Beruflich Dokumente

Kultur Dokumente

Design Aspects On Steel Fiber-Reinforced

Hochgeladen von

jayanthOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Aspects On Steel Fiber-Reinforced

Hochgeladen von

jayanthCopyright:

Verfügbare Formate

Design Aspects on Steel Fiber-Reinforced

Concrete Pavements

Beatrice Belletti1; Roberto Cerioni2; Alberto Meda3; and Giovanni Plizzari4

Downloaded from ascelibrary.org by Vidya Vikas Institute Of Tech, Mysore on 11/05/17. Copyright ASCE. For personal use only; all rights reserved.

Abstract: A numerical study on the fracture behavior of steel fiber-reinforced concrete 共SFRC兲 slabs on grade for industrial pavements

is presented. Finite element analyses have been carried out by using a commercial finite element code where user subroutines based on

nonlinear fracture mechanics have been implemented to describe the progressive cracking behavior of SFRC. The model is capable of

simulating both primary and secondary cracks when they occur in concrete and it has been validated by comparing numerical predictions

with experimental observations of full-scale tests on slabs on elastic subgrade under point loads in different positions. A real pavement

with contraction or construction joints has been numerically simulated to investigate the stress and the strain fields for the most significant

positions of point loads.

DOI: 10.1061/共ASCE兲0899-1561共2008兲20:9共599兲

CE Database subject headings: Pavements; Slabs; Joints; Reinforced concrete; Fiber reinforced materials; Concrete structures;

Fracture; Nonlinear analysis.

Introduction positioning of the reinforcement 共the top welded mesh can seldom

stay in the correct position during casting operations兲 and reduce

Major progress in concrete technology has allowed the enhance- cracking phenomena, which may be significant in pavements

ment of several concrete properties, such as workability, durabil- 共Meda and Plizzari 2004兲. However, fibers are also widely used in

ity, early age strength, fatigue and impact resistance, fire shotcrete for tunnels 共as early-stage lining兲, for final tunnel lin-

resistance, toughness, etc. The latter property is mainly provided ings 共both conventional and segmental兲, and for precast elements.

by steel or special synthetic fibers properly added to the concrete Structural applications of FRC will further increase since design

matrix and is particularly important for high strength concrete rules for FRC structures are now available 共ACI 1988; RILEM

which is characterized by a more brittle behavior 共Balaguru and 2000; CNR 2007兲 and sections on FRC are under development

Shah 1992; Naaman and Reinhardt 2003; di Prisco et al. 2004兲. within the new fib Model Code 共2008兲 共unpublished兲 and ACI

Toughness properties of fiber-reinforced concrete 共FRC兲 can be 共2008兲 共unpublished兲.

measured by using one of the widely available Standards 共ASTM Design methods for FRC pavements were traditionally based

2002, 2006; CEN 2004, 2006; JCI 1984; UNI 2003兲. on the elastic response 共Westergaard 1926兲; more recently, limit-

Research studies on structural applications of FRC performed analysis methods based on the yield line theory 共Johansen 1962兲

during the last 10 years clearly shows the benefits from using were proposed 共Concrete Society 2003; Meda 2003兲. However, an

fibers in addition to or in substitution for conventional reinforce- elastic approach is not suitable since fibers activate after cracking

ment 共di Prisco et al. 2004兲. In fact, fibers represent an optimized of the concrete matrix, where structural behavior is markedly

reinforcement for diffused stresses and are particularly appealing nonlinear. On the other hand, a design approach based on the

for reducing labor time and for ensuring a distributed reinforce- yield line theory may provide a reasonable approximation of the

ment in elements with complex geometries 共di Prisco and Felicetti ultimate load when 共1兲 material behavior is plastic in the post-

1999兲. cracking regime but this rarely occurs with the usual fiber rein-

One of the most important applications of FRC nowadays is forcement adopted for slabs on ground, and 共2兲 the yield lines are

represented by industrial pavements where fibers provide correct known. Furthermore, the yield line approach only provides the

ultimate load while service conditions are particularly important

1

Dept. of Civil and Environmental Engineering and Architecture, for slabs on grade in terms of deformation and, especially, crack

Univ. of Parma, via Usberti 181/a, 43100 Parma, Italy. control.

2

Dept. of Civil and Environmental Engineering and Architecture, Correct methods of analysis should be based on nonlinear frac-

Univ. of Parma, via Usberti 181/a, 43100 Parma, Italy. ture mechanics 共NLFM兲 that properly consider the postcracking

3

Dept. of Engineering Design and Technologies, Univ. of Bergamo, behavior of concrete 共Hilleborg et al. 1976兲, also for strain-

V.le Marconi 5, 24044 Dalmine 共BG兲, Italy. softening materials, as usually occurs in FRC for pavements. In

4

Dept. DICATA, Univ. of Brescia, Via Branze 43, 25123 Brescia, fact, postcracking behavior of FRC with a volume fractions of

Italy. fibers lower than 1% 共as normally occurs in FRC pavements兲, is

Note. Associate Editor: Nemkumar Banthia. Discussion open until

usually strain softening 共Fig. 1兲; therefore, fibers are particularly

February 1, 2009. Separate discussions must be submitted for individual

papers. The manuscript for this paper was submitted for review and pos- suitable for use in structures with a high degree of redundancy,

sible publication on August 13, 2007; approved on January 28, 2008. This such as slabs on grade, where a significant stress redistribution is

paper is part of the Journal of Materials in Civil Engineering, Vol. 20, possible 共di Prisco and Plizzari 2004兲.

No. 9, September 1, 2008. ©ASCE, ISSN 0899-1561/2008/9-599–607/ In this paper, NLFM analyses of steel FRC 共SFRC兲 slabs on

$25.00. grade are performed by using a finite element 共FE兲 Model pro-

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / SEPTEMBER 2008 / 599

J. Mater. Civ. Eng., 2008, 20(9): 599-607

Downloaded from ascelibrary.org by Vidya Vikas Institute Of Tech, Mysore on 11/05/17. Copyright ASCE. For personal use only; all rights reserved.

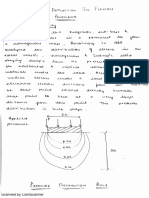

Fig. 1. Aggregate and fiber roles in FRC softening 共f c = 70 MPa,

V f = 2%, s ⬅ w兲

posed herein. The adopted constitutive model is able to describe

the behavior of uncracked and cracked concrete with both pri-

mary and secondary cracks. A strain-softening law, which takes

into account the bridging action due to aggregates and fibers 共Li

et al. 1993兲, is used to determine the relationship between stresses

共after fracture in Modes I and II兲 and crack opening and sliding.

The proposed model is validated by comparing the results of

numerical simulations with the results of an intensive experimen-

tal program on full-scale slabs on grade 共Sorelli et al. 2004,

2006兲. Afterwards, it is used to study SFRC industrial pavements

with contraction or construction joints. Finally, an optimized re-

inforcement based on the presence of both fibers and welded

mesh is proposed.

