Beruflich Dokumente

Kultur Dokumente

90MM Plastic Waste Reprocess Plant - 2020

Hochgeladen von

aayasirOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

90MM Plastic Waste Reprocess Plant - 2020

Hochgeladen von

aayasirCopyright:

Verfügbare Formate

REF: OEPL/PM/2019-20/6918

DATE: 5TH MARCH, 2020

TO

MR. YASIR ARAFATH

INDIA

MOBILE : +918870622638

E-MAIL : aayasir@gmail.com

KIND ATTN : MR. YASIR ARAFATH

SUBJECT : 90MM SEMI AUTOMATIC PLASTIC WASTE REPROCESS PLANT

DEAR SIR,

WELCOME TO OCEAN EXTRUSIONS PVT LTD.

WE HAVE PLEASURE TO GIVE YOU OUR LOWEST OFFER FOR THE ABOVE PLANT.

SCREW SIZE 90 MM

L:D RATIO 28:1

LD/PP/HDPE/HM/HIPS/ABS

MATERIAL TO BE PROCESS

(GRINDING WASTE AFTER AGLO PROCESS)

PRODUCTION CAPACITY (PER HOUR) 150 KG/HR**

(**Depends on Material)

PLANT DIMENSION (L X W X H) 35 FEET X 6 FEET X 8 FEET

CONNECTING POWER REQUIRED 63 KW FOR REPROCESS PLANT

COMMERCIAL PRICE (EX-WORKS AHMEDABAD)

90MM AUTOMATIC PLASTIC WASTE

INR: 13,75,000/-

REPROCESS PLANT

OPTIONAL

18” INCH GRINDER MACHINE (20 HP)

INR: 4,25,000/-

150 KG/HR

24” INCH AGLO MACHINE (30 HP)

INR: 5,25,000/-

150 KG/HR

PLASTIC MIXTURE MACHINE (25 HP)

INR: 1,75,000/-

100 KG/HR

GST EXTRA @ 18%

OCEAN EXTRUSIONS PVT. LTD.

Plot No: 1, Survey No: 325, B/h: Jalaram Saw Mill, Kujad Village,

Daskroi, Ahmedabad-382 430, Gujarat, India.

W: www.oceanextrusions.com | E: sales@oceanextrusions.com

Ph: +91-73595 94554

PLASTIC REPROCESS PLANT

TECHNICAL DATA

SS HOPER

- For Material Feeding

MAIN EXTRUDER:

Screw Size : 90 mm

L:D Ratio : 28:1

Screw Length : 2520 mm

Screw Material : EN41B Nitro alloy Steel duty Gas Nitride (Moscow Material)

Barrel Material : EN41B Nitro alloy Steel duty Gas Nitride (Moscow Material)

Gearbox : Helical Gearbox with Heavy duty thrust bearing

Main Motor : 30 Kw AC Motor with A.C Inverter Drives

Heating Zones : 5 Zones

Heating Load : 20 Kw

Cooling Blower : 5 Nos

Structure : MS fabricated heavy-duty structure made from Angles, channels

and covered with sheet.

OCEAN EXTRUSIONS PVT. LTD.

Plot No: 1, Survey No: 325, B/h: Jalaram Saw Mill, Kujad Village,

Daskroi, Ahmedabad-382 430, Gujarat, India.

W: www.oceanextrusions.com | E: sales@oceanextrusions.com

Ph: +91-73595 94554

HYDRAULIC SCREEN CHANGER WITH POWER PACK:

Heating load : 5.6 KW

Motor : 3.0 HP for Power Pack

Screening Area : 6”

DIE:

One Die for Reprocess with Heaters attach with Screen Changer Unit.

SS WATER TANK:

Cooling Tank made out from SS304 Sheet

Size: 96” L X 16" W X 16" H

STAND PALLETISER:

Stand Palletiser with Rotating Blades and One Fix Blade driven by 7.5 HP AC Motor with AC

Inverter Drive.

ELECTRIC CONTROL PANEL:

Uniquely designed control panel with powder coated body.

Temperature Controllers : Microprocessor based P.I.D. Temp. Controllers

MCB : All standard make MCBS in line with every heating zone

Other electrical outfits : A Meter, Contactors, Standard code wiring

With PVC conduits channel framing.

