Beruflich Dokumente

Kultur Dokumente

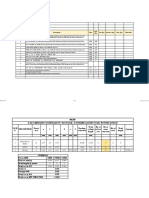

Base Equipment 257 496

Hochgeladen von

Jorge Luis HernándezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Base Equipment 257 496

Hochgeladen von

Jorge Luis HernándezCopyright:

Verfügbare Formate

Pipe

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

using Colebrook equation. Default

value corresponds to commercial steel.

Geometric specification option

Allowable options are:

0 = BASIC

1 = DERIVED DERIV

GeomSpec KI ED

No

If equal to BASIC, Volume, Metal Mass, and Area will

be calculated from Diameter, Length, and Thickness.

If equal to DERIVED, Volume, Metal Mass, and Area

must be specified.

Pipe length

Len Length of the Pipe. Must be specified if GeomSpec is KD 50 Yes m

set to BASIC.

Metal mass

Metal mass is used to determine thermal capacitance

Mm of metal walls. This value must be specified if KD 1220 Yes kg

GeomSpec is DERIVED. If GeomSpec is BASIC, metal

mass is calculated.

Metal density

Rm Metal density. The default value is typical of carbon KD 7760 Yes kg/m3

steel.

Pipe wall Thickness.

Thk Metal thickness used to calculate metal mass. Only KD 0.006 Yes m

used if GeomSpec is set to BASIC.

Dynamic viscosity

Dynamic viscosity of the fluid. If this value is not

specified, a fully turbulent Reynold's number

Visc KD Yes CP

will be used to calculate the friction factor. Future

development will allow viscosity calculation using

thermo system..

Volume

Fluid volume of Pipe. This value must be specified if

Vol KD 1 Yes m3

GeomSpec is DERIVED. If GeomSpec is BASIC,

volume is calculated.

Elevation

E KD Yes m

Elevation relative to local ground level.

Number of segments

NHoldup KI 1 No

Total number of segments

Base Equipment Version 5.3.2, December 2016 251

Pipe

Pipeline Profile

Parameter Dft Eq Arr

Description Dft Cls UOM

Name Val Ok Siz

Pipeline Profile flag

Pipeline Profile Flag

PipeProfileFlag KB 0 No

0 - No Pipeline Profile (default).

1 - Pipeline Profile enabled.

Pipe segment length

This length overrides the pipe

length entered in the GEOMETRY tab.

The data requested here is not the

LenData KD 0 Yes

cumulative length from the inlet

of the pipeline, but the length

of a section of pipe associated

with an outlet elevation change.

Pipe segment outlet elevation change

The Elevation change can be a positive

total or a negative number, as long

as its magnitude is less than or equal

to the pipe segment length associated

ElevData KD 0 Yes

with it. A positive number indicates

an elevation increase.

A negative number indicates an

elevation decrease.

The default elevation increase is zero.

Fittings

Parameter Description Dft Dft Eq Arr UO

Name Cls Val Ok Siz M

Num90Stan Number of 90 degree elbows KI 0 No

dardDegElb This number is used for the calculation of

ow resistance because of 90 degree elbows present in

the pipeline. The resistance coefficient for 90

degree elbows is 30.

Num45Stan Number of 45 degree elbows KI 0 No

dardDegElb This number is used for the calculation of

ow resistance because of 45 degree elbows present in

the pipeline. The resistance coefficient for 45

degree elbows is 16.

NumBranch Number of Branch Tees KI 0 No

Tee This number is used for the calculation of

resistance because of branch tees present in the

pipeline. The resistance coefficient for branch tee

is 60.

NumRunTee Number of Run Tees KI 0 No

This number is used for the calculation of

resistance because of run tees present in the

pipeline. The resistance coefficient for run tee is

20.

NumGateVa Number of Gate Valves KI 0 No

Base Equipment Version 5.3.2, December 2016 252

Pipe

lves This number is used for the calculation of

resistance because of gate valves present in the

pipeline. The resistance coefficient for gate valves

is 8.

NumGlobeV Number of Globe Valves KI 0 No

alves This number is used for the calculation of

resistance because of globe valves present in the

pipeline. The resistance coefficient for globe

valves is 340.

NumBallVal Number of Ball Valves KI 0 No

ves This number is used for the calculation of

resistance because of ball valves present in the

pipeline. The resistance coefficient for ball valves

is 3.

NumCheck Number of Check Valves KI 0 No

Valves This number is used for the calculation of

resistance because of check valves present in the

pipeline. The resistance coefficient for check

valves is 400 (varies with the type of check

valve).

NumExit Number of exits KI 0 No

This number is used for the calculation of

resistance because of pipe exits. The resistance

coefficient for exit effects is 1.

NumEntranc Number of entrance KI 0 No

e This number is used for the calculation of

resistance because of pipe entrance. The

resistance coefficient for entrance effects is 0.78.

AddLen Additional equivalent length KD 0 Yes m

Additional equivalent length will be added to the

straight pipe length for the calculation of the

resistance coefficient.

AddK Additional K-factor (fL/D) KD 0 Yes

K-factor to model pipe fittings and pressure loss

not associated with straight pipe. K-factor is

equivalent to fL/D where f is moody friction

factor, L is length, and D is diameter of Pipe.

Heat Transfer

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Forced convection heat transfer coefficient.

kW/m2-

Uf Forced convection heat transfer coefficient (film) scaled KD 0.1 Yes

K

by flow rate (Sum of all inlet mass flows / Wref ) ^0.8.

Ambient loss heat transfer coefficient. kW/m2-

Ul KD 0.01 Yes

Heat transfer coefficient from metal to ambient. K

Natural convection heat transfer coefficient kW/m2-

Un KD 0.1 Yes

Natural convection heat transfer (film) coefficient for K

Base Equipment Version 5.3.2, December 2016 253

Pipe

heat transfer from fluid to metal.

Reference flow rate

Reference mass flow to calculate forced convection heat

Wref KD 5000000 Yes kg/sec

transfer. The forced convection heat transfer coefficient

is scaled by (Sum of all inlet mass flows / Wref) ^0.8.

Exponent for heat transfer coefficient.

Exponent for heat transfer (film) coefficient with flow

UExp KF 0.8 Yes m3

rate. The forced convection heat transfer coefficient (Uf)

is scaled by (mass flow / Wref)^UExp.

Reactions

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Reaction flag

RxnFlag This flag turns on or off the all of the reactions in the reactor. KB false No

The default value is no reactions (0).

External Inputs

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Imposed heat to fluid

Qimp DD 0 Yes kJ/sec

External heat imposed on the fluid.

Ambient temperature

Tamb Ambient temperature. Normally associated with DD TAMBIENT Yes K

global standalone point TAMBIENT.

Advanced

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Liquid filled threshold.

Fraction used to determine if pipe holdup is liquid

KLf filled. If holdup’s liquid volume fraction is greater KI 0.99 Yes fraction

than specified value, it is changed to liquid filled

mode.

Debug Flags

DebugFlags This parameter is a collection of binary flags. Each KI 0 No

equipment model interprets the flags its own way.

Implicit energy holdup flag

This parameter is used to enable

the implicit energy holdup calculation.

ImplicitEnergyFlag KI 0 No

Valid entries are.

0 - disabled

1 - enabled (default)

Integrating composition and enthalpy.

SpecificStates Set when integrating composition and enthalpy DI 0 Yes

rather than moles and energy.

Base Equipment Version 5.3.2, December 2016 254

Pipe

Calculated Values

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Moody friction factor

Calculated from Reynolds number and roughness

Ff using the Colebrook Equation. If Viscosity is not DD 0.015 No

specified, this is the friction factor in the zone of

complete turbulence.

Sonic pressure

Ps Calculated sonic tip pressure when flow DD 101.325 No kPa

calculation type is Darcy with sonic.

Heat loss fluid to metal

Qf Heat loss from fluid to metal. A negative value DD 0 No kJ/sec

indicates that the fluid is losing heat to the metal.

Heat loss metal to ambient

Heat loss from metal to ambient. A negative

Ql DD 0 No kJ/sec

value indicates that the metal is losing heat to the

surroundings.

Reynolds number

Reynolds number. If viscosity is not specified,

Re DD 1.0E8 No

this value is

set to 10^8 for the zone of complete turbulence.

