Beruflich Dokumente

Kultur Dokumente

Longitudinal Joint Construction Techniques For Asphalt Pavements

Hochgeladen von

Prof. Prithvi Singh KandhalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Longitudinal Joint Construction Techniques For Asphalt Pavements

Hochgeladen von

Prof. Prithvi Singh KandhalCopyright:

Verfügbare Formate

Longitudinal Joint Construction Techniques for Asphalt

Pavements

By

Prithvi S. Kandhal, Associate Director, National Center for Asphalt Technology

Rajib b. Mallick, Research Associate, National Center for Asphalt Technology

ABSTRACT

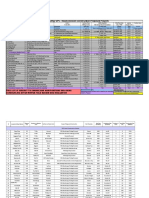

Thirty hot mix asphalt (HMA) test sections were constructed in Michigan (1992),

Wisconsin (1992), Colorado (1994), and Pennsylvania(1995) to evaluate the

effectiveness of twelve different longitudinal joint construction techniques. The

performance of these test sections was evaluated in 1996 after one to four years in

service.

The joints with high densities generally show better performance than those with

relatively low densities. The Michigan joint technique (12.5 mm vertical offset and

12:1 taper) appears to have the best potential of obtaining a satisfactory longitudinal

joint. The cutting wheel and the edge restraining device techniques have good

potential but are too much operator dependent to obtain consistent results. Among the

three different joint rolling techniques used in all four projects, rolling the joint from

hot side generally gave the best performance followed by rolling from hot side

152mm away from the joint. Paver manufacturers should consider modifying the

paver design to obtain a Michigan type, high density unconfined wedge in the lane

paved first. Highway agencies should specify minimum compaction levels to be

achieved at the longitudinal joint

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Quality Control and Quality Assurance in Bituminous Road Construction in IndiaDokument21 SeitenQuality Control and Quality Assurance in Bituminous Road Construction in IndiaProf. Prithvi Singh Kandhal100% (4)

- Review of Practices For Improving Ride Quality and Periodical Renewal of Bituminous Pavements in IndiaDokument26 SeitenReview of Practices For Improving Ride Quality and Periodical Renewal of Bituminous Pavements in IndiaProf. Prithvi Singh Kandhal100% (2)

- Q and A With A Highway Engineer About Roads Developing Potholes During Monsoons in India - 12 April 2024Dokument7 SeitenQ and A With A Highway Engineer About Roads Developing Potholes During Monsoons in India - 12 April 2024Prof. Prithvi Singh KandhalNoch keine Bewertungen

- Proposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalDokument14 SeitenProposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalProf. Prithvi Singh KandhalNoch keine Bewertungen

- Letter To Hon. PM Narendra Modi To Ban Undesirable Bituminous Mixes On Indian RoadsDokument8 SeitenLetter To Hon. PM Narendra Modi To Ban Undesirable Bituminous Mixes On Indian RoadsProf. Prithvi Singh KandhalNoch keine Bewertungen

- Letter To Highway Colleagues On New PG Specification For PMB IS 15462:2019 - 4 July 2019Dokument4 SeitenLetter To Highway Colleagues On New PG Specification For PMB IS 15462:2019 - 4 July 2019Prof. Prithvi Singh Kandhal100% (6)

- Open Letter To Hon. Gadkari MORTH On Savings of Over One Lakh Crores Per Year - 14 August 2021Dokument6 SeitenOpen Letter To Hon. Gadkari MORTH On Savings of Over One Lakh Crores Per Year - 14 August 2021Prof. Prithvi Singh KandhalNoch keine Bewertungen

- Investigation of Premature Pavement Distresses On Typical National Highway ProjectDokument28 SeitenInvestigation of Premature Pavement Distresses On Typical National Highway ProjectProf. Prithvi Singh Kandhal100% (2)

- Blog "Asphalt For India" by Prof. Prithvi Singh KandhalDokument73 SeitenBlog "Asphalt For India" by Prof. Prithvi Singh KandhalProf. Prithvi Singh Kandhal100% (2)

- Why Do Many Roads Constructed in India Fail Prematurely?Dokument2 SeitenWhy Do Many Roads Constructed in India Fail Prematurely?Prof. Prithvi Singh Kandhal100% (1)

- Kandhal Q and A Part 6 On Marshall Mix Design - Letter To Highway Colleagues - 15 September 2019Dokument5 SeitenKandhal Q and A Part 6 On Marshall Mix Design - Letter To Highway Colleagues - 15 September 2019Prof. Prithvi Singh Kandhal100% (1)

- Kandhal Asphalt Literature For India Rev. 3 January 2019Dokument27 SeitenKandhal Asphalt Literature For India Rev. 3 January 2019Prof. Prithvi Singh Kandhal100% (1)