Modeling

An extension of the physical approach for reinforced concrete

共PARC兲 model 共Belletti et al. 2001兲 has been adopted to describe

the nonlinear mechanical behavior of SFRC structural elements

subjected to plane stresses 共Belletti et al. 2003兲. In the uncracked Fig. 2. 共a兲 Doubly cracked element subjected to plane stress; 共b兲

stage, reinforced concrete has been modeled as an orthotropic notations for primary and secondary cracking; 共c兲 kinematic param-

material having symmetry axes coincident with principal direc- eters of primary cracking; and 共d兲 kinematic parameters of secondary

tions of strain. The biaxial state of stress is described by means of cracking

two equivalent uniaxial states 共Darwin and Pecknold 1977兲. The

maximum strength values, corresponding to the “equivalent”

uniaxial states, have been determined through the analytical biax- and Blaauwendraad 1989兲. It is based on the following assump-

ial strength envelope suggested by Kupfer et al. 共1969兲. tions: 共1兲 when secondary cracks start, primary cracks are not

When the maximum principal stress becomes greater than the subjected to closing and reopening; 共2兲 total strain is obtained by

concrete tensile strength, concrete cracks and the PARC model is adding the strain due to primary cracks to that due to secondary

adopted for modeling the cracked SFRC. Primary cracks are ide- cracks; 共3兲 the stress field is the same both for primary and sec-

alized as fixed and equally spaced at a distance am that is assumed ondary cracks; 共4兲 primary and secondary cracks are assumed to

as equal to the fiber length 共Fig. 2兲. act one by one; thus their behavior is hypothesized unrelated to

The PARC stiffness matrix is evaluated by taking into account each other; and 共5兲 crack spacing is assumed to be the same both

the softening of cracked concrete in compression 共Vecchio and for primary and secondary cracks. A more exhaustive explanation

Collins 1993兲, the aggregate interlock 共Gambarova 1983兲, and the of the theoretical approach proposed, in the case of secondary

cohesive stresses of cracked SFRC 共Bazant and Gambarova cracking, can be found in Belletti et al. 共2004兲.

1980兲.

When the stress field in the SFRC between two cracks pro-

duces a maximum principal stress greater than the tensile Comparison with Experimental Evidence

strength, a secondary crack forms 共Fig. 2兲. In the case of double

cracking, a generalization of the PARC model is here adopted, The behavior of SFRC slabs on grade was experimentally studied

following the approach of strain decomposition proposed by other by performing tests on full-scale specimens having a square ge-

authors 共De Borst and Nauta 1985; Riggs and Powell 1986; Rots ometry with a side of 3,000 mm and a thickness of 150 mm

600 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / SEPTEMBER 2008

J. Mater. Civ. Eng., 2008, 20(9): 599-607

Downloaded from ascelibrary.org by Vidya Vikas Institute Of Tech, Mysore on 11/05/17. Copyright ASCE. For personal use only; all rights reserved.

Fig. 3. Spring stiffness

共Sorelli et al. 2004; 2006兲. The experimental model aims to rep- Fig. 4. Point positions of applied loads 共measured in mm兲

resent an area of pavement included among the joints 共the differ-

ent boundary conditions are discussed in the following section兲.

The slabs were made of a normal strength concrete 共C25/ 30兲, until failure is an essential requirement in slab design both for the

typical for pavement use, reinforced with hooked fibers having a serviceability limit state and the ultimate limit state.

length 共l f 兲 of 50 mm, a diameter 共 f 兲 of 1 mm, an aspect ratio The satisfactory agreement between the numerical and experi-

共l f / f 兲 of 50, and volume fraction 共V f 兲 equal to 0.38%. In order to mental results demonstrates the effectiveness of the proposed nu-

determine the fracture properties of the materials, four-point merical procedure in describing the nonlinear behavior of SFRC

bending tests were performed on beams 共150⫻ 150⫻ 600 mm兲, slabs on grade. The sensitivity of the slab behavior to the stiffness

having a notch added midspan with a depth of 45 mm, as required and the modeling of springs has been evaluated by analyzing the

by the Italian Standard 共UNI 11039 2003兲; test parameters con- slab with a load in the center. Fig. 7共a兲 shows a comparison be-

cern the tensile and the postcracking flexural strength. For the tween the load-displacement curve obtained by concentrating the

determination of the parameter representing the material behavior 64 springs as in the experiments 共at a distance of 375 mm兲 or

in uniaxial tension, an inverse analysis was carried out by adopt- distributing them in all the nodes of the FE model to better simu-

ing the bending test results. late the elastic subgrade. The good agreement between numerical

In order to reproduce a Winkler soil, the slabs were placed on and experimental curves evidences that the spring arrangement

steel springs equally spaced 共at a distance of 375 mm in both during the test properly reproduces the actual behavior of slabs on

directions兲 that were designed to simulate a subgrade modulus grade.

significant for practice 共k = 0.08 N / mm3兲. Before performing the Traditional design of concrete pavements 共without fibers兲 is

slab tests, the stiffness of each spring was experimentally deter- based on the Westregaard 共1926兲 approach, which considers slab

mined, by applying several loading cycles; a typical result is failure when the first crack appears. Up to the latter load level

shown in Fig. 3. The nonlinear response of the springs, namely 共first cracking兲, slab uplift is not present and all the subbase

the no-tension behavior and the bilinear shape of the compression springs are compressed. Since fibers activate after cracking of the

part, was taken into account by the numerical model as a trilinear concrete matrix when slab uplift occurs, a correct modeling of

law 共Fig. 3兲. Further details on the experimental program are nonlinear springs is necessary. The role played by tension resis-

published elsewhere 共Sorelli et al. 2004, 2006兲. The load was tance of springs is shown in Fig. 7共b兲, where it is clear that only

monotonically applied in different positions of the slabs 共Fig. 4兲 the no-tension spring behavior must be used for modeling the

by means of a hydraulic jack, while linear variable differential subgrade after concrete cracking; on the contrary, the ultimate

transformers were used to measure the vertical displacements at load prediction is not so significantly dependent on the elastic or

different locations. elastic-plastic trend chosen for the compressive part.

The experiments were simulated by nonlinear FE analyses car-

ried out by using the multipurpose FE code ABAQUS. A mesh of

isoparametric multilayered shell elements were adopted. The Design Aspects in Slabs on Grade

PARC stiffness matrix, implemented into a user subroutine, de-

scribes the nonlinear behavior at each integration point of layers As mentioned above, real pavements are characterized by the

which characterizes the geometrical and mechanical features of presence of construction and/or contraction joints 共the latter are

the shell cross section. made for limiting shrinkage cracking兲. For this reason, further

Comparisons between experimental and numerical results, in nonlinear finite-element 共NLFE兲 analyses have been carried out to

terms of applied load versus vertical displacement of the loaded evaluate this practical situation of slabs with joints subjected to

point, are illustrated in Fig. 5. Since pavement failure was asso- loads applied at different positions 关Fig. 8共a兲兴. Contraction joints

ciated with the formation of a collapse mechanism with yield are made by sawing the slab for a depth of 50 mm from the top

lines along the main flexural cracks 共no punching cracks oc- surface; the joint width is assumed to be equal to 6 mm 关Fig.

curred; Falkner et al. 1995兲, the numerical ultimate load was con- 8共b兲兴. Fig. 8共c兲 shows the FE modeling adopted for multilayered

ventionally assumed as the load corresponding to a sudden shell elements: Each layer is 50 mm thick; therefore, three-layer

increment of the opening of main cracks. 共in the slab兲 and two-layer 共along the joints兲 shell elements

Numerical and experimental final crack patterns are shown in 关marked in light grey and dark grey in Fig. 8共c兲兴 indicate the slab

Fig. 6. The numerical prediction of the crack pattern development and joint thickness, respectively. In this study, different mechani-

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / SEPTEMBER 2008 / 601

J. Mater. Civ. Eng., 2008, 20(9): 599-607

Downloaded from ascelibrary.org by Vidya Vikas Institute Of Tech, Mysore on 11/05/17. Copyright ASCE. For personal use only; all rights reserved.

