Beruflich Dokumente

Kultur Dokumente

16025911

Hochgeladen von

btwarriorOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

16025911

Hochgeladen von

btwarriorCopyright:

Verfügbare Formate

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

27” Dryer This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

MDE9700A*

MDG9700A*

16025911

March 2005

©2005 Maytag Services

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however, that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts,

testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

! WARNING

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.MAYTAG.COM ............................................. 1-800-688-9900

CAIR Center in Canada ........................................... 1-800-688-2002

Recognize Safety Symbols, Words, and Labels

! DANGER

DANGER—Immediate hazards which WILL result in severe personal injury or death.

! WARNING

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

! CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16025911 Rev. 0 ©2005 Maytag Services

Important Information .................................................... 2

Important Safety Information ......................................... 4

General Information

Model Identification .................................................... 8

Serial Label Location ................................................. 8

Model Nomenclature .................................................. 9

Troubleshooting

Troubleshooting General Symptoms ......................... 10

Component Testing Information

Component Testing Information ................................. 14

Disassembly Procedures

Door Reversal/Disassembly ...................................... 16

Interior Light .............................................................. 17

Top Removal ............................................................. 17

Drum Baffle Removal ................................................. 18

Console Removal ...................................................... 18

Front Panel Removal ................................................. 19

Heater Assembly Removal ........................................ 19

Front Bulkhead Removal ........................................... 21

Moisture Sensor Removal ......................................... 22

Belt Removal ............................................................. 22

Belt Switch Removal ................................................. 23

Drum Removal .......................................................... 23

Motor/Blower Assembly Removal .............................. 32

Rear Bulkhead Removal ............................................ 26

Rear Roller Removal .................................................. 27

Gas Model Disassembly Procedures

Igniter Removal ......................................................... 27

Burner Removal ........................................................ 28

Appendix A

Installation Instructions ............................................. 29

Appendix B

Use And Care ........................................................... 42

©2005 Maytag Services 16025911 Rev. 0 3

Important Safety Information

! WARNING

To avoid risk of fire, electric shock, serious injury, or death when using your dryer, follow these basic precautions:

1. Read all instructions before 11. Do not repair or replace any part 21. Always read and follow

using dryer. of dryer or attempt any service, manufacturer’s instructions on

2. Install dryer according to unless specifically recommended packages of laundry aids. Heed

Installation Instructions. Refer to in user-maintenance instructions all warnings or precautions. To

the Grounding Instructions in the or in published user-repair reduce risk of poisoning or

Installation Instructions for instructions that you understand chemical burns, keep products

proper grounding of the dryer. and have skills to carry out, if you away from children at all times,

3. Do not dry articles that have are a consumer. preferably, in a locked cabinet.

been cleaned in, washed in, 12. To reduce risk of electric shock or 22. Never operate dryer with guards

soaked in, or spotted with fire, do not use extension cords or and/or panels removed.

gasoline, dry-cleaning solvents, adapters to connect dryer to 23. Do not operate dryer with

or other flammable or explosive electrical power source. missing or broken parts.

substances. Vapors could ignite 13. Use the dryer only for its intended 24. Do not bypass safety devices.

or explode. purpose, drying clothes. 25. Keep area around the exhaust

4. Do not use dryer to dry clothes 14. Always disconnect dryer from opening and adjacent

which have traces of any electrical supply before surrounding areas free from

flammable substance, such as attempting any service. accumulation of lint, dust, and

vegetable oil, cooking oil, Disconnect power cord by dirt.

machine oil, flammable grasping the plug, not the cord. 26. Interior of dryer and exhaust duct

chemicals, thinner, etc., or 15. Do not use heat to dry articles should be cleaned periodically

anything containing wax or containing foam rubber or by qualified service personnel.

chemicals, such as mops and similarly textured rubberlike 27. Dryer will not operate with

cleaning cloths. Flammable materials. loading door open. DO NOT

substances may cause fabric to 16. Always clean the lint filter after bypass door safety switch by

catch fire by itself. every load. A layer of lint in the permitting dryer to operate with

5. Do not store or use gasoline or filter reduces drying efficiency and door open. Dryer will stop

other flammable vapors and prolongs drying time. tumbling when door is opened.

liquids near this or any other 17. Use only fabric softeners or Do not use dryer if it does not

appliance. products to eliminate static that stop tumbling when door is

6. Do not allow children to play on are appropriate for automatic opened or starts tumbling

or in dryer. Close supervision of dryers. without pressing or turning the

children is necessary when 18. Keep your dryer in good condition. START mechanism. Remove the

dryer is used near children, a Bumping or dropping dryer can dryer from use and call

safety rule for all appliances. damage safety features. If the service person.

