Beruflich Dokumente

Kultur Dokumente

Plano PDF

Hochgeladen von

ENERIETHOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Plano PDF

Hochgeladen von

ENERIETHCopyright:

Verfügbare Formate

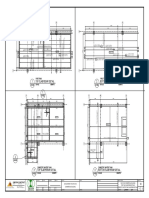

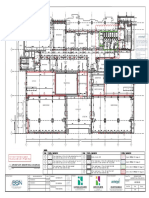

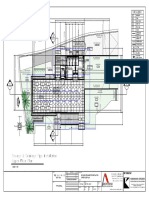

205 995 800 The host and the metope of interference will dig

R1 710 680 groove (600 x800 x120 measures how deep) wide,

such as interior wall, elevator installation is reserved

hole through and access door (maintenance platform Hook

and climbing the ladder are supplied by the user)

supplied by user

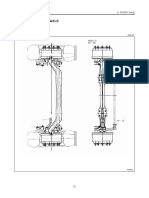

1085

Speed

Hook limiter

550

190200

485

CD=1400

270 330

B Put

th

after e mach

HD=2000

in

com the rese e beam

200

p rv

supp letion o ed hole before

lied f an

by th the insta after the d

550

Before and after bearing girder e us llatio

er n fill

915

(must set aside)

supplied by the user

beam

500

500

Ring ed by

30

1200

li

supp

The lintel above was

supplied by the user

70 user

90

Bearing R1 OP=800 Control cabinet

beam SOW=1000 reserved hole after the

K=4800

completion of the

before and 625 CW=1100 225 installation fill

after must supplied by the user

set aside 120 HW=2000

1. POWER SUPPLY TO MAIN CIRCUIT BREAKER PER

supplied by ELEVATOR TO BE NEAR TO THE CONTROLLER ON TOP

user FLOOR. AND ONE EARTHING WIRE TO BE SET NEAR TO

After the The THE CONTROLLER TOO, THE SECTION OF EARTHING

top

decoration floo

r aft

floor er dec ,THE WIRE FROM GROUND TO

orati MACHINE ROOM SHOULD BE INSULATED.

o n

2. MAIN POWER SUPPLY TO BE 3PHASE AC380V, 50HZ,

Well spacing for each lamp lights700

AC220V.

Fixed guide bracket beam spacing for each file.2000

3. THE SHAFT TO BE OF GOOD VERTICALITY, THE SHAFT

SIZE INDICATED IN PLANE SHALL BE MIN. AVAILABLE

NET SIZE, VERTICAL DEFLECTION RANGE: 0

After the 205 995 800 +25mm(SHAFT HEIGHT<30M), 0 +35mm(30M

decoration

floor SHAFT HEIGHT 60M), 0 +50mm(60M<SHAFT

4. PIT GROUND SHALL BE WATER-PROOF AND SMOOTH.

300

light

5. A POWER SOCKET (2P+ PE) SHALL BE SET IN THE PIT.

Glass curtain wall

supplied by user

Speed 6. THERE SHALL BE CONCRETE BEAMS IN SHAFT WALL

T=18900

1085

CWT DWG=900

limiter WITH INTERVAL 2000MM (UNLESS THE INTERVAL HAS

250 buffer SPECIAL REQUIREMENT IN CONTRACT), BEAM HEIGHT

190200

135 SHALL MIN. 300MM, THE LOWEST BEAM SHOULD BE

CD=1400

After the 510 510

285

700MM ABOVE THE PIT GROUND, THE HIGHEST BEAM

HD=2000

decoration SHOULD BE 300MM BELOW THE SHAFT TOP SLAB.

floor 200 7. THE DECORATION FOR LANDING DOOR ENTRANCE AND

OTHER RESERVED HOLES SHOULD BE DONE AFTER

795

915

DWG=1280 ELEVATOR INSTALLATION COMPLETION.

8. IF THE SPACE UNDER PIT IS ACCESSABLE FOR PEOPLE,

THE PIT GROUND SHALL BE ABLE TO BEAR 5000N/M

30

LOAD, AND BUFFER SUPPORT SHALL BE SOLID

SOH=2200

70 COLUMN EXTEND TO THE GROUND.

90

9. WHEN TWO ADJACENT LANDING DOOR SILL DISTANCE IS

OP=800 ABOVE 11M, SAFETY EXIT TO BE SET ON THE SHAFT

1000

SOW=1000 WALL IN MIDDLE. AND THE EXIT DOOR SHALL COMPLY

625 CD=1100 225 WITH EN81.

10. CABLE FROM GUARDS' ROOM TO SHAFT PIT TO BE SET

HW=2000

S=1300

BY OTHERS.

jx

dz

11. ON TOP OF CONTROLLER, PERMANENT LIGHT TO BE

SET, AND ILLUMINATION NOT SMALLER THAN 200LX.

