Beruflich Dokumente

Kultur Dokumente

6820-02 - ISS - UPRVUNL - TO-BE - FSCM-Coal Requirement Planning - V1.3

Hochgeladen von

Krishna PremeeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

6820-02 - ISS - UPRVUNL - TO-BE - FSCM-Coal Requirement Planning - V1.3

Hochgeladen von

Krishna PremeeCopyright:

Verfügbare Formate

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

To-Be Process Document for SAP S/4HANA Fuel Supply

Chain Module (FSCM): Coal Requirement Planning

Project Name: IMSS Implementation at UPRVUNL

Project ID: 6820-02 Document ID: FSCM_TO-BE_01

Document Version / Details: V-1.3/16.05.2020

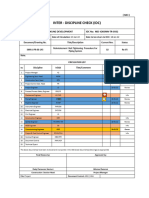

Record of Release

LTI & UPRVUNL Confidential Page 2 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Version Prepared By Reviewed By Authorized Release Modifications Done

No. By Date

1.0 Ganesh J.Sathianarayanan Imtiyaz 18.02.2020 Released for internal review

Swaminathan Ahmad

1.1 Ganesh J.Sathianarayanan Imtiyaz 07.03.2020 Changes as suggested have

Swaminathan Ahmad been included

1.2 Ganesh J.Sathianarayanan Imtiyaz 30.03.2020 Changes in the number

Swaminathan Ahmad format of the sections

1.3 Ganesh J.Sathianarayanan Imtiyaz 16.05.2020 Updated Core team review

Swaminathan Ahmad comments

Abbreviation

Abbreviation Description

AE Assistant Engineer

LTI & UPRVUNL Confidential Page 3 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Abbreviation Description

AHD Ash Handling Division

A-TPS A- Thermal Power Station

ABT Availability based tariff

BMD Boiler Maintenance Division

B-TPS B-Thermal Power Station

CE Chief Engineer

CEA Central Electricity Authority

CGM Chief General Manager

CHD Coal handling division

CIMD Control and Instrumentation Maintenance Division

CMD Coal movement division

CI Capacity Index

CIL Coal India limited

D-TPS D- Thermal Power Station

DM De-mineralized (water)

Dy-GM Deputy General Manager or SE

EE Executive Engineer

EMD Electrical Maintenance Division

ESP Electrostatic Precipitator

FPD Fuel Purchase Division

F-note Forwarding note

F&A Finance and Accounts

GM General Manager

HP/ LP High Pressure and Low-Pressure pumps

IL Instrumentation Limited

JE Junior Engineer

KPI Key performance indicator

MB Measurement Book.

MCB Main control board

MIS Management of Information Systems

NA Not Available

NCL Northern coalfields limited

O&M Operations and Maintenance

OEM Original equipment manufacturer

OGD Operation General Division

ORT Operation review technology

PLF Plant Load Factor

LTI & UPRVUNL Confidential Page 4 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Abbreviation Description

R&M Refurbishment and Modernization Circle

RR Railway receipt

SE Superintendent Engineer (Deputy General Manager)

SOC (Power) Send out capability.

TMD Turbine Maintenance Division

TOM Thermal Operations and Monitoring

TSD Technical Services Division

UCB Unit control board

UI Unscheduled Interchange

UPRVUNL Uttar Pradesh Rajya Vidyut Utpadan Nigam Ltd.

WTP Water Treatment Plant

WMDR Work memo debit receipt

FSA Fuel Supply Agreement

CRP Coal Requirement Planning

ACQ Actual Contracted Quantity

MIQ Monthly Indented Quantity/Monthly Rake Program

MSQ Monthly Scheduled Quantity

PLF Plant Load Factor

BPO Business Process Owner

FOIS Freight operation information system

Band Declared Grade/Actual Grade

FRS Functional Requirement Specification

LTI & UPRVUNL Confidential Page 5 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Table of Contents

1. Business Outlook..........................................................................................6

2. Business Scenario’s in Fuel Supply Chain Management (FSCM)................................8

2.1 Coal Requirement Planning.............................................................................................8

3. Organization Structure..................................................................................9

3.1 Company Code...........................................................................................................10

3.2 Plant......................................................................................................................10

3.3 Purchase Organization.................................................................................................10

3.4 Purchasing Group.......................................................................................................11

3.5 Storage Location........................................................................................................11

4. Master Data..............................................................................................12

4.1 Material Master Data..................................................................................................12

4.2 Vendor Master...........................................................................................................13

4.3 Vendor Account Group:................................................................................................13

4.4 Batch Class and Characteristics......................................................................................14

4.5 Batch Class...............................................................................................................14

4.6 Batch Characteristic:...................................................................................................14

4.7 Transportation and In-Transit stock Master Data.................................................................14

4.8 Location..................................................................................................................14

4.9 Transport System.......................................................................................................15

4.10 Partner Role.............................................................................................................15

5. Business Process: Coal Requirement Planning in Fuel Supply Chain Management.......16

5.1 Requirements of Business Process...................................................................................16

5.2 Proposed Solution......................................................................................................18

5.3 Process Flow.............................................................................................................20

5.4 Process Steps............................................................................................................21

5.5 System Configuration Values.........................................................................................21

5.6 Integration Points......................................................................................................22

5.7 Fit-Gap Analysis.........................................................................................................22

5.8 Technical Developments...............................................................................................22

5.9 Organization/Entities Impacted......................................................................................24

5.10 High Level Data Migration/Cut over requirements with priority...............................................24

5.11 Standard and Customized Reports...................................................................................24

5.12 Change Management and Business Impact Assessment...........................................................24

5.13 Additional details (if any).............................................................................................24

5.14 Assumptions & dependencies (if any)...............................................................................24

5.15 Constraints...............................................................................................................24

6. Sign-off (Approval) for this document:.............................................................25

LTI & UPRVUNL Confidential Page 6 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

1.Business Outlook

UPRVUNL is wholly owned state thermal power utility with present generating capacity of 5160

MW, operating 4 Thermal Power Projects within Uttar Pradesh.

Uttar Pradesh Rajya Vidyut Utpadan Nigam Limited (UPRVUNL) was constituted on dated

25.08.1980 under the Companies' Act 1956 for generation of thermal power in the state sector.

Today it is looking after operations of 4 thermal power plants located in different parts of U.P.,

with a total generation capacity of 5160 MW as follows

Name of Power Installed Derated Capacity Upcoming Remarks

Station Capacity Capacity

ANPARA, 3X210 MW 3X210 MW = 630 N/A N/A

SONEBHADRA 2X500 MW MW

2X500MW 2X500 MW = 1000

MW

2X500MW = 1000

MW

OBRA, 1X100 MW 1X94 MW = 94 MW 2x660 94 MW under

SONEBHADRA 5X200 MW 5X200 MW = 1000 MW deletion

2X660 MW MW 2X660 MW under

construction

PARICHHA, 2X110 MW 2X110 MW = 220 1140 MW 2X110 MW under

JHANSI 2X210 MW MW deletion

2X250 MW 2X210 MW =420

MW

2X250 MW =500

MW

HARDUAGANJ, 1X110 MW 1X110 MW = 110 1x660 660 MW under

ALIGARH 2X250 MW MW MW construction

2X250 MW = 500

MW

PANKI, N/A N/A 1x660MW 660 MW under

KANPUR construction

JAWAHARPUR N/A N/A 2x660 1320 MW

MW = Under construction

1320MW JVUNL –

Subsidiary of

UPRVUNL

Uttar Pradesh Rajya Vidyut Utpadan Nigam Limited (UPRVUNL) is currently in the process of

implementing SAP ERP S/4 HANA as a central ERP application for managing overall business

LTI & UPRVUNL Confidential Page 7 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

functions. L&T Infotech (LTI) a division of Larsen & Toubro Group Company has been selected as

the external service provider for providing services to UPRVUNL for this project.

