Beruflich Dokumente

Kultur Dokumente

TR 10 RTD PDF

Hochgeladen von

Jhon Piter ManaluOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TR 10 RTD PDF

Hochgeladen von

Jhon Piter ManaluCopyright:

Verfügbare Formate

Electrical

temperature measurement

Threaded resistance thermometer

Model TR10-D, miniature design

WIKA data sheet TE 60.04

for further approvals

see page 5

Applications

■■ Machine building, plant and vessel construction

■■ Propulsion technology

■■ Air-conditioning and refrigeration systems

Special features

■■ Application ranges from -200 ... +500 °C (-328 ... +932 °F)

■■ Compact design

■■ Universal application

■■ Direct installation into the process

■■ Explosion-protected versions

Description

Resistance thermometers of this series are used for the

Threaded resistance thermometer, miniature design,

measurement of liquid or gaseous media at low and medium

model TR10-D

pressures.

The resistance thermometer is screwed directly into the

process. The electrical connection is made via connection

terminals in the connection head (splash-proof). The measu-

ring inserts are available in two variants, depending upon the

application. The choice is between a replaceable, spring-

loaded miniature measuring insert and a non-replaceable,

permanently screwed-in design.

Insertion length, process connection and sensor can each be

selected for the respective application.

WIKA data sheet TE 60.04 ∙ 04/2016 Page 1 of 5

Data sheets showing similar products:

Thermocouple for additional thermowell; model TC10-B; see data sheet TE 65.02

Cable resistance thermometer; model TR40; see data sheet TE 60.40

Sensor Measuring insert

The sensor is located in the tip of the thermometer or Removable design

measuring insert, respectively. Using two screws and springs, the measuring insert can be

mounted into a connection head (form J), replaceable and

Sensor connection method mounted spring-loaded into the thermowell.

■■ 2-wire

■■ 3-wire

■■ 4-wire Fixed design

The measuring insert is manufactured as a unit (as a tube

Sensor tolerance value per DIN EN 60751 assembly in a thermowell) and thus cannot be replaced.

■■ Class B

■■ Class A With this design, the temperature range is limited to max.

■■ Class AA 250 °C.

Combinations of 2-wire connection and class A or class AA

are not allowed.

Transmitter (option)

For detailed specifications for Pt100 sensors, see Technical

Within the model JS connection head a model T91.20

information IN 00.17 at www.wika.com.

analogue temperature transmitter can be factory-fitted.

It is mounted in place of the terminal block.

The version with temperature transmitter is not suitable for

use in hazardous areas.

For further specifications on the model T91.20 temperature

transmitter please refer to WIKA data sheet TE 91.01.

Components model TR10-D

3157966.01

Legend:

Connection head

Process connection

Thermowell

Terminal block

Connection head

JS

JS BS BSZ, BSZ-K BSZ-H, BSZ-HK BSS BS

Model Material Cable outlet Ingress protection Cap Surface

JS Aluminium M16 x 1.5 1) IP65 Cap with 2 screws Blue, lacquered 2)

1) Standard

2) RAL 5022

Page 2 of 5 WIKA data sheet TE 60.04 ∙ 04/2016

Thermowell Permanent threaded connection

Material: stainless steel The connection is permanently fixed to the thermowell.

The standard neck length is N (MH) = 55 mm

Thermowell Ø Insertion length U1 in mm

in mm 50 75 100 150 160 250 400

6 x x x x x x x

Compression fitting

8 - - x x x x x

The compression fitting enables simple, on-site adjustment

to the required insertion length.

Permissible temperature ranges

The self-extending nature of the compression fitting results in

the smallest possible neck length, N (MH), of approx. 55 mm.

Class Sensor construction

Wire-wound Thin-film Since the compression fitting is adjustable on the thermowell,

Class B -200 ... +500 °C -50 ... +500 °C the size of the insertion length, A, and the neck length,

Class A 1) -100 ... +450 °C -30 ... +300 °C N (MH), are stated as the values for the delivered item.

Class AA 1) -50 ... +250 °C 0 ... 150 °C ■■ Ferrule material: stainless steel or PTFE

1) Not with 2-wire connection method Ferrules from stainless steel are only adjustable once; once

the fitting has been loosened, sliding along the thermowell is

For detailed specifications for Pt100 sensors, see Technical no longer possible.

information IN 00.17 at www.wika.com.

Ferrules from PTFE can be adjusted numerous times; once

■■ At the head: -40 ... +80 °C the fitting has been loosened it can again be tightened onto

■■ Storage: -40 ... +80 °C the thermowell.