7. Before dryer is removed from damage occurs, have dryer 28. Remove laundry immediately

service or discarded, remove checked by qualified service after the dryer stops.

doors to drying compartment. technician. 29. ALWAYS follow the fabric care

8. Do not reach into dryer if 19. Replace worn power cords and/or instructions supplied by the

cylinder is revolving. loose plugs. garment manufacturer.

9. Do not install or store dryer 20. Do not tumble fiberglass curtains

where it will be exposed to water and draperies unless the label

and/or weather. says it can be done. If they are

10. Do not tamper with dryer dried, wipe out the cylinder with a

controls. damp cloth to remove particles of

fiberglass.

Save These Instructions

4 16025911 Rev. 0 ©2005 Maytag Services

Important Safety Information

Electrical Service Information ! WARNING

To reduce the risk of fire and exposure to combustion

Electrical Dryers

gases, the dryer MUST be exhausted to the outdoors.

• 240 VAC, 60 Hz, 30 Amps,

DO NOT exhaust dryer air into a window well, gas vent,

3–wire or 4–wire installations

chimney or enclosed, unventilated area, such as an

attic, wall, ceiling, crawl space under a building or

Gas Dryers

concealed space of a building.

• 120 VAC, 60 Hz, 15 Amps, 3–wire installations

Gas Dryer Power Supply

About Ground Wires This equipment MUST be grounded. In the event of an

In the event of an electrical short circuit, a ground wire electrical short circuit, grounding reduces the risk of

reduces the risk of electric shock by providing an escape electric shock by providing an escape wire for the

wire for the electric current. electrical current. This unit is equipped with a cord

Standard accepted color coding for ground wires is green having a grounding wire with a grounding plug. The plug

or green with a yellow stripe. must be plugged into an outlet that is properly installed

Grounding wires and wires colored like grounding wires and grounded.

are NOT to be used as current carrying conductors.

Consult a qualified electrician or servicer if grounding

! WARNING instructions are not completely understood, or if doubt

exists as to whether the equipment is properly grounded.

To reduce the risk of fire, electric shock, serious injury

or death, all wiring and grounding must conform with Do not use an extension cord. If the product power cord

the latest edition of the National Electric Code, or the is too short, have a qualified electrician install a three–

Canadian Electrical Code, and such local regulations slot receptacle. This unit should be plugged into a

as might apply. It is the customer’s responsibility to separate 60 hertz circuit with the electrical rating as

have the wiring and fuses checked by a qualified shown on the serial plate.

electrician to make sure your home has adequate

electrical power to operate the dryer. Proper Grounding and Polarization for 120 Volts

Wall Outlets

For the safety of our customers and the service techni-

! WARNING cian ALL Amana gas dryers have a three–prong power

cord and MUST be connected to a properly polarized and

To avoid risk of personal injury or death due to grounded wall outlet. This information was written for

electrical shock: those who do not understand grounding and polarization

• Observe all local codes and ordinances. of a wall outlet. A 120 VAC wall outlet must always be

• Disconnect electrical power to unit before servicing. wired as shown below.

• Ground appliance properly.

Ground

• Check with a qualified electrician if you are not sure Neutral

L1

this appliance is properly grounded.

• DO NOT ground to gas line.

• DO NOT ground to cold water pipe if pipe is Neutral

interrupted by plastic, nonmetallic gaskets, or other side

115–12 0

insulating (nonconducting) materials. V.A.C. V.A.C.

• DO NOT modify plug on power cord. If plug does not

fit electrical outlet, have proper outlet installed Round

by qualified electrician. grounding 115–12

V.A.C.

• DO NOT have a fuse in the neutral or ground circuit. prong

A fuse in the neutral or ground circuit could result in

an electrical shock. Explanation

• DO NOT use an extension cord with this appliance. Polarization–This means that the larger slot must be

• DO NOT use an adapter plug with this appliance. neutral and the small slot must be hot (live).

• DO NOT pinch power cord. Mispolarized–The outlet is miswired so that the larger

slot is hot (live) and the smaller slot is neutral.

Grounded–This means the round hole connection is

connected to ground through a connection to the main

power panel.

Ungrounded–The round hole connection is not

connected to a ground and/or the main power panel.

©2005 Maytag Services 16025911 Rev. 0 5

Important Safety Information

Gas Connection Information

! WARNING

To avoid death, personal injury or property damage,

from fire or explosion, information in this manual must

be followed exactly.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

! WARNING

To reduce the risk of fire and exposure to combustion

gases, the dryer MUST be exhausted to the outdoors.

