Beruflich Dokumente

Kultur Dokumente

Gibbscam Rotary Milling and Gibbscam 4-Axis Options

Hochgeladen von

simioncristescuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gibbscam Rotary Milling and Gibbscam 4-Axis Options

Hochgeladen von

simioncristescuCopyright:

Verfügbare Formate

GibbsCAM Rotary Milling and GibbsCAM 4-Axis Options

GibbsCAM 4th Axis Programming

Capitalizing on the ability to produce parts in a single setup and improve

productivity without sacrificing floor space, simultaneous rotary milling provides

ROTARY MILLING a cost-effective way to expand the range of parts a shop can produce and win new

ROTARY POCKETING

business. Simultaneous rotary milling machines radial parts on a mill, mill-turn,

or multi-task machine tool using the A, B, or C rotary axis.

To easily handle a wide range of rotary milling applications, GibbsCAM offers

separate and complementary solutions for the machining of complex shapes that

cannot be produced on a standard mill or lathe. GibbsCAM Rotary Milling is

designed to easily accomplish common tasks such as threading, engraving or

milling based on flat or radial geometry. GibbsCAM 4-Axis creates NC code for

ROTARY MILLING more complex rotary applications based on solid models such as camshafts and

FEED SCREW pockets or grooves with variable tapers on the floors and walls. These two options

work great alone or use them together to address all your rotary milling needs.

In addition, the GibbsCAM 5-Axis option can also be used for 4th axis programming.

Refer to the GibbsCAM 5-Axis data sheet for additional information.

GibbsCAM Rotary Milling GibbsCAM 4-Axis

Rotary Milling increases the productivity of Offering a rich programming environment,

GibbsCAM Production Milling with support for GibbsCAM 4-Axis provides simultaneous rotary

ROTARY MILLING continuous rotary machining. Readily program machining of 3D wireframe geometry, surfaces, solid

WRAPPED FLAT GEOMETRY

rotary contouring, pocketing, threading, and faces or geometry extracted from solid models. With

engraving as wrapped tool path with continuous complete control over the cutting tool’s orientations

rotary motion. Capabilities also include face and relative to the part, GibbsCAM 4-Axis supports

OD milling for mill/turn and multi-task machines. off-center, Y-axis machining to ensure the integrity

of straight or tapered walls.

An ideal choice for threading, engraving and the

machining of parts defined with flat geometry, Ideal for non-circular parts like cam shafts that require

such as roller dies or tool centerline grooves, positioning moves as well as rotary motion, 3D

Rotary Milling works best for parts which can be geometry that wraps more than 360 degrees around the

made with the tool on centerline. CNC Polar and diameter, and parts with variable floor and wall tapers,

4-AXIS Cylindrical Interpolation output is supported to 4-Axis works best with machines that have a Y-axis.

OFF-CENTER, Y-AXIS MILLING produce optimal multi-revolution output on a

Cut with the side or the bottom of the tool for

single G-code line.

maximum efficiency. Use a surface or two curves

Wrap any shape or text around a cylindrical part to control the tilt of the tool or have the tool follow

via rotary axis interpolation. Start with flat one curve at a user-defined lean angle. Progressive

geometry or text and then wrap it around a defined tool lean gives finite control over the tool angle

diameter or switch to radial mode to create from the start to the end of the cut. Create

geometry directly in its wrapped position. Rotary pocketing operations directly from cylindrical

Milling works great for repeated patterns. Simply surfaces. There is no need to select geometry.

define the initial pattern and then enter the number 4-Axis is smart enough to keep the tool normal to

of times to reproduce it around the diameter. the surface at the user-defined angular tolerance.

4-AXIS

OFF-CENTER, LEAD MILLING

GibbsCAM Rotary Milling GibbsCAM 4-Axis

Interface Easily switch between simple position moves Multiple parameters provide full control

and continuous rotary motion. Quickly over tool alignment, clearance planes, tool

view flat geometry in its actual wrapped orientation, constant and variable depths of

configuration around the center of rotation cut, and whether to cut shapes with the side

or create geometry directly in radial mode. or the bottom of the tool.