Fig. 6. Comparison between experimental and numerical crack pat-

terns at failure of 共a兲 bottom side of slab loaded at the center; 共b兲 top

side of slab loaded along the median; and 共c兲 top side of slab loaded

at the corner

steel dowels. In the present paper, equally spaced dowels

共distance= 500 mm兲 having a diameter of 16 mm 关Fig. 8共c兲兴 were

adopted. These dowels are embedded for a length of 600 mm in

one slab and are unbonded 共due to presence of a plastic tube兲 in

the adjacent slab 共the contraction joint reinforcement adopted

herein is typical in construction practice兲. Shear transfer across

contraction joints is guaranteed by the concrete continuity under

the joint while, across construction joints, it is made possible by

the dowels.

The dowel behavior is simulated by a theoretical model pro-

posed by Gelfi et al. 共2002兲; according to this model, the dowel is

schematically approximated with an initial linear elastic behavior

followed by a plastic response 关Figs. 9共a and b兲兴. In the elastic

stage the dowel is assumed to behave as a traditional beam on an

elastic foundation of unlimited length 共Johansen 1949兲 and the

ultimate load of the connection is reached when two plastic

Fig. 5. Comparison between experimental and numerical results in hinges develop in the dowel shank.

the case of load applied 共a兲 at the center; 共b兲 at a border; and 共c兲 at a By assuming a concrete-to-concrete connection, the local stiff-

corner of the slab ness 共Ks兲 becomes

cal properties were adopted for slab and joint elements; in fact, V 12␣6c ESIS

since the contraction joints may be precracked by shrinkage phe- KS = = 63 共1兲

s ␣c t + 6␣5c t2 + 12␣4c t + 12␣3c

nomena, in the constitutive law an initial strain equal to the crack-

ing strain was assumed. where Ks is expressed in N/mm; Es = Young modulus of the steel

Slabs separated by construction joints are often connected by stud 共MPa兲

602 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / SEPTEMBER 2008

J. Mater. Civ. Eng., 2008, 20(9): 599-607

Downloaded from ascelibrary.org by Vidya Vikas Institute Of Tech, Mysore on 11/05/17. Copyright ASCE. For personal use only; all rights reserved.

Fig. 7. Slab response depending on 共a兲 spring arrangement; 共b兲 spring response

␣c = 冑4 kc / 4ESJS

IS = · d4/64

共mm 兲; kc = equivalent elastic soil stiffness

4 lc =

冉 冑

−t 1⫾ 1+

4f sy 2

3f hct2

d 冊 共3兲

2

关N / mm2兴; d = stud diameter 共mm兲.

The ultimate shear load can be determined as where t = joint width equal to 6 mm and f sy = steel stress at yield-

ing.

Vu = f hcdlc 共2兲 The model requires both concrete elastic stiffness 共kc兲 and

dowel bearing strength 共f hc兲 as input data in Eqs.共1兲 and 共2兲; in

where f hc = dowel bearing strength the present paper, these values were conventionally assumed as

Fig. 8. Slabs with contraction or construction joints: 共a兲 positions of applied load; 共b兲 details of a contraction joint; 共c兲 FE modeling of

multilayered shell elements; and 共d兲 details of a construction joint with a steel dowel 共measured in mm兲

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / SEPTEMBER 2008 / 603

J. Mater. Civ. Eng., 2008, 20(9): 599-607

Fig. 9. Shear load versus relative displacement of a steel stud

Downloaded from ascelibrary.org by Vidya Vikas Institute Of Tech, Mysore on 11/05/17. Copyright ASCE. For personal use only; all rights reserved.

10390 N / mm and 120 MPa, respectively 共Fig. 9兲.

In order to compare the numerical results 共from multiple slabs兲

with the experimental results 共where a single slab specimen was

tested; Sorelli et al. 2004, 2006兲, the same geometrical and mate-

rial properties of the experimental slabs were adopted: 150 mm

thickness, joints placed at a distance of 3,000 mm in both direc-

tions 关by doing so, square slabs having a side of 3,000 mm are

limited by joints; Fig. 8共a兲兴. The aim of the NLFM analyses is to

determine the actual service behavior and bearing capacity of a

Fig. 11. Additional conventional reinforcement along the perimeter

pavement by considering a point load in different positions and to

of the pavement 共measured in mm兲

investigate the capability of transferring the load between adja-

cent slabs.

Fig. 10 exhibits the load-deflection 共of the loaded point兲

Owing to the crack development into contraction joints, the slab

curves for SFRC slabs 共single and multiple兲 with and without

with a load applied near the contraction joints has a more brittle

conventional reinforcement along the perimeter; for the sake of

behavior 关Fig. 12共a兲兴. Furthermore, the bearing capacity of the

comparison, the curve from a single slab with a point load in the

slabs on grade increases when adjacent slabs are present because

center is also plotted. It can be noted that the behavior of single

of the capability of transferring the load through the joints.

and multiple slabs with a load applied along the external borders

However, by considering that the concentrated load can be

or at the external corners is similar and, as was shown Fig. 5, the

applied in different positions of the pavement 共especially when it

bearing capacity of slabs with the load along the border or at the

is related to the presence of vehicles兲, the bearing capacity of the

corner is remarkably lower than that of the slab with a center

worst case of the multiple slabs 共central load in an external slab兲

load. When this loading condition occurs in practice, the bearing

is not so different from the case of a load in a single slab 共Fig.

capacity of SFRC pavements can be increased by using additional

12兲. This aspect becomes significant by considering that, for

conventional reinforcement 共transversal and longitudinal steel re-

single slabs with a load in the center, design charts based on

bars兲 along the perimeter of the pavement 共Fig. 11兲. Fig. 10 shows

NLFM can be easily produced 共Meda and Plizzari 2004兲; these

the remarkable increase in the bearing capacity of slabs with ad-

charts are helpful for design offices where nonlinear numerical

ditional reinforcement, which becomes similar to that correspond-

tools are not always available.

ing to a single slab loaded at the center. Figs. 12共a and b兲 show

the comparisons between numerical results obtained from mul-

tiple slabs and a single slab with the load in the center point.

Joint Effects

In order to better understand the behavior of slabs connected by

contraction or construction joints, the crack pattern of a single

slab 共3 ⫻ 3 m兲 is compared with the crack pattern of multiple

slabs 共9 ⫻ 9 m兲. Fig. 13共a兲 shows the load-displacement 共at the

load point兲 curves of slabs 共single or multiple兲 with a single load

applied in the center. It should be noted that, because of the lim-

ited bearing capacity of dowel connectors adopted

共116/ 500 mm兲, slabs with construction joints have a trend in-

termediate between the single slab and the slab with contraction

joints; the final crack patterns, shown in Figs. 13共b–e兲 are evi-

dence of this aspect. In fact, the collapse mechanism in the slab

depends on the different boundary conditions 共Meda 2003兲:

• When free boundaries are present in a single square slab, a

point load acting in the slab center produces two main cracks

that develop along the median or the diagonal lines 关Fig.