DO NOT exhaust dryer air into a window well, gas

vent, chimney or enclosed, unventilated area, such as

an attic, wall, ceiling, crawl space under a building or

concealed space of a building.

6 16025911 Rev. 0 ©2005 Maytag Services

Important Safety Information

©2005 Maytag Services 16025911 Rev. 0 7

General Information Service

Keep a copy of sales receipt for future reference or in

Model Identification case warranty service is required. To locate an authorized

Complete registration card and promptly return. If servicer:

registration card is missing: • For Maytag product call 1-800-462-9824 or visit the

• For Maytag product call 1-800-688-9900 or visit the Web Site at www.maytag.com

Web Site at www.maytag.com • For product in Canada call 1-866-587-2002 or visit the

• For product in Canada call 1-866-587-2002 or visit the Web Site at www.maytag.com

Web Sites at www.maytag.com or www.jennair.com Warranty service must be performed by an authorized

When contacting provide product information located on servicer. We also recommend contacting an authorized

rating plate. Record the following: servicer, if service is required after warranty expires.

Model Number: ___________________

Manufacturing Number: ___________________ Parts and Accessories

Serial or S/N Number: ___________________ Purchase replacement parts and accessories over the

Date of purchase: ___________________ phone. To order accessories for your product call:

Dealer’s name and address: ___________________ • For Maytag product call 1-800-462-9824 or visit the

Web Site at www.maytag.com

• For product in Canada call 1-866-587-2002 or visit the

Web Sites at www.maytag.com or www.jennair.com

Extended Service Plan

We offer long-term service protection for this new oven.

• Dependability PlusSM Extended Service Plan is

specially designed to supplement Maytag’s strong

warranty. This plan covers parts, labor, and travel

charges.

Call 1-800-925-2020 for information.

Serial Label is located in the lower center of the door

opening and back panel.

8 16025911 Rev. 0 ©2005 Maytag Services

General Information

27” Dryer Nomenclature

M D E 9 7 0 0 A Y W

Color

Brand W White

M Maytag M Platinum

Product Type Listing

DE Dryer Electric W 120V-60hz

Y 240V-60hz

DG Dryer Gas

Z Canada 240V-60hz

Y 220-240 V / 50-60 Hz

Marketing Code

Feature Content This identifies which

9700 Feature Package version of production the

unit is.

Troubleshooting Guide is Located on the

back of the unit.

©2005 Maytag Services 16025911 Rev. 0 9

Troubleshooting Procedures

! WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

Place dryer into Service Mode and check for diagnostic codes. See Technical Data Sheet taped to rear

panel.

Will Not Run Will Not Dry Gas Models

Will not start or run: Poor Gas Ignition

• All wires are hooked up to their corresponding When the dryer is operated on a heat setting, the

terminals. igniter should be energized and burner shall fire within

• Dryer is plugged in. 45 seconds at 120 VAC. The failure of a component in

• Blown fuse or circuit breaker. this system will usually be indicated by one of three

• Door switch functional...door closed. Check for symptoms:

error code 3 (See Table for code definition).

• Start/Pause rotary selector dial functional. The igniter does not glow. If the igniter does not

• Control Board operational. heat up, remove power and using an ohmmeter,

• Drive motor functional. check the following:

• Check motor winding resistance: 2.88ohms • Open flame sensor

between pin #3 and 4, 3.5ohms between pin #4 • Open igniter

and 5. • Shorted booster coil

• Open wiring

Motor runs/ tumbler will not turn: • Bad motor switch ( Neutral supply)

• Belt off or broken/damaged. • No power from control ( L1 supply)

• Idler tension spring too weak or stretched. Igniter glows - No gas ignition. If the igniter heats

• Idler pulley jammed or stuck. up but the main burner flame is not ignited, remove

power and using an ohmmeter, check the following:

Runs a few minutes and then stops: • Open secondary coil

• Lint buildup around drive motor. • Open holding coil

• Low voltage present. • Open wire harness

• Blower impeller blocked in blower • Stuck flame sensor (Stuck closed)

housing. The gas is ignited but the flame goes out. If a

• Drive motor - start switch contacts stuck closed. normal ignition takes place and after a short while the

flame goes out, check for the following:

Blows fuses or trips circuit breaker: • Radiant sensor contacts opening

• The amperage readings are at 240 volts. One line prematurely.

will be 24 amps and the other line will be 21 amps. • Weak gas valve coil may open when

The neutral line will be at 3 amps. If the above stressed by higher temperatures.

amperages are present, then the house wiring, • Weak Hi-Limit

fuse box or circuit breaker should be suspect. • Poor venting

• Shorted heating element to housing. • Bad drum seals

• Incorrect wiring or a wire shorting to ground.