SAP S/4 HANA Solution is expected to integrate all the related business processes in scope and

provide business decision support for functions such as business planning, budgeting etc.,

The following modules of SAP S/4 HANA are being implemented as part of this Project:

With the implementation of S/4 HANA, UPRVUNL wishes to achieve the following key

objectives and business benefits;

Business process/function standardization and process integration.

Data harmonization, ensuring clean and accurate data.

Enhanced dependability and performance.

Higher job satisfaction and motivation for employees.

Enterprise-wide access to all asset-related data repositories.

Improved information management to enable information availability.

Enable adoption of best practices.

Effective monitoring

Increased efficiency and productivity.

Reducing costs.

Streamlining processes.

Employee data maintained centrally and would be up to date, thus reducing efforts of

maintaining data at multiple systems and locations.

Provide more transparency and reduce the cycle time in employee HR process via ESS.

Increase data accuracy that will in turn lead to reduction in human errors and rework if

any.

Seniors / Supervisors would be able to take various decisions / approvals thru MSS.

Migrating certain manual paper-based process to SAP ERP thus reducing the cycle

time, cost and efforts.

LTI & UPRVUNL Confidential Page 8 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Fuel handling unit at the plants is responsible for fuel planning, handling and purchase. The unit

handles coal, furnace oil and high-speed diesel. The Fuel handling unit is headed by GM

(general manager) at the plants. There is a fuel department at headquarters which headed by CE.

Its primary role is to ensure proper linkage, continuous monitoring of fuel at the plants and to

manage different situations related to transportation and availability of fuel. Based on the

position of coal stock at various plants, the headquarters can facilitate reallocation of coal by

diverting coal destined for one plant to others.

Currently the sources of fuel are CIL and its subsidiaries (NCL, WCL, CCL and BCC).

2.Business Scenario’s in Fuel Supply Chain Management (FSCM)

Business scenarios in Fuel Supply Management at UPRVUNL are as follows.

1. Coal Requirement Planning

2. Coal Procurement (Transportation & Logistics)

3. Coal Inspection (Quality Management)

2.1 Coal Requirement Planning

Objectives of Fuel Management:

1. Planning and Procurement of appropriate quantity and quality of Coal suitable for the design

parameters of the plant and achieving the generation targets.

2. Proper coordination with collieries and railways

3. Effective fuel handling to minimize the wastage and demurrage charges to have stock for

meeting the Coal lean periods and to ensure quality preservation during stocking

4. Continuous monitoring of the fuel quantity and consumption for continuous improvement.

5. Efficient consumption to achieve the targets set by the regulator

6. Have a proper fuel accounting

7. Ensure continuous feeding of Coal to the generating units by proper operation and

maintenance of Plant.

Requirement Planning – Coal

1. Quarterly requirement of fuel is estimated based on the planned outage plans, generation

targets and the average specific consumption of the fuel.

2. Data from all the thermal power stations is collected and sent to the headquarters.

3. The total fuel requirement is sent to the Standing Linkage Committee (SLC).

4. Linkage Committee allocates the Coal mines

5. Quantity of Coal allocated, and monthly dispatch schedule is sent to the plants.

6. The minutes of meeting, in which the quantity of Coal is allocated to the plants, is sent to the

managing director, UPRVUNL.

7. CE (Chief Engineer), Fuel receives daily stock position at different plants.

Requirement Planning – Oil

1. Oil Storage level is monitored by the fuel handling division. The consumption of oil is

measured daily by the fuel handling division.

2. A proper lead time is calculated based on the specific consumption and generation

targets.

3. In order to avail the best offer, the price bids are invited from the Oil companies. Oil is

purchased only from selected Oil PSU’s.

LTI & UPRVUNL Confidential Page 9 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

4. The best offer is availed, and an order is placed mentioning the delivery schedule.

3.Organization Structure

Organization structure in SAP S/4 HANA represents the Clients Organization Structure from

the perspective of conducting the business. The Organization structure of the Client need to be

properly represented in the system in order to derive the desired results. SAP S/4 HANA works

on the nodes of the Organizational Units and Master Data. While the data flows from Master

data, the data is being maintained and reported based on Organizational Units.

UNL (Uttar Pradesh Rajya Vidyut Utpadan Nigam Limited) and JNL (Jawaharpur Vidyut

Utpadan Nigam Limited) is created as a Company Codes which are separate Legal entities.

Various plants and Storage locations will be created under these Company Codes to monitor

Inventory Management and Quality Management.

Organization Structure: Fuel Supply Chain Management

Organization Structure SAP S/4 HANA

LTI & UPRVUNL Confidential Page 10 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

3.1 Company Code

Definition:

The Company code is the central Organizational Unit of external accounting within SAP

System. The business transactions relevant for Financial Accounting are entered, saved, and

evaluated at Company Code level. You usually create a legally independent Company in the

SAP System with one Company Code.

Use:

a. All business transactions related to FSCM are processed within a Company Code.

b. UPRVUNL will have 2 Company Codes namely UNL and JNL as follows.

Company Code Company code Name

UNL Uttar Pradesh Vidyut Utpadan Nigam Limited

JNL Jawaharpur Vidyut Nigam Limited

3.2 Plant

Definition:

Plant is an Organizational Unit serving to subdivide an enterprise according to Production,

Procurement, Maintenance, and Materials Planning aspects. It is a place where either material is

produced, or goods and services are provided or where maintenance is carried out or

Depots/Godowns/Branch Office from where the materials are stocked and sold to Customer.

Use:

a. The Material stocks are valuated at Plant level.

b. The Material Stocks are managed within a plant

c. Material requirements are planned for each Plant

Structure:

Plant Code in S/4 HANA is 4-character alpha numeric structure with name.

Plant Code Plant Name

1000 UPRVUNL Corporate Office

1001 Anpara Thermal Power Station

1002 Obra Thermal Power Plant

1003 Harduaganj Thermal Power Plant

1004 Parichha Thermal Power Plant

1005 Panki Thermal Power Station

2001 Jawaharpur Thermal Power Plant

3.3 Purchase Organization

Definition:

An Organizational Unit which is responsible for procuring materials or services for one or more

plants and for negotiating general conditions of purchase with the Vendors. The Purchase

Organization assumes Legal responsibility for all the external Purchase transactions. Purchase

Organization has alpha numeric naming convention with 4 digits.