- Hot Mix Recycling of Asphalt Pavements in India - It's Long Overdue!Dokument5 SeitenHot Mix Recycling of Asphalt Pavements in India - It's Long Overdue!Prof. Prithvi Singh KandhalNoch keine Bewertungen

- Kandhal Lecture 2 On Grading of Bitumen and Polymer Modified Bitumen (PMB) - Handouts OnlyDokument10 SeitenKandhal Lecture 2 On Grading of Bitumen and Polymer Modified Bitumen (PMB) - Handouts OnlyProf. Prithvi Singh Kandhal100% (3)

- Letter To Hon. Narendra Singh Tomar About Wastage of Funds in Blacktopping Rural Roads in IndiaDokument6 SeitenLetter To Hon. Narendra Singh Tomar About Wastage of Funds in Blacktopping Rural Roads in IndiaProf. Prithvi Singh KandhalNoch keine Bewertungen

- Are Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerDokument5 SeitenAre Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerProf. Prithvi Singh KandhalNoch keine Bewertungen

- Recycling of Asphalt Pavements: An OverviewDokument12 SeitenRecycling of Asphalt Pavements: An OverviewProf. Prithvi Singh Kandhal100% (1)

- Durable and Economical Technology For Bituminous Surfacing of Rural Roads in IndiaDokument6 SeitenDurable and Economical Technology For Bituminous Surfacing of Rural Roads in IndiaProf. Prithvi Singh Kandhal50% (2)

- Kandhal Q and A Part 4 On Bitumen Content of Bituminous Paving Mixes in India - Letter To Highway Colleagues - 9 August 2018Dokument6 SeitenKandhal Q and A Part 4 On Bitumen Content of Bituminous Paving Mixes in India - Letter To Highway Colleagues - 9 August 2018Prof. Prithvi Singh KandhalNoch keine Bewertungen

- A Simple Guide For Producing and Placing Readymade Pothole Patching Mix in Accordance With IRC:116-2014Dokument14 SeitenA Simple Guide For Producing and Placing Readymade Pothole Patching Mix in Accordance With IRC:116-2014Prof. Prithvi Singh KandhalNoch keine Bewertungen

- Open Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsDokument6 SeitenOpen Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsProf. Prithvi Singh KandhalNoch keine Bewertungen

- Open Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaDokument3 SeitenOpen Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaProf. Prithvi Singh KandhalNoch keine Bewertungen

- Letter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatDokument4 SeitenLetter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatProf. Prithvi Singh Kandhal100% (1)

- Kandhal Lecture 8 On Quality Control and Quality Assurance in Bituminous Construction (Handouts)Dokument6 SeitenKandhal Lecture 8 On Quality Control and Quality Assurance in Bituminous Construction (Handouts)Prof. Prithvi Singh Kandhal100% (2)

- Kandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyDokument8 SeitenKandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyProf. Prithvi Singh KandhalNoch keine Bewertungen

- Use Readymade, Idiotproof, Permanent Pothole Patching Mix Throughout The YearDokument5 SeitenUse Readymade, Idiotproof, Permanent Pothole Patching Mix Throughout The YearProf. Prithvi Singh Kandhal100% (1)

- Kandhal Q and A Part 1 On Confusion From Overlapping Viscosity Ranges of VG-30 and VG-40 Bitumen - 16 August 2017Dokument4 SeitenKandhal Q and A Part 1 On Confusion From Overlapping Viscosity Ranges of VG-30 and VG-40 Bitumen - 16 August 2017Prof. Prithvi Singh Kandhal100% (1)

- Kandhal Lecture 7 On Bituminous Mix Compaction and Field Inspection (Handouts)Dokument6 SeitenKandhal Lecture 7 On Bituminous Mix Compaction and Field Inspection (Handouts)Prof. Prithvi Singh Kandhal100% (1)

- Kandhal Lecture 9 On Bituminous Pavement Distresses - Causes and Cures (Handouts)Dokument8 SeitenKandhal Lecture 9 On Bituminous Pavement Distresses - Causes and Cures (Handouts)Prof. Prithvi Singh KandhalNoch keine Bewertungen

- Kandhal Lecture 10 On Maintenance of Bituminous Pavements (Handouts)Dokument10 SeitenKandhal Lecture 10 On Maintenance of Bituminous Pavements (Handouts)Prof. Prithvi Singh Kandhal100% (2)

- X7 X8 X9 X10 X11 X12 X13 X14 X15 X16: Tikrit HospitalDokument1 SeiteX7 X8 X9 X10 X11 X12 X13 X14 X15 X16: Tikrit HospitalhazimNoch keine Bewertungen

- Dfe-B01-Ele-Dwg-Gpr-003 - General Power Layout For Second FloorDokument1 SeiteDfe-B01-Ele-Dwg-Gpr-003 - General Power Layout For Second FloorElectrical PCBL TeamNoch keine Bewertungen