ALL ABOVE AC FREQUENCY DRIVES ARE SYNCHRONIZED BY ONE MASTER CONTROL.

AC FREQUENCY DRIVE:

Programmable variable speed AC drive suitable for efficient & trouble free control of

Following motors

40.0 HP : For Extruder Unit Motor

7.5 HP : For Palletize Unit Motor

GENERAL DETAIL:

ALL AC MOTOR ARE SIEMENS MAKE

ALL GEARBOX ARE GREAVES MAKE (PREMIUM MODEL)

ALL AC FREQUANCY DRIVE ARE MITSHUBISHI MAKE

ALL TEMPERATURE CONTROLER ARE PID BASE OMRON/ALFA/SELEC MAKE

ALL ELECTRIC ACESSORY ARE L&T/SCHNEIDER MAKE

TOTAL STRUCTER ARE HEAVY DUTY BOX SUCTION, MS PLATE AND C CHENAL

STANDARD SPARE ITEM WITH PLANT:

TEMPERATURE CONTROLLER 1NO

THERMOCOUPLE 1NO

STANDARD TOOL KIT 1NO

STANDARD ALLENKY SET 1NO

HEATER SET 1SET

OCEAN EXTRUSIONS PVT. LTD.

Plot No: 1, Survey No: 325, B/h: Jalaram Saw Mill, Kujad Village,

Daskroi, Ahmedabad-382 430, Gujarat, India.

W: www.oceanextrusions.com | E: sales@oceanextrusions.com

Ph: +91-73595 94554

CUSTOMER HAS TO ARRANGE FOLLOWING EQUIPMENT

WATER PUMP – 1 HP

CHILLER OR COOLING TOWER – 5 TR

OTHER COMMERCIAL DETAILS

Our Commercial Terms and conditions are attached with the offer for your kind perusal.

We hope our offer is in line to your requirement and should you require any clarification, please feel

free to contact us.

Thanking you,

Yours faithfully,

FOR, OCEAN EXTRUSIONS PVT. LTD

PARTH MEVADA

+91 – 97243 25404

PRAVIN BHATT

+91-97243 25403

OCEAN EXTRUSIONS PVT. LTD.

Plot No: 1, Survey No: 325, B/h: Jalaram Saw Mill, Kujad Village,

Daskroi, Ahmedabad-382 430, Gujarat, India.

W: www.oceanextrusions.com | E: sales@oceanextrusions.com

Ph: +91-73595 94554

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 4 ElectromagnetismDokument38 Seiten4 ElectromagnetismCart Kartika100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Adjusting and Maintaining DC GeneratorsDokument10 SeitenAdjusting and Maintaining DC GeneratorssandyNoch keine Bewertungen

- Battery Compartment Right Rear of Machine: Electrical System 320D ExcavatorDokument2 SeitenBattery Compartment Right Rear of Machine: Electrical System 320D ExcavatorJoycee ReyesNoch keine Bewertungen

- Topic: Visual::Worksheet Number:154Dokument7 SeitenTopic: Visual::Worksheet Number:154kunjal_radiaNoch keine Bewertungen

- AutoCAD 2013Dokument264 SeitenAutoCAD 2013panosscribd100% (1)

- AutoCAD 2013Dokument264 SeitenAutoCAD 2013panosscribd100% (1)

- 321 12 - Tamil Civilization and Culture Upto 1336AD - MA History PDFDokument186 Seiten321 12 - Tamil Civilization and Culture Upto 1336AD - MA History PDFMital L100% (1)

- AAC-MS-EL-0005 Earthing & Lightning Protection System, 25 July 2013Dokument25 SeitenAAC-MS-EL-0005 Earthing & Lightning Protection System, 25 July 2013aayasirNoch keine Bewertungen

- Acfrogdqwiqzrbpa - Dx5iq8b7boh87u6kfmmlgnazpqsruasluj3lrkl8cz1klidl6zhvbkhemqm3ohteid1cehhsqyfkvzds1mczx1hqj7y Amtzrb0yip1nr3yabt B0hkqfygawg8bkmeaDokument326 SeitenAcfrogdqwiqzrbpa - Dx5iq8b7boh87u6kfmmlgnazpqsruasluj3lrkl8cz1klidl6zhvbkhemqm3ohteid1cehhsqyfkvzds1mczx1hqj7y Amtzrb0yip1nr3yabt B0hkqfygawg8bkmeaRafaela Saar100% (1)