Use:

a. Purchase Organization has its own Vendor Master Data

LTI & UPRVUNL Confidential Page 11 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

b. All items of an external purchasing document that is, request for quotation, purchase order,

contract, or scheduling agreement, belong to a Purchase Organization.

c. A Purchase Organization can be divided into several purchase groups that are responsible

for different operational areas.

d. The Purchase Organization is the highest level of aggregation for Purchasing statistics.

e. Vendor evaluation is carried out at Purchase Organization level.

f. Purchase info record, and Source list master data contains reference to Purchase

Organization.

Structure

A centralized purchase organization will be created for UNL and JNL respectively. This will

meet the needs of local and central procurements for both the Company Codes.

Sr. Purchase Org Purchase Plants

No Organization Code

1 Uttar Pradesh Rajya Vidyut Utpadan 1000 All Thermal power plants

2 Jawaharpur Vidyut Utpadan 2000 Jawaharpur TPS

3.4 Purchasing Group

Definition:

Purchase Group is a set of buyer or group of buyers responsible for certain purchasing activities.

Use:

a. A Purchasing group can also act/work for several purchasing organizations i.e. Purchasing

groups are global and client specific.

b. Purchasing group are assigned to Materials at Plant level (In the material master record, in

purchasing view, purchasing groups are assigned to a material. If a buyer is common for more

than one plant that it is possible to assign the same purchasing group in all plants.

c. The Purchasing group is further subdivided into buyer groups, which are responsible for day

to

day buying activities.

3.5 Storage Location

Definition:

A Storage location is the place where stock is physically kept within a plant. Storage location is

an Organizational Unit that allows differentiation of Stocks within a Plant.

Use:

a. Storage location have a 4-digit alpha numeric code and are assigned to the plant code.

b. Physical Inventories are carried out at storage location level

c. List of Storage locations.

Plant Plant Type of Coal Storage Location nos.

Code

Anpara Thermal Power Plant 1001 Crushed

Anpara Thermal Power Plant 1001 Uncrushed

Obra Thermal Power Plant 1002 Crushed

Obra Thermal Power Plant 1002 Uncrushed

Harduaganj Thermal Power Plant 1003 Crushed

Harduaganj Thermal Power Plant 1003 Uncrushed

Parichha Thermal Power Plant 1004 Crushed

Parichha Thermal Power Plant 1004 Uncrushed

LTI & UPRVUNL Confidential Page 12 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Panki Thermal Power Plant 1005 Crushed

Panki Thermal Power Plant 1005 Uncrushed

4.Master Data

Master data contains information that is used over a long period of time. Master data forms the

basis of Fuel Supply Chain Management. Data about the products as well as about business

partners (Vendors) are stored in the master data and is the basis for Coal Supply Chain. Master

data is the building structure in SAP. Various Master data elements are required which also has

certain integration elements of cross modules such as;

1. Material Master

2. Vendor Master

3. Batch Class and Characteristics

4. Location

5. Transport System

6. Partner

7. Vehicle

8. Transport Unit

4.1 Material Master Data

The Material master contains information’s on all the materials that UPRVUNL procures, stores

and consumes. It is UPRVUNL central source for retrieving material specific data. This

information is stored in the individual material master records in S/4 HANA.

The material master is used by all components in the SAP Logistics System. The integration of

all material data in a single database object eliminates redundancy in data storage. In the SAP

Logistics System, the data contained in the material master is required, for example, for the

following functions.

1. In Purchasing for Ordering

2. In Inventory Management for goods movement postings and physical inventory.

3. In Invoice verification for posting invoices

Material Type:

Material having similar attributes are categorized together and assigned to a material type;

Following standard material types are being used in UPRVUNL

Sr. Material Type Material Type Price Number Example

No Code Description Control Range

1 ROH Raw Material S External Coal

Material Group:

Material group is a key that, is used to group together several materials or services with the

same attributes. Each Material or Service is assigned to a particular material group. Material

group is used for reporting purpose and we can restrict the scope of analyses and search material

master records via search helps.

Keeping in view of the business process of Coal supply chain mapping the following fields will

be maintained for creating the Material Master;

Screen View Field Remark

Basic Data 1 Unit of measure Mandatory

Material Group Optional

Classification Class (Batch Class) Mandatory

LTI & UPRVUNL Confidential Page 13 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Screen View Field Remark

Purchasing Purchasing group Mandatory

Batch Management indicator Mandatory

Quality Management Inspection Type Optional

Accounting 1 Valuation class Mandatory

Costing 1 Price Control Mandatory

Profit Center Mandatory

Storage Location Stock Storage location Mandatory

Process steps for Material Master (Coal)

Process Steps Transaction Explanation, variations and Business

Code exceptions Role/Actor

MM-01-01-01 MM01 Create Material Master Central team

MM-01-01-02 MM02 Change Material Master Central team

MM-01-01-03 MM03 Display Material Master Central team

4.2 Vendor Master

Definition:

The Vendor Master database contains information about the Vendors who supply the material

or service to UPRVUNL. The information is stored in individual Vendor Master records. A

Vendor master record contains the Vendor’s name and address as well as data such as currency,

terms of payment, and pricing group.

Since Vendor’s are generally Creditors (Accounts Payable) the Vendor master record also

contains accounting information such as relevant control account (reconciliation account) in the

general ledger.

Use:

a. To create purchase orders and contracts

b. Payment processing for Vendors

4.3 Vendor Account Group:

Vendors are broadly grouped into different group by using Vendor Account Group. During the

Vendor master creation every Vendor needs to be assigned to a Vendor Account Group.

Following Vendor Account Groups will be created and the same will be available during

Vendor master creation;

Sr. No Vendor Account Group Description Number Range

1 ZDOM Domestic vendors 100000-199999

2 ZIMP Import vendors 200000-299999

4.3.1 Vendor category:

Following Vendor category options are available in basic view of Vendor master and same need

to be chosen from dropdown while creating Vendor Master;

1. Supplier-Coal Companies

2. Contractor-Third Party Inspection Agencies

3. Transport-Railways

LTI & UPRVUNL Confidential Page 14 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

4.4 Batch Class and Characteristics

Batch classification is a functionality to store batch specific data such as Ash content, Moisture,

Grade, GCV etc.

Characteristic are criteria or test attribute against which values are entered in batch class.

4.5 Batch Class

One Class of type batch class will be created for Coal inspection process. This object

encapsulates the characteristics that with criteria

Batch Class Type Description

023 Coal Sample

4.6 Batch Characteristic:

In the Coal inspection process at UPRVUNL, Characteristics is created while creating and

assigned to class. Two different types of Characteristics shall be created

1. User defined characteristics such as Grade, GCV, Ash content, Inherent moisture.

2. Characteristics for which values are posted automatically e.g. Dispatched date.

4.7 Transportation and In-Transit stock Master Data

An in-transit plant and an in-transit storage location are entered in the transport system master

data record to represent stock which is being transported.

4.8 Location

Definition:

Location is fixed point in Supply Chain where is Coal is handled in supply source such as

Railway siding or receiving source such as power plants where loading or discharge activities

takes place respectively where stock holdings exist.

