a 7-15 degree angle with the grain

GRAIN: Closed.

Second Cut: 60 straight with the grain

VARIATIONS WITHIN SPECIES AND GRADES: High

Third Cut: 80 or 100

degree of color variability. Hard Plate: 100 or 120

First Screen: 100

Properties Second Screen: 120 or 150

HARDNESS (JANKA): 1375; (7% harder than North-

FINISHING: Knots may cause drying problems with

ern red oak). some finishes. (See finishing comments on page 6.)

DIMENSIONAL STABILITY: Excellent (2.8; 67% more

COMMENTS: Potential for respiratory/allergic reca-

stable than Northern red oak). However, actual tions.

installations have demonstrated significant move-

ment.

Origin

Workability: Australia.

SAWING/MACHINING: Good machining qualities.

NAILING: Can be brittle (like Brazilian cherry); splits

Availability

tongues easily. Readily available.

SANDING: Tendency to clog paper due to high resin

content. Hardplating and screening may leave swirls;

screening more than twice may be necessary. The

knots are extremely hard and may cause wave in the

floor. A 12-by-18-inch oscillating sander is recom-

26 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

GUM, SPOTTED

Corymbia maculata (formerly Eucalyptus maculata)

water-based finish

oil-based finish

Appearance Second Screen: 120

FINISHING: No known problems.

COLOR: Heartwood is light to dark brown, sapwood

is pale and may be as wide as 3.12 inches (8 cm).

GRAIN: Interlocked, moderately coarse. Frequent Origin

presence of wavy grain produces “fiddleback” grain. Australia.

Slightly greasy; gum veins are common.

Availability

Properties Moderately available.

HARDNESS (JANKA): 2473 (92% harder than

Northern red oak).

DIMENSIONAL STABILITY: Data not available.

Workability

SAWING/MACHINING: Good.

NAILING: Pre-drilling and hand-nailing may be pre-

ferred.

SANDING: No known problems.

Suggested Sequence

First Cut: 50 at a 7-15 degree angle with the grain

Second Cut: 60 or 80 straight with the grain

Third Cut: 100

Hard Plate: 120

First Screen: 100

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 27

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

GUM, SYDNEY BLUE

Eucalyptus saligna

water-based finish

oil-based finish

Appearance Second Screen: 120

FINISHING: No known finishing problems.

COLOR: Wide range from pinks to burgundy reds;

regrowth timber may be a pale straw color with pink

highlights. Colors mute over time and darken to a Origin

medium brown-red. Australia.

Properties Availability

HARDNESS (JANKA): 2023 (57% harder than North- Moderately available.

ern red oak).

DIMENSIONAL STABILITY: Data not available.

Workability

SAWING/MACHINING: Very hard—carbide blades

and bits required.

NAILING: Pre-drilling and hand-nailing may be pre-

ferred.

SANDING: No known problems.

Suggested Sequence

First Cut: 50 at a 7-15 degree angle with the grain

Second Cut: 60 or 80 straight with the grain

Third Cut: 100

Hard Plate: 120

First Screen: 100

28 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

IROKO

Kambala

Chlorophora excelsa

water-based finish

oil-based finish

Appearance Third Cut: 100

Hard Plate: 120

COLOR: Light to medium brown when newly

First Screen: 100

installed; has a significant color change and turns to

Second Screen: 120

brown/dark brown over time.

FINISHING: Staining and/or bleaching this species

GRAIN: Interlocked medium to coarse texture.

may be difficult. No finish compatibility problems are

VARIATIONS WITHIN SPECIES AND GRADES: Dramatic

known.

difference between quartersawn and flatsawn prod-

COMMENTS: Dust is known to cause both contact

ucts.

dermatitis and respiratory reactions.

Properties Origin

HARDNESS (JANKA): 1260 (2% softer than Northern

Africa.

red oak).

DIMENSIONAL STABILITY: Excellent (3.8; 66% more

stable than Northern red oak). Availability

Moderately available.

Workability

SAWING/MACHINING: Somewhat stringy—may

split and splinter when resanding or ripping.