Fluid Velocity

Vel The average velocity of the fluid. Calculated when DD 0 No m/sec

the Basic geometry is specified.

Secondary flow rate

kg-

FSecondary Secondary flow rate is equal to the change in the DD No

mol/sec

feed molar flow rate due to reaction.

DP Pressure drop across flow device DD 0 No kPa

Pressure difference due to static head

This is the pressure difference due to

DPHead static head based on inlet minus DD 0 No kPa

outlet. It is calculated by the pressure

flow solver.

Pressure difference due to forward static head

This is the pressure difference due to

DPHeadFSeg DI 0 No

forward static head based on inlet minus

outlet.

Pressure difference due to reverse static head

This is the pressure difference due to

DPHeadRSeg DI 0 No

reverse static head based on inlet minus

outlet.

Pressure difference due to static head

This is the pressure difference due to

DPHeadSeg static head based on inlet minus DI 0 No

outlet. It is calculated by the pressure

flow solver.

DPSeg Pressure drop across flow device DD 0 No

Fi Inlet flow rate DD 0 No Kg-

Base Equipment Version 5.3.2, December 2016 255

Pipe

mol/sec

FiSeg Inlet flow rate DD 0 No

Kg-

Fx Exit flow rate DD 0 No

mol/sec

FxSeg Exit flow rate DD 0 No

Total holdup

Total holdup moles in the pipe. This

Mt DD 0 No Kg-mol

is approximate unless HoldupFlag or

FlashFlag are turned ON.

Total holdup

Total holdup moles in the pipe. This

MtSeg DD 0 No

is approximate unless HoldupFlag or

FlashFlag are turned ON.

Simultaneous solver pressure offset

POffSeg Pressure offset due to internal volume change of DI 0 No

contents.

Pressure

Pressure of pipe segment. This is only

a state for EXPLICIT solution with

PSeg DD 101.325 No

INCOMPRESSIBLE dynamics to break

large flow networks. Use KDPS to

tune dynamics.

Sonic tip pressure of the segment

PsSeg Calculated sonic tip pressure when flow DD 101.325 No

calculation type is Darcy with sonic.

Heat loss fluid to heatstream

Heat loss from fluid to heatstream.

QfH A negative value indicates that DD 0 No kJ/sec

the fluid is losing heat to the

heatstream.

Heat loss fluid to metal

Heat loss from fluid to metal.

QfSeg A negative value indicates that DD 0 No

the fluid is losing heat to the

metal.

Heat loss metal to ambient

Heat loss from metal to ambient.

QlSeg A negative value indicates that DD 0 No

the metal is losing heat to the

surroundings.

Heat loss metal to heatstream

Heat loss from metal to heatstream.

QmH A negative value indicates that DD 0 No kJ/sec

the metal is losing heat to the

heatstream.

Fluid Velocity

VelSeg The average velocity of the fluid. Calculated DD 0 No

when the Basic geometry is specified.

FlowPatternSeg Flow pattern across flow device DD 0 No

Base Equipment Version 5.3.2, December 2016 256

Pipe

FlowPattern contains the flow regimes

encountered during multiphase flow.

For BBHV:

0 - No flow pattern

1 - Segregated

2 - Intermittent

3 - Distributed

4 - Transition

5 - Single phase gas

6 - Single phase liquid

Cumulative Pipe Segment Length

The length of each segment depends on

LenSeg the number of holdups. The more holdups, DD 0 No

the less the segment lengths. Please

note that all segments have equal length.

Cumulative Pipe Segment Elevation

If the number of rows in the elevation

profile table are the same as the

ElevSeg number of conductances (holdups -1), DD 0 No

then these values will be the same

as the cumulative elevation change

in the elevation profile table.

Slip holdup from correlation across flow

This value is calculated when using

hydraulic correlations like BBMHV.

It is calculated for each

HlsSeg flow conductance and is defined DD 0 No

as the fraction of an element of the

pipe that is occupied by liquid at

a given instant of time.

A value of -1 indicates 'Not calculated'.

Derivatives

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Size

dHSeg Specific enthalpy derivative DD 0 No 0

Metal temperature derivative

dTmSeg Derivative of metal temperature. A positive value indicates DD 0 No 0

that the metal is getting hotter.

Total Internal Energy derivative.

Derivative of header internal energy calculated from the

flowing enthalpy of all streams connected to the header, fluid

dUtSeg DD 0 No 0

heat stream duty, and heat loss to metal. Only used for

COMPRESSIBLE dynamics. Will be zero for

INCOMPRESSIBLE where dH is used instead.

Base Equipment Version 5.3.2, December 2016 257

Pipe

States

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Specific enthalpy state

H DD 0 No kJ/kg-mol

Energy state used for fluid holdup.

Metal temperature

Tm DD 298 No K

Metal temperature

Total Internal Energy state.

UtSeg Total internal energy state for COMPRESSIBLE DD 0 No 0

dynamics.

Specific enthalpy state

HSeg DD 0 No 0

Energy state used for fluid holdup.

Metal temperature

TmSeg DD 0 No 0

Metal temperature

Solution Options

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Dynamics Option

For INCOMPRESSIBLE, pressure is

calculated by solving a flow balance.

For COMPRESSIBLE, pressure is

calculated by integration of mass and

energy derivatives. INCOMPRESSIBLE is

DynamicsOption KB false No

recommended even for vapor systems when

the header volume is small.

0 - INCOMPRESSIBLE

1 -COMPRESSIBLE

2-DEFAULT_INCOMPRESSIBLE

3-NOHOLDUP

Flow calculations option.

Darcy’s Law is used for normal flow. Sonic flow

calculations are done for the last segment if

DARCYSONICLASTSEGONLY is selected and

for all segments if DARCYSONICEACHSEG is

selected. Darcy equation with Fluid Inertia is used

FlowCalcOptions if INERTIA is selected. KB false No

0 - DARCY

1 - DARCYSONICLASTSEGONLY

2- DARCYSONICEACHSEG

3- INERTIA

4- BEGGSBRILLHV

5-DEFAULT_DARCY

Solution Option.

Allowable options are Simultaneous and Explicit.

SolutionOption KB false No

0- SIMULTANEOUS

1- EXPLICIT

Base Equipment Version 5.3.2, December 2016 258

Pipe

Calculate kinetic energy change flag

When true, kinetic energy changes will be

calculated

CalcKEFlag from the conductances before and after KB 0 No

the current holdup. Once calculated,

this term is added to the energy balance equation

in the holdup calculations.

Legend:

Dfl Cls Default parameter class:

KB - Static Boolean SB - State Boolean DB - Dynamic Boolean

KI - Static Integer SI - State Integer DI - Dynamic Integer

KF - Static Float SF - State Float DF - Dynamic Float

KD - Static Double SD - State Double DD - Dynamic Double

Dft Val A value here indicates the parameter’s default value. If the parameter is static, no

value indicates that the parameter is optional unless otherwise noted.

Eq Ok An equation can be attached to the parameter if the corresponding value is Yes.

Arr Siz A value here if indicates the size of the array. No value indicates that the parameter is

not a vector.

UOM Internal units of measure.

Please refer to the Base Equipment Fundamentals section for pressure node base

parameters, flow device base parameters, and parameters associated with the flash or

reaction submodel.

Base Equipment Version 5.3.2, December 2016 259

Pipe

FAQ

Q. My flow calculation does not seem correct for the conductance that I calculated.

A. The sonic flow or fluid inertia calculations may have been turned on. Also, if the pressure

drop is very low, the flow is calculated as a linear function of delta pressure rather than as the

square root of delta pressure. This will be the case if the delta pressure is less than the value of

the flow path first stream parameter DPLin. DPLin can be increased to avoid flow instability

around zero flow conditions.

Q. How do I tune the heat loss to ambient?

A. The heat loss to ambient default values is set for common heat transfer coefficients that

should work in most cases. The default value for ambient natural convection is usually good for

bare pipe. A lower value should be used if there is insulation. The default value for fluid natural

convection is good for liquids. The user may improve the default value for vapor systems.

Please use the Basic geometry flag option for Pipe and Header. If you use Derived, be sure that

the volume, mass, and area are consistent for reasonable heat loss to ambient calculations.

An effective way to tune heat loss is to first make the metal mass very small by specifying a very

low metal wall thickness. Thickness cannot be too small or dynamic results will be unstable.