Location is categorized as origin or destination location E.g. Siding is an origin location and

Plant can be origin location or destination location

Vendors shall be set as locations during In-Transit.

The following structural parameters are defined to set up Location.

Parameters Description

Location ID Unique Identification of Location (Siding or Plant etc.)

Location Type Origin or Destination location

Location name Detailed description of Location

*ROM Coal, Washed Coal, Deshaled Coal materials are assigned to the defined

locations

4.9 Transport System

Transport system is the in-transit stock holding object of Coal representing the Mode of

Transport (Railways)

One of the functions of a transport system is to link the locations in the supply chain. As a

result, at least two locations must be assigned to a transport system. A location can either be an

origin for the transport system (supplies Coal into transport system), or the location can be a

destination of the transport system (receives Coal from the transport system). A location can

also be defined as both an origin and a destination. As a result, the Coal Supply network is

defined in terms of loading and discharge points for each transport system.

An in-transit plant and an in-transit storage location are created in transport system is a pre-

requisite master data set up required to represent stock available in transport system

LTI & UPRVUNL Confidential Page 15 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

The key parameters required to set up transport system.

Parameters Description

The transport system ID and transport system

Transport System ID

description are freely definable

Shipping Type Defines the Mode of transport (Railways)

An in-transit plant and an in-transit storage location

In-Transit plant and Storage Location are entered in the transport system master data record

to represent stock which is being transported

The tolerance level is used to check actual movement

Tolerance level

quantities against the quantities available from FOIS

4.10 Partner Role

The Partner role Master Data is used to define various business partners associated with Coal

Supply Chain. The Various partners that are identified are Vendor (Railways), Receiver

(Thermal Power Plant), Inspection agencies, Supplier (Coal Companies) etc.

Parameters Details

Partner object To define if it’s a Vendor or Plant

1.Vendor-Railways

Role Type 2.Vendor-Inspection agency

3.Receiver-Plant

Differentiator To define Transport System (Railways)

Partner Roles for Transport System

5.Business Process: Coal Requirement Planning in Fuel Supply Chain Management

Process Number: FSCM-01

Name of Business Process: Fuel Supply Chain Management (FSCM)

Name of Sub Process / Scenario: Coal Requirement Planning (FSCM-01)

Flow Chart of Activities: UPRVUNL-FSCM-Flowchart- FSCM-01

6820-02-IMSS_UPRV 6820-02_IMSS_UPR

VUNL_TO-BE_FSCM-Coal Requirement Planning_V1.3.pdf

UNL_FSCM_Coal_Requirement_Planning_V1.1.vsd

5.1 Requirements of Business Process

a. Ability to generate Annual, Quarterly and Monthly Plan for Coal procurement

b. Ability to Perform Planning process considering the available stock on Hand

LTI & UPRVUNL Confidential Page 16 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

c. Ability to consider unit wise demand and to consolidate per Power Station

d. Ability to also consolidate the overall demand across power stations

e. Ability to estimate the fuel requirement for new projects based on standard formulae

for fuel consumption.

f. Ability to calculate the fuel shortage based on the requirement and the available fuel

sourcing options

Pain areas

g.All the planning activities are mostly performed today manually in spreadsheets.

h.No central Planning system is available with real time data across the plants.

Process Requirement Detailed Description of Functional and Compliance Reference

ID Tracking Non - Functional Requirement (Standard/Custom/N Process ID/

Number ot possible/Third Section No.

Party/Not Reqd.)

FSCM- FRS-FSCM-1.1 Ability to produce the annual fuel Custom Development FSCM-01-03

01 procurement plan based on consumption

data, Long-term contracts and fuel

sourcing options available etc.

FSCM- FRS-FSCM-1.2 Ability to estimate the fuel requirement Custom Development 5.8.5

01 for new projects based on standard

formulae for fuel consumption

FSCM- FRS-FSCM-1.3 Can a database of fuel sources be Custom development FSCM-02-

01 generated and managed in a Coal

deregulated environment? Procurement

FSCM- FRS-FSCM-1.4 Ability to calculate the fuel shortage Custom Development 5.8.6

01 based on the requirement and the

available fuel sourcing options

FSCM- FRS-FSCM-1.5 Can a database of fuel sources be Custom development FSCM-02-

01 generated and managed in a regulated Coal

environment? Procurement

FSCM- FRS-FSCM-1.6 Can the details of the Fuel supply Fully FSCM-01-02

01 agreements (FSA) with various suppliers

be maintained in a database?

FSCM- FRS-FSCM-1.7 Can the fuel supply Fully FSCM-01-02

01 agreement (FSA) be recorded and

revisions maintained centrally?

FSCM- FRS-FSCM-1.8 Can the consolidated Custom Development 5.8.7

01 fuel budget for all the plants be produced

based on the procurement plan?

FSCM- FRS-FSCM-1.9 Can the actual Custom Development 5.8.8

01 Utilization of fuel-budget be tracked

based on payments to supplier?

FSCM- FRS-FSCM- Can the details of regular Enhancement 5.8.9

01 1.10 interactions with external agencies be

compiled and stored in the system?

FSCM- FRS-FSCM- Can the record of these interactions be Enhancement 5.8.10

01 1.11 recorded centrally in a chronological

order, for review when formulating fuel

LTI & UPRVUNL Confidential Page 17 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Process Requirement Detailed Description of Functional and Compliance Reference

ID Tracking Non - Functional Requirement (Standard/Custom/N Process ID/

Number ot possible/Third Section No.

Party/Not Reqd.)

sourcing strategies?

FSCM- FRS-FSCM- Ability to forecast daily requirements for Custom development 5.8.12

01 1.12 Coal based on generation schedule, coal

stock, available source of Coal etc,

FSCM- FRS-FSCM- For gas-based stations, Custom Development MM-Report

01 1.13 can daily requirement for gas be

forecast based on generation schedule

and fuel stock?

FSCM- FRS-FSCM- Ability to create delivery schedule based Custom Development FSCM-02-

01 1.14 on supply-agreements while taking the Coal

requirement into consideration Procurement

FSCM- FRS-FSCM- Ability to calculate the amount of coal Custom Development. 5.8.15

01 1.15 supplied by vendors against FSA

FSCM- FRS-FSCM- Can a 'procurement Fully MM

01 1.16 process' like procurement of inventory -Procurement

items be followed for the procurement of Process

fuel-oil?

LTI & UPRVUNL Confidential Page 18 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

5.2 Proposed Solution

Raw Coal Planning

1.Fuel Supply Agreement (FSA/Coal Supply agreement) is signed between UPRVUNL and

Coal Company (Subsidiaries of CIL) with 20-year Agreement

2.Before the expiry of 5 years of Fuel Supply Agreement correspondences / meeting may be

held with coal companies regarding revision of quantity, terms and conditions, etc., if

required.