■■ Max. temperature at process connection: 150 °C

Process connections

Double nipple

All process connections are manufactured from stainless

steel. Other materials are available on request. Using a double-sided threaded nipple, the thermometer

can be screwed directly into the process. In this case the

The insertion length A (U1 or U2) can be customised. permissible temperature ranges must be observed.

The neck length, N (MH), depends on the type of the process The neck length, N (MH), for parallel threads depends on the

connection selected. height of the hexagon. This is 10 mm.

The neck length N (MH) of NPT threads not only includes the

Extended process connection hexagon height but also half of the thread height. This gives

us a neck length, N (MH), of approx. 19 mm.

Connection heads, connecting leads/wires and the optional

transmitter must only be used within the above-mentioned

temperature ranges. Without process connection

If the thermometer will operate at temperatures outside of the This version is designed mainly for mounting in one of the

temperature limits, the clearance between the connection available compression fittings.

head and the hot or cold surfaces must be increased.

The neck length, N (MH), in this case only specifies the

This neck length is dependent upon the intended application height of the hexagon on the head of the thermowell.

and generally serves as isolation or as a cooling element N (MH) is always 7 mm.

between the process and the connection head.

The resistance thermometers of the TR10-D series are designed for direct installation into the process. Using it in an additional

thermowell only makes sense in exceptional cases.

WIKA data sheet TE 60.04 ∙ 04/2016 Page 3 of 5

Dimensions in mm

Extended process connection

11346418.01

Without process Threaded connection Compression fitting

connection Double nipple (welded) (adjustable)

Thread

Legend:

A (U1) Insertion length N (MH) Neck length

(with parallel threads) (U) Insertion length per DIN 43772

A (U2) Insertion length (U1) Insertion length in accordance with international standards

(with tapered threads) Ød Measuring insert diameter

Electrical connection

1 x Pt100, 2-wire 1 x Pt100, 3-wire 1 x Pt100, 4-wire 2 x Pt100, 2-wire

3383942.03

black yellow

white red white red white red white red

red red red

red red red

white

white white white black

white

yellow

For the electrical connections of built-in temperature transmitters see the corresponding data sheets or operating instructions.

Page 4 of 5 WIKA data sheet TE 60.04 ∙ 04/2016

Explosion protection (option) Certificates (option)

Resistance thermometers of the TR10-D series are available Certification type Measuring Material

with an EC-type examination certificate for “intrinsically safe”, accuracy certificate

Ex i, ignition protection. 2.2 test report x x

These instruments comply with the requirements of the ATEX

3.1 inspection certificate x -

directive for gases and dusts.

DKD/DAkkS calibration x -

certificate

The permissible power Pmax as well as the permissible

ambient temperature for the respective category can be seen The different certifications can be combined with each other.

on the EC-type examination certificate and in the operating

instructions.

Approvals

Logo Description Country

EC declaration of conformity European Community

■■ EMC directive 1)

EN 61326 emission (group 1, class B) and interference immunity (industrial application)

■■ ATEX directive (option)

IECEx (option) IECEx member states

Hazardous areas

EAC (option) Eurasian Economic

■■ Import certificate Community

■■ Hazardous areas

GOST (option) Russia

Metrology, measurement technology

INMETRO (option) Brasil

■■ Metrology, measurement technology

■■ Hazardous areas

NEPSI (option) China

Hazardous areas

KOSHA (option) South Korea

Hazardous areas

- PESO (option) India

Hazardous areas

1) Only for built-in transmitter

Approvals and certificates, see website

Ordering information

Model / Version / Measuring insert / Explosion protection / Process connection / Version and material of threaded connection /

Thread size / Measuring element / Connection method / Temperature range / Design of the sensor tip / Sensor diameter /

Insertion length A / Neck length N (MH) / Certificates / Options

© 2008 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

WIKA data sheet TE 60.04 ∙ 04/2016 Page 5 of 5

04/2016 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

Das könnte Ihnen auch gefallen

- Caliber Modulo PCM PinoutDokument7 SeitenCaliber Modulo PCM PinoutManuel Suarez100% (3)

- SOF CUB EzCad2UNI V2 1 EN Manual 20100528 PDFDokument141 SeitenSOF CUB EzCad2UNI V2 1 EN Manual 20100528 PDFIslam ElgammalNoch keine Bewertungen

- Repair Manual B200Dokument460 SeitenRepair Manual B200slawny7789% (9)

- Energy Manipulation and MeditationDokument6 SeitenEnergy Manipulation and Meditationapi-246292178100% (1)