Now, if the equipment model has a forced convection film coefficient, set the Wref parameter to

the typical mass flow rate and set Uf, Un, and Ul to appropriate values. Since the metal mass is

small, the heat loss Ql and Qf and metal temperature Tm should come to equilibrium very

quickly. Observe the Tm, Ql and Qf values and adjust the heat transfer coefficients as necessary.

Note that Un will have no affect except at zero or very low flow. Once the heat transfer

coefficients are tuned, and then reset thickness Thk to the correct value to restore proper

dynamics.

Q. How do I model long gas pipelines?

A. The Pipe can be divided into multiple segments for the simulation of a long gas pipeline. The

number of segments depends on the pressure drop across the pipeline. For high pressure drop,

consider that each section should not have more than 10% of the inlet pressure drop per section.

Use Compressible DynamicsOption for gas pipelines.

Q. Can I model water hammer in long liquid pipelines?

A. Yes. Use FlowCalcOption as Darcy with Fluid Inertia, DynamicsOption as Incompressible

and a multi segmented Pipe model to model water hammer in long liquid pipelines.

Q. What strategy should be adapted to model pipes with large frictional pressure drop?

A. Pipes having large frictional pressure drops should be discretized, especially when using sonic

velocity limiting algorithm. The pipe that has choking limit should have a modest frictional

pressure drop. If the pipe is choking and (Pi-ps)/Pi > 0.5 the flow prediction should be carefully

validated.

Base Equipment Version 5.3.2, December 2016 260

Pipe

Q. How do I avoid residence time warning message?

A. The residence time warning message is displayed when the pipe segment fluid residence time

is less than 5 time steps. You can decrease the number of segments, increase the volume, or

reduce the size of time step.

Base Equipment Version 5.3.2, December 2016 261

Pump

Pump

Introduction

Pump is a flow device that is used to model a centrifugal pump. The Pump calculates the

available head based on the pressure differential across it. The volumetric flow rate is

interpolated from the user provided performance curve based on the calculated head. Power is

calculated from the user provided efficiency curve. Reverse flow through a shut down Pump is

allowed.

Pump performance is characterized by a cubic spline or linear curve fit and may be specified by

either entering three or more points from the manufacturer characteristic curve (head vs.

volumetric flow) or entering one design point (head and volumetric flow) using a default curve.

The parameters DHScale and QScale are used to scale the Pump performance. The fan laws scale

the Pump curve with speed.

There are three operating regions for a Pump:

• Normal Pump operation where the head is always positive

• Hydraulic turbine or wind milling region where the suction pressure is higher than

discharge pressure

• Reverse flow region when the head developed is not sufficient enough to pump the fluid

against the discharge pressure.

Pump calculates the shaft power, fluid flow, and fluid enthalpy rise. The speed is calculated

externally from a Shaft or Motor and is transferred to the Pump by a mechanical stream. The

Pump sets the required power in the mechanical stream. Alternatively, speed can be fixed.

Pump does not include either fluid or metal thermal holdup.

Base Equipment Version 5.3.2, December 2016 262

Pump

Fundamentals

Head Calculations

The available Head is calculated based on the differential pressure across the Pump.

1000 ⋅ ∆P

DH =

9.81 ⋅ R f ⋅ MW

where:

DH - Head (m)

MW - Molecular weight (kg/kg-mol)

Rf - Inlet stream density (kg-mol/m3)

∆P - Pressure difference across the Pump (kPa)

Power Calculation

The mechanical shaft power required for any Pump is determined by using the following

relationship

Hi − H x

∆H =

ETA

Power = ∆H ⋅ F

where:

ETA - Isentropic efficiency of the Pump

F - Flow (kg-mol/sec)

Hi - Inlet enthalpy (kJ/k-mol)

Hx - Exit enthalpy (kJ/k-mol)

Power - Power consumed by the Pump (kW)

∆H - Change in enthalpy (kJ/k-mol)

Since power is consumed to drive the Pump, it has a negative value. In case of wind milling

power will be generated by the Pump and will be positive.

Base Equipment Version 5.3.2, December 2016 263

Pump

Flow Calculations

The performance curve is used to interpolate the values of volumetric flow (Q) based on the head

(DH) using a cubic spline or linear interpolation method. Prior to interpolation the Q and DH

data are adjusted by corresponding scaling factors and speed.

Q= AdjustedPerformanceCurve(DH )

where:

DH - Head at operating speed (kJ/kg)

Q - Flow rate at operating speed (m3/sec)

Default Performance Curve

The Pump has a default normalized performance curve that can be modified by the scaling

parameters to suit the users’ requirement. There are a total of 10 points in the default curve. The

user has to specify the design flow and head with the parameters QScale and DHScale

respectively. These values are used to scale the default performance curve, with the 5th point

representing the design point at the reference speed.

QData DHData

0.6 1.187

0.7 1.147

0.8 1.114

0.9 1.0625

1.0 1.0

1.1 0.9279

1.2 0.8474

1.3 0.75

1.4 0.62

1.6 0.24

The following example shows how two sets of values can vary the shape of the curve for QScale

and DHScale.

Base Equipment Version 5.3.2, December 2016 264

Pump

Default performance curve

300

Qscale - 2, DHScale : 200

250 QScale - 3, DHScale - 150

200

Head

150

100

50

0

0 1 2 3 4 5 6

Volumetric flow

User Defined Performance Curve

The user can input the Pump curve data (Q vs. DH) if available. The minimum number of data

points that the user has to provide is three. DYNSIM model ensures that the performance curve is

monotonic. If user has provided non-monotonic performance curves, then the curve is modified

to a monotonic curve based on the parameters KHMin and KHMax. The end points will be

automatically generated if not provided.

User defined performance curve

1.4 Entered Data

1.2 Adjusted Data

0.8

Head

0.6

0.4

0.2

0

0 0.5 1 1.5 2

Volumetric Flow

Performance Curve Adjustments

The parameters QScale and DHScale adjust the performance curve accordingly. When using the

user defined curve, either the curve data can include the actual curve values and the scale

parameters can be one, or the curve can be normalized and the scale data can include design or

Base Equipment Version 5.3.2, December 2016 265

Pump

operating conditions. What is important is that the product of the curve data and the scale

parameters equal the user desired curve.

Both the default curves and the user entered curve can be adjusted for speed. Since the

performance curve data QData and DHData are dimensionless, the UOM of the performance

curves are solely specified by the Scale parameters QScale and DHScale. Also the performance

curves are adjusted for different speeds based on the reference speed and the performance curves

for speed change is based on the fan laws by default.

QSExp

Speed

AdjustedQData = QScale ⋅ QData ⋅

Speed

ref

HSExp

Speed

AdjustedDHData = DHScale ⋅ DHData ⋅

Speed

ref

AdjustedETAData = ETAScale ⋅ ETAData

where:

DHData - Performance curve head data (dimensionless)

DHScale - Head scaling factor (m)

ETAData - Performance curve efficiency data (dimensionless)

ETAScale - Performance curve efficiency data (fraction)

HSExp - Exponent of head for speed

QData - Performance curve flow data (dimensionless)

QScale - Flow scaling factor (m3/sec)

QSExp - Exponent of flow for speed

Speed - Pump operating speed (rpm)

Speedref - Pump reference speed (rpm)

The defaults value for HSExp is 2 and for QSExp is 1. The user can change these coefficients if

they are not suitable for their case.

Wind milling and Reverse Flow

Wind milling

Forward flow through the Pump when the suction pressure is greater than discharge pressure is

termed as wind milling. Wind milling and forward flow through non operating Pump are

modeled as simple flow through a conductance,

F0 = R f ⋅ Q0

∆P ⋅ R f ⋅ MW

F = F0 + J ⋅

MW

Base Equipment Version 5.3.2, December 2016 266

Pump

where:

F0 - Flow at zero head (kg-mol/sec)

Rf - Inlet stream density (kg-mol/m3)

Q0 - Flow at zero head obtained from Pump curve (m3/sec)

∆P - Pressure difference across the Pump (kPa)

F - Flow rate (kg-mol/sec)

J - Flow conductance ((kg/sec)/sqrt(kPa-kg/m3))

MW - Molecular weight (kg/kg-mol)

The power calculated by the Pump during wind milling will take into account the force applied by

the fluid being flowing through the Pump.