3.However, UPRVUNL requires to plan and regulate the supply and Procurement of Coal at

Yearly /Quarterly and monthly basis

4.This enables to;

a.Plan and commit power production

b.Plan more efficiently the monthly Rail movement program and Inform Coal companies

and Railways for optimized Stock supply

c.Enables Optimized stock storage of Coal at each TPS

d.Avoids frequent quota transfer

FSCM Solution and Planning

1. SAP FSCM offers very efficient Fuel Planning and supply system

2. Coal is maintained with Units of Measure (Weight unit-TO and the Proportionated heat

content based GCV)

3. Coal Supply Management Process

Coal Supply is managed considering the following Input Factors

a. Annual Contracted Quantity

b. No. of Days of stock available

c. MSQ (Monthly Scheduled Quantity) as per Contract

d. Quantity/Percentage dispatched till date

With the above factors a production plan is derived for each plant for the amount to be produced

based on following dependent factors.

5.2.1 Coal Requirement Planning Process

Pre-Requisite Data:

1. Data from FSA on Quantity Per Coal Company for all Thermal Power Stations

2. Anpara Thermal Power Station-e.g. 1001 against it

3. Coal Company (Name of the Coal Company supplying Coal)

4. ACQ-Quantity in Tonnes

5. Grade Band of ROM Coal-e.g.: G5-G15- This is fixed in FSA

6. Per Day Consumption/Unit/Plant-85% of PLF and Considering Specific Coal

Consumption of 650 grams

7. Ratio/Qtr: Q1:Q2: Q3:Q4-25:22:25:28

8. No. of Days of stock to be maintained

Execute a custom Report Z_CoalPlan to get information for Coal requirement for the

subsequent month

The following information is available to enable the user to plan

a. Material

b. Plant

c. Coal Company

LTI & UPRVUNL Confidential Page 19 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

d. Available Stock (Raw Coal at multiple Storage locations+ Crushed Coal-Grade Wise)

e. No. of Days of stock, Plant wise and Coal Company wise with multiple options of MIQ

(Monthly Indented quantity) for the subsequent month is Proposed considering certain

parameters in various options.

5.2.2 MIQ (Monthly Indented Quantity) Proposal- 1-Planned as Pro-rata

1. Quantity that should have been received as Per ACQ –Pro Rata basis till date

2. Remaining to be dispatched for the year-As Per Pro-rata

3. Quantity for the subsequent month based on Pro-rata based on the ratio of the Quarter

Difference quantity on the no. of days of stock available and required days stock (Distributed

based on ACQ received per coal company and as per the Quantity to be received for the

current Quarterly ratio)

5.2.3 MIQ (Monthly Indented Quantity) Proposal 2-Based on Quantity received

1. Quantity Actually Dispatched till Previous month

2. Percentage Quantity Dispatched till Previous month (Pro-rata Basis)

1. 90% or More received –Invites Performance Incentive (PI)-

2. 75% less –Invites Penalty-

3. The above percentage will be modified based on inputs on flexi utilization

3. Quantity Actually Dispatched

4. For the current month till date

4. Percentage Quantity Dispatched till date for current month (Pro-rata Basis)

5. Quantity Actually dispatched

5. For the current year till date (Month wise to be consolidated)

Percentage Quantity Dispatched till date for the year till date (Pro-rata Basis)-On ACQ

Basis also

6. Remaining to be consumed for the current Quarter as per the quarterly ratio

Quantity for the subsequent month based on Actual receipts for the current quarter and

remaining to be received

7. Difference quantity on the no. of days of stock available and required days stock

((Distributed based on ACQ received per coal company and as per the Quantity to be

received for the current Quarterly ratio))

5.2.4 MIQ (Monthly Indented Quantity) Proposal 3-Based on history of Dispatches/

Materialization (3 years)

1. Average Quantity based on the dispatches/Materialization for the subsequent month during

the past 3 years.

5.2.5 MIQ (Monthly Indented Quantity) Proposal 4-Based on history of weighted average

consumption (3 years)

1. Average Quantity based on the Consumption pattern for the subsequent month.

e.g. If the subsequent month is October, the weighted average consumption of October for

the past 3 or 5 years is calculated based on the data available and proposed.

2. Difference quantity on the no. of days of stock available and required days of stock.

Coal Planning report

Coal Planning.xlsx

5.2.6 Cost effective distribution of MIQ Quantity and prioritize the Coal Company Per

Plant

1. With the above Proposal options available on MIQ user is provided with the information on

quantity in Tons to be planned for rake movement /Per Coal Company

LTI & UPRVUNL Confidential Page 20 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

2. With information on Proposed Quantity in Tons being available it is possible to optimize

quantity of MIQ and prioritize the Coal company for each plant and considering Flexible

utilization based on.

a) Cost of Coal/Grade/Unit (Kg or Ton)

b) Weighted Average GCV of coal based on past sampling results per 1000 GCV Cost

Based on the above factors the most cost-effective Coal grades and priority list is prepared

With Already available information on Coal Companies and Grades that are supplied it is now

Possible; To Proportionally distribute the quantity Per Coal Company/Per Plant for the rake

program

Optimization and communicate to FOIS

1. Based on the above decision points Rake program is prepared and maintained/uploaded in

FOIS

Document type

Serial Document type for Description (XX-Char) Number Range (XX

Number Purchase.Order Char)

1 ZUNB Standard Purchase Order

5.3 Process Flow

Process Diagram: Coal requirement planning

5.4 Process Steps

Process Process Narration T-code Role &

Step Responsibility

FSCM-01- Fuel Supply Agreement (FSA/Coal Supply Z_Contract SE/EE/AE

01 agreement) is signed between UPRVUNL (Fuel Purchase

LTI & UPRVUNL Confidential Page 21 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Process Process Narration T-code Role &

Step Responsibility

and Coal Company (Subsidiaries of CIL) Division)

with 20-year Agreement

DMS-XX- FSA document is uploaded in SAP and the CV01N SE/EE/AE

XX revisions to the same is recorded and (Fuel Purchase

maintained centrally in SAP DMS. Division)

The FSA document will be assigned to the

Contract (optional)

FSCM-01- Report –Provides multiple Proposal options Z_CoalPla SE/EE/AE

03 for MIQ (Multiple Indented Quantity) based n (Fuel Purchase

on various parameters. Division)

With the above Proposal options available on

MIQ user is provided with the information on

quantity in Tons to be planned for rake

movement /Per Coal Company

FSCM-01- Requirement Plan from all the Thermal SAP SE/EE/AE

04 power stations (A, B and D) is BPC/BI/B (Fuel Purchase

collated/aggregated and sent to CE (Fuel), W Division)

headquarters

FSCM-01- Quantity of MIQ and prioritization of Coal Z_Cost EE/SE/CE - Fuel

05 company per plant is optimized based on (Headquarters)

Cost of Coal/ Grade/ Unit (Kg or Ton) and

weighted average GCV.

Based on the above factors a report is

generated to provide the most cost-effective

Coal grades and priority list.

FSCM-01- Total fuel requirement is sent to the standing Manual N.A.

06 linkage committee (short-term)

FSCM-01- Standing Linkage committee accepts or External N.A.

07 reduces the proposed quantity.