13共b兲; Falkner et al. 1995兴;

• The presence of construction joints with dowels produce a

behavior similar to simply supported slabs: a point load acting

in the centroid of the slab produces diagonal main cracks

Fig. 10. Effect of reinforcement at the slab edge 关Figs. 13共b and d兲兴; and

604 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / SEPTEMBER 2008

J. Mater. Civ. Eng., 2008, 20(9): 599-607

fiber reinforcement 共as well as by welded mesh兲, yield lines may

develop and the slab continues to carry load until a collapse

mechanism occurs 共Meda and Plizzari 2004兲. Usually, the pres-

ence of fiber reinforcement prevents the occurrence of punching

failure that may happen in a pavement with a welded mesh. For

larger 共real兲 slabs with construction and contraction joints, the

behavior of centrally loaded slabs is stiffer and also depends on

the amount of load that can be transferred across the joint; there-

fore, a different crack pattern occurs depending on the slab and

subgrade stiffness as well as on the joint behavior.

Downloaded from ascelibrary.org by Vidya Vikas Institute Of Tech, Mysore on 11/05/17. Copyright ASCE. For personal use only; all rights reserved.

Concluding Remarks

Fiber-reinforced concrete is no longer simply a promising mate-

rial since it is already used in many applications and its use will

further increase since design guidelines are now available. A nu-

merical study focused on the design aspects of SFRC slabs on

grade is presented in this paper. The numerical model is based on

NLFM to properly consider the fiber contribution to concrete

toughness and to better simulate pavement behavior both at ser-

viceability and ultimate limit states. The numerical analyses were

performed with the multipurpose code ABAQUS with user sub-

routines that allow simulation of the developments of both pri-

mary and secondary cracks. Comparisons with experimental

results of full-scale tests validated the proposed model and pro-

vided evidence of the usefulness of NLFM to analyze SFRC

structures.

The bearing capacity of slabs on grade is markedly dependent

on the load position and, since loads may be present everywhere

共not only the mobile loads of the vehicles兲, they have to be con-

sidered in the most unfavorable positions that are close to the

joints 共either construction or contraction兲. The bearing capacity of

pavements with a single load close to the joints is quite similar to

that of a single slab on grade 共with free borders兲 with a load in the

Fig. 12. Comparison between load-displacement curves from a center that can be easily tested. For this simple slab, design charts

single slab with a load in the center and multiple slabs with contrac- to provide the minimum slab thickness can be produced. Rein-

tion joints 共a兲, construction joints 共b兲, and load placed in different forcement provided by fibers provides good bearing capacity for

positions the inner areas of the pavement; when loads are applied along the

external free borders, the reinforcement can be optimized by

using additional rebars along the perimeter.

• The presence of uncracked contraction joints can be consid-

ered as a full continuity restraint: In this case the slab tends to

behave axisymmetrically close to the load and many cracks Acknowledgments

develop radially from the point load at the top side 关Fig.

13共e兲兴. The writers wish to express their gratitude and sincere apprecia-

Vertical displacements, contoured in Fig. 14, are evidence that the tion to the Ministry of University and Research 共MIUR兲 for par-

increase in the bearing capacity observed for multiple slabs with tially financing this research work. The research project was also

joints is due to load transfer to adjacent slabs 共the restraint exerted supported by Officine Maccaferri S.p.A. 共Bologna, Italy兲. A spe-

by adjacent slabs prevents parts of loaded slab from rising up; as cial acknowledgement goes to Ms. Eng. Andrea Di Marco for his

a consequence, the subgrade can react on a greater slab exten- assistance in performing the numerical analyses.

sion兲. Therefore, lower stresses are present, with respect to a

single slab, for the perimetral restraint, due to the presence of

joints. For the reasons mentioned above, Fig. 14 also shows that, Notation

for slabs with construction joints 关Fig. 14共c兲兴, the values of ver-

tical displacement are between those from a single slab 关Fig. The following symbols are used in this paper:

14共a兲兴 and those from a slab with contraction joints 关Fig. 14共b兲兴. Ø f ⫽ fiber diameter;

From Figs. 13 and 14, the overall behavior of the pavement Es ⫽ Young’s modulus of steel;

can be better understood. In the experimentally investigated case d ⫽ stud diameter;

of a single square slab 共3 ⫻ 3 m兲 with a central loading, the slab f sy ⫽ steel yielding stress;

begins slowly setting into the subgrade until it cracks at the bot- f hc ⫽ dowel bearing strength;

tom, forming a failurelike mechanism. When the slabs have suf- Is ⫽ stud moment of inertia;

ficient moment capacity and ductility that can be provided by l f ⫽ fiber length;

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / SEPTEMBER 2008 / 605

J. Mater. Civ. Eng., 2008, 20(9): 599-607

Downloaded from ascelibrary.org by Vidya Vikas Institute Of Tech, Mysore on 11/05/17. Copyright ASCE. For personal use only; all rights reserved.

Fig. 13. Load applied at the center of the slabs: 共a兲 Load versus displacement 共at the point load兲 curves and crack pattern at failure for 共b兲 single

slab 共3 ⫻ 3 m; bottom view兲; 共c兲 multiple slab 共9 ⫻ 9 m兲 with contraction joints 共bottom view兲; 共d兲 共top view兲; and 共e兲 multiple slab 共9 ⫻ 9 m兲

with construction joints 共bottom view兲

Fig. 14. Load applied at the center of the slabs: vertical displacements for 共a兲 3 ⫻ 3 m single slab, 9 ⫻ 9 m slab with 共b兲 contraction joints, and

共c兲 construction joints

606 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / SEPTEMBER 2008

J. Mater. Civ. Eng., 2008, 20(9): 599-607

k ⫽ subgrade Winkler constant; material properties to structural applications.” Proc., BEFIB 2004,

Ks ⫽ stud stiffness; RILEM PRO 39, Varenna, Italy.

s ⫽ shear displacement of a stud; Falkner, H., Huang, Z., and Teutsch, M. 共1995兲. “Comparative study of

t ⫽ joint width; plain and steel fiber reinforced concrete ground slabs.” Concr. Int.,

V ⫽ shear action on a single stud; 17共1兲, 45–51.

Vf ⫽ volume fraction of fibers; and Gambarova, P. 共1983兲. “On the shear transfer in cracked r.c. bidimen-

Vu ⫽ shear capacity of the stud connector. sional elements.” Proc., AICAP Conf., AICAP, 141–156, Bari, Italy

共in Italian兲.

Gelfi, P., Giuriani, E., and Marini, A. 共2002兲. “Stud shear connection

design for composite concrete slab and wood beams.” J. Struct. Eng.,

References 128共12兲, 1544–1550.

Hillerborg, A., Modèer, M., and Petersson, P. E. 共1976兲. “Analysis of

Downloaded from ascelibrary.org by Vidya Vikas Institute Of Tech, Mysore on 11/05/17. Copyright ASCE. For personal use only; all rights reserved.