Reverse Flow

Reverse flow through the Pump occurs when the Pump is off and the discharge line pressure is

much higher than the suction line pressure or when the Pump is operating and the head developed

is not sufficient enough for forward flow against the discharge pressure.

The shutoff head is calculated from the performance curve at zero flow.

9.81 ⋅ DH 0 ⋅ R f ⋅ MW

∆P0 =

1000

P0 = Pi + ∆P0

The reverse flow is calculated assuming the Pump behaves like any other flow device. The

conductance equation is used to calculate the flow under these conditions.

∆P = Pi − Px + ∆P0

∆P⋅ R f ⋅ MW

F = J ⋅ KJ r

MW

where:

DH0 - Maximum Pump head at zero flow (m)

J - Flow conductance (kg-mol/sqrt(kPa-kg/m3))

KJr - Reverse flow conductance factor

MW - Molecular weight (kg/kg-mol)

Pi - Pipe suction pressure (kPa)

Px - Pipe discharge pressure (kPa)

Rf - Inlet density (kg-mol/m3)

∆P - Pressure difference across the Pump (kPa)

∆P0 - Shutoff pressure drop (kPa)

Reverse flow through a non-operating Pump is adjusted using the KJr factor. If no reverse flow

is desired, set KJr to 0.

Base Equipment Version 5.3.2, December 2016 267

Pump

Flash Calculations

Pump has an optional flash calculation called Flash. By default, the flash is turned off so that

outlet properties are not calculated. Stream properties Temperature, Density, and Vapor Fraction

will be copied from the inlet stream to the exit stream in the case of forward flow and exit stream

to inlet stream in the case of reverse flow. If the flash is turned on, these stream properties will be

calculated at the downstream pressure.

NPSH Calculations

Pump has an optional NPSH calculation for cavitation prediction. By default, the flag is false.

When this flag is turned on, user has an option to select Vapor pressure calculation method out of

SIMPLE and RIGOROUS options. SIMPLE option requires user input of Fluid vapor pressure

and when RIGOROUS option is selected, Pump model does a bubble point flash at the pump inlet

to predict the vapor pressure of the fluid when there is no vapor in inlet stream. NPSH

requirement needs to be supplied by the user. Default value of NPSHR is zero.

NPSH available is calculated by the equation below:

1000 ⋅ ( Pi + StHead − Pvap )

NPSHA =

g ⋅ R f ⋅ MW f

(iStrmEi − iStrmEx ) × g × Rf × MWf

StHead =

1000

where:

NPSHR – Net Positive Suction Head Required (m)

NPSHA – Net Positive Suction Head Available (m)

Pi – Inlet Pressure (kPa)

StHead – Static Head acting at pump suction (kPa)

Pvap – Vapor pressure of fluid at pump inlet (kPa)

g – Acceleration due to gravity (9.80665m/sec2)

Rf – Forward Density of inlet fluid (kg-mol/m3)

MWf – Forward Molecular weight of inlet fluid (kg/kg-mol)

iStrmEi –Inlet Stream elevation connected to upstream flow or pressure node Ei (m)

iStrmEx –Inlet Stream elevation connected to pump Ex (m)

If NPSHA < NPSHR, the fluid is vaporizing at pump inlet and pump is cavitating. The Cavitating

Flag of Pump is set to True.

Otherwise if NPSHA > NPSHR, the fluid is all liquid and there is no problem of Cavitation in

pump and hence Cavitating Flag is set to False.

Base Equipment Version 5.3.2, December 2016 268

Pump

Example

The following example shows the configuration of a Pump with default operating curve. A

centrifugal Pump (P1) is used to Pump water flowing at the rate of 36 m3/hr from 110 kPa to

936.5 kPa. The suction pressure of the Pump is maintained at 110 kPa using a pressure PID

controller (PC1).

Since a default performance curve is used only one design point needs to be specified which is set

through the scaling parameters. Therefore QScale is 36 m3/hr and DHScale is 84.5 m. It is

assumed that the Pump has a uniform efficiency of 0.8. The reference speed of the Pump is set at

3600 rpm. The Motor sets the speed of the Pump. The Motor is connected to pump via a

mechanical stream. Reverse flow is expected to occur when the head across the Pump exceeds

the shutoff head; so reverse flow conductance is set at 1. The suction and discharge Valves have

Cv of 100.

SOURCE: WATER

Parameter Assignment UOM Description

OProdStream[0] S1 Source product stream connecting to Valve XV1

Mb[H2O] 1 fraction Boundary composition

Spec PT Boundary condition specification

Pb 120 kPa Boundary pressure

Tb 300 K Boundary temperature

VALVE: XV1

Parameter Assignment UOM Description

OFeedStream S1 Valve feed stream connecting from Source WATER

OProdStream S2 Valve product stream connecting to Header H2

Cv 100 Valve Cv

Op PC1.OUT fraction Pressure PID controller output connected to Valve

open command

HEADER: H2

Parameter Assignment UOM Description

OFeedStream[0] S2 Header feed stream connecting from Valve XV1

OProdStream[0] S3 Header product stream connecting to Pump P1

Vol 6 m3 Header volume

Base Equipment Version 5.3.2, December 2016 269

Pump

PID: PC1

Parameter Assignment UOM Description

Header pressure attached to the PV

PV H2.P kPa

of pressure PID controller

Set point of the pressure PID

SP 110 kPa

controller

Action SP-PV PID controller action

KP 1 PID controller proportional gain

KI 0.025 1/sec PID controller integral gain

Hi_In 500 kPa High limit on PID controller input

Lo_In 0 kPa Low limit on PID controller input

Hi_Out 1 High limit on PID controller output

Lo_Out 0 Low limit on PID controller output

PUMP: P1

Parameter Assignment UOM Description

OFeedStream S3 Pump feed stream connecting from Header H2

OProdStream S4 Pump product stream connecting to Valve

XV2

Interpolation LINEAR Performance curve interpolation method

Method

QScale 36 m3/hr Scale factor for flow

DHScale 84.5 m Scale factor for head

ETAScale 0.8 fraction Scale factor for efficiency

SpeedRef 3600 rpm Reference speed

J 0.05 (kg/sec)/sqrt Wind milling flow conductance

(kPa-kg/m3)

KJr 1 fraction Reverse flow factor

OMechStream MS1 Mechanical stream attached to the Pump

MOTOR: MS1

Parameter Assignment UOM Description

Mechanical stream attached to the

OMechStream MS1

Pump

SpeedRef 3600 rpm Full speed reference

VALVE: XV2

Parameter Assignment UOM Description

OFeedStream S4 Valve feed stream connecting from Pump P1

OProdStream S6 Valve product stream connecting to Sink SNK1

Cv 100 Valve Cv

Op 1 fraction Valve open command

SINK: SNK1

Parameter Assignment UOM Description

Sink feed stream connecting from

OFeedStream[0] S6

Valve XV2

Pb 919 kPa Boundary pressure

Base Equipment Version 5.3.2, December 2016 270

Pump

Data Entry Window Usage

Basic Tab

Pump Design Conditions

The flow curve scale corresponds to the QScale parameter. To configure the default performance

curve, set the design flow using this parameter. It is also used for scaling user defined

performance curve if one is provided.

The head curve scale corresponds to the DHScale parameter. To configure the default

performance curve, set the design head value with parameter. It is also used for scaling user

defined performance curve if one is provided.

Base Equipment Version 5.3.2, December 2016 271

Pump

The efficiency curve scale corresponds to the ETAScale parameter. The default efficiency curve

assumes a uniform efficiency of 1. It can be used to scale the default curve or user defined

efficiency curve.

The reference Shaft speed corresponds to the SpeedRef parameter. The design speed of the

Pump is set here. It is used to adjust the Pump curves based on fan laws. The actual value is only

required if speed is set by a Motor or Shaft using a mechanical stream.

Wind milling and Reverse Flow

The flow conductance corresponds to the J parameter. The Pump performs like any simple flow

device when operating at zero speed or when wind milling. The default value can be used if flow

at zero speed or wind milling is not important.

The reverse flow factor corresponds to the KJr parameter. If there is a check valve in line with

the Pump, use the default value of zero.