FSCM-01- The proposal from the Linkage committee is Manual CE-Fuel

08 sent to UPRVUNL, HQ Headquarters

FSCM-01- Based on the above decision points Rake Outside Railways

08 program is prepared and uploaded in FOIS SAP

5.5 System Configuration Values

6820-02_IMSS_UPR

VUNL_Key Data Structure_FSCM_V1.1.xlsx

5.6 Integration Points

Module

Integration

Process ID Process Step Description Integrated

Solution details

with

FSCM-01 Coal Generation of MM Org. Structure set up

Requirement Contract/Purchase PO Document type

planning Order

LTI & UPRVUNL Confidential Page 22 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

5.7 Fit-Gap Analysis

Requirement Tracking Process Details

Reason for non-resolution

Number

NA NA NA

5.8 Technical Developments

Solution Type

Detailed Description of

(Enhancement

Sr. No Description Functional and Non - Functional

/Configuration/ Form/

Requirement

Interface/ Others)

Custom table with ACQ/Plant/Coal

Company/Per Day Average Custom table

1 Z_Contract

Consumption (85% PLF)/No. of

Days of stock

Report –Provides multiple Proposal

options for MIQ (Monthly Indented Custom Report

2 Z_CoalPlan

Quantity) based on various

parameters

Report –Provides information with

Custom Report

3 Z_Cost Priority of Coal Company based on

cost and GCV

Technical Developments: FRS Items

Sr. No Requirement Detailed Description of Solution Type

Tracking Functional and Non - (Enhancement

number Functional Requirement /Configuration/ Form/

Interface/ Others)

4 FRS-FSCM-1.1 System should be able to SAP BI/BW

automatically aggregate the

requirement of Coal at station and

plant level to calculate the total

requirement at the plants.

5 FRS-FSCM-1.2 Can the fuel requirement for new A custom report will have to

projects be estimated based on be developed in SAP

standard formulae for fuel S/4HANA for calculating the

consumption? requirements for the new

projects based on standard

formulae for fuel

consumption

6 FRS-FSCM-1.4 A custom report provides the fuel Custom report is to be

shortage based on the developed to show the fuel

requirements. shortage based on

requirements

(Coal Stock Card)

7 FRS-FSCM-1.8 Can the consolidated Consolidated fuel budget

LTI & UPRVUNL Confidential Page 23 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

Sr. No Requirement Detailed Description of Solution Type

Tracking Functional and Non - (Enhancement

number Functional Requirement /Configuration/ Form/

Interface/ Others)

fuel budget for all the plants be could be produced based on

produced based on the the procurement plan in SAP

procurement plan? BPC

8 FRS-FSCM-1.9 Can the actual utilization of fuel- The actual

budget be tracked based on utilization/consumption of

payments to supplier? fuel budget takes place

during Invoice/GR or

Payments. Reports are

available to track the actual

consumption of the budget

against the payments made

to suppliers

9 FRS-FSCM- Can the details of regular Details of the regular

1.10 interactions with external interactions with the external

agencies be compiled and stored agencies will be complied

in the system? and stored in SAP DMS

system.

10 FRS-FSCM- Can the record of these Record of the interactions

1.11 interactions be recorded centrally with the external agencies

in a chronological order, for can be maintained in SAP

review when formulating fuel DMS in a chronological

sourcing strategies? order.

11 FRS-FSCM- Can the system calculate the The amount of Coal supplied

1.15 amount of coal supplied by by the Vendors is captured in

vendors against FSA? a custom table at the

unloading point/Plant. This

data is compared with the

contracted quantity, as per

FSA, in a custom report.

12 FRS-FSCM- Ability to calculate the coal Report will be developed to

1.XX quantity required on daily basis calculate the daily coal

on the schedule of power requirement considering the

generation GCV(average) and the

power required based on SG

schedule

5.9 Organization/Entities Impacted

The Fuel Supply Management functionalities in SAP S/4 HANA will be implemented in all the

Thermal power stations

5.10 High Level Data Migration/Cut over requirements with priority

(M=Mandatory, O=Optional, H=High)

S. No Master Data Priority

1 Location Master Mandatory

LTI & UPRVUNL Confidential Page 24 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

S. No Master Data Priority

2 Partner Role Date Mandatory

3 Transport System Data Mandatory

5.11 Standard and Customized Reports

Report Title Transaction Report Description

Code

Stock Requirement list MD04 Real-time Stock/ Requirement List

Collective Stock Requirement MD06/MD0

Collective Stock /Requirement List

List 7

Information of stock with batch and

characteristics values. For e.g. Search

Batch Information Cockpit BMBC

based on Moisture content, Ash % Grade

etc.

Information of Rake no, Coal Co.,

Custom T-

Rake Movement Register Colliery, Date of Loading, Declared Grade,

code

Railway, Date of Receipt, Date of Release,

5.12 Change Management and Business Impact Assessment

Change Management – The business processes in Coal Handling division is mainly paper

based and email based including the Fuel Supply Contract with Coal Company, correspondence

between internal departments which are geographically in different locations, all Statutory

documents etc.,

The way the processes are being conducted at present would require change management to suit

the business processes as defined/mapped in SAP S/4 HANA.

Business Impact Assessment – There would be none or minimal impact on the business.

5.13 Additional details (if any)

Process step Additional details

N.A. NA

5.14 Assumptions & dependencies (if any)

Process step Assumptions

N.A. NA

5.15 Constraints

Process step Constraints

N.A. N.A.

6.Sign-off (Approval) for FSCM: Coal Requirement Planning

S. Name Designation & Organization Signature

No.

LTI & UPRVUNL Confidential Page 25 of 26

To-Be Process Document for SAP S/4HANA Fuel Supply Chain Module (FSCM): Coal Requirement Planning

1 Ganesh Swaminathan SAP Consultant - LTI

2 J. Sathianarayanan SAP Solution Architect - LTI

IMSS Pragati Team

3 Mr. Vinod Kumar Shahi (AE)

Coordinator - UPRVUNL

Mr. Sandeep Rastogi (SE)

Mr. Pradeep Kumar Asthana

(EE) IMSS Core Team Members -

4

UPRVUNL

Mr. Santosh Kumar (AE)

Mr. Saurabh Singh Yadav (AE)

IMSS Core Team Head-

5 Mr. A.K Singh (CE)

UPRVUNL

LTI & UPRVUNL Confidential Page 26 of 26

Das könnte Ihnen auch gefallen

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsVon EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsBewertung: 3 von 5 Sternen3/5 (5)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- 6820-02 - IMSS - UPRVUNL - TO-BE - FSCM - Coal Inspection - V1.3Dokument26 Seiten6820-02 - IMSS - UPRVUNL - TO-BE - FSCM - Coal Inspection - V1.3Krishna PremeeNoch keine Bewertungen

- 2 PDFDokument112 Seiten2 PDFOnatNoch keine Bewertungen

- Ims Emd 9Dokument125 SeitenIms Emd 9Nageswar MakalaNoch keine Bewertungen

- Ventilation DBRDokument16 SeitenVentilation DBRVignesh GandhirajNoch keine Bewertungen