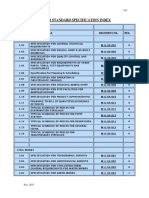

- Water Standard Specification Index As On Dec 2015Dokument10 SeitenWater Standard Specification Index As On Dec 2015afp15060% (1)

- Sonda Temperatura Wika DS TE6010 GB 2032Dokument6 SeitenSonda Temperatura Wika DS TE6010 GB 2032Emilio AlmedaNoch keine Bewertungen

- WIKA DS TE 60.03 Resistance Thermometer Model TR10-C With Fabricated ThermowellDokument6 SeitenWIKA DS TE 60.03 Resistance Thermometer Model TR10-C With Fabricated ThermowellŽeljko KasunićNoch keine Bewertungen

- Twin-Temp Thermometer OptionsDokument2 SeitenTwin-Temp Thermometer Optionsfabianrico2Noch keine Bewertungen

- RAK TR.1000S H DatabladDokument4 SeitenRAK TR.1000S H DatabladPhuc HuynhNoch keine Bewertungen

- Omnigrad T TST310: Technical InformationDokument12 SeitenOmnigrad T TST310: Technical InformationArief SetyawanNoch keine Bewertungen

- Contact Connection 1-3: 6 (2.5) A, AC 250 V: Building TechnologiesDokument4 SeitenContact Connection 1-3: 6 (2.5) A, AC 250 V: Building TechnologiesDavid NguyenNoch keine Bewertungen

- Omnigrad M TR12: Technical InformationDokument20 SeitenOmnigrad M TR12: Technical InformationPravin BoteNoch keine Bewertungen

- Bimetal Temperature Switch Model TFS35: ApplicationsDokument4 SeitenBimetal Temperature Switch Model TFS35: Applicationsمحمد فرحاتNoch keine Bewertungen

- MTR11 R5 Produk SensorDokument18 SeitenMTR11 R5 Produk SensorHengki ANoch keine Bewertungen

- Servo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionDokument10 SeitenServo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionYacineNoch keine Bewertungen

- TR95, TC95Dokument8 SeitenTR95, TC95greatNoch keine Bewertungen

- 5) Hd651enCP VarithermDokument3 Seiten5) Hd651enCP VarithermAnish KarthikeyanNoch keine Bewertungen

- DS - TW9512 - GB - 724 - Poço de Proteção FLG Materiais EspeciaisDokument4 SeitenDS - TW9512 - GB - 724 - Poço de Proteção FLG Materiais EspeciaisThomasFrenchNoch keine Bewertungen

- TPC100Dokument12 SeitenTPC100greatNoch keine Bewertungen

- DB GB NK10Dokument4 SeitenDB GB NK10cadhoaNoch keine Bewertungen

- HD 652 CaDokument2 SeitenHD 652 Caseno irawanNoch keine Bewertungen

- TR88 Ac1e3x2c2000Dokument24 SeitenTR88 Ac1e3x2c2000Xavier MonroyNoch keine Bewertungen

- Catalogo Tecnico PresostatoDokument32 SeitenCatalogo Tecnico PresostatoRonulfo GutierrezNoch keine Bewertungen

- Termostato S6410 TecsisDokument3 SeitenTermostato S6410 TecsisRolando Jara YoungNoch keine Bewertungen

- Technical Information Omnigrad M TR10: Modular RTD Assembly Thermowell and Neck Tube, ThreadDokument22 SeitenTechnical Information Omnigrad M TR10: Modular RTD Assembly Thermowell and Neck Tube, ThreadLuisaNoch keine Bewertungen

- TIP 651mHNK - enDokument4 SeitenTIP 651mHNK - enJanez PartNoch keine Bewertungen

- Omnigrad M TR10: Technical InformationDokument20 SeitenOmnigrad M TR10: Technical InformationMilan BojicNoch keine Bewertungen

- 9884 - Duct Temperature Sensor FK-TP - 200 - enDokument4 Seiten9884 - Duct Temperature Sensor FK-TP - 200 - enMinh nhut LưuNoch keine Bewertungen

- 12.17 Temperature Transmitter TR10, E&HDokument20 Seiten12.17 Temperature Transmitter TR10, E&HTichaonaNoch keine Bewertungen

- SP210.M 23 03Dokument32 SeitenSP210.M 23 03tranvietphi0710Noch keine Bewertungen

- Windvane Thiesfirstclasstmr s21110hDokument4 SeitenWindvane Thiesfirstclasstmr s21110hSteven RuiterNoch keine Bewertungen