Geometry Definition 2D planar geometry, radial geometry and 3D geometry extracted from a solid model,

text. 3D geometry can be converted to flat/ surfaces and 3D radial geometry. 2D geom-

radial geometry. etry is not supported.

Part Compatibility Ideal for parts defined with flat geometry Ideal for parts defined by solid models or

such as roller dies with repeated patterns or surfaces with variable floor and wall tapers.

tool centerline grooves. Excellent for Excellent for swarf cuts and non-circular

threading and engraving on an angle. parts such as cams and extrusion screws.

Machine Compatibility Works well with machines that do not have Works best with Y-axis machines. Does not

a Y-axis such as some mill/turns and multi- work well with machines that do not have

task machines. a Y-axis.

Cutting Operations Contouring, pocketing, threading, engraving Contouring and pocketing. Contouring

and rotary face milling on mill/turns and supports variable chamfers that progressively

multi-task machines. move the tool to the user-defined lean angle.

Depth and Tapers Works well with constant depth milling. Works well with constant or variable depth

Not suitable for variable-depth floors. milling. Offers a variety of variable-depth

floor capabilities.

Wall Angles and Suitable for parts dimensioned with axial Supports a variety of part wall angle orien-

Y Offsets lengths and degrees of revolution. The tool tations and Y offsets. Drive the tool along

is always a radial tool. There is no Y offset of a piece of geometry and a face for swarf

the tool path, restricting wall angle options. cuts or drive the tool along one piece of

geometry at a user-defined lean angle.

Cutter Control Always cuts with the tool on centerline. Provides ability to control cutter contact by

specifying lead/lag and lean.

Multi-revolution Produces optimal multi-revolution G-code Does not produce single line or single block

Output output for unlimited revolutions on a single multi-revolution output.

G-code line.

Interpolation Options Supports CNC Polar and Cylindrical Does not support Polar or Cylindrical

interpolation output options. Interpolation interpolation output.

is created during post processing so the same

toolpath can be used on any machine.

Gibbs Post Any Basic or Advanced post processor Any Basic or Advanced post processor can

Compatibility which does not already support the Rotary be updated to be a 4-axis simultaneous post

Milling option can be updated to support it. processor.

MLG134/2.5M/06-07

© 2007, Gibbs and Associates. All right reserved. The Gibbs and GibbsCAM logos, GibbsCAM, Virtual Gibbs, SolidSurfacer, Gibbs SFP, MTM and “Powerfully Simple. Simply

Powerful.” are either trademark(s) or registered trademark(s) of Gibbs and Associates in the United States and/or other countries.

Gibbs and Associates | Tel 805.523.0004 | 800.654.9399 | Fax 805.523.0006 | www.GibbsCAM.com

Das könnte Ihnen auch gefallen

- NX Total MachiningDokument6 SeitenNX Total MachiningtriNoch keine Bewertungen

- SingleBlade 5 Axis Cam Software HyperMILL enDokument4 SeitenSingleBlade 5 Axis Cam Software HyperMILL enPaul VeramendiNoch keine Bewertungen

- Milling: History of The Milling MachineDokument11 SeitenMilling: History of The Milling MachineNikhil PrasannaNoch keine Bewertungen

- Millingmachinehusain 151003135158 Lva1 App6891 PDFDokument49 SeitenMillingmachinehusain 151003135158 Lva1 App6891 PDFpatlninadNoch keine Bewertungen

- MillingDokument37 SeitenMillingKemba DonyeNoch keine Bewertungen

- BRO Millturn HypermillDokument4 SeitenBRO Millturn HypermillPaul VeramendiNoch keine Bewertungen

- Milling NotesDokument20 SeitenMilling NotesleoandresmessiNoch keine Bewertungen

- MillingDokument33 SeitenMillingraidahNoch keine Bewertungen

- Groove-Turn Tools PDFDokument413 SeitenGroove-Turn Tools PDFbrusilicaNoch keine Bewertungen

- Benefits of Positional 5 Axis MachiningDokument2 SeitenBenefits of Positional 5 Axis MachiningQm Lương Văn MinhNoch keine Bewertungen