- Dasar Teori FEMDokument163 SeitenDasar Teori FEMNurhidayat Dayat100% (3)

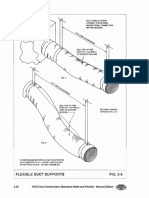

- Support Length LimitationDokument1 SeiteSupport Length LimitationaayasirNoch keine Bewertungen

- Malik Jabar SadikDokument2 SeitenMalik Jabar SadikaayasirNoch keine Bewertungen

- Rectangular Ducts Product GuideDokument94 SeitenRectangular Ducts Product GuideaayasirNoch keine Bewertungen

- File 16081432951056215326Dokument50 SeitenFile 16081432951056215326aayasirNoch keine Bewertungen

- Job Vacancies (Electrical) - Meinhardt BangaloreDokument2 SeitenJob Vacancies (Electrical) - Meinhardt BangaloreaayasirNoch keine Bewertungen

- Posts Included in The Combined Engineering Services Examination List-IiDokument3 SeitenPosts Included in The Combined Engineering Services Examination List-IiaayasirNoch keine Bewertungen

- IC Billing Statement 85521Dokument4 SeitenIC Billing Statement 85521aayasirNoch keine Bewertungen

- Flexible Duct Limiting LengthDokument1 SeiteFlexible Duct Limiting LengthaayasirNoch keine Bewertungen

- g2 Air Conditioning Service Tools Amp EquipmentDokument6 Seiteng2 Air Conditioning Service Tools Amp EquipmentaayasirNoch keine Bewertungen

- 3 Sanitation Try.Dokument19 Seiten3 Sanitation Try.aayasirNoch keine Bewertungen

- Trans Service Net Main Doc 1Dokument73 SeitenTrans Service Net Main Doc 1aayasirNoch keine Bewertungen

- DR Cast Iron Fittings CharlotteDokument124 SeitenDR Cast Iron Fittings CharlotteMohamad NohayliNoch keine Bewertungen

- National Highways: TH THDokument2 SeitenNational Highways: TH THaayasirNoch keine Bewertungen

- Employment Offer - Yasir ArafathDokument2 SeitenEmployment Offer - Yasir ArafathaayasirNoch keine Bewertungen

- NFHL LK : Jpuney Ntyp: Jpuney Ntyp GZ LF Rhiyiag GHH Itapl L MWPF If Rpwpa Futpj JSTHLK Minor Tools and Plants CL NFHL LKDokument1 SeiteNFHL LK : Jpuney Ntyp: Jpuney Ntyp GZ LF Rhiyiag GHH Itapl L MWPF If Rpwpa Futpj JSTHLK Minor Tools and Plants CL NFHL LKaayasirNoch keine Bewertungen

- 01-2019drb Asst CCB Renotification 10.3.20739435 - 1583819051 PDFDokument8 Seiten01-2019drb Asst CCB Renotification 10.3.20739435 - 1583819051 PDFaayasirNoch keine Bewertungen

- Pampers 7 PDFDokument10 SeitenPampers 7 PDFAdeelNoch keine Bewertungen

- Bottle Caps: 1. Process of ManufacturingDokument5 SeitenBottle Caps: 1. Process of ManufacturingReza KurniawanNoch keine Bewertungen

- TN PSC Ranking List for Assistant Engineer (AgriculturalDokument7 SeitenTN PSC Ranking List for Assistant Engineer (AgriculturalaayasirNoch keine Bewertungen

- Arrival Registration R8952727Dokument1 SeiteArrival Registration R8952727aayasirNoch keine Bewertungen

- ch21 PDFDokument5 Seitench21 PDFaayasirNoch keine Bewertungen

- 01-2019drb Asst CCB Renotification 10.3.20739435 - 1583819051 PDFDokument8 Seiten01-2019drb Asst CCB Renotification 10.3.20739435 - 1583819051 PDFaayasirNoch keine Bewertungen

- Manufacture Small Plastic Blow Moulded ContainersDokument5 SeitenManufacture Small Plastic Blow Moulded Containersperu1975Noch keine Bewertungen