- Foxboro RTDDokument12 SeitenFoxboro RTDJonathanGonzalezDiazNoch keine Bewertungen

- 02122020-Gen - Cat - EuropeDokument32 Seiten02122020-Gen - Cat - EuropeABDULSALAMNoch keine Bewertungen

- Endress-Hauser RTD-Assembly U S Style T14 ENDokument4 SeitenEndress-Hauser RTD-Assembly U S Style T14 ENangel uscangaNoch keine Bewertungen

- 03 - Thermostat & Accessories - EmailDokument24 Seiten03 - Thermostat & Accessories - EmailTanveer AzizNoch keine Bewertungen

- 137 Amot 8253 Product Document - AshxDokument4 Seiten137 Amot 8253 Product Document - AshxEliecer DiazNoch keine Bewertungen

- Ps TsapxxxDokument1 SeitePs TsapxxxEko SetiawanNoch keine Bewertungen

- Thermon HPTDokument2 SeitenThermon HPTParag B HatwarNoch keine Bewertungen

- TC85Dokument4 SeitenTC85greatNoch keine Bewertungen

- Endress-Hauser RTD Thermometer TSM187 ENDokument3 SeitenEndress-Hauser RTD Thermometer TSM187 ENScaylierNoch keine Bewertungen

- Technical Information T13, T14 and T15Dokument24 SeitenTechnical Information T13, T14 and T15Raul I. GarzaNoch keine Bewertungen

- Traceado KSX 20Dokument2 SeitenTraceado KSX 20odgp215800Noch keine Bewertungen

- Operating Instructions: Leister Twinny TDokument12 SeitenOperating Instructions: Leister Twinny TMuhammad Fadhil natsirNoch keine Bewertungen

- TAF16Dokument20 SeitenTAF16Miguel CastanhoNoch keine Bewertungen

- PT1000 DataSheetDokument3 SeitenPT1000 DataSheetmiguelpazosNoch keine Bewertungen

- Minco Tip Sensitive RTDDokument24 SeitenMinco Tip Sensitive RTDsudipta_kolNoch keine Bewertungen

- Twisto-B: Connection SystemDokument2 SeitenTwisto-B: Connection Systemheri fauziNoch keine Bewertungen

- HBM Strain Gage CatalogDokument100 SeitenHBM Strain Gage CatalogJonathan OlsonNoch keine Bewertungen

- IOM Transmitter T32Dokument33 SeitenIOM Transmitter T32TreeNoch keine Bewertungen

- Wika TTDokument11 SeitenWika TTgautom neogNoch keine Bewertungen

- ManualDokument179 SeitenManualFidel FloresNoch keine Bewertungen

- 42TPM English PDC 60Hz V4Dokument16 Seiten42TPM English PDC 60Hz V4maqsood ahmedNoch keine Bewertungen

- Catalogo SensoresDokument100 SeitenCatalogo Sensorestakenalready85Noch keine Bewertungen

- EMO-T EN LowDokument8 SeitenEMO-T EN Low윤병택Noch keine Bewertungen

- DS TV3501 en Co 25303Dokument4 SeitenDS TV3501 en Co 25303Alexsandro TorezinNoch keine Bewertungen

- Thermometer TR61Dokument20 SeitenThermometer TR61Migos MareNoch keine Bewertungen

- Siemems RCDDokument4 SeitenSiemems RCDDavid LimNoch keine Bewertungen

- Omnigrad TST410: RTD ThermometerDokument4 SeitenOmnigrad TST410: RTD ThermometerTCP.MT.2014 TCP.MT.2014Noch keine Bewertungen

- Thermowell Omnigrad M TR10 (TT-101, TT-201, TT-301, TT-302, TT-303A, TT-303B) PDFDokument20 SeitenThermowell Omnigrad M TR10 (TT-101, TT-201, TT-301, TT-302, TT-303A, TT-303B) PDFfitrichynNoch keine Bewertungen

- Thermo WellDokument3 SeitenThermo Wellhisaj4uNoch keine Bewertungen

- Temperature SwitchDokument6 SeitenTemperature Switchkriss05Noch keine Bewertungen

- AVA-S400.25 Smart Modulating Rev2 AUG 16Dokument3 SeitenAVA-S400.25 Smart Modulating Rev2 AUG 16Jhon Piter ManaluNoch keine Bewertungen

- Isometric PRDS MulindoDokument1 SeiteIsometric PRDS MulindoJhon Piter ManaluNoch keine Bewertungen

- Poziv Susret 2018Dokument11 SeitenPoziv Susret 2018Husejin MehmedovićNoch keine Bewertungen