• Drive motor winding shorting to ground. Improper drying/clothes wrinkled/ rough

Gas Models texture/long dry time:

• During ignition the dryer will draw X amps. With the • Lint filter is not clean.

burner ON, the dryer will draw X amps. If the dryer • Restriction in exhaust.

is drawing amperages above this, then the house • Outside exhaust hood damper door stuck closed.

wiring, fuse box or circuit breaker is suspected to • Exhaust too long, too many elbows, flex ductwork

be at fault. installed.

• Igniter harness loose and shorted to base. • Poor intake air available for the dryer.

• Incorrect wiring or wire shorted to ground. • Incorrect tumbler speed. Tumbler belt slipping.

• Drive motor winding shorting to ground. • Blower impeller bound; check for foreign material

in blower area.

Will Not Dry • Customer overloading dryer.

Will not heat (motor runs): • Check clothing labels for fabric content and cycle

• Open heating element. selected.

• Hi-Limit trips easily or is open. • Clothes too wet due to insufficient spin out by

• Regulating thermostat trips easily or is open. washer.

• Membrane switch open.

• Check Thermistor. Will Not Shut Off

• Check Membrane Pad.

10 16025911 Rev. 0 ©2005 Maytag Services

Troubleshooting Procedures

! WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

Troubleshooting the electronic Press the following keys to access:

control circuit: Key Press Special

• Check for miswiring of the electrical connector at Test/Function

the electronic control board. Wrinkle Prevent Display list of

Displays “d” diagnostic codes.

Noisy and/Or Vibration

• Thumping Check for loose tumbler baffle, rear Then rotate the Cycle To sequence thru

tumbler roller(s) worn or misaligned, out-of-round Selector Knob the diagnostic

tumbler or high weld seam on tumbler. and help codes.

• Ticking Check for loose wire harness or object

caught in blower wheel area. Temperature Key Display software

• Scraping Check for front or rear bulkhead felt seal revision number

out of position or worn tumbler front bearings.

• Roaring Check for blower wheel rubbing on blower Start or pause

housing or bad motor bearings. Start/Pause cycle running but

• Popping or squealing sound. Check for a sticky remain in

or frayed belt. diagnostic mode.

Display the

number of cycles

Service Mode ago the

This mode provides Service Personnel the ability to diagnostic code

verify the operation of the dryer. occurred.

The Service Mode can be implemented at any time, System Check Mode

including the middle of a dry cycle. While in the While in Service Mode, pressing the

Service Mode, the Technician can start special Time and Wrinkle Prevent keys for 3 seconds, will

diagnostic tests such as a System Check Mode, LED put the dryer into the System Check mode and "in"

Switch/Check, Display Software version number and will display. The following table lists the various

display diagnostic/help code listings. functions based on the keys being pressed.

Enter Service Mode: System Check Mode Table

Dryer must be on before Service Mode can be

entered. Press Chime and Temperature Keys for 3 Key Pressed: Function

seconds, or until 3 beeps are heard. The machine will Performed

now be in Service Mode. Upon entry into Service

Start/Pause rotary Cycles the motor

Mode, the Sensor Bar Touch

selector dial on/off.

Data is to be displayed.

Rotate the Cycle Selector LED’s and 7

Knob to Delicates segment display

flash.

Exit Service Mode

Press the OFF key to exit Service Mode or repeat the Rotate the Cycle Selector View current

Chime and Temperature sequence. Knob to Sensor cycle temperature

Dry in Celsius.

Diagnostic Tests

The following table lists the various tests available Rotate the Cycle Selector Segment display

while in the Service Mode. Before advancing to the Knob to Wrinkle Control is “1” for sensor

next test, the current test running must be terminated. bar short, “0” for

sensor bar open

Rotate the Cycle Selector View current

Knob to Time Dry cycle

temperature in

Fahrenheit.

©2005 Maytag Services 16025911 Rev. 0 11

Troubleshooting Procedures

! WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

LED/Switch Check Clearing Diagnostic Codes

While in Service Mode, pressing the Chime and To clear the diagnostic code list press the Sensor Dry

Wrinkle Prevent keys for 3 seconds, will start a Level and Time keypads together for 3 seconds while

LED/Switch Test. To exit the test at any point, press viewing the list. The cycle count for each diagnostic

the same keys again for 3 seconds or press the OFF code will be reset to 0, but not the machine cycle

key to exit Service Mode. count.

Perform the check by pressing the keys, which toggle Diagnostic Codes

the LED’s on and off.