Other Parameters

Calculate Outlet Properties corresponds to the FlashFlag parameter. Check this box to calculate

outlet stream parameters such as temperature, density, and vapor fraction rather than pass them

down from the upstream conditions. This selection will not have any impact on the overall energy

balance, but may impact the pressure profile since the density to the downstream flow device, if

there is one, will be calculated.

Predict Cavitation by NPSHA corresponds to the CalcNPSH parameter. Check this box to

calculate Net Positive Suction Head Available and predict cavitation of pump. When this flag is

turned on, user has an option to select Vapor pressure calculation method out of SIMPLE and

RIGOROUS options. SIMPLE option requires user input of Fluid vapor pressure and when

RIGOROUS option is selected, Pump model does a bubble point flash at the pump inlet to predict

the vapor pressure of the fluid when there is no vapor in inlet stream.

Base Equipment Version 5.3.2, December 2016 272

Pump

Curves Tab

Use default curve corresponds to the UseDefaultCurve parameter. Check this box to use the

default performance curve. The design flow and head can be set through the parameters QScale

and DHScale when default curve is used.

When the check box to use default performance curve is not checked, the user specified

performance curve can be set. The flow rate, head and efficiency correspond to the parameters

QData, DHData and ETAData respectively. A minimum of three data points should be

specified. The user can add more points by adding new rows to the existing table. It is not

possible to specify the UOM of the QData, DHData, and ETAData curves because the curve

UOM is defined by the scale parameters on the Basic tab.

The parameters QScale, DHScale, and ETAScale adjust both the default curve or the user

specified curve. Either the curve data can be normalized or the scale values can be normalized.

What is important is that the product of the data and the scale parameters equal the user desired

curve.

Base Equipment Version 5.3.2, December 2016 273

Pump

Solution Options Tab

The interpolation method corresponds to the InterpolationMethod parameter. If the number of

user defined points is less than five, Cubic Spline should be preferred over Linear.

Base Equipment Version 5.3.2, December 2016 274

Pump

External Inputs Tab

The External Inputs Tab is used to set dynamic parameters. Only the initial value of these

parameters can be set through the Data Entry Window. Parameter references and equations can

be attached to these parameters. The numerical value of these parameters cannot be changed in

the running engine through Data Entry Window and will have no affect on the running model.

External Speed Calculations

Shaft speed corresponds to the Speed parameter. No entry is required if the Pump is connected

with a mechanical stream.

Base Equipment Version 5.3.2, December 2016 275

Pump

Thermo Tab

Thermo Options

Component slate corresponds to the CompSlate parameter, Method Slate to the MethodSlate

parameter, Local thermo options to the LocalThermoOption parameter, and Local flash options

to the LocalFlashOption. To avoid having set these parameters for each new equipment on the

flowsheet, specify the defaults in the SIM4ME thermo GUI.

Phase Options

Internal Phases corresponds to the InternalPhases parameter. Use this to specify the kind of

flash performed by SIM4ME Thermo. The default value is VLE. However, Pump execution

speed should be faster if this parameter is changed to Liquid.

Base Equipment Version 5.3.2, December 2016 276

Pump

Notes Tab

Base Equipment Version 5.3.2, December 2016 277

Pump

Parameter Table

Basic

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Scale factor for head curve

DHScale multiplied by the DHData array define

DHScale the performance curve head data. If DHData and

KD 1 Yes m

QData are not specified, DHScale defines the

normal operating head using the default internal

performance curve.

Scale factor for efficiency curve

ETAScale multiplied by the ETAData array define

the efficiency curve data. If QData and ETAData

ETAScale DD 1 Yes fraction

are not specified, ETAScale defines the normal

operating efficiency using the default internal

performance curve.

Flash flag

Flag to perform a flash on the outlet stream to

calculate properties for the downstream equipment.

FlashFlag If false, outlet density, temperature, and vapor KI 0 No

fraction will be assumed the same as the upstream

conditions. Setting to true increases computation

time.

Interpolation method

Allowable options are:

0 = CUBICSPLINE

Interpolation

1 = LINEAR KI 0

Method

If the number of user defined points is less than

five, CUBICSPLINE should be preferred over

LINEAR..

Flow Conductance

(kg-sec)/

Flow conductance defined by the equation W = J *

J KD 0.05 Yes sqrt(kPa-

sqrt (∆P * R) where W is mass flow, ∆P is pressure

kg/m3)

drop, and R is mass density in internal units.

Reverse flow factor

This factor represents the fraction of the forward

KJr flow conductance available for reverse flow. A KD 0 Yes fraction

value of zero will make the conductance device act

like a check valve.

Scale factor for volumetric flow curve

QScale multiplied by the QData array define the

performance curve volumetric data. If DHData

QScale and KD 0.000277 Yes m3/sec

QData are not specified, QScale defines the normal

operating flow using the default internal

performance curve.

Shaft speed reference

SpeedRef KD 3600 Yes rpm

This is the reference speed used by the performance

Base Equipment Version 5.3.2, December 2016 278

Pump

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

curve. Performance at other speeds is predicted

using the fan laws.

Curves

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Head curve

DHScale multiplied by the DHData array define the

performance curve head data. If DHData and User

DHData KD 0 Yes

QData are not specified, DHScale defines the Defined

normal operating head using the default internal

curve.

Efficiency curve

ETAScale multiplied by the ETAData curve

User

ETAData represents the efficiency points of the performance KD 1 Yes

Defined

curve. If ETAData is not specified, ETAScale

defines a constant efficiency.

Volumetric flow curve

QScale multiplied by the QData curve represents the

flow portion of the performance curve. If DHData User

QData KD 0 Yes

and QData are not specified, QScale represents the Defined

reference flow using the default internal

performance curve.

Use default curve

Flag to use default performance curve. The user

can use the built in performance curve by specifying

UseDefaultCurve KI 1 No

the operating point against the flow and head

scaling parameters. If this flag is not checked, the

user should set the performances curve.

External Inputs

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Pump speed

When no mechanical stream is connected the user can set the

Speed speed directly or through parameter referencing. This value DD 3600 Yes rpm

is set by a Shaft or Motor if a mechanical stream is connected

to the Pump.

Base Equipment Version 5.3.2, December 2016 279

Pump

Advanced

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Exponent of head for speed

HSExp KD 2 Yes

Exponent for speed on Head, defaults to fan law value of 2.0

Maximum slope of the curve

The performance curve may be adjusted by this value to ensure

KHMax that the actual curve used by the model is monotonic. A higher KD 3 Yes

value leads to a steeper curve near the zero head range that

can lead to potential pressure flow convergence problems.

Minimum slope of the curve

The performance curve may be adjusted by this value to ensure

KHMin that the actual curve used by the model is monotonic. A lower KD 0.2 Yes

value defines a flatter curve near the zero flow range that can

lead to potential pressure flow convergence problems.

Exponent of flow for speed

QSExp KD 1 Yes

Exponent for speed on flow, defaults to fan law value of 1.0

Calculated values

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Actual head

DH DD 0 No m

Pump head defined in length units.

Pump efficiency

ETA DD 1 No fraction

Pump isentropic efficiency

Pump power demand

Power required by the Pump. This value is negative. The

Power DD 0 No kW

power required to drive a Pump can be obtained from a

Expander, Motor connected via a mechanical stream.

Actual volumetric flow

Q DD 0 No m3/sec

Actual volumetric flow through the Pump.

Topology

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Feed Stream

Pump feed stream. Identifies the feed, or inlet,

stream and its associated fluid properties. This entry

must be unique to all other feed streams in the

OFeedStream flowsheet. However, this entry can be the same as a STREAM

product stream identifier from another unit.

OFeedStream and OProdStream cannot be the same.

Only one feed stream can be connected to the flow

devices.

Mechanical stream connection

OMechStream Identifies the mechanical stream and associated STREAM

mechanical properties. This entry can be same as

Base Equipment Version 5.3.2, December 2016 280

Pump

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

mechanical stream identifier to another unit. When a

mechanical stream is connected to the Shaft, the Shaft

sets the speed of the Pump. Only one mechanical

stream can be connected from an Pump.

Product Stream

Pump product stream. Identifies the product, or

outlet, stream and its associated fluid properties.

Enter up to twelve alphanumeric characters. This

entry must be unique to all other product streams in

OProdStream STREAM

the flowsheet. However, this entry can be the same

as a feed stream identifier to another unit.

OFeedStream and OProdStream can not be the same.

Only one product stream can be connected from the

flow devices.