American Concrete Institute 共ACI兲. 共1988兲. “Design consideration for crack formation and crack growth in concrete by means of fracture

steel fiber reinforced concrete.” SP-182 1988, ACI Committee 544, mechanics and finite elements.” Cem. Concr. Res., 6, 773–782.

American Concrete Institute, Farmington Hills, Mich. Kupfer, H., Hilsdorf, H. K., and Rusch, H. 共1969兲. “Behavior of concrete

ASTM. 共2002兲. “Standard test method for flexural toughness of fiber- under biaxial stresses.” ACI J., 66共8兲, 656–666.

reinforced concrete 共using centrally loaded round panel兲.” ASTM C JCI. 共1984兲. “Method of tests for flexural strength and flexural toughness

1550, West Conshohocken, Pa. of fiber reinforced concrete.” JCI standard SF4, Japan Concrete Insti-

ASTM. 共2006兲. “Standard test method for flexural performance of fiber- tute, 45–51.

reinforced concrete 共using beam with third-point loading兲.” ASTM Johansen, K. W. 共1949兲. “Theory of timber connections.” Int. Assoc.

C1609/C1609M-06, West Conshohocken, Pa. Bridge Struct. Engng., 9, 249–262.

Balugaru, P., and Shah, S. P. 共1992兲. “Fiber reinforced cement.” Compos- Johansen, K. W. 共1962兲. Yield line theory, William Clowes & Sons, Ltd.,

ites, McGraw-Hill, New York. London.

Bazant, Z. P., and Gambarova, P. 共1980兲. “Rough cracks in reinforced Li, V., Stang, H., and Krenchel, H. 共1993兲. “Micromechanics of crack

concrete.” J. Struct. Div., 106共4兲, 819–842. bridging in fiber—Reinforced concrete.” Mater. Struct., 26, 486–494.

Meda, A. 共2003兲. “On the extension of the yield-line method to the design

Belletti, B., Bernardi, P., Cerioni, R., and Iori, I. 共2003兲. “On a fibre-

of SFRC slabs on grade.” Studies and researches, Politecnico di Mi-

reinforced-concrete constitutive model for NLFE analysis.” Studies

lano, 24, 223–239.

and Researches Politecnico di Milano, 24, 23–50.

Meda, A., and Plizari, G. A. 共2004兲. “New design approach for steel

Belletti, B., Cerioni, R., and Iori, I. 共2001兲. “A physical approach for

fiber-reinforced concrete slabs-on-ground based on fracture mechan-

reinforced concrete 共PARC兲 membrane elements.” J. Struct. Eng.,

ics.” ACI Struct. J., 101共3兲, 298–303.

127共12兲, 1412–1426. Naaman, A. E., and Reinhardt, H. W., eds. 共2003兲. “High performance

Belletti, B., Cerioni, R., Meda, A., and Plizzari, G. A. 共2004兲. “Experi-

fibre reinforced cement composites—HPFRCC4.” Proc., RILEM

mental and numerical analyses of FRC slabs on grade.” Proc., FRAM-

PRO, Ann Arbor, Mich.

COS5 Conf., Vail, Colo., 973–980. Riggs, H. R., and Powell, G. H. 共1986兲. “Rough crack model for analysis

CEN. 共2004兲. “Testing sprayed concrete—Part 5: Determination of en- of concrete.” J. Eng. Mech., 112共5兲, 448–464.

ergy absorption capacity of fibre reinforced slab specimens.” EN RILEM. 共2000兲. “TC 162 TDF. Part 1: Test and design method for steel

14488-5-CEN/TC, 104, CEN, Brussels, 1–7. fiber reinforced concrete—Recommendations: Part 2: - method.”

CEN. 共2006兲. “Precast concrete products—Test method for metallic fibre Mater. Struct., 33, 75–81.

concrete—Measuring the flexural tensile strength.” EN 14651-5, Rots, J. G., and Blaauwendraad, J. 共1989兲. “Crack models for concrete:

CEN, Brussels, 15. Discrete or smeared? Fixed, multidirectional, or rotating?” Heron,

CNR. 共2007兲. “Guidelines for the design, construction, and production 34共1兲, 1–59.

control of fibre reinforced concrete structures.” DT 204, National Re- Sorelli, L., Meda, A., Plizzari, G. A., and Rossi, B. 共2004兲. “Experimental

search Council of Italy. investigation on slabs on grade: Steel fibers vs. conventional rein-

The Concrete Society. 共2003兲. “Concrete industrial ground floors. A guide forcement.” Proc., BEFIB 2004 Conf., Varenna, Italy.

to design and construction.” Tech. Rep. No. 34, 3rd Ed.

Sorelli, L., Meda, A., and Plizzari, G. A. 共2006兲. “Steel fiber concrete

Darwin, D., and Pecknold, D. A. 共1977兲. “Non-linear biaxial stress-strain slabs on ground: A structural matter.” ACI Struct. J., 103共4兲, 551–

law for concrete.” J. Engrg. Mech. Div., 103共2兲, 229–241. 558.

De Borst, R., and Nauta, P. 共1985兲. “Non-orthogonal cracks in a smeared UNI. 共2003兲. “Steel fibre reinforced concrete—Part I: Definitions, classi-

finite element model.” Eng. Comput., 2共2兲, 35–46. fication specification and conformity. Part II: Test method for measur-

di Prisco, M., and Felicetti, R. 共1999兲. “HSC thin-web roof-elements: An ing first crack strength and ductility indexes.” Italian Board for

experimental investigation on steel fibre benefits.” Proc., 5th Int. Standardization.

Symp. Utilization of HS/HP Concrete, Sandefjord, Norway, 546–555. Vecchio, F. J., and Collins, M. P. 共1993兲. “Compression response of

di Prisco, R., Felicetti, R., and Plizzari, G. A., Eds. 共2004兲. Proc. 6th cracked reinforced concrete.” J. Struct. Eng., 119共12兲, 3590–3610.

RILEM Symp. on Fibre Reinforced Concretes (FRC), RILEM PRO, Westergaard, H. M. 共1926兲. “Stresses in concrete pavements computed by

39, Varenna, Italy. theoretical analysis.” Mem. Fac. Sci., Kyoto Univ., Ser. Phys., Astro-

di Prisco, M., and Plizzari, G. A. 共2004兲. “Precast SFRC elements: From phys., Geophys. Chem, 7共2兲, 25–35.