500

500

12. SHAFT CONCRETE WALL TO BE SOUND, COMPRESSION

STRENGTH NOT BE LOWER THAN 30MPA, WALL

THICKNESS NOT BE SMALLER THAN 150MM.

Client Signature Supply Signature

Date Date

STAR elevator Group

Das könnte Ihnen auch gefallen

- Drawing PlanDokument1 SeiteDrawing PlanJoshua SitholeNoch keine Bewertungen

- A-06 DOORS AND WINDOW SCHEDULE, STAIR DETAILSfDokument1 SeiteA-06 DOORS AND WINDOW SCHEDULE, STAIR DETAILSfX XNoch keine Bewertungen

- MB Tầng 1Dokument1 SeiteMB Tầng 1Huong PhamNoch keine Bewertungen

- Plano 10RH11330220SSS 000025 2Dokument1 SeitePlano 10RH11330220SSS 000025 2Bao LeNoch keine Bewertungen

- UntitledDokument1 SeiteUntitledSteven SahaniNoch keine Bewertungen

- Plano Mecanico Preliminar - Ducto Barra - Usil InsigniaDokument1 SeitePlano Mecanico Preliminar - Ducto Barra - Usil InsigniaJUAN CAYETANONoch keine Bewertungen

- Sasa Ground FP PDFDokument1 SeiteSasa Ground FP PDFRygiem Dela CruzNoch keine Bewertungen

- 39 Gfc-P2c3-Tu02-Crp-Dr-Btn-73112-01-ADokument1 Seite39 Gfc-P2c3-Tu02-Crp-Dr-Btn-73112-01-ASUBHASH KUMARNoch keine Bewertungen

- APPBTM-002-CIV-CD-0002.2 - FOUNDATION & REINFORCEMENT TYPE 8 (Revisi)Dokument1 SeiteAPPBTM-002-CIV-CD-0002.2 - FOUNDATION & REINFORCEMENT TYPE 8 (Revisi)Adalah SiapaNoch keine Bewertungen

- General Detail Abut & WWDokument1 SeiteGeneral Detail Abut & WWUmesgNoch keine Bewertungen

- Mini VRF Carrier DC PD CPDokument5 SeitenMini VRF Carrier DC PD CPRaul RamirezNoch keine Bewertungen

- WHG - CS301 Wateproofing DetailsDokument1 SeiteWHG - CS301 Wateproofing Detailstintitn larayaNoch keine Bewertungen

- Venezuela Graphic Design DrawingsDokument1 SeiteVenezuela Graphic Design DrawingsJose AlbarezNoch keine Bewertungen

- Gate Canopy WDDokument1 SeiteGate Canopy WDMwesigwa DaniNoch keine Bewertungen

- 7Dokument1 Seite7Modasser NewazNoch keine Bewertungen

- Proposed 3 Bedroom 2 Car Garage HouseDokument2 SeitenProposed 3 Bedroom 2 Car Garage HousemwiingaNoch keine Bewertungen

- CulvertsDokument2 SeitenCulvertsengoleNoch keine Bewertungen

- CombinepdfDokument3 SeitenCombinepdfkhim tugasNoch keine Bewertungen

- Computer Aided Design AssignmentDokument1 SeiteComputer Aided Design AssignmentsilasbyarugNoch keine Bewertungen

- Shrink Wrap Conveyor Plan, CAD 2013-ModelDokument1 SeiteShrink Wrap Conveyor Plan, CAD 2013-ModelAndri YansyahNoch keine Bewertungen

- Masterpact NT RETURN Masterpact NW RETURN NS1600b... 3200 RETURN NS630b... 1600 RETURN NSX100... 250 RETURN NSX400... 630 54444Dokument1 SeiteMasterpact NT RETURN Masterpact NW RETURN NS1600b... 3200 RETURN NS630b... 1600 RETURN NSX100... 250 RETURN NSX400... 630 54444Anas BasarahNoch keine Bewertungen

- LAYOUT OF LINTEL AT +5.25m LVLDokument1 SeiteLAYOUT OF LINTEL AT +5.25m LVLAnoop NairNoch keine Bewertungen

- First Layout-Revised 03-11-06 (2) - ModelDokument1 SeiteFirst Layout-Revised 03-11-06 (2) - Modelmcpl.virajNoch keine Bewertungen

- OF-19012 (A) (Layout Copper Plating Line) (Drawing)Dokument1 SeiteOF-19012 (A) (Layout Copper Plating Line) (Drawing)Nguyen Thanh TrungNoch keine Bewertungen