- Pavement Detailed Design Report - Rev.2 English - 08-06-2021Dokument141 SeitenPavement Detailed Design Report - Rev.2 English - 08-06-2021Adrian FrantescuNoch keine Bewertungen

- Faarfield: FAARFIELD V 1.42 - Airport Pavement DesignDokument2 SeitenFaarfield: FAARFIELD V 1.42 - Airport Pavement Designtbl atkpsbyNoch keine Bewertungen

- Tactile Study - ClarificationDokument4 SeitenTactile Study - ClarificationJohn Jay BenavidezNoch keine Bewertungen

- 3.0 Stairways, Ramps, Stiles, Walkways, and Platforms: 3.1 Section ContentsDokument32 Seiten3.0 Stairways, Ramps, Stiles, Walkways, and Platforms: 3.1 Section ContentsBoy AlfredoNoch keine Bewertungen

- Fire Exit RailingDokument1 SeiteFire Exit RailingVongoley FamigliaNoch keine Bewertungen

- StaircasesDokument65 SeitenStaircasesMohammad AkmalNoch keine Bewertungen

- Bao GiaDokument25 SeitenBao GiahuynhvanNoch keine Bewertungen

- Floor FinishesDokument42 SeitenFloor FinishesLawrence TingNoch keine Bewertungen

- 4 - Surfacing Design - UNH - EstimeDokument67 Seiten4 - Surfacing Design - UNH - EstimeDavid KisaluNoch keine Bewertungen

- Flooring2020 ENDokument372 SeitenFlooring2020 ENMarianneNoch keine Bewertungen

- B-PERKERASAN-1 (Struktur-Perkerasan) PERESDokument22 SeitenB-PERKERASAN-1 (Struktur-Perkerasan) PERESNuno TilmanNoch keine Bewertungen

- A Comparative Study On Effect of Different Fillerson Stone Matrix Asphalt MixDokument6 SeitenA Comparative Study On Effect of Different Fillerson Stone Matrix Asphalt MixAdvanced Research PublicationsNoch keine Bewertungen

- Kerteh - Mixed Development-R2 - 23.8.2019Dokument2 SeitenKerteh - Mixed Development-R2 - 23.8.2019abd razak haronNoch keine Bewertungen

- Floor: Neha Thakur Lecturer JngecDokument21 SeitenFloor: Neha Thakur Lecturer JngecnehaNoch keine Bewertungen

- SAIC-Q-1061 Conventional Asphalt & Sulfur Extended Asphalt Concrete Receiving, Placement and Testing InspectionDokument7 SeitenSAIC-Q-1061 Conventional Asphalt & Sulfur Extended Asphalt Concrete Receiving, Placement and Testing InspectionAbdul HannanNoch keine Bewertungen

- 2019 Construction ListDokument4 Seiten2019 Construction ListWXYZ-TV Channel 7 Detroit100% (1)

- AASHTO Design Example 2Dokument6 SeitenAASHTO Design Example 2Yasser AlghrafyNoch keine Bewertungen

- Flooring FinalDokument30 SeitenFlooring FinalRahul PrasadNoch keine Bewertungen

- Solution: (CITATION Lon17 /L 13321)Dokument3 SeitenSolution: (CITATION Lon17 /L 13321)Maxwell ReyesNoch keine Bewertungen

- AtlasConcorde Catalog 2022Dokument253 SeitenAtlasConcorde Catalog 2022rakacNoch keine Bewertungen

- Status of TestDokument271 SeitenStatus of TestMichael LabayoNoch keine Bewertungen

- TST Pages From Nha-General-Specification-E-35-Volum-Ii PDFDokument7 SeitenTST Pages From Nha-General-Specification-E-35-Volum-Ii PDFMuhammad Shahbaz KhokharNoch keine Bewertungen

- Variation JewelleryDokument1 SeiteVariation JewelleryAnish ChandranNoch keine Bewertungen

- Construction Schedule and S-CurveDokument3 SeitenConstruction Schedule and S-CurveJudy Ann CacutNoch keine Bewertungen

- Road ConstructionDokument32 SeitenRoad ConstructionESAM ALHASHEDINoch keine Bewertungen

- PRESENTATION ON FLOOR FINISHES (TANISHKA) - Converted-Compressed PDFDokument34 SeitenPRESENTATION ON FLOOR FINISHES (TANISHKA) - Converted-Compressed PDFRajaNoch keine Bewertungen

- Mech STONE MASTIC ASPHALTDokument13 SeitenMech STONE MASTIC ASPHALTsachin guptaNoch keine Bewertungen

- Jurnal TransportasiDokument7 SeitenJurnal TransportasiDewa Gede TesaNoch keine Bewertungen