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / SEPTEMBER 2008 / 607

J. Mater. Civ. Eng., 2008, 20(9): 599-607

Das könnte Ihnen auch gefallen

- Design Aspects On Steel Fiber-ReinforcedDokument9 SeitenDesign Aspects On Steel Fiber-Reinforced2023rce9005Noch keine Bewertungen

- N Fea S - C C S: Onlinear Nalysis of Teel Oncrete Omposite Tructures by Wendel M. Sebastian and Richard E. McconnelDokument13 SeitenN Fea S - C C S: Onlinear Nalysis of Teel Oncrete Omposite Tructures by Wendel M. Sebastian and Richard E. Mcconnelnithya kjNoch keine Bewertungen

- Nonlinear FE Analysis of Steel-Concrete Composite StructuresDokument13 SeitenNonlinear FE Analysis of Steel-Concrete Composite StructuresxavierNoch keine Bewertungen

- (2-6) (ASCE Structure) Experimental and Nonlinear Numerical Analysis of Precast Concrete Column Splices With High-Yield Metal PlatesDokument15 Seiten(2-6) (ASCE Structure) Experimental and Nonlinear Numerical Analysis of Precast Concrete Column Splices With High-Yield Metal PlatesPhạm Tiến ĐạtNoch keine Bewertungen

- Flexural Strength of RC Beams With GFRP Laminates: Sing-Ping Chiew, M.ASCE Qin Sun and Yi YuDokument10 SeitenFlexural Strength of RC Beams With GFRP Laminates: Sing-Ping Chiew, M.ASCE Qin Sun and Yi YuAjay KumarNoch keine Bewertungen

- Structural Assessment of Corroded Reinforced Concrete Beams Modeling GuidelinesDokument11 SeitenStructural Assessment of Corroded Reinforced Concrete Beams Modeling GuidelinesnagarajuNoch keine Bewertungen

- Llaves de CorteDokument12 SeitenLlaves de CorteJose Luis Martinez SaavedraNoch keine Bewertungen

- TEC Compo BeamDokument11 SeitenTEC Compo BeamvardhangargNoch keine Bewertungen

- 2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteDokument18 Seiten2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteHamid GoodarziNoch keine Bewertungen

- Bond-Slip Model For Detailed Finite-Element AnalysisDokument10 SeitenBond-Slip Model For Detailed Finite-Element AnalysisSilver rayleighNoch keine Bewertungen

- 1 Shear fb73Dokument10 Seiten1 Shear fb73Dr.K.Rajeswara RaoNoch keine Bewertungen

- Creep Behavior of Asphalt Concrete Core Materials in Embankment Dams Under A Stepped Loading PathDokument10 SeitenCreep Behavior of Asphalt Concrete Core Materials in Embankment Dams Under A Stepped Loading PathSaraNoch keine Bewertungen

- Pre-Cast Concrete Slab/Column Joints: Experiments and Design ModelsDokument11 SeitenPre-Cast Concrete Slab/Column Joints: Experiments and Design ModelsDesign explorer olomizanaNoch keine Bewertungen

- Micromechanical Modelling of Pervious Concrete Reinforced With Treated FibresDokument11 SeitenMicromechanical Modelling of Pervious Concrete Reinforced With Treated FibresPawelNoch keine Bewertungen

- Mathematical Models For Tensile Resistance Capacities of ConcreteDokument10 SeitenMathematical Models For Tensile Resistance Capacities of ConcretekashifNoch keine Bewertungen

- (5-1) ASCE Construction Interlocking Mechanical Joints Using CouplersDokument12 Seiten(5-1) ASCE Construction Interlocking Mechanical Joints Using CouplersPhạm Tiến ĐạtNoch keine Bewertungen

- Chen 2018Dokument10 SeitenChen 2018Fauziah AzizNoch keine Bewertungen

- Punching Capacity Nguyen-Minh2012Dokument12 SeitenPunching Capacity Nguyen-Minh2012Ashraf Gomah Mohamed ElshamandyNoch keine Bewertungen

- Full Depth Precast, Prestressed Concrete Bridge Deck SystemDokument17 SeitenFull Depth Precast, Prestressed Concrete Bridge Deck SystemAfdhal LazuardiansyahNoch keine Bewertungen

- Behavior of High-Strength Friction-Grip Bolted Shear Connectors in Sustainable Composite BeamsDokument12 SeitenBehavior of High-Strength Friction-Grip Bolted Shear Connectors in Sustainable Composite BeamsvardhangargNoch keine Bewertungen

- Analysis of Exterior Reinforced Concrete Beam Column Joint: S.Gomathi, K.SelviDokument4 SeitenAnalysis of Exterior Reinforced Concrete Beam Column Joint: S.Gomathi, K.SelviMarjorie BlossiersNoch keine Bewertungen

- Nonlinear Analysis of Beams Reinforced IDokument12 SeitenNonlinear Analysis of Beams Reinforced IMike MatshonaNoch keine Bewertungen

- Tekban Lanjut 4Dokument7 SeitenTekban Lanjut 4Bastian Artanto AmpangalloNoch keine Bewertungen

- Connection Performance in Steel - Concrete Composite Truss Bridge StructuresDokument16 SeitenConnection Performance in Steel - Concrete Composite Truss Bridge StructuresmulualemNoch keine Bewertungen

- 2007 - Seracino - Bond Strength of NSM FRP Strip To Concrete JointsDokument9 Seiten2007 - Seracino - Bond Strength of NSM FRP Strip To Concrete JointsshaunakchatNoch keine Bewertungen

- Numerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionDokument10 SeitenNumerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionNasar KhanNoch keine Bewertungen

- Behaviour of CulvertDokument10 SeitenBehaviour of CulvertIbrahim KhanNoch keine Bewertungen

- Interface Characteristics and Laboratory Constructability Tests of Novel Fiber-Reinforced Polymer/Concrete PilesDokument10 SeitenInterface Characteristics and Laboratory Constructability Tests of Novel Fiber-Reinforced Polymer/Concrete PilesAliNoch keine Bewertungen

- Gkournelos Triantafillou 2023 Out of Plane Behavior of in Plane Damaged Masonry Infills Retrofitted With TRM andDokument14 SeitenGkournelos Triantafillou 2023 Out of Plane Behavior of in Plane Damaged Masonry Infills Retrofitted With TRM andN.prem kumarNoch keine Bewertungen

- Engineering Structures: Eduardo Cavaco, Ilton Pacheco, José CamaraDokument14 SeitenEngineering Structures: Eduardo Cavaco, Ilton Pacheco, José CamaraElber Cuya PillacaNoch keine Bewertungen

- Unconfirmed 401821.crdownloadDokument16 SeitenUnconfirmed 401821.crdownloadNurin UmairahNoch keine Bewertungen

- Deformation Analysis of Prestressed Continuous Steel-Concrete Composite BeamsDokument13 SeitenDeformation Analysis of Prestressed Continuous Steel-Concrete Composite BeamsSaul Max Huayta AguilarNoch keine Bewertungen

- Review On Optimization of Post Tension of Concrete Floor SlabDokument4 SeitenReview On Optimization of Post Tension of Concrete Floor SlabSaja AliNoch keine Bewertungen

- 1 Artig 1Dokument9 Seiten1 Artig 1rpierottNoch keine Bewertungen

- Behavior of Masonry-Infilled Nonductile Reinforced Concrete FramesDokument9 SeitenBehavior of Masonry-Infilled Nonductile Reinforced Concrete FramesSuhail Ahmad AhangerNoch keine Bewertungen

- Load Capacity of Reinforced Concrete Continuous Deep Beams: K. H. Yang and A. F. AshourDokument11 SeitenLoad Capacity of Reinforced Concrete Continuous Deep Beams: K. H. Yang and A. F. AshourJoão Paulo MendesNoch keine Bewertungen

- TextDokument16 SeitenTextAras H.MNoch keine Bewertungen

- Buildings 13 00437Dokument18 SeitenBuildings 13 00437jarumy cantorin lazaroNoch keine Bewertungen

- 1 s2.0 S235201242300108X MainDokument13 Seiten1 s2.0 S235201242300108X MainSaidronaNoch keine Bewertungen

- Rational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsDokument13 SeitenRational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsRayan MahgoubNoch keine Bewertungen