NAILING: No known problems.

SANDING: No known problems.

Suggested Sequence

First Cut: 50 at a 7-15 degree angle with the grain

Second Cut: 60 or 80 straight with the grain

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 29

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

JARRAH

Eucalyptus marginata

water-based finish

oil-based finish

Appearance wall treatments.

Suggested Sequence

COLOR: Heartwood is uniformly pinkish to dark red,

First Cut: 50 at a 7-15 degree angle with the grain

often a rich, dark red mahogany hue, turning a deep Second Cut: 60 or 80 straight with the grain

brownish red with age and exposure; sapwood is Third Cut: 100

pale. Frequent black streaks with occasional in- Hard Plate: 120

grown grain. First Screen: 100

GRAIN: Frequently interlocked or wavy. Texture is

Second Screen: 120

even and moderately coarse. FINISHING: Red color can bleed into some finishes—

VARIATIONS WITHIN SPECIES AND GRADES: Moderate

a problem when mixing species.

to high color variation. COMMENTS: Resistant to termites and fungus.

Properties Origin

HARDNESS (JANKA): 1910 (48% harder than

Australia.

Northern red oak).

DIMENSIONAL STABILITY: Below average (11.0; 28%

less stable than Northern red oak).

Availability

Moderately available.

Workability

SAWING/MACHINING: Difficult to work because of

high density and irregular grain; carbide tooling

recommended.

NAILING: No known problems.

SANDING: Sands well, but dust can stain fabric and

30 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

MAHOGANY, SANTOS

Myroxylon balsamum

water-based finish

oil-based finish

Appearance Hard Plate: 100

First Screen: 80

COLOR: Dark reddish brown.

Second Screen: 100 or 120

GRAIN: Striped figuring in quartersawn selections;

FINISHING: Oil residue may be a problem. This can

texture is even and very fine.

be eliminated by wiping with the appropriate 100

VARIATIONS WITHIN SPECIES AND GRADES: Moderate

percent pure (not recycled) solvent before the sealer

color variation.

is applied. (See finishing comments on page 6.)

COMMENTS: Some respiratory/allergic reaction

Properties potential.

HARDNESS (JANKA): 2200 (71% harder than

Northern red oak).

DIMENSIONAL STABILITY: Above average (6.2; 28%

Origin

South America.

more stable than Northern red oak).

Workability Availability

Readily available.

SAWING/MACHINING: Moderately difficult due to

hardness; carbide tooling recommended.

NAILING: No known problems.

SANDING: Sands satisfactorily.

Suggested Sequence

First Cut: 40 or 50 at a 7-15 degree angle with the

grain

Second Cut: 60 or 80 straight with the grain

Third Cut: 100

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 31

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

MAPLE, BRAZILIAN

Pau marfim, Guatambu

Balfourodendron riedelianum

water-based finish

oil-based finish

Appearance Third Cut: 100

Hard Plate: 100

COLOR: Pale cream to yellow cream; no contrast

First Screen: 100

between sapwood and heartwood.

Second Screen: 120 or 150

GRAIN: Straight, fine, uniform.

FINISHING: Takes finish well. May be difficult to stain.

VARIATIONS WITHIN SPECIES AND GRADES: Lower

grades may have darker tan/brown colors.

Origin

Properties South America.

HARDNESS (JANKA): 1500 (16% harder than

Northern red oak). Availability

DIMENSIONAL STABILITY: Average (8.8; 2% less sta- Moderately available.

ble than Northern red oak). Very sensitive to mois-

ture fluctuations.

Workability

SAWING/MACHINING: Works cleanly; requires a

wide set for ripping; very hard on router bits.

NAILING: No known problems.

SANDING: Sands satisfactorily if correct sanding

sequence is followed.

Suggested Sequence

First Cut: 50 at a 7-15 degree angle with the grain

Second Cut: 60 or 80 straight with the grain

32 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

MERBAU

Ipil, Kwila

Intsia spp.