NPSH

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Indication that pump is Cavitating. Calculated by DB 0 No

NPSH calculations from suction fluid vapor pressure

Cavitating

and inlet stream pressure. This value is for display

only and does not affect the solution.

CalcNPSH If set to true, NPSH calculations are enabled to KB 0 No

predict pump cavitation.

NPSHR NPSH Required needs to be supplied for performing KD 0 No m

NPSH calculations.

NPSHA NPSH available is calculated by pump model to DD 0 No m

predict cavitation condition

Pvap Vapor pressure of fluid at pump inlet conditions. It DD 0 Yes kPa

will be predicted by bubble point flash at pump inlet.

PvapUser Vapor pressure of fluid at pump inlet conditions. DD 0 Yes kPa

Needs to be supplied if VPCalcMethod is SIMPLE.

VPCalcMethod Vapor pressure calculations for NPSH calculations. KI SIMPLE No

Options include:

0 – SIMPLE

1 – RIGOROUS

NPSHFlashFreq Frequency of NPSH bubble point flash calculation. KI 1 No

At this user specified time interval, a T-VF(Bubble

Point) flash will be performed on the inlet fluid

conditions with VF = 0.0 to predict vapor pressure

of the fluid.

FlashTime Elapsed time steps when VPCalcMethod is KI No

RIGOROUS. For internal viewing only.

Base Equipment Version 5.3.2, December 2016 281

Pump

Legend:

Dfl Cls Default parameter class:

KB - Static Boolean SB - State Boolean DB - Dynamic Boolean

KI - Static Integer SI - State Integer DI - Dynamic Integer

KF - Static Float SF - State Float DF - Dynamic Float

KD - Static Double SD - State Double DD - Dynamic Double

Dft Val A value here indicates the parameter’s default value. If the parameter is static, no

value indicates that the parameter is optional unless otherwise noted.

Eq Ok An equation can be attached to the parameter if the corresponding value is Yes.

Arr Siz A value here if indicates the size of the array. No value indicates that the parameter is

not a vector.

UOM Internal units of measure.

Please refer to the Base Equipment Fundamentals section for pressure node base

parameters, flow device base parameters, and parameters associated with the flash or

reaction submodel.

Base Equipment Version 5.3.2, December 2016 282

Pump

FAQ

Q. What are the Pump and Compressor scale parameters for?

A. If you do not have a performance curve, use the scale parameters to set the design conditions

to use the default built in curve. If you do have a Pump curve, use the scale parameter to adjust

the performance curve without having to reenter all the performance curve data. When you enter

your own curve, you have the option of either normalizing the curve and inputting the design

parameters in the scale values, or putting the curve in as it is and making the scale values one.

Either way, it is the product of the scale parameter and the performance curve that defines the

actual curve used by DYNSIM model.

Q. How do I start a Compressor or Pump?

A. You must attach a driver. The simplest way is to place a Motor on the canvas. Connect the

Motor to the Compressor or Pump with a mechanical stream. Specify the maximum Motor

speed. When you start the simulation, double-click on the Motor to bring up its operator panel.

Then press start button.

Q. How do I add more rows to my Pump curve table?

A. Refer to the FAQ section under Compressor for details on inserting rows in a user defined

curve table.

Base Equipment Version 5.3.2, December 2016 283

Shaft

Shaft

Introduction

Shaft is a mechanical torque coupling for Pumps, Compressors, Expanders and Motors. When a

Motor is not connected, the Shaft models the rotational inertia of all the rotating equipment on the

Shaft to calculate the angular acceleration. When connected to a Motor, the Motor sets the Shaft

speed.

When multiple speed setting devices are connected to the shaft, the last connected driver

will set the speed of the shaft and rest are ignored.

Base Equipment Version 5.3.2, December 2016 284

Shaft

Fundamentals

Power Balance Algorithm

The rotational net power balance equation determines the net rotational power on the Shaft.

Mechanical NJapply NJload

J Net = ∑

Streams

Power + ∑ J Apply −

i =1

∑J Load − J Friction

Speed

R=

Speed Re f

J Friction = J Friction Re f ⋅ [ KA + KB * (R ) + KC * (R ) + KD * (R ) + KE * (R )

2 3 FExp

]

where:

FExp - Exponent of the KE term

JApply - Additional power applied to the Shaft (kJ/sec)

JFrictionRef - Reference power loss due to friction (kJ/sec)

JLoad - Additional power load on Shaft (kJ/sec)

JNet - Net shaft power (kJ/sec)

KA, KB, KC, KD, and KE - Friction coefficients

NJapply - Number of additional powers apply to the Shaft

NJload - Number of additional powers load to the Shaft

Power - Power transmitted from Expander/Pump/Compressor/Motor to Shaft (kJ/sec)

Speed - Shaft speed (rpm)

Speed Ref - Reference Shaft speed (rpm)

The rate of change of speed is given by the following equation

d J Net

Speed = KACNV ⋅

dt I ⋅ Speed

When Speed is below a user specified threshold value (SpeedLin) the following equation is used

d J Net

Speed = KACNV ⋅

dt I ⋅ SpeedLin

where:

10 3

KACNV - Conversion factor =

(2π / 60)2

I - Inertia of the Shaft (kg-m2)

Speed - Current Shaft speed (rpm)

SpeedLin - Linearized Shaft speed (rpm)

Base Equipment Version 5.3.2, December 2016 285

Shaft

Speed set by Motor

If a Motor object is attached to the Shaft, the Motor will set the speed of the Shaft and the

rotational inertia will not be used. The dynamics will be determined by the Motor ramp time.

Base Equipment Version 5.3.2, December 2016 286

Shaft

Example

The following example shows the application of a Shaft (SHAFT1) to drive two pumps (P1,P2).

Motor (M1) supports only one mechanical stream, so if it has to be connected to more than one

Pump then a Shaft must be used. A Motor is connected to the Shaft via a mechanical stream. So

Motor sets the speed of the Shaft. The Shaft is connected to the two pumps via two different

mechanical streams. So the Shaft sets the speed of the pumps.

MOTOR: M1

Parameter Assignment UOM Description

OMechStream[0] MS1 Mechanical stream connecting

Motor to the Shaft SHAFT1

SHAFT: SHAFT1

Parameter Assignment UOM Description

OMechStream[0] MS1 Mechanical stream connecting

Motor M1 to the Shaft

OMechStream[1] MS2 Mechanical stream connecting

Shaft to the Pump P1

OMechStream[2] MS3 Mechanical stream connecting

Shaft to the Pump P2

SOURCE: SCR1

Parameter Assignment UOM Description

OProdStream[0] S1 Source product stream connecting to Pump P1

OProdStream[1] S3 Source product stream connecting to Pump P2

Mb[H2O] 1 fraction Boundary composition

Spec PT Boundary condition specification

Pb 110 kPa Boundary pressure

Tb 300 K Boundary temperature

Base Equipment Version 5.3.2, December 2016 287

Shaft

PUMP: P1

Parameter Assignment UOM Description

OMechStream[0] MS2 Mechanical stream connecting

Shaft SHAFT1 to the Pump

OFeedStream S1 Pump feed stream connecting from

Source SCR1

OProdStream S2 Pump product stream connecting to

Sink SNK1

QScale 5 m3/hr Scale factor for flow

DHScale 25 m Scale factor for head

PUMP: P2

Parameter Assignment UOM Description

OMechStream[0] MS3 Mechanical stream connecting

Shaft SHAFT1 to the Pump

OFeedStream S3 Pump feed stream connecting from

Source SCR1

OProdStream S4 Pump product stream connecting to

Sink SNK1

QScale 5 m3/hr Scale factor for flow

DHScale 25 m Scale factor for head

SINK: SNK1

Parameter Assignment UOM Description

Sink feed stream connecting from

OFeedStream[0] S2

Pump P1

Sink feed stream connecting from

OFeedStream[0] S4

Pump P2

Pb 250 kPa Boundary pressure

Base Equipment Version 5.3.2, December 2016 288

Shaft

Data Entry Window Usage

Basic Tab

Shaft Inertia

Inertia of rotor and all components correspond to the Inertia parameter. It affects the speed

dynamics of the Shaft. For faster dynamics lower value of inertia should be used. The user

should use manufacturer supplied data. If data is not available adjust this value for desired speed

dynamics.