- NX Advanced 5-Axis Machining: Siemens PLM SoftwareDokument6 SeitenNX Advanced 5-Axis Machining: Siemens PLM SoftwareAmr KamelNoch keine Bewertungen

- Milling MachinesDokument39 SeitenMilling MachinesSahil Sheth0% (1)

- Operations of Milling MachineDokument8 SeitenOperations of Milling MachineAbdul AhadNoch keine Bewertungen

- Operations of Milling MachineDokument9 SeitenOperations of Milling MachineSeth Jeremiah A. EusteNoch keine Bewertungen

- MillingmachineDokument46 SeitenMillingmachineAmman ButtNoch keine Bewertungen

- Milling Machine & Operations (PROF GHW)Dokument35 SeitenMilling Machine & Operations (PROF GHW)VINEET VYASNoch keine Bewertungen

- 6 Notes Milling Shaping & PlaningDokument14 Seiten6 Notes Milling Shaping & PlaningSanket KumarNoch keine Bewertungen

- Siemens PLM NX CAM 2 5 Axis Milling Add On Fs Tcm1023 118151Dokument2 SeitenSiemens PLM NX CAM 2 5 Axis Milling Add On Fs Tcm1023 118151rasgeetsinghNoch keine Bewertungen

- Alphacam 5 AxisDokument2 SeitenAlphacam 5 AxisAlen ĐipaloNoch keine Bewertungen

- ch8 1Dokument1 Seitech8 1Dumisani SitholeNoch keine Bewertungen

- Project Report DrillDokument22 SeitenProject Report Drillsumit bijwe100% (1)

- 2 Machine Tools - Milling, & ShaperDokument73 Seiten2 Machine Tools - Milling, & ShaperGAURAV DEVNoch keine Bewertungen

- QB114433Dokument12 SeitenQB114433Saravanan ShriNoch keine Bewertungen

- Revo 540Dokument34 SeitenRevo 540eduardo_garcia_v100% (1)

- Chapter 4 EditedDokument142 SeitenChapter 4 EditedgashawletaNoch keine Bewertungen

- Topic: Milling MachineDokument47 SeitenTopic: Milling MachineViasNoch keine Bewertungen

- Minimax Gen. - Rev01 - Jan18 - IngDokument136 SeitenMinimax Gen. - Rev01 - Jan18 - IngWagner MenezesNoch keine Bewertungen

- Standard Chucking MechanismsDokument28 SeitenStandard Chucking Mechanismscalidad_bogotaNoch keine Bewertungen

- Midsize 5-Axis Buyer's Guide: A Survey of Midsize Full 5-Axis Machine Tools From The Top ManufacturersDokument12 SeitenMidsize 5-Axis Buyer's Guide: A Survey of Midsize Full 5-Axis Machine Tools From The Top Manufacturerswulfgang66Noch keine Bewertungen

- Hexagon MI EDGECAM Product Brochure A4 Web ENDokument28 SeitenHexagon MI EDGECAM Product Brochure A4 Web ENHoang MaiNoch keine Bewertungen

- Lec 2 MillingDokument51 SeitenLec 2 MillingHammad RazaNoch keine Bewertungen

- MillingDokument47 SeitenMillingAvinash KankipatiNoch keine Bewertungen

- Review QuestionsDokument8 SeitenReview QuestionsJhon Ashley NahibuanNoch keine Bewertungen

- Shaper MachineDokument4 SeitenShaper MachineJaydeep Sakariya60% (5)

- Shaping & Grinding and Realated OperationsDokument26 SeitenShaping & Grinding and Realated OperationsIzi86% (7)

- NX MULTI AXIS MACHINING ConceptDokument22 SeitenNX MULTI AXIS MACHINING ConceptMATHI KRISHNAN100% (1)

- Type of Computer Numerical Control (CNC Milling)Dokument5 SeitenType of Computer Numerical Control (CNC Milling)amerNoch keine Bewertungen