- Evaluasi Pertama On The Job Training-Gema SetyawanDokument37 SeitenEvaluasi Pertama On The Job Training-Gema SetyawanGema SetyawanNoch keine Bewertungen

- Glossary of Abbreviations of Report No 5 of 2017 - Public Sector Undertakings Government of Tamil NaduDokument4 SeitenGlossary of Abbreviations of Report No 5 of 2017 - Public Sector Undertakings Government of Tamil Nadumohamedali tharvesh maideenNoch keine Bewertungen

- 17 AcronymsDokument8 Seiten17 AcronymsesrinivasaNoch keine Bewertungen

- 06-SOP For Belt Conveyor 4ABDokument14 Seiten06-SOP For Belt Conveyor 4ABTamil VananNoch keine Bewertungen

- Annex 16.1 SAMAST DPR - FINAL HPSLDC 2018 25092018 1Dokument71 SeitenAnnex 16.1 SAMAST DPR - FINAL HPSLDC 2018 25092018 1praveen dubeyNoch keine Bewertungen

- Part - C Technical SchedulesDokument63 SeitenPart - C Technical SchedulesMridulHasanNoch keine Bewertungen

- Managing Fleet Performance 1.0Dokument23 SeitenManaging Fleet Performance 1.0KURNIAWANNoch keine Bewertungen

- Glossary of Abbreviations: Future Ready For Smart ChoicesDokument3 SeitenGlossary of Abbreviations: Future Ready For Smart ChoicesHarry EdwardNoch keine Bewertungen

- 07-SOP For Belt Conveyor 5ABDokument14 Seiten07-SOP For Belt Conveyor 5ABTamil VananNoch keine Bewertungen

- ITD-GEN-000-DCC-PCD-0006 - 1 - Vendor Document & Data ManagementDokument39 SeitenITD-GEN-000-DCC-PCD-0006 - 1 - Vendor Document & Data ManagementSudeepDPoojaryNoch keine Bewertungen

- NorthDokument21 SeitenNorthxenopnnorthNoch keine Bewertungen

- Training Copy Not For Execution: Sop No. Supersedes Effective Date Next Review DateDokument12 SeitenTraining Copy Not For Execution: Sop No. Supersedes Effective Date Next Review Datemanohar kumarNoch keine Bewertungen

- Opal Applieed For Mechanical MainantenceengDokument3 SeitenOpal Applieed For Mechanical MainantenceengJimit ShahNoch keine Bewertungen

- DG Sizing Calculation Rev00Dokument3 SeitenDG Sizing Calculation Rev00epe civil100% (1)

- 001.PG - Genset - Not Emission - El - Sys - Spec - Dec2017Dokument24 Seiten001.PG - Genset - Not Emission - El - Sys - Spec - Dec2017bekheet222Noch keine Bewertungen

- JNKIN-026-001 - Study ReportDokument20 SeitenJNKIN-026-001 - Study ReportJayeshNoch keine Bewertungen

- 08-SOP For Belt Conveyor 6ABDokument14 Seiten08-SOP For Belt Conveyor 6ABTamil VananNoch keine Bewertungen

- We Are Hiring-1Dokument2 SeitenWe Are Hiring-1msnkrishnanNoch keine Bewertungen

- 206-Operating Procedures For Wagon Tippler Operations PDFDokument30 Seiten206-Operating Procedures For Wagon Tippler Operations PDFSatyaranjan mahapatraNoch keine Bewertungen

- Annexure VI QAP For 30KW PMA and ControllerDokument27 SeitenAnnexure VI QAP For 30KW PMA and Controllerrakesh bardepurNoch keine Bewertungen

- 00 VRMP OverallDokument11 Seiten00 VRMP OverallDeepak KatiyarNoch keine Bewertungen

- PM00 - PM OverviewDokument12 SeitenPM00 - PM OverviewAkhilesh ShuklaNoch keine Bewertungen

- Engine Selection Guide-MANDokument294 SeitenEngine Selection Guide-MANlgbrangelNoch keine Bewertungen

- Lista AbrevieriDokument3 SeitenLista AbrevieriDaniel StefanNoch keine Bewertungen

- Form-1 Summary SheetDokument9 SeitenForm-1 Summary SheetgireeshNoch keine Bewertungen

- Design Calculation: Larsen & Toubro Limited ECC Division - EDRCDokument16 SeitenDesign Calculation: Larsen & Toubro Limited ECC Division - EDRCSantoshNoch keine Bewertungen

- MS Format-Tata Projects HosurDokument19 SeitenMS Format-Tata Projects HosurSukhdeb BiswakarmaNoch keine Bewertungen

- Operation & Maintenance Cost Methodology: Joseph Albers, PE. Principal Engineer, Engineering Projects DivisionDokument11 SeitenOperation & Maintenance Cost Methodology: Joseph Albers, PE. Principal Engineer, Engineering Projects DivisionBenjaminNoch keine Bewertungen

- Vol II Main Report - Structural Design Report - DRAFT FINAL April 2019 PDFDokument139 SeitenVol II Main Report - Structural Design Report - DRAFT FINAL April 2019 PDFBinamra SNoch keine Bewertungen

- Dnit - 4.5 MLD 25 - 01 - 2022 FinalDokument223 SeitenDnit - 4.5 MLD 25 - 01 - 2022 Finalsiraj AhmedNoch keine Bewertungen

- Quality Manual - StampedDokument46 SeitenQuality Manual - Stampedyogesh pachankarNoch keine Bewertungen

- Report (Rajeev Ranjan 66) PDFDokument77 SeitenReport (Rajeev Ranjan 66) PDFrbdubey2020Noch keine Bewertungen

- AA & F S For RMO Work For Year 2021 22Dokument7 SeitenAA & F S For RMO Work For Year 2021 22ashishNoch keine Bewertungen

- Sabp A 004Dokument79 SeitenSabp A 004KemoHNoch keine Bewertungen

- Relay Setting Calculation SheetDokument25 SeitenRelay Setting Calculation SheetSARAVANAN A100% (7)

- Asme Sec Ix AWS API ASME B 31.8Dokument25 SeitenAsme Sec Ix AWS API ASME B 31.8smdriyazbashaNoch keine Bewertungen

- Oil & Grease RequirementDokument11 SeitenOil & Grease RequirementmanoranjanaclcppNoch keine Bewertungen

- TPL 069 Abb Yn1m 301 542 Zab P0Dokument43 SeitenTPL 069 Abb Yn1m 301 542 Zab P0litu_67100% (1)

- UntitledDokument17 SeitenUntitledShüßhû KätârëNoch keine Bewertungen

- GS 03 Part I 4mar2010Dokument238 SeitenGS 03 Part I 4mar2010SupriyaRongNoch keine Bewertungen

- APSPDCL LR To AMISP Allied & Crystal - GTP & GAD Conditional Approval With Remarks 29.02.2024Dokument25 SeitenAPSPDCL LR To AMISP Allied & Crystal - GTP & GAD Conditional Approval With Remarks 29.02.2024RaviNoch keine Bewertungen