Power required to start roll corresponds to the JBreak parameter. The default value can be used

in most of the cases.

Base Equipment Version 5.3.2, December 2016 289

Shaft

Friction Loss Tab

Shaft Friction

Power loss at reference speed corresponds to the JFrictionRef parameter. The user may change

this value to account for friction losses. The power loss due to friction is usually negligible when

default setting is used.

Reference Shaft speed corresponds to the SpeedRef parameter. It is used in the power loss due to

friction calculations.

Friction loss coefficients correspond to the KA, KB, KC, KD, and KE parameters. User defined

exponent of KE term corresponds to the FExp.

Base Equipment Version 5.3.2, December 2016 290

Shaft

External Inputs Tab

Only parameter references can be entered on this Data Entry Window.

Power Applied

Other power applied to Shaft corresponds to the JApply parameter. Any number of other powers

can be applied on the Shaft.

External Loads

Other power loads on the Shaft corresponds to the JLoad parameter. Any number of external

power loads can be applied on the Shaft.

Base Equipment Version 5.3.2, December 2016 291

Shaft

Notes Tab

Base Equipment Version 5.3.2, December 2016 292

Shaft

Parameter Table

Basic

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Moment of inertia for the Shaft

Inertia A large value makes the Shaft respond more slowly. A value KD 15000 Yes kg-m2

too, small can lead to numerical instability.

Power to start roll

JBreak The Shaft will not start turning until this minimum power is KD 0.1 No kJ/sec

applied.

Friction Loss

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Exponent of KE term 1

FExp KD Yes

Friction exponent term

Frictional power loss at ref speed

The Shaft loses this much power due to friction at the

JFrictionRef KD 0.001 No kJ/sec

reference speed. Friction loss is a function of the speed

squared.

Friction coefficient

KA KD 0 Yes

Friction coefficient

Friction coefficient

KB KD 0 Yes

Friction coefficient

Friction coefficient

KC KD 1 Yes

Friction coefficient

Friction coefficient

KD KD 0 Yes

Friction coefficient

Friction coefficient

KE KD 0 Yes

Friction coefficient

Reference Shaft speed

SpeedRef KD 3600 No rpm

Reference speed for friction loss.

External Inputs

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Other power applied to Shaft

User-

JApply Additional power to applied to Shaft. A positive value DD Yes kJ/sec

Defined

will increase Shaft speed

Other power loads on Shaft

User-

JLoad Additional power load on Shaft A positive value will DD Yes kJ/sec

Defined

decrease Shaft speed.

Base Equipment Version 5.3.2, December 2016 293

Shaft

Advanced

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Linearization Speed

Derivative of Shaft speed is linear with JNet when speed is

SpeedLin KD 60 No rpm

below SpeedLin and linear with Jnet /Speed when speed is

above SpeedLin.

Critical coast down speed

SpeedZero Speed will be instantly set to zero when the speed drops KD 2 No rpm

below this value.

Speed derivative limit

This value limits the derivative of shaft speed (DSPEED).

DSpeed Max KD 500 No rpm/sec

Mathematically,

-DSPEEDMAX=<DSPEED<=DSPEEDMAX

Base Equipment Version 5.3.2, December 2016 294

Shaft

Calculated Values

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Speed Derivative

Derivative of Shaft speed. This value is calculated from the

dSpeed work balance of all the components connected to the Shaft DD 0 No rpm/sec

(JNet). A positive value of Net Power (Jnet) indicates that

the Shaft is speeding up.

Net shaft power

JNet DD 0 No kJ/sec

Sum of all power applied to Shaft and loads on Shaft.

Gross shaft power

JGross DD 0 No kJ/sec

Sum of all power applied

Power loss due to friction

JFriction DD 0 No kJ/sec

Friction loss is a function of the speed squared.

Shaft speed

Speed Speed of the Shaft. Sets the speed of all devices connected to SD 0 No rpm

it other than a Motor. A Motor can set the Shaft speed.

Derivatives

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Speed Derivative

Derivative of Shaft speed. This value is calculated from the

dSpeed work balance of all the components connected to the Shaft DD 0 No rpm/sec

(JNet). A positive value of Net Power (Jnet) indicates that

the Shaft is speeding up.

States

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Shaft speed

Speed Speed of the Shaft. Sets the speed of all devices connected to it SD 0 No rpm

other than a Motor. A Motor can set the Shaft speed.

Topology

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Mechanical Streams

MECH

OMechStream Mechanical stream connected to Motor or other

STREAM

devices like Expander with the Shaft.

Base Equipment Version 5.3.2, December 2016 295

Shaft

Legend:

Dfl Cls Default parameter class:

KB - Static Boolean SB - State Boolean DB - Dynamic Boolean

KI - Static Integer SI - State Integer DI - Dynamic Integer

KF - Static Float SF - State Float DF - Dynamic Float

KD - Static Double SD - State Double DD - Dynamic Double

Dft Val A value here indicates the parameter’s default value. If the parameter is static, no

value indicates that the parameter is optional unless otherwise noted.

Eq Ok An equation can be attached to the parameter if the corresponding value is Yes.

Arr Siz A value here if indicates the size of the array. No value indicates that the parameter is

not a vector.

UOM Internal units of measure.

Please refer to the Base Equipment Fundamentals section for pressure node base

parameters, flow device base parameters, and parameters associated with the flash or

reaction submodel.

Base Equipment Version 5.3.2, December 2016 296

Sink

Sink

Introduction

Sink is a pressure node that sets the outlet boundary conditions for any simulation. It can take

any number of feed streams. Sink does not perform any flash calculations.

Sink should be used only when reverse flow is not expected. Upstream flow devices should

include a check valve. If reverse flow to the Sink is to be allowed, use a Source model instead

which can set the composition and energy for the reversing stream.

Base Equipment Version 5.3.2, December 2016 297

Sink

Fundamentals

Boundary Specifications

The Sink is used for setting outlet boundary pressure in any simulation. The boundary value sets

the pressure for all streams connected to it.

Feed Streams

The Sink can be used only for setting the outlet boundary conditions. It can take only feed

streams. No product stream can be connected to Sink. It can take any number of feed streams.

Reverse flow

Sink should not be used when reverse flow is expected since the user cannot set composition and

energy content during reverse flow. If reverse flow does occur, the Sink reflects the feed stream’s

composition and enthalpy. For predictable reverse flow calculations, use a Source model with

feed streams connected to it. If it is not required to model reverse flow, set the KJr parameter for

a flow device in each flow path entering the Sink zero.

Elevation

Elevation can be specified for a Sink relative to a reference common to all pressure nodes. The

specified elevation impacts the pressure drop calculations in the network, which in turn influences

the flow calculations in the associated flow devices.

Base Equipment Version 5.3.2, December 2016 298

Sink

Example

The following example shows use of a Sink unit in specifying a pressure boundary and elevation

settings. The Sink is used for setting boundary pressures for a Valve (XV1), Stream Set (SS1)

and Pump (P1). The Source unit SRC1 supplies water at 250 kPa and 300 K. The pressure drop

across the valve and Stream Set is 140 kPa and the Sink boundary pressure is set at 110 kPa. The

Pump delivers water to a unit at the same pressure as the Source but over an elevation head of

8m. The Sink pressure and elevation are set at 250 kPa and 8 m, respectively.