- Sepeda Udara BDokument1 SeiteSepeda Udara BDimas WiryaNoch keine Bewertungen

- 1847 HP CocD300 190615Dokument2 Seiten1847 HP CocD300 190615Hoàng NguyênNoch keine Bewertungen

- Platform For MOV-8100Dokument1 SeitePlatform For MOV-8100Ali QureshiNoch keine Bewertungen

- Check Structure Layout2Dokument1 SeiteCheck Structure Layout2WesNoch keine Bewertungen

- Check Structure Layout2Dokument1 SeiteCheck Structure Layout2Elaine Joyce GarciaNoch keine Bewertungen

- A B C D E F G: RC Slab 150Th RC Slab 150ThDokument1 SeiteA B C D E F G: RC Slab 150Th RC Slab 150Thpatrick munyaoNoch keine Bewertungen

- Quay-Prop & Exist Pile Locations 02-09-2021-A3-Gen PlanDokument1 SeiteQuay-Prop & Exist Pile Locations 02-09-2021-A3-Gen PlandikiNoch keine Bewertungen

- DR-002-121212-PD-23 - Insulated - Sheet - S1 - Column GridDokument1 SeiteDR-002-121212-PD-23 - Insulated - Sheet - S1 - Column GriddisneyNoch keine Bewertungen

- General Surgery - Female Ward (30 Beds) : NorthDokument1 SeiteGeneral Surgery - Female Ward (30 Beds) : Northkiran raghukiranNoch keine Bewertungen

- 6 ST Ar MH Es Det 001Dokument1 Seite6 ST Ar MH Es Det 001Jacob FryeNoch keine Bewertungen

- Cascadia Roads 11092019-Layout1Dokument1 SeiteCascadia Roads 11092019-Layout1Daniel KariukiNoch keine Bewertungen

- South Elevation: Roof MonitorDokument1 SeiteSouth Elevation: Roof Monitorshabab mohsinNoch keine Bewertungen

- Mæt B NGDokument1 SeiteMæt B NGbanhbaonongNoch keine Bewertungen

- ROFC065330w ADokument1 SeiteROFC065330w AchetanbakkerNoch keine Bewertungen

- A3 - Doors & Window ScheduleDokument1 SeiteA3 - Doors & Window Schedule62296bucoNoch keine Bewertungen

- A2 PDFDokument1 SeiteA2 PDFCRISCHOUEL ALIMORONGNoch keine Bewertungen

- Plan LayoutDokument1 SeitePlan LayoutmaxNoch keine Bewertungen

- Annex 1 - Drawings-StripfondationDokument1 SeiteAnnex 1 - Drawings-StripfondationamonbrightsonNoch keine Bewertungen

- Wat Area BaseDokument4 SeitenWat Area BaseHeng KimsanNoch keine Bewertungen

- Layout STP 1 System (Gambar Lama)Dokument1 SeiteLayout STP 1 System (Gambar Lama)Saeful Design-AceNoch keine Bewertungen

- Index: Service Floor Working Plan S (LVL + 23200MM)Dokument1 SeiteIndex: Service Floor Working Plan S (LVL + 23200MM)Ranu GaurNoch keine Bewertungen

- A-114 Elevation Aixs A-K K-A PDFDokument1 SeiteA-114 Elevation Aixs A-K K-A PDFdothi aiuyenNoch keine Bewertungen

- 1100x600x130 TDN-1P.C 1100x600x130 TDN-1P.C 1100x600x130 TDN-1P.CDokument1 Seite1100x600x130 TDN-1P.C 1100x600x130 TDN-1P.C 1100x600x130 TDN-1P.CHipolito MBNoch keine Bewertungen

- Lift DetailDokument1 SeiteLift DetailGphone100% (1)

- FP SDP 20X30 PalanogbirthinghomeDokument1 SeiteFP SDP 20X30 Palanogbirthinghomeflor johnNoch keine Bewertungen

- Reference Drawing MLA - KANONDokument3 SeitenReference Drawing MLA - KANONriandiNoch keine Bewertungen

- BMS Table-ModelDokument1 SeiteBMS Table-ModelGarlapati TrinadhNoch keine Bewertungen

- General Medicine & Opthalmology - Male Ward (30 Beds)Dokument1 SeiteGeneral Medicine & Opthalmology - Male Ward (30 Beds)kiran raghukiranNoch keine Bewertungen

- ME SEWAGE Upper Floor AR - NB - 01 Floor PlanDokument1 SeiteME SEWAGE Upper Floor AR - NB - 01 Floor PlanDewa SuciartaNoch keine Bewertungen