- Ezzeldin 2016Dokument13 SeitenEzzeldin 2016William AvilaNoch keine Bewertungen

- (2003) Flexural Design of Reinforced Concrete Frames by Genetic AlgorithmDokument13 Seiten(2003) Flexural Design of Reinforced Concrete Frames by Genetic AlgorithmJONATHAN JUSTINO APOS CASSIMIRONoch keine Bewertungen

- Engineering Structures: Ehsan Nasiri, Yi LiuDokument14 SeitenEngineering Structures: Ehsan Nasiri, Yi LiuMaruthish KvNoch keine Bewertungen

- Slab Deflections in The Cardington In-Situ Concrete Frame BuildingDokument12 SeitenSlab Deflections in The Cardington In-Situ Concrete Frame BuildingwaynectwNoch keine Bewertungen

- 5022 - KIM S. ELLIOTT - The Stability of Precast Concrete Skeletal StructuresDokument19 Seiten5022 - KIM S. ELLIOTT - The Stability of Precast Concrete Skeletal StructuressamiNoch keine Bewertungen

- Comparative Study of R.C.C & Structural Steel - Concrete Composite Frame For Linear and Non-Linear AnalysisDokument10 SeitenComparative Study of R.C.C & Structural Steel - Concrete Composite Frame For Linear and Non-Linear AnalysisAnonymous kw8Yrp0R5r100% (1)

- Bond of Deformed Bars To Concrete: Effects of Confinement and Strength of ConcreteDokument6 SeitenBond of Deformed Bars To Concrete: Effects of Confinement and Strength of ConcreteMarimuthu Kaliyamoorthy100% (1)

- Analysis of FRP-Strengthened RC Beam-Column JointsDokument11 SeitenAnalysis of FRP-Strengthened RC Beam-Column JointsCu ToànNoch keine Bewertungen

- Seismic of Encased BeamDokument21 SeitenSeismic of Encased BeamvardhangargNoch keine Bewertungen

- ProposalDokument8 SeitenProposalMisganaw YeshiwasNoch keine Bewertungen

- Modeling, Analysis, and Behavior of Load-Carrying Precast Concrete Sandwich PanelsDokument13 SeitenModeling, Analysis, and Behavior of Load-Carrying Precast Concrete Sandwich PanelsAristotle MedinaNoch keine Bewertungen

- Construction and Building Materials: P.K.V.R. Padalu, Y. Singh, S. DasDokument21 SeitenConstruction and Building Materials: P.K.V.R. Padalu, Y. Singh, S. DasMAYANK GANGWARNoch keine Bewertungen

- Finite Element Modeling of Reinforced Concrete Cladding PanelsDokument11 SeitenFinite Element Modeling of Reinforced Concrete Cladding PanelsTariqul IslamNoch keine Bewertungen

- Finite Element Modeling of Reinforced Concrete Cladding PanelsDokument11 SeitenFinite Element Modeling of Reinforced Concrete Cladding PanelsTariqul IslamNoch keine Bewertungen

- Transverse Post-Tensioning Design and Detailing of Precast, Prestressed Concrete Adjacent-Box-Girder BridgesDokument16 SeitenTransverse Post-Tensioning Design and Detailing of Precast, Prestressed Concrete Adjacent-Box-Girder BridgesLorenzo LeardiniNoch keine Bewertungen

- Buildings: A Novel Shear Strengthening of Existing RC Shear Walls Using Steel Wire Mesh and Polymer MortarDokument19 SeitenBuildings: A Novel Shear Strengthening of Existing RC Shear Walls Using Steel Wire Mesh and Polymer Mortarjiliang liuNoch keine Bewertungen

- An Investigation On The Behavior of A New Connection For Precast Structures Under Reverse Cyclic LoadingDokument10 SeitenAn Investigation On The Behavior of A New Connection For Precast Structures Under Reverse Cyclic LoadingMohammad AkbarNoch keine Bewertungen

- Li 2016Dokument15 SeitenLi 2016fahmi aballiNoch keine Bewertungen

- Effects of Seismically Induced Pounding at Expansion Joints of Concrete BridgesDokument10 SeitenEffects of Seismically Induced Pounding at Expansion Joints of Concrete BridgesJuan BravoNoch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Student Name USNDokument4 SeitenStudent Name USNjayanthNoch keine Bewertungen

- Strength of Materials Jan 2017 (2010 Scheme)Dokument2 SeitenStrength of Materials Jan 2017 (2010 Scheme)jayanthNoch keine Bewertungen

- Crack Identification in RCC Beams Using ANSYS SoftwareDokument9 SeitenCrack Identification in RCC Beams Using ANSYS SoftwareUmesh BasappaNoch keine Bewertungen

- Crack Identification in RCC Beams Using ANSYS SoftwareDokument9 SeitenCrack Identification in RCC Beams Using ANSYS SoftwareUmesh BasappaNoch keine Bewertungen

- 1 .Finite Element Modeling of Reinforced Concrete Corners Under Opening Bending MomentDokument11 Seiten1 .Finite Element Modeling of Reinforced Concrete Corners Under Opening Bending MomentjayanthNoch keine Bewertungen

- CT Lecturing ApproachDokument1 SeiteCT Lecturing ApproachjayanthNoch keine Bewertungen

- Innovative Teaching ReportDokument1 SeiteInnovative Teaching ReportjayanthNoch keine Bewertungen

- HalahlaDokument9 SeitenHalahlaalhassanNoch keine Bewertungen

- Construction and Building Materials: M.N. Soutsos, T.T. Le, A.P. LampropoulosDokument7 SeitenConstruction and Building Materials: M.N. Soutsos, T.T. Le, A.P. LampropoulosAhmad MuhammadNoch keine Bewertungen

- Flexural Behaviour of RC Beams in Fibre Reinforced ConcreteDokument8 SeitenFlexural Behaviour of RC Beams in Fibre Reinforced ConcretejayanthNoch keine Bewertungen

- Keywords: ANSYS Software, ANSYS Parametric Design Language, Discrete, Cracking, Yielding, Non-Linear andDokument11 SeitenKeywords: ANSYS Software, ANSYS Parametric Design Language, Discrete, Cracking, Yielding, Non-Linear andsanjusamsonNoch keine Bewertungen

- Flexural Strength of Steel Fibre Reinforced Concrete BeamsDokument6 SeitenFlexural Strength of Steel Fibre Reinforced Concrete BeamsjayanthNoch keine Bewertungen

- Microcracking and Stress-Strain Curves For Concrete in TensionDokument4 SeitenMicrocracking and Stress-Strain Curves For Concrete in TensionjayanthNoch keine Bewertungen

- Effects of Fibre Geometry and Volume Fraction On The Flexural Behaviour of Steel-Fibre Reinforced ConcreteDokument7 SeitenEffects of Fibre Geometry and Volume Fraction On The Flexural Behaviour of Steel-Fibre Reinforced ConcreteHrishav SinghNoch keine Bewertungen

- New Horizon College of Engineering Day Wise Lesson PlanDokument9 SeitenNew Horizon College of Engineering Day Wise Lesson PlanjayanthNoch keine Bewertungen

- Experimental Evaluation of Fibre Reinforced Concrete Fracture PropertiesDokument8 SeitenExperimental Evaluation of Fibre Reinforced Concrete Fracture PropertiesjayanthNoch keine Bewertungen