- Process SteamDokument7 SeitenProcess SteamJhon Piter ManaluNoch keine Bewertungen

- Eset Nod 7Dokument2 SeitenEset Nod 7Jhon Piter ManaluNoch keine Bewertungen

- Hosts UmbrellaDokument1 SeiteHosts UmbrellaFabsor SoralNoch keine Bewertungen

- Hosts UmbrellaDokument1 SeiteHosts UmbrellaFabsor SoralNoch keine Bewertungen

- Zelio Logic RelaysDokument16 SeitenZelio Logic Relayswww.otomasyonegitimi.comNoch keine Bewertungen

- Apn GSMDokument2 SeitenApn GSMJhon Piter ManaluNoch keine Bewertungen

- Introduction to Concrete Components and ClassificationDokument29 SeitenIntroduction to Concrete Components and ClassificationUsama AliNoch keine Bewertungen

- CZ-RTC4 - Service ManualDokument68 SeitenCZ-RTC4 - Service ManualAnonymous 31Airw50% (2)

- Load Flow and SC ETAPDokument4 SeitenLoad Flow and SC ETAPmuraliNoch keine Bewertungen

- Water Level IndicatorDokument5 SeitenWater Level IndicatorRahul JadhavNoch keine Bewertungen

- SteckDokument354 SeitenStecknaruto100% (1)

- Report 04.02.20Dokument4 SeitenReport 04.02.20Kartik SoniNoch keine Bewertungen

- Solex Adj ProcedureDokument6 SeitenSolex Adj Procedureprivate 2Noch keine Bewertungen

- Projects Oil and Gas BrochureDokument20 SeitenProjects Oil and Gas BrochureRussel John RamosNoch keine Bewertungen

- IGBTDokument22 SeitenIGBTumeshgangwar100% (1)

- Principle Heat TransferDokument34 SeitenPrinciple Heat TransferZick HaziqNoch keine Bewertungen

- Ama Drainer & Ama Porter: Vertical Monobloc Dewatering PumpsDokument2 SeitenAma Drainer & Ama Porter: Vertical Monobloc Dewatering Pumpssmita reddyNoch keine Bewertungen

- 3512TA - 1000kVA - LV - Spec Sheet PDFDokument5 Seiten3512TA - 1000kVA - LV - Spec Sheet PDFavinash_1229Noch keine Bewertungen

- Screw Compressor Units: For Sodium Carbonate Production (Soda Ash)Dokument2 SeitenScrew Compressor Units: For Sodium Carbonate Production (Soda Ash)Jaswindersingh BhatiaNoch keine Bewertungen

- Industrial ReactorsDokument10 SeitenIndustrial ReactorssarahNoch keine Bewertungen

- System Sensor 2WTR-B Data SheetDokument2 SeitenSystem Sensor 2WTR-B Data SheetJMAC SupplyNoch keine Bewertungen

- Quantum Mechanics 1Dokument88 SeitenQuantum Mechanics 1Mehul GuptaNoch keine Bewertungen

- Ed Current DynamometerDokument3 SeitenEd Current DynamometerOM MUNGELWARNoch keine Bewertungen

- American Zettler AZ8 1CH 24DSEDokument4 SeitenAmerican Zettler AZ8 1CH 24DSEadiegooscarNoch keine Bewertungen

- DPDC MaintenanceDokument5 SeitenDPDC MaintenanceArfana Akter BanogirNoch keine Bewertungen

- TMX53DC 1607 121 (Drawings Electric)Dokument13 SeitenTMX53DC 1607 121 (Drawings Electric)ChristianNoch keine Bewertungen

- 3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhaDokument3 Seiten3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhadcoolsamNoch keine Bewertungen

- Principle Design Solenoid ValvesDokument28 SeitenPrinciple Design Solenoid Valveshassan alrokabNoch keine Bewertungen

- Introduction To Pressure TransducersDokument2 SeitenIntroduction To Pressure TransducersTEUKUNoch keine Bewertungen

- R6.3 TR-XXL Parameter Settings ReleaseDokument493 SeitenR6.3 TR-XXL Parameter Settings Releasemishu35Noch keine Bewertungen

- High Efficiency Battery Charger Using DC-DC ConverterDokument4 SeitenHigh Efficiency Battery Charger Using DC-DC ConvertersanilNoch keine Bewertungen

- A Novel ZVS-ZCS Bi-Directional Flyback DC-DCDokument6 SeitenA Novel ZVS-ZCS Bi-Directional Flyback DC-DCArceu CamposNoch keine Bewertungen