- SMN-J-PR-00-145 - Rev02 - Re-Instatement, Bolt Tightening Procedure For Piping SystemDokument12 SeitenSMN-J-PR-00-145 - Rev02 - Re-Instatement, Bolt Tightening Procedure For Piping Systemono_czeNoch keine Bewertungen

- Cm-Mech - (42 To 43) - Send To MGPS at ( 27-07-2020)Dokument2 SeitenCm-Mech - (42 To 43) - Send To MGPS at ( 27-07-2020)ali morisyNoch keine Bewertungen

- Sow-Process EngineeringDokument38 SeitenSow-Process EngineeringPaary AtNoch keine Bewertungen

- Final Report FullDokument48 SeitenFinal Report FullMoosa NaseerNoch keine Bewertungen

- Industrial Training PresentationDokument14 SeitenIndustrial Training PresentationNik AmirNoch keine Bewertungen

- Module 5 - Eng ContDokument38 SeitenModule 5 - Eng ContWilliam Ruiz100% (2)

- 2X235 MW Attarat Oil Shale Power Plant Jordan Acronyms and AbbreviationsDokument3 Seiten2X235 MW Attarat Oil Shale Power Plant Jordan Acronyms and Abbreviationsscribd birdNoch keine Bewertungen

- 04 Org Chart - ArTu Process HandlingDokument8 Seiten04 Org Chart - ArTu Process HandlingFaizFzNoch keine Bewertungen

- Short Circuit Analysis TRF and DG ModeDokument409 SeitenShort Circuit Analysis TRF and DG ModeBalamurugan ArumugamNoch keine Bewertungen

- TECH MIN Full ReportDokument102 SeitenTECH MIN Full ReportNILESHNoch keine Bewertungen

- PCA To Empty Out T-302 Below LL (Until Pump Cavitate)Dokument7 SeitenPCA To Empty Out T-302 Below LL (Until Pump Cavitate)Muhammad Syukri Abdul AzizNoch keine Bewertungen

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryVon EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNoch keine Bewertungen

- Ats Om Bugdet LkoDokument4 SeitenAts Om Bugdet LkoKrishna PremeeNoch keine Bewertungen

- 6820-02-UPRVUNL-PM-Equipment Master Review Log - CHD-I - V1.0Dokument5 Seiten6820-02-UPRVUNL-PM-Equipment Master Review Log - CHD-I - V1.0Krishna PremeeNoch keine Bewertungen

- OM Reg. IGRS ConvenerDokument1 SeiteOM Reg. IGRS ConvenerKrishna PremeeNoch keine Bewertungen

- Booking Confirmed: HtlhnupcnaDokument4 SeitenBooking Confirmed: HtlhnupcnaKrishna PremeeNoch keine Bewertungen

- CV 1Dokument2 SeitenCV 1Krishna PremeeNoch keine Bewertungen

- BHEL 2006 Placement PaperDokument11 SeitenBHEL 2006 Placement PaperKrishna PremeeNoch keine Bewertungen

- Power GridDokument7 SeitenPower GridKrishna PremeeNoch keine Bewertungen

- Step 1Dokument3 SeitenStep 1Krishna PremeeNoch keine Bewertungen

- Suggestions On How To Prepare The PortfolioDokument2 SeitenSuggestions On How To Prepare The PortfolioPeter Pitas DalocdocNoch keine Bewertungen

- Actara (5 24 01) PDFDokument12 SeitenActara (5 24 01) PDFBand Dvesto Plus CrepajaNoch keine Bewertungen

- Glory in The Cross - Holy Thursday - Schutte PDFDokument1 SeiteGlory in The Cross - Holy Thursday - Schutte PDFsharon0murphyNoch keine Bewertungen

- MultiZone Limitations and HintsDokument2 SeitenMultiZone Limitations and HintsRubén Darío Becerra GalindoNoch keine Bewertungen

- Enzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaDokument8 SeitenEnzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaKimberly Mae MesinaNoch keine Bewertungen

- ISP SFD PDFDokument73 SeitenISP SFD PDFNamo SlimanyNoch keine Bewertungen

- HSG Vs SonohysterographyDokument4 SeitenHSG Vs Sonohysterography#15Noch keine Bewertungen

- Major Stakeholders in Health Care SystemDokument5 SeitenMajor Stakeholders in Health Care SystemANITTA S100% (1)

- Study of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaDokument8 SeitenStudy of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaPratikDedhia99Noch keine Bewertungen

- BQ - Structural Works - CompressedDokument163 SeitenBQ - Structural Works - CompressedLee YuxuanNoch keine Bewertungen

- Introduction To Human MovementDokument5 SeitenIntroduction To Human MovementNiema Tejano FloroNoch keine Bewertungen

- A List of 142 Adjectives To Learn For Success in The TOEFLDokument4 SeitenA List of 142 Adjectives To Learn For Success in The TOEFLchintyaNoch keine Bewertungen

- B1 Editable End-of-Year TestDokument6 SeitenB1 Editable End-of-Year TestSyahira Mayadi50% (2)

- Enzymes WorksheetDokument5 SeitenEnzymes WorksheetgyunimNoch keine Bewertungen

- 1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050Dokument2 Seiten1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050DennisSendoyaNoch keine Bewertungen

- N164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackDokument2 SeitenN164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackRaniaTortueNoch keine Bewertungen

- INDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor PositioningDokument8 SeitenINDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor Positioningzeeshan ahmedNoch keine Bewertungen

- The Innovator - S SolutionDokument21 SeitenThe Innovator - S SolutionKeijjo Matti100% (1)

- Market Structure and TrendDokument10 SeitenMarket Structure and TrendbillNoch keine Bewertungen

- Data SheetDokument14 SeitenData SheetAnonymous R8ZXABkNoch keine Bewertungen

- Top Survival Tips - Kevin Reeve - OnPoint Tactical PDFDokument8 SeitenTop Survival Tips - Kevin Reeve - OnPoint Tactical PDFBillLudley5100% (1)

- How To Build Yam Chips Production PlantDokument11 SeitenHow To Build Yam Chips Production PlantVu Thieu TuanNoch keine Bewertungen

- Protected PCM USB Memory Sticks For Pa3X.Dokument1 SeiteProtected PCM USB Memory Sticks For Pa3X.mariuspantera100% (2)

- 42ld340h Commercial Mode Setup Guide PDFDokument59 Seiten42ld340h Commercial Mode Setup Guide PDFGanesh BabuNoch keine Bewertungen

- Mythology GreekDokument8 SeitenMythology GreekJeff RamosNoch keine Bewertungen

- Exam Ref 70 483 Programming in C by Wouter de Kort PDFDokument2 SeitenExam Ref 70 483 Programming in C by Wouter de Kort PDFPhilNoch keine Bewertungen

- Unix SapDokument4 SeitenUnix SapsatyavaninaiduNoch keine Bewertungen

- Group 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasDokument12 SeitenGroup 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasSeyell DumpNoch keine Bewertungen

- New KitDokument195 SeitenNew KitRamu BhandariNoch keine Bewertungen

- English 8 q3 w1 6 FinalDokument48 SeitenEnglish 8 q3 w1 6 FinalJedidiah NavarreteNoch keine Bewertungen