SOURCE: SRC1

Parameter Assignment UOM Description

Source product stream connecting to

OProdStream[0] S1

the Valve XV1

Source product stream connecting to

OProdStream[1] S3

the Stream Set SS1

Source product stream connecting to

OProdStream[2] S5

the Pump P1

Mb[H20] 1 kg-mol Boundary composition

Spec PT Boundary condition specification

Pb 250 kPa Boundary pressure

Tb 300 K Boundary temperature

VALVE: XV1

Parameter Assignment UOM Description

Valve feed stream connecting from

OFeedStream S1

Source SRC1

Valve product stream connecting to

OProdStream S2

Sink SNK1

Cv 100 Cv Valve Cv

Op 1 fraction Valve opening command

Base Equipment Version 5.3.2, December 2016 299

Sink

STREAM SET: SS1

Parameter Assignment UOM Description

Stream Set feed stream connecting

OFeedStream S3

from Source SRC1

Stream Set product stream

OProdStream S4

connecting to Sink SNK1

kg-sec/sqrt(kPa-

J 0.01 Stream Set flow conductance

kg/m3)

SINK: SNK1

Parameter Assignment UOM Description

Sink feed stream connecting from

OFeedStream[0] S2

Valve XV1

Sink feed stream connecting from

OFeedStream[1] S4

Stream Set SS1

Pb 110 kPa Boundary pressure

PUMP: P1

Parameter Assignment UOM Description

Pump feed stream connecting from

OFeedStream S5

Source SRC1

Pump product stream connecting to

OProdStream S6

Sink SNK2

QScale 0.01 m3/sec Pump flow scale curve parameter

DHScale 10 m Pump head scale curve parameter

SINK: SNK1

Parameter Assignment UOM Description

Sink feed stream connecting from

OFeedStream[0] S6

Pump P1

Pb 250 kPa Boundary pressure

Elevation 8 m Sink elevation

Base Equipment Version 5.3.2, December 2016 300

Sink

Data Entry Window Usage

Basic Tab

Boundary Conditions

The boundary pressure corresponds to the Pb parameter.

Pressure Node Elevation

Relative elevation corresponds to the E parameter. It is the elevation of the Sink with respect to

other pressure nodes. If no elevation effects are required, the default value can be left in place.

Base Equipment Version 5.3.2, December 2016 301

Sink

Notes Tab

Base Equipment Version 5.3.2, December 2016 302

Sink

Parameter Table

Basic

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Elevation

E Elevation relative to local KD 0 No m

ground level.

Boundary Conditions

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Boundary pressure

Pb Boundary pressure in the Sink. KD Yes kPa

Must be specified.

Topology

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Feed streams

Sink feed stream. Can be connected only from

flow devices. Identifies the feed, or inlet, stream

and its associated fluid properties. This entry

must be unique to all other feed streams in the User

OFeedStream STREAM No

flowsheet. However, this entry can be the same Specified

as a product stream identifier from another unit.

OFeedStream and OProdStream cannot be the

same. Any number of feed streams can be

connected to the Sink.

Legend:

Dfl Cls Default parameter class:

KB - Static Boolean SB - State Boolean DB - Dynamic Boolean

KI - Static Integer SI - State Integer DI - Dynamic Integer

KF - Static Float SF - State Float DF - Dynamic Float

KD - Static Double SD - State Double DD - Dynamic Double

Dft Val A value here indicates the parameter’s default value. If the parameter is static, no

value indicates that the parameter is optional unless otherwise noted.

Eq Ok An equation can be attached to the parameter if the corresponding value is Yes.

Arr Siz A value here if indicates the size of the array. No value indicates that the parameter is

not a vector.

UOM Internal units of measure.

Please refer to the Base Equipment Fundamentals section for pressure node base

parameters, flow device base parameters, and parameters associated with the flash or

reaction submodel.

Base Equipment Version 5.3.2, December 2016 303

Sink

FAQ

Q. How do I model the correct reverse flow properties from a Sink?

A. A Sink model cannot effectively model reverse flow. It is recommended that you either

prevent reverse flow to the Sink by setting one of the flow device KJr parameters to zero, or

replace the Sink with a Source model. If you use a Source, you can specify the composition and

energy content of the fluid used for reverse flow, as you would specify it in any other Source

model.

Base Equipment Version 5.3.2, December 2016 304

Source

Source

Introduction

Source is pressure node that sets the inlet and outlet boundary conditions for the simulation

model. It is the starting point for all the flowsheets. Any number of feed and product streams can

be connected to it.

Source can also be used to model a Sink where reverse flow may occur. For this case the Source

accepts feed streams. When the feed stream flow reverses, the Source will set the feed stream

composition and energy content.

Source cannot model a flow boundary. A Stream Set must be used to force the flow at the

beginning of a simulation. The user should provide a Source followed by a Stream Set followed

by a pressure node for this configuration.

Source can be used to initialize the holdup in other equipment models. Please refer to Holdup

Initialization in the Base Equipment Fundamentals.

Base Equipment Version 5.3.2, December 2016 305

Source

Fundamentals

Boundary specifications

The Source is the starting point for all simulations. The user sets the inlet composition and

specifies the boundary conditions. There are three different boundary specification conditions

that can be set in the Source. They are Pressure-Temperature, Pressure-Enthalpy, and Pressure-

Vapor Fraction. Source does appropriate flash calculations based on the type of specification and

sets all the properties of the connected streams accordingly.

Pressure-Temperature specification is used for most cases. Pressure-Enthalpy specification can

be used when the enthalpy values are known, used typically with single component slates such as

steam. Pressure-VaporFraction specification is used when the feed temperature is at the bubble

point, dew point, or between these two points.

Feed and Product Streams

Source is infinite source of inventory. Any number of product streams can be connected to it.

Source can also act as a Sink, such that it can act as an end point in the Flowsheet. It can take any

number of feed streams. Since Source is a pressure node, only flow devices can be directly

connected to it.

Flash

The type of flash performed depends on the type of boundary specification selected. Product

stream properties are updated based on the flash in forward flow while it sets only the pressure in

case of reverse flow. Similarly, feed stream properties are updated based on the flash for reverse

flow and only the pressure is set in the case of forward flow.

Reverse Flow

Source should be used as Sink when reverse flow is expected. It sets the user defined

composition and temperature in the inlet stream.

Initialization of Equipment Holdups

Any equipment model with holdup, like Header, Pipe, Heat Exchanger, Drum or Separator, can

be initialized with the conditions of a Source model. The Source can be standalone or part of the

model. Usually Source close to the upstream of the holdup device is used for initialization. This

will help the system get initialized to conditions close to the steady state when the model is

loaded. When there is no Source with conditions close to desired steady state, a standalone

Source without any stream connections can be used for initialization of the holdup device. The

component, method slates, and other thermodynamic conditions and the flash options should be

same for the holdup device and the Source to which it is initialized.

Base Equipment Version 5.3.2, December 2016 306

Source

Elevation

Elevation can be specified for a Source relative to a reference common to all pressure nodes. The

specified elevation impacts the pressure drop calculations in the network, which in turn influences

the flow calculations in the associated flow devices.

Base Equipment Version 5.3.2, December 2016 307

Source

Data Entry Window Usage

Basic Tab

Boundary Conditions

Flash specification corresponds to the Spec parameter. Pressure-Temperature specification is

used for most cases. Pressure-Enthalpy specification can be used when the enthalpy values are

known, used typically with single component slates. Pressure-VaporFraction specification is

typically used when the feed temperature is between the bubble point and dew point.

Boundary Pressure, Temperature, Enthalpy and Vapor fraction correspond to Pb, Tb, Hb and

VFb parameters. Pb should be set for all cases. The other parameters should be set, based on the

boundary specification type.

Base Equipment Version 5.3.2, December 2016 308

Source

Unnormalized Composition

Composition basis corresponds to the CompBasis parameter.

Unnormalized composition corresponds to the Mb parameter. The composition can be set in

terms of mole fractions or component moles. The user should set these values.

Pressure Node Elevation

Relative elevation corresponds to the E parameter. It is the elevation of the pressure node with

respect to the reference ground level. If no elevation effects are required, the default value can be

left in place.

Base Equipment Version 5.3.2, December 2016 309

Source

Thermo Tab

Thermo Options

Component slate corresponds to the CompSlate parameter, Method Slate to the MethodSlate

parameter, Local thermo options to the LocalThermoOption parameter, and Local flash options

to the LocalFlashOption To avoid having to set this parameter for each new equipment on the

flowsheet, specify the defaults in the SIM4ME thermo GUI.

Phase Options

Internal Phases corresponds to the InternalPhases parameter. Use this to specify the kind of

flash performed by SIM4ME Thermo. External Phases correspond to the ExternalPhases

parameter.

Base Equipment Version 5.3.2, December 2016 310

Source

Notes Tab

Base Equipment Version 5.3.2, December 2016 311

Source

Parameter Table

Basic

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Elevation

E KD 0 No m

Elevation relative to local ground level.

Boundary Conditions

Parameter Dft Dft Eq Arr

Description UOM

Name Cls Val Ok Siz

Name of assay

This entry specifies the name of the assay used for the

AssayName initialization of composition. This should be a specified KI None No

if the composition basis is ASSAY. Should be consistent

with the component slate.

Composition basis specification