- 1Dokument5 Seiten1IndhumathiNoch keine Bewertungen

- 1Dokument5 Seiten1IndhumathiNoch keine Bewertungen

- Comportamiento Estructural de PilasDokument8 SeitenComportamiento Estructural de PilasSolis EdwinNoch keine Bewertungen

- Tutorial Class Starts This WeekDokument32 SeitenTutorial Class Starts This WeekChinchili MohitNoch keine Bewertungen

- EEC 239... EEC 232 ND Yr 2 PT ELECTRICAL CIRCUIT THEORY 1 EEC 239 EEC 232Dokument1 SeiteEEC 239... EEC 232 ND Yr 2 PT ELECTRICAL CIRCUIT THEORY 1 EEC 239 EEC 232Muhyideen Bashir AbdulkareemNoch keine Bewertungen

- LED Technology GuideDokument27 SeitenLED Technology GuideUmeshNoch keine Bewertungen

- Underwater Noise Measurement and Simulation For Offshore Wind Farm in TaiwanDokument7 SeitenUnderwater Noise Measurement and Simulation For Offshore Wind Farm in TaiwanWL HsuNoch keine Bewertungen

- Worksheet (Time and Motion) Answer KeyDokument7 SeitenWorksheet (Time and Motion) Answer Keykatira rashmiNoch keine Bewertungen

- Ceramic Fiber Blanket CatalogDokument7 SeitenCeramic Fiber Blanket Catalogevelyn reksaNoch keine Bewertungen

- Settlement of Piled Foundations Using Equivalent Raft ApproachDokument17 SeitenSettlement of Piled Foundations Using Equivalent Raft ApproachSebastian DraghiciNoch keine Bewertungen

- Math ProblemsDokument6 SeitenMath ProblemsEurydiceNoch keine Bewertungen

- BOARD QUESTIONSDokument15 SeitenBOARD QUESTIONSAadikeshav SinhaNoch keine Bewertungen

- 4Dokument16 Seiten4api-3700944Noch keine Bewertungen

- Calculation of Natural Gas Isentropic ExponentDokument8 SeitenCalculation of Natural Gas Isentropic ExponentsekharsamyNoch keine Bewertungen

- Laplace Table ProofsDokument20 SeitenLaplace Table Proofskujong agacerNoch keine Bewertungen

- Inverter & Soft-StarterDokument13 SeitenInverter & Soft-StarterErnest ShachipukaNoch keine Bewertungen

- Thursday 02 Investigation of Load - Deflection Characteristics of A Helical Spring Under TensionDokument10 SeitenThursday 02 Investigation of Load - Deflection Characteristics of A Helical Spring Under TensionFatima ImamNoch keine Bewertungen

- Design, Fabrication, Properties and Applications of Smart and Advanced MaterialsDokument499 SeitenDesign, Fabrication, Properties and Applications of Smart and Advanced MaterialsKaihuanZhangNoch keine Bewertungen

- Electronic Ignition Units: EBI4 SeriesDokument4 SeitenElectronic Ignition Units: EBI4 SeriesfdfrNoch keine Bewertungen

- 2HFF4 2Dokument12 Seiten2HFF4 2AhmmedNoch keine Bewertungen

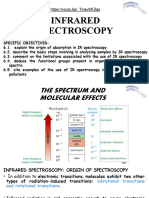

- 2.1. IR SpectrosDokument56 Seiten2.1. IR Spectroshussaini polackNoch keine Bewertungen

- The Design of A Ship Hull The Structural Design of The Hull of A ShipDokument6 SeitenThe Design of A Ship Hull The Structural Design of The Hull of A ShipJosephNoch keine Bewertungen

- Norma Prueba Acelerada de CorrosionDokument3 SeitenNorma Prueba Acelerada de CorrosionVictor FLNoch keine Bewertungen

- Mechanical Engineering Design Elective Module on Industrial TribologyDokument8 SeitenMechanical Engineering Design Elective Module on Industrial TribologyNarayan ManeNoch keine Bewertungen

- 3 Kinematics-Motion GraphsDokument3 Seiten3 Kinematics-Motion GraphsRavi LallNoch keine Bewertungen

- List of Hardened Concrete TestsDokument5 SeitenList of Hardened Concrete TestsGeorges Abi JaoudeNoch keine Bewertungen