- Surveying II Unit 5 Hydrographic SurveyingDokument47 SeitenSurveying II Unit 5 Hydrographic Surveyinghana chatoNoch keine Bewertungen

- Shore Line Survey and SoundingDokument2 SeitenShore Line Survey and SoundingjayanthNoch keine Bewertungen

- All Are Cordially Invited: Department of Civil EngineeringDokument8 SeitenAll Are Cordially Invited: Department of Civil EngineeringjayanthNoch keine Bewertungen

- Effect of Aspect Ratio and Volume Fraction of Steel Fiber On The Mechanical Properties of SFRC PDFDokument4 SeitenEffect of Aspect Ratio and Volume Fraction of Steel Fiber On The Mechanical Properties of SFRC PDFjaysern7Noch keine Bewertungen

- Criterion 7 Continuous Improvement: Target Level 1.89 Attainment LevelDokument9 SeitenCriterion 7 Continuous Improvement: Target Level 1.89 Attainment LeveljayanthNoch keine Bewertungen

- RCC Civ52 CoDokument3 SeitenRCC Civ52 CojayanthNoch keine Bewertungen

- DR - Vinay Kumar BM - 10-05-21 To 15-05-21 (Weekly Report)Dokument1 SeiteDR - Vinay Kumar BM - 10-05-21 To 15-05-21 (Weekly Report)jayanthNoch keine Bewertungen

- New Horizon College of Engineering, Bangalore (Autonomous College Affiliated To VTU, Accredited by NAAC With A' Grade)Dokument14 SeitenNew Horizon College of Engineering, Bangalore (Autonomous College Affiliated To VTU, Accredited by NAAC With A' Grade)jayanthNoch keine Bewertungen

- The Governance of The Institution Is Reflective of An Effective Leadership in Tune With The Vision and Mission of The InstitutionDokument2 SeitenThe Governance of The Institution Is Reflective of An Effective Leadership in Tune With The Vision and Mission of The InstitutionjayanthNoch keine Bewertungen

- The Governance of The Institution Is Reflective of An Effective Leadership in Tune With The Vision and Mission of The InstitutionDokument2 SeitenThe Governance of The Institution Is Reflective of An Effective Leadership in Tune With The Vision and Mission of The InstitutionjayanthNoch keine Bewertungen

- Assignment Front SheetDokument1 SeiteAssignment Front SheetjayanthNoch keine Bewertungen

- Rent AgreementDokument3 SeitenRent AgreementjayanthNoch keine Bewertungen

- NHCE Mentors Checklist TemplateDokument3 SeitenNHCE Mentors Checklist TemplatejayanthNoch keine Bewertungen

- Unit 2Dokument12 SeitenUnit 2jayanthNoch keine Bewertungen

- Kingbond S: Mild Steel General Purpose (MSGP)Dokument1 SeiteKingbond S: Mild Steel General Purpose (MSGP)satnamNoch keine Bewertungen

- Design Report FinalDokument68 SeitenDesign Report FinalAsiri MihiranNoch keine Bewertungen

- E 1211 - 97 - RteymtetukveDokument6 SeitenE 1211 - 97 - RteymtetukveLENDNoch keine Bewertungen

- 343r 95Dokument158 Seiten343r 95INGIMFBNoch keine Bewertungen

- Ressure Test Procedure For Piping SystemDokument5 SeitenRessure Test Procedure For Piping SystemKyaw Kyaw AungNoch keine Bewertungen

- 004 VSL Datasheets US-ADokument22 Seiten004 VSL Datasheets US-Akmabd100% (1)

- OsmaDrain Jointing Quick GuideDokument2 SeitenOsmaDrain Jointing Quick GuideHatem AbdelnabiNoch keine Bewertungen

- LUBCON Printing ServicesDokument2 SeitenLUBCON Printing ServicesOmin PostingNoch keine Bewertungen

- Quick Guide To ISO-14692Dokument12 SeitenQuick Guide To ISO-14692maninventor100% (5)

- المواسيرDokument15 SeitenالمواسيرshamashergyNoch keine Bewertungen

- Gears: Pinion Gear, Step Down DriveDokument42 SeitenGears: Pinion Gear, Step Down DriveIshan VermaNoch keine Bewertungen

- XXXX Evacuation Area ESDokument45 SeitenXXXX Evacuation Area ESRifatAlAhmedNoch keine Bewertungen

- Issue103 PDFDokument84 SeitenIssue103 PDFHS itNoch keine Bewertungen

- FLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedDokument92 SeitenFLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedWilliam O OkolotuNoch keine Bewertungen

- Handbook For Use and Maintenance and Directive ATEX: Elvem S.R.LDokument18 SeitenHandbook For Use and Maintenance and Directive ATEX: Elvem S.R.LE.ANANDANNoch keine Bewertungen

- D475a-5gen00051 Fa-03Dokument240 SeitenD475a-5gen00051 Fa-03Gabo GaboNoch keine Bewertungen

- Bibby CouplingsDokument25 SeitenBibby CouplingsKemoy JohnsonNoch keine Bewertungen

- Francis Urbines Litostroj Power Product SheetDokument2 SeitenFrancis Urbines Litostroj Power Product SheetНенад АритоновиќNoch keine Bewertungen

- Ornek Sorular Cilt1Dokument52 SeitenOrnek Sorular Cilt1ThorisNoch keine Bewertungen

- SSP 336Dokument36 SeitenSSP 336Зоран Ѓорѓиевски100% (2)

- Lecture PDFDokument7 SeitenLecture PDFRitikNoch keine Bewertungen

- Metallurgical Features of NANOHITEN and Application To Warm StampingDokument6 SeitenMetallurgical Features of NANOHITEN and Application To Warm Stampingdhafi keceNoch keine Bewertungen

- Underground Construction TechnologyDokument74 SeitenUnderground Construction TechnologyChin Thau WuiNoch keine Bewertungen

- Motion and Machinery: Displacement, Velocity and Acceleration, Linkage and ConstraintsDokument41 SeitenMotion and Machinery: Displacement, Velocity and Acceleration, Linkage and ConstraintsJhEan LoUiseNoch keine Bewertungen

- Conval Clampseal Catalog 2019Dokument44 SeitenConval Clampseal Catalog 2019Roger SeaverNoch keine Bewertungen

- Piston Pump (Steering) High Pressure Stall - Test and AdjustDokument6 SeitenPiston Pump (Steering) High Pressure Stall - Test and AdjustDidi PrawiraNoch keine Bewertungen

- Qeehs Departmental Manual Maintenance (Electrical) : DOC NO. SOP For Transformer Oil Sample CollectionDokument2 SeitenQeehs Departmental Manual Maintenance (Electrical) : DOC NO. SOP For Transformer Oil Sample CollectionSiemens OLM BorlNoch keine Bewertungen

- Standards For Nuts Bolts and Washers Rev EDokument326 SeitenStandards For Nuts Bolts and Washers Rev EValentinNoch keine Bewertungen

- Resolvers HaroweDokument8 SeitenResolvers Harowemcantraks17Noch keine Bewertungen

- Surface Tension PDFDokument7 SeitenSurface Tension PDFNsBhasinNoch keine Bewertungen