Code Description Trigger Action Taken

All switch pads must be pressed within 5 minutes for Dryer The Check for:

1

this test to pass. PA will be displayed for five (5) Thermistor Thermistor - Clogged lint

seconds once all switch pads have been pressed and Short Sensed resistance is screen.

this test is completed. Following 10 seconds of very low. - Restricted vent

system.

inactivity at any point, the test will exit without any

- Check Thermistor

display. The Power Off switch pad must be pressed resistance.

twice within thirty (30) seconds to cancel this test. 2 Thermistor The Check for:

Open Sensed Thermistor - Low ambient

resistance is temperature in

Switch Action very high room (Below

Wrinkle Prevent Press once º º

50 F/10 C).

Chime Press twice - Outside vent

Adjust Time Press once damper is stuck

open in wintertime.

Time Press four times - Loose or open

Temperature Press three times wire terminals.

Dryness Level Press four times - Check Thermistor

resistance.

Selector Knob Rotate 1 position Door Circuit Invalid state Check for:

3

Start Pause Press once Failure for more - Loose or open

Off Press once than 256 wire terminals in

milliseconds Door Sense

circuit.

Diagnostic Codes Possible motor If either Check for:

4

The Diagnostic Codes are identified when the severity transistor error motor - Loose connections

level of the abnormality detected is higher and service transistor is in motor circuit.

may be required. seen open or - Run System

shorted Check Mode and

during check the motor

When a problem with the dryer is detected a startup relay function.

Diagnostic Code is assigned, and can be displayed. - If relay functions,

The Control Board will not log multiple same codes disregard the

per cycle; however, it will log as many Diagnostics as diagnostic code.

- If relay does not

possible for the machine to continue running. function, replace

machine control

Access Diagnostic Codes by entering the Service board.

Mode and pressing Wrinkle Prevent. A d will be

displayed.

Rotate the Cycle Selector Knob in either direction to

step through the list of codes one code at a time.

Once an initial direction is selected by the user (either

Clockwise or Counterclockwise), subsequent

movements of the knob in the same direction will

show older codes. If the user changes direction and

turns the knob in the opposite direction, the more

recent code will be displayed.

While a diagnostic code is displayed, if the

Start/Pause button in the center of the Rotary Cycle

Selector is pressed and held, the machine will display

the number of cycles ago the diagnostic code

occurred. When the Start/Pause button is released,

the diagnostic code is again displayed.

12 16025911 Rev. 0 ©2005 Maytag Services

Troubleshooting Procedures

! WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

Code Description Trigger Action Taken FE Power Invalid Check for:

Stuck Key A key is Run membrane pad

source power - Not using

8

sensed to be check and replace frequency source regular

pressed console w/membrane Error Frequency power

more than pad if necessary. source

75 seconds,

the key shall

frequency

be assumed - Invalid

to be stuck. power

10 No Wet Clothes Sensor Check for: frequency

bar - Running dryer sense

detects no with circuit

wet no wet clothes in

clothes sensor dry cycle dC Door Circuit Invalid state Check for:

while a Failure for more - Loose or

Sensor than open

Dry 256 wire

Cycle milliseconds terminals in

Door Sense

circuit.

Display Fault/Error Codes - Check for

Display Description Trigger Action diagnostic

Taken code 3

tS Dryer The Check for: hE Heater Error Invalid Check for:

Thermistor Thermistor - Clogged lint heating - Restricted

Short resistance is screen. temperature vent

Sensed very low. - Restricted in running system.

vent the - Check

system. dryer Thermistor

- Check resistance.

Thermistor

resistance.

- Check for

diagnostic

code 1

do Door Open Running the Check for:

dryer with - Close the

door open door,

and run the

dryer

- Loose or

open

wire

terminals in

Door Sense

circuit.

- Check for

diagnostic

code 3

©2005 Maytag Services 16025911 Rev. 0 13

Component Testing Information

! WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

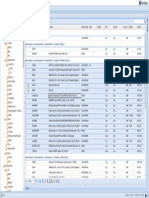

Illustration Component Test Procedure Results

Thermistor Unplug harness connector and test

from wire insertion side.

Pin #2 and Pin #6 of CN6 10000 ohms @ 77° F/25°C

Door Switch Unplug connectors and test switch

terminals.

Door open terminals COM to NC/ 1 to Infinity

3

Door open terminals COM to NO/1 to

2 Less than 1 ohm

Door closed terminals COM to NC/ 1

to 3 Infinity

Door closed terminals COM to NO/ 1 Less than 1 ohm

to 2

Light Unplug connectors and test switch

terminals.

Check across terminals 80 to 100 ohms

Belt Switch Unplug connectors and test switch

terminals.