- Unit III Milling Machine and Slotter 4SEM MP GCOE S N GANDHAREDokument20 SeitenUnit III Milling Machine and Slotter 4SEM MP GCOE S N GANDHARE40 siddhesh petkarNoch keine Bewertungen

- Accord 25 FX - Rev00 - Mag17 - Ing - 00L0372819LDokument24 SeitenAccord 25 FX - Rev00 - Mag17 - Ing - 00L0372819Lakcelerator100% (1)

- Milling MachineDokument20 SeitenMilling MachineMohd Radzi Kaki Limo100% (1)

- ch8 7Dokument1 Seitech8 7Dumisani SitholeNoch keine Bewertungen

- Unit 5Dokument106 SeitenUnit 5Sudharshan IyengarNoch keine Bewertungen

- Shaper Machine SeminrDokument20 SeitenShaper Machine SeminrSoumya Banerjee80% (5)

- Unit - Iv: Milling MachineDokument74 SeitenUnit - Iv: Milling MachineDevarakonda KondayyaNoch keine Bewertungen

- CNC Process Planning and Machining - Getting Started (Is+dl)Dokument9 SeitenCNC Process Planning and Machining - Getting Started (Is+dl)PAVAN KALYANNoch keine Bewertungen

- 003 MillingDokument59 Seiten003 MillingKalikene MwambeloNoch keine Bewertungen

- Lecture - 5 Notes: Milling Basic Mechanical Engineering (Part - B, Unit - I) 1Dokument7 SeitenLecture - 5 Notes: Milling Basic Mechanical Engineering (Part - B, Unit - I) 1Roop LalNoch keine Bewertungen

- Unit - IIIDokument30 SeitenUnit - IIISai RamNoch keine Bewertungen

- Visi Machining 3D: Fast and Intelligent ToolpathsDokument4 SeitenVisi Machining 3D: Fast and Intelligent Toolpathskimo480Noch keine Bewertungen

- P4 Abt: Range of Automatic Panel Benders. More Flexible, More Versatile, More ProductiveDokument16 SeitenP4 Abt: Range of Automatic Panel Benders. More Flexible, More Versatile, More ProductiveNevres Gutic100% (1)

- Milling & Related OperationsDokument22 SeitenMilling & Related OperationsIzi80% (5)

- Ilovepdf MergedDokument53 SeitenIlovepdf Merged208048022Noch keine Bewertungen

- Metal Cutting and Machine Tools Unit - III ObjectiveDokument27 SeitenMetal Cutting and Machine Tools Unit - III ObjectivePyla Ravi KumarNoch keine Bewertungen

- Attachments For MillingDokument59 SeitenAttachments For MillingLibin AbrahamNoch keine Bewertungen

- Angle and Tilting Vice - SynopsisDokument6 SeitenAngle and Tilting Vice - SynopsisTanvi Khurana100% (3)

- Drilling and Hole MakingDokument8 SeitenDrilling and Hole MakingMarcl Andrs SampdroNoch keine Bewertungen

- V Machining ConventionalDokument22 SeitenV Machining Conventionalroamer10Noch keine Bewertungen

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingVon EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingBewertung: 5 von 5 Sternen5/5 (2)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsVon EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsBewertung: 5 von 5 Sternen5/5 (1)

- Slid e 4-1Dokument67 SeitenSlid e 4-1Rashe FasiNoch keine Bewertungen

- Sarcosine MsdsDokument41 SeitenSarcosine MsdsAnonymous ZVvGjtUGNoch keine Bewertungen

- Book of Abstracts: Philippine Projects To The Intel International Science and Engineering FairDokument84 SeitenBook of Abstracts: Philippine Projects To The Intel International Science and Engineering FairJimarie BithaoNoch keine Bewertungen

- St10 Flasher DLL: Stmicroelectronics ConfidentialDokument10 SeitenSt10 Flasher DLL: Stmicroelectronics Confidentialeshwarp sysargusNoch keine Bewertungen

- I-Lt-Cyclomax 3.7-3Dokument10 SeitenI-Lt-Cyclomax 3.7-3Luis Fernando OrtigozaNoch keine Bewertungen