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 60 at a 7-15 degree angle with the grain

COLOR: Heartwood is yellowish to orange-brown

Second Cut: 60 or 80 straight with the grain

when freshly cut, turning brown or dark red-brown

Third Cut: 100

upon exposure.

Hard Plate: 120

GRAIN: Straight to interlocked or wavy; coarse texture.

First Screen: 100

VARIATIONS WITHIN SPECIES AND GRADES: Moderate

Second Screen: 120

to high variation in color.

FINISHING: Takes neutral finish well. May be difficult

to stain.

Properties COMMENTS: High resistance to termites.

HARDNESS (JANKA): 1925 (49% harder than

Northern red oak).

DIMENSIONAL STABILITY: Excellent (4.6; 47% more

Origin

Southeast Asia.

stable than Northern red oak). However, actual

installations have shown significant movement in

use. Availability

Moderately available.

Workability

SAWING/MACHINING: Sawing is difficult; wood

gums saw teeth and dulls cutting edges; carbide

tooling recommended.

NAILING: No known problems.

SANDING: Sands satisfactorily if correct sanding

sequence is followed.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 33

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

OAK, TASMANIAN

Victorian ash

Eucalyptus regnans/obliqua/delegatensis

water-based finish

oil-based finish

Appearance Second Cut: 60 or 80 straight with the grain

Third Cut: 80 or 100

COLOR: Pale straw with occasional pinkish high-

Hard Plate: 80 or 100

lights, tan colors, some medium gray/brown colors;

First Screen: 80

over time overall color variation is muted with an

Second Screen: 100 or 120

ambering of the straw colors to darker tan.

FINISHING: No known finishing problems.

GRAIN: All riftsawn.

COMMENTS: Has been known to cause contact der-

VARIATIONS WITHIN SPECIES AND GRADES: Even

matitis.

range of color shadings.

Properties Origin

Australia.

HARDNESS (JANKA): 1350 (5% harder than Northern

red oak).

DIMENSIONAL STABILITY: Data not available. Availability

Moderately available.

Workability

SAWING/MACHINING: Cuts easily; some splintering

when routing.

NAILING: No known problems.

SANDING: Sands satisfactorily if correct sanding

sequence is followed.

Suggested Sequence

First Cut: 50 or 60 at a 7-15 degree angle with the

grain

34 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

PADAUK

Pterocarpus soyauxii

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 40 at a 7-15 degree angle with the grain

COLOR: Heartwood is vivid reddish orange when

Second Cut: 60 or 80 straight with the grain

freshly cut, darkening to reddish- or purple-brown

Third Cut: 80 or 100

or black over time. Sapwood is cream-colored. Very

Hard Plate: 100

uniform in color.

First Screen: 80

GRAIN: Straight to interlocked; coarse texture.

Second Screen: 100 or 120

VARIATIONS WITHIN SPECIES AND GRADES:

FINISHING: Because of the oil in the wood, oil-modi-

Slight variation in color.

fied finishes may require long dry times. Waterborne

finishes are often recommended. Has a tendency to

Properties bleed. Conversion varnishes also have been known

HARDNESS (JANKA): 1725 (34% harder than to work well. (See finishing comments on page 6.)

Northern red oak). COMMENTS: Dermatological and respiratory allergic

DIMENSIONAL STABILITY: Excellent (5.2; 40% more potential.

stable than Northern red oak).

Origin

Workability Africa.

SAWING/MACHINING: Saws well, but requires a slow

feed rate; carbide tooling recommended. Machines

easily, with some tearing of the interlocked grain.

Availability

Moderately available.

NAILING: No known problems.

SANDING: Sands satisfactorily. Job site furniture,

walls, etc., should be protected from the fine red

powder produced when sanding.

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 35

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

PURPLEHEART

Amaranth

Peltogyne spp.

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 50 at a 7-15 degree angle with the grain

COLOR: Heartwood is brown when freshly cut, turning

Second Cut: 60 or 80 straight with the grain

deep purple to purplish-brown over time. Sapwood is a

Third Cut: 80 or 100

lighter cream color.

Hard Plate: 100

GRAIN: Usually straight; medium to fine texture.