Check across terminals switch closed Less than 1 ohm

Check across terminals switch open Infinity

Motor Unplug harness connector and test

motor circuits.

Pin #4 and Pin #5 (Windings) 2 ohms

Pin #1 and Pin #2 (Centrifugal switch) Open

Thermostat Unplug connectors and test

Thermostat terminals.

185°F/85°C 25A

Check across terminals Less than 1 ohm

Hi Limit Unplug connectors and test

Thermostat terminals.

210°F/99°C 25A

Check across terminals Less than 1 ohm

Thermal Cut Off Unplug connectors and test

Thermostat terminals.

Check across terminals Less than 1 ohm

Heater Element Unplug connectors and test Heater

terminals 10 ohms

14 16025911 Rev. 0 ©2005 Maytag Services

Component Testing Information

! WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

Illustration Component Test Procedure Results

Sensor Bars Unplug harness connector and test

from wire insertion side.

Pin #4 to Pin # 5 of CN6

Infinity dry load 190ohms ± 10% wet

load

Radiant Sensor Unplug connectors and test sensor

terminals. Closed

TH2 Safety Unplug connectors and test

Thermostat Thermostat terminals. Less than 1ohm

Gas Valve Unplug connectors and test valve

terminals.

Check across terminals #1 and #3

(Booster Coil). 550ohms

Check across terminals #1 and #2

(Holding Coil). 1350ohms

Check across terminals #2 and #3

(Both coils in series). Check across 1900ohms

terminals #4 and #5 (Secondary Coil).

1300ohms

Motor Contacts

Gas Valve

Function 1M 2M 3M 5M 6M

Start

Run

= Contact closed

Centrifugal Switch (Motor)

123 45

©2005 Maytag Services 16025911 Rev. 0 15

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

Door Reversal/Disassembly

1. Disconnect power supply to unit.

2. Remove four screws and Door Strike.

6. Remove Inner Panel.

3. Remove two screws attaching Door Hinge.

7. Remove Gasket.

4. Install Door and Strike on opposite sides or continue

with Door disassembly.

5. Remove screws around perimeter of Door Inner

Panel.

16 16025911 Rev. 0 ©2005 Maytag Services

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

8. Remove Inner Door Glass. Interior Light

1. Disconnect power supply to unit.

2. Remove Lens screw and Lens. Bulb is a screw in

base 10W 120V AC.

9. Remove outer door viewing panel. Insert screwdriver

in slot to disengage latch.

Top Removal

1. Disconnect power supply to unit.

2. Remove 2 10mm screws from dryer back.

3. Slide Top Cover towards the rear and lift from unit.

©2005 Maytag Services 16025911 Rev. 0 17

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

Console Removal

1. Disconnect power supply to unit.

2. Remove Top Cover.

3. Remove two screws mounting the Heater PCB Board.

4. Disconnect the black and white connectors.

Drum Baffle Removal

1. Disconnect power supply to unit.

2. Remove Top Cover.

3. Remove four screws located at the sound dampening

seem.

5. Remove four screws attaching Console to washer.

18 16025911 Rev. 0 ©2005 Maytag Services

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

6. Rotate Console down and remove from dryer.

Front Panel Removal

1. Disconnect power supply to unit.

2. Remove Top Cover.

3. Remove Console.

4. Remove four screws attaching Front Panel to dryer.

5. Remove two screws in the door area.

Heater Assembly Removal

1. Disconnect power supply to unit.

2. Remove Top Cover.

6. Pull Front Panel forward and disconnect the Interior

3. Remove Console.

Light harness.

4. Remove Front Cover.

5. Remove Heater Assembly retaining screw.

7. Lift the Front Panel off the three tabs across the

bottom and remove.

©2005 Maytag Services 16025911 Rev. 0 19

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

6. Slide Heater Assembly out the front of dryer..

8. Reinstall by aligning the tabs on the back bulkhead

with the notches in the Heater Assembly .

7. Remove the wiring terminals from the Heater

Assembly.

20 16025911 Rev. 0 ©2005 Maytag Services

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

Front Bulkhead Removal

1. Disconnect power supply to unit.

2. Remove Top Cover.

3. Remove Console.

4. Remove Front Panel.

5. Remove screws retaining Console Back Cover.

6. Disconnect Interior Light wiring harness.

8. Remove four Bulkhead retaining screws

7. Disconnect Moisture Sensor wiring harness.

©2005 Maytag Services 16025911 Rev. 0 21

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

9. Lift Bulkhead from Cabinet and remove. 6. Remove sensor attachment screw.

Belt Removal

1. Disconnect power supply to unit.

2. Remove Top Cover.

3. Remove Console.

4. Remove Front Panel.

5. Remove belt from Idler Pulley

Moisture Sensor Removal

1. Disconnect power supply to unit.

2. Remove Top Cover.

3. Remove Console.

4. Remove Front Panel.

5. Disconnect Moisture Sensor wire harness.

22 16025911 Rev. 0 ©2005 Maytag Services

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

Drum Removal

1. Disconnect power supply to unit.

Pull Idler 2. Remove Top Cover.