- Boarding PassDokument1 SeiteBoarding PassFajarNoch keine Bewertungen

- Reading 36 Using Multifactor Models - AnswersDokument23 SeitenReading 36 Using Multifactor Models - Answersdhanh.bdn.hsv.neuNoch keine Bewertungen

- L - HRF22B0301 - Hose & Pulley Block (ZM, METRIC)Dokument5 SeitenL - HRF22B0301 - Hose & Pulley Block (ZM, METRIC)Gustavo RodriguezNoch keine Bewertungen

- Scala and Spark For Big Data AnalyticsDokument874 SeitenScala and Spark For Big Data AnalyticsSneha SteevanNoch keine Bewertungen

- Artificial Intelligence/Search/Heuristic Search/astar SearchDokument6 SeitenArtificial Intelligence/Search/Heuristic Search/astar SearchAjay VermaNoch keine Bewertungen

- BS en 12285-1-2003 (2006)Dokument162 SeitenBS en 12285-1-2003 (2006)dahzahNoch keine Bewertungen

- Excel Tips TricksDokument26 SeitenExcel Tips Tricksskondra12Noch keine Bewertungen

- HCL Corporate-PresentationDokument14 SeitenHCL Corporate-Presentationtony_reddyNoch keine Bewertungen

- Lamaran NongyiDokument12 SeitenLamaran NongyiTonoTonyNoch keine Bewertungen

- Picasso OperatingInstructions Manual 211018 WEBDokument27 SeitenPicasso OperatingInstructions Manual 211018 WEBBill McFarlandNoch keine Bewertungen

- Suplayer Metal Working Sipil and Fabrication: Company ProfileDokument10 SeitenSuplayer Metal Working Sipil and Fabrication: Company ProfileRuntian TeaNoch keine Bewertungen

- Business PlanDokument11 SeitenBusiness PlanIsaac ManarinNoch keine Bewertungen

- PV1800VPM SEREIS (1-5KW) : Pure Sine Wave High Frequency Solar Inverter With MPPT InsideDokument4 SeitenPV1800VPM SEREIS (1-5KW) : Pure Sine Wave High Frequency Solar Inverter With MPPT InsideHuber CallataNoch keine Bewertungen

- Biodiversity Management Bureau: Repucjuf The Philippines Department of Environment and Natural ResourcesDokument36 SeitenBiodiversity Management Bureau: Repucjuf The Philippines Department of Environment and Natural ResourcesMarijenLeañoNoch keine Bewertungen

- GG&G 2012 CatDokument111 SeitenGG&G 2012 Cattyrant88Noch keine Bewertungen

- Muscovy DucksDokument27 SeitenMuscovy DucksStephenNoch keine Bewertungen

- OS Lab ManualDokument37 SeitenOS Lab ManualVenkatanagasudheer ThummapudiNoch keine Bewertungen

- Bharati AXA Life InsuranceDokument57 SeitenBharati AXA Life InsuranceNaina_Dwivedi_6514100% (3)

- (L) Examples of Machine Shop Practice (1910)Dokument54 Seiten(L) Examples of Machine Shop Practice (1910)Ismael 8877100% (1)

- Retail Scenario in IndiaDokument10 SeitenRetail Scenario in IndiaSeemaNegiNoch keine Bewertungen

- Test Help StatDokument18 SeitenTest Help Statthenderson22603Noch keine Bewertungen

- PDF Applied Failure Analysis 1 NSW - CompressDokument2 SeitenPDF Applied Failure Analysis 1 NSW - CompressAgungNoch keine Bewertungen

- Pulido VsDokument14 SeitenPulido Vsroyel arabejoNoch keine Bewertungen

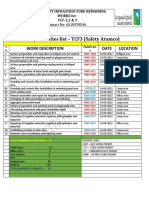

- Daily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationDokument2 SeitenDaily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationSheri DiĺlNoch keine Bewertungen

- 2.how To Boost Your Coating SalesDokument23 Seiten2.how To Boost Your Coating SalesAjaz Noor KhattakNoch keine Bewertungen