First Screen: 80

Presence of minerals in some boards may cause

Second Screen: 100 or 120

uneven coloration.

FINISHING: Takes finishes well; some have found

VARIATIONS WITHIN SPECIES AND GRADES: Moderate

that water-based finishes hold color better. Tendency

to high color variation.

to bleed with some finishes. (See finishing com-

ments on page 6.)

Properties COMMENTS: Often used as a feature strip or as part

HARDNESS (JANKA): 2890 (124% harder than of an inlay.

Northern red oak).

DIMENSIONAL STABILITY: Above average (6.1; 29%

more stable than Northern red oak).

Origin

Mexico, Central and South America.

Workability Availability

SAWING/MACHINING: Moderately difficult due to

Limited availability.

hardness; frequent sharpening of tools required;

slow feed rate and carbide tooling recommended.

NAILING: Good holding ability.

SANDING: Moderately difficult.

36 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

SAPELE

Entandrophragma cynlindricum

water-based finish

oil-based finish

Appearance First Screen: 100 or 120

Second Screen: 150

COLOR: Medium to dark red-brown; darkens over

FINISHING: Staining may over-darken the wood. No

time.

known finishing problems.

GRAIN: Fine, interlocked.

VARIATIONS WITHIN SPECIES AND GRADES: Quarter-

sawn material has a ribbon-striped effect. Origin

Africa.

Properties

HARDNESS (JANKA): 1500 (16% harder than Availability

Northern red oak). Moderately available.

DIMENSIONAL STABILITY: Above average (7.4; 14%

more stable than Northern oak).

Workability

SAWING/MACHINING: Saws easily.

NAILING: No known problems.

SANDING: Sands satisfactorily if correct sanding

sequence is followed.

Suggested Sequence

First Cut: 50 at a 7-15 degree angle with the grain

Second Cut: 80 straight with the grain

Third Cut: 100

Hard Plate: 100 or 120

© 2004 NATIONAL WOOD FLOORING ASSOCIATION 37

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

TEAK, BRAZILIAN

Cumaru, Tonka, Southern Chestnut, Brazilian Chestnut

Dipteryx odorata

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 50 at a 7-15 degree angle with the grain

COLOR: At first, red-brown or purple-brown with

Second Cut: 60 or 80 straight with the grain

light yellow-brown or purple streaks; after exposure,

Third Cut: 100

uniform light brown or yellow-brown.

Hard Plate: 100

GRAIN: Fine texture, interlocked, waxy or oily feel.

First Screen: 80

VARIATIONS WITHIN SPECIES AND GRADES: Dramatic

Second Screen: 100 or 120

shading that mellows as the floor matures.

FINISHING: Test all products before using them on

the actual job site. Oil-modified finishes may not dry

Properties when applied over this wood if standard procedures

HARDNESS (JANKA): 3540 (174% harder than North- are followed. Moisture-cure urethane, conversion

ern red oak). varnish and waterborne finishes are generally more

DIMENSIONAL STABILITY: Average (7.6; 12% more successful with this species. (See finish comments

stable than red oak). on page 6.)

COMMENTS: Has been known to cause contact

Workability dermatitis.

SAWING/MACHINING: Works well, but is very

hard—use carbide blades and bits. Origin

NAILING: Pre-drilling and hand-nailing are preferred. South America.

SANDING: Difficult. Scratches are easily seen—each

sanding must carefully remove the scratches from

the previous cut, or sanding marks will be visible in

Availability

Moderately available.

the finish.

38 © 2004 NATIONAL WOOD FLOORING ASSOCIATION

NATIONAL WOOD FLOORING ASSOCIATION TECHNICAL PUBLICATION No. A200

TEAK, THAI/BURMESE

Tectona grandis

water-based finish

oil-based finish

Appearance Suggested Sequence

First Cut: 50 or 60 at a 7-15 degree angle with the

COLOR: Heartwood varies from yellow-brown to dark

grain

golden brown; turns rich brown under exposure to

Second Cut: 60 or 80 straight with the grain

sunlight. Sapwood is a lighter cream color.

Third Cut: 100