Pulley 3. Remove Console.

4. Remove Front Panel.

5. Remove Console Back Cover.

6. Remove Front Bulkhead.

7. Remove belt from Idler Pulley.

8. Grasp the Drum with one hand and the belt with the

other. Lift the Drum and slide out the front. Carefully

spread the cabinet as needed to gain additional

clearance.

Belt Switch Removal

1. Disconnect power supply to unit.

2. Remove five screws retaining Vent Tube cover.

3. Remove Belt Switch mounting screw.

Motor/Blower Assembly Removal

1. Disconnect power supply to unit.

2. Remove Top Cover.

3. Remove Console.

4. Remove Front Panel.

5. Remove Console Back Cover.

6. Remove Belt from Idler Pulley.

7. Remove Drum.

8. Remove the two screws securing the Blower Intake

Panel to the Blower Housing. Remove Blower Intake

Panel.

Belt

Switch

©2005 Maytag Services 16025911 Rev. 0 23

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

10.Remove the blower attachment screw under the

Thermistor.

11. Remove two screws attaching the motor bracket to

the base.

9. Removed the screw at the bottom of the blower

housing.

24 16025911 Rev. 0 ©2005 Maytag Services

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

12.Disconnect the Motor wire harness and the two wires

to the belt switch.

13.Slide the Motor Blower Assembly toward the heater

and lift to disengage the tabs on the motor from the NOTE: A wrench can be placed on both ends of the

slots in the base. Motor Output Shaft.

15.Remove Blower Wheel.

14.Remove the 14mm nut securing the blower wheel to

the shaft. The nut is a left hand thread. 16.Remove the three screws securing the blower

housing to the motor bracket.

©2005 Maytag Services 16025911 Rev. 0 25

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

17.Remove the three screws securing the blower Rear Bulkhead Removal

housing to the motor bracket . 1. Disconnect power supply to unit.

2. Remove Top Cover.

3. Remove Console.

4. Remove Front Panel.

5. Remove Console Back Cover.

6. Remove Belt from Idler Pulley.

7. Remove Drum.

8. Remove 7 screws from the back.

18.Use a wide blade screwdriver to pop off the motor

retention clamps.

9. Lift the rear bulkhead off the right and left side

hangers.

26 16025911 Rev. 0 ©2005 Maytag Services

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

Rear Roller Removal

1. Disconnect power supply to unit.

2. Remove Rear Bulkhead.

3. Remove Roller Keeper and nut.

Gas Model Disassembly

Igniter Removal

1. Disconnect power supply to unit.

2. Remove Top Cover.

3. Remove Console.

4. Remove Front Panel.

5. Loosen the single screw attaching the igniter to the

Burner Assembly. Slide the Igniter back and remove.

©2005 Maytag Services 16025911 Rev. 0 27

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

! WARNING death; disconnect power to unit before servicing.

NOTE: The Igniter Bar is fragile. Be careful not to

! WARNING damage Igniter when removing Burner

Assembly.

To avoid risk of personal injury or death; shut off gas

supply to unit before servicing Burner Assembly.

Burner Removal

1. Disconnect power supply to unit.

2. Shut off gas supply.

3. Disconnect gas line.

5. Remove the two screws attaching the housing to the

burner bracket. The screws are recessed from view.

6. Slide Burner Assembly from dryer.

4. Remove two screws securing burner to bracket.

28 16025911 Rev. 0 ©2005 Maytag Services

Appendix A

©2005 Maytag Services 16025911 Rev. 0 29

30 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 31

32 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 33

34 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 35

36 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 37

38 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 39

40 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 41

Appendix B

42 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 43

44 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 45

46 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 47

48 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 49

50 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 51

52 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 53

54 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 55

56 16025911 Rev. 0 ©2005 Maytag Services

©2005 Maytag Services 16025911 Rev. 0 57

58 16025911 Rev. 0 ©2005 Maytag Services

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Iso 5852 SDokument37 SeitenIso 5852 SGhasem A. JavidNoch keine Bewertungen

- Sensor LaserDokument3 SeitenSensor LaserAbraham del Hoyo SotoNoch keine Bewertungen

- MCCB 400A-600A Eaton Cutler HammerDokument8 SeitenMCCB 400A-600A Eaton Cutler HammerWiratama TambunanNoch keine Bewertungen

- eMan-KSB ETAPUMP® Solar Water Pump Instruction ManualDokument43 SeiteneMan-KSB ETAPUMP® Solar Water Pump Instruction ManualMoly69xNoch keine Bewertungen

- Report - Guide To Microwave Project Installation Materials Survey-20090728-B-1.3Dokument16 SeitenReport - Guide To Microwave Project Installation Materials Survey-20090728-B-1.3Julio Jose Villa GuerreroNoch keine Bewertungen

- ECM Process ExplainedDokument15 SeitenECM Process Explainedpratik thakareNoch keine Bewertungen

- Exam Questions on Electricity and MagnetismDokument14 SeitenExam Questions on Electricity and MagnetismJatinNoch keine Bewertungen

- An 9005Dokument15 SeitenAn 9005MANOEL SAMPAIONoch keine Bewertungen

- Datasheet STD724 TRANSISTORDokument10 SeitenDatasheet STD724 TRANSISTORArnoldo DazaNoch keine Bewertungen

- Ifc 300 PDFDokument44 SeitenIfc 300 PDFahmed nawazNoch keine Bewertungen

- Work Practice Manual PDFDokument728 SeitenWork Practice Manual PDFMANOLOTEDIAZMURILLO100% (1)

- ELECS1 Module 1 Introduction and HistoryDokument20 SeitenELECS1 Module 1 Introduction and HistoryJuan Miguel VillarroelNoch keine Bewertungen

- Root Category: # Free Space (1 Part(s) )Dokument1 SeiteRoot Category: # Free Space (1 Part(s) )MiguelNoch keine Bewertungen

- Gv-241 User ManualDokument23 SeitenGv-241 User ManualJim CNoch keine Bewertungen

- Huawei OptiX Metro 1000 Commissioning Guide (V300R007)Dokument143 SeitenHuawei OptiX Metro 1000 Commissioning Guide (V300R007)Thunder-Link.comNoch keine Bewertungen

- Cgah Chiller IomDokument28 SeitenCgah Chiller IomLuong Dao100% (2)

- PA-2 Circuit Diagram and Parts ListDokument8 SeitenPA-2 Circuit Diagram and Parts Listfazenda sao gabrielNoch keine Bewertungen

- Standard Power Cable Details and RatingsDokument5 SeitenStandard Power Cable Details and RatingsMartynas PreisaitisNoch keine Bewertungen

- South Bihar Power Citizen Charter for ConsumersDokument2 SeitenSouth Bihar Power Citizen Charter for ConsumersAlok AmanNoch keine Bewertungen

- Masatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsDokument225 SeitenMasatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsPo48HSDNoch keine Bewertungen

- Design and Development of Two Wheeler To Avoid Trible Riders and AccidentsDokument6 SeitenDesign and Development of Two Wheeler To Avoid Trible Riders and Accidentsvenkat krishnanNoch keine Bewertungen

- An 1001Dokument10 SeitenAn 1001martin_powell_15Noch keine Bewertungen

- WileyCMOS Circuit Design, Layout, and Simulation, 3rd EditionDokument2 SeitenWileyCMOS Circuit Design, Layout, and Simulation, 3rd EditionRoshdy AbdelRassoulNoch keine Bewertungen

- AP Physics 2: Algebra-Based 2015 Free-Response QuestionsDokument11 SeitenAP Physics 2: Algebra-Based 2015 Free-Response QuestionsAdam El TohamyNoch keine Bewertungen

- Introduction To Safety Precautions & Lab Equipment: Power Transmission and Distribution LabDokument16 SeitenIntroduction To Safety Precautions & Lab Equipment: Power Transmission and Distribution LabMuhammad Saad AbdullahNoch keine Bewertungen

- Experiment No. 5 The Wound Rotor Induction MotorDokument8 SeitenExperiment No. 5 The Wound Rotor Induction MotorJoshua DimasalangNoch keine Bewertungen

- Ae-02r1 Ohe2-1 PDFDokument1 SeiteAe-02r1 Ohe2-1 PDFAbhishek GuptaNoch keine Bewertungen

- Toshiba 32bv700b Chassis 17mb45m-3 PDFDokument66 SeitenToshiba 32bv700b Chassis 17mb45m-3 PDFRobert VojakNoch keine Bewertungen

- Growatt 1500-US/2000-US/3000-US TL technology datasheetDokument2 SeitenGrowatt 1500-US/2000-US/3000-US TL technology datasheetJonathan León100% (1)

- 80010292Dokument2 Seiten80010292Anonymous ZYBA1RNoch keine Bewertungen