- Arch Ad 16Dokument1 SeiteArch Ad 16subramanyam kumarNoch keine Bewertungen

- General Surgery - Male Ward (30 Beds) : Duct DuctDokument1 SeiteGeneral Surgery - Male Ward (30 Beds) : Duct Ductkiran raghukiranNoch keine Bewertungen

- Beechwood Culvert Tall Access ChamberDokument1 SeiteBeechwood Culvert Tall Access ChamberSandipan DharNoch keine Bewertungen

- First Floor Beams Details (1 of 3) : Sheet NameDokument3 SeitenFirst Floor Beams Details (1 of 3) : Sheet NameEric OwusuNoch keine Bewertungen

- 564 Villa G+1 SampleDokument7 Seiten564 Villa G+1 Samplealbarajeel consultantsNoch keine Bewertungen

- 133 Ground Floor PlanDokument1 Seite133 Ground Floor Planhemant.kumarNoch keine Bewertungen

- EG2000 Manual 1Dokument620 SeitenEG2000 Manual 1mayphatbaoson_512242Noch keine Bewertungen

- Sla 4070Dokument1 SeiteSla 4070JoniNoch keine Bewertungen

- SG110CX: Multi-MPPT String Inverter For SystemDokument2 SeitenSG110CX: Multi-MPPT String Inverter For Systemmr NguyenNoch keine Bewertungen

- Lab Manual: Nada R Saraswathi Co Llege of Engineering and Tech NologyDokument108 SeitenLab Manual: Nada R Saraswathi Co Llege of Engineering and Tech Nologynar11Noch keine Bewertungen

- LG GW-305 Service ManualDokument153 SeitenLG GW-305 Service ManualCah NgaloefNoch keine Bewertungen

- Suggested Tightening Torque1 Values To Produce Corresponding Bolt Clamping Loads PDFDokument1 SeiteSuggested Tightening Torque1 Values To Produce Corresponding Bolt Clamping Loads PDFdesc82Noch keine Bewertungen

- Re15206 2009-07 PDFDokument18 SeitenRe15206 2009-07 PDFВладиславМасарскийNoch keine Bewertungen

- Method Statement For Fan Coil UnitsDokument6 SeitenMethod Statement For Fan Coil UnitsTawrez KhatibNoch keine Bewertungen

- ABB Review 2-2010 - 72dpi PDFDokument4 SeitenABB Review 2-2010 - 72dpi PDFNguyễn Văn HưngNoch keine Bewertungen

- Hisense Hle4213rt PDFDokument46 SeitenHisense Hle4213rt PDFAngel Luciano Ramon GomezNoch keine Bewertungen

- LIGHT SOURCE LX 2300 (Xenon 300W) : Servicing ManualDokument24 SeitenLIGHT SOURCE LX 2300 (Xenon 300W) : Servicing ManualJorge AnayaNoch keine Bewertungen

- Cambridge Azur 640r SMDokument62 SeitenCambridge Azur 640r SMYannisNoch keine Bewertungen

- 3M Solutions Catalogue 2014Dokument24 Seiten3M Solutions Catalogue 2014hkg1997Noch keine Bewertungen

- 8.3 Description of The Hydraulic System: 8.3.1 Technical DataDokument15 Seiten8.3 Description of The Hydraulic System: 8.3.1 Technical DataOsvaldo UrbanoNoch keine Bewertungen

- Bombardier Skidoo 1998-99 Electric Wiring DiagramDokument41 SeitenBombardier Skidoo 1998-99 Electric Wiring Diagramsupernovadave57% (14)

- Cambridge Igcse Ict Coursebook With Cd-Rom Revised EditionDokument10 SeitenCambridge Igcse Ict Coursebook With Cd-Rom Revised EditionRini SandeepNoch keine Bewertungen

- ATPL (A) Nortávia Flight School José Miguel Cavaleiro MendesDokument11 SeitenATPL (A) Nortávia Flight School José Miguel Cavaleiro MendesJoséMendesNoch keine Bewertungen

- Ball Bearing Installation and MaintenanceDokument12 SeitenBall Bearing Installation and Maintenancecengiz kutukcuNoch keine Bewertungen

- Catalogo EBC Frenos Moto 2020Dokument888 SeitenCatalogo EBC Frenos Moto 2020Diego MartinsonNoch keine Bewertungen

- CC & CVT Instruction ManualDokument18 SeitenCC & CVT Instruction Manualcuongnv_19100% (1)

- Shift Report - December 06, 2023-2nd ShiftDokument4 SeitenShift Report - December 06, 2023-2nd Shiftbobowapthree19Noch keine Bewertungen

- Why Compressors Fail?Dokument83 SeitenWhy Compressors Fail?Neil LachicaNoch keine Bewertungen

- Adjust Valve EC200DDokument5 SeitenAdjust Valve EC200DHeru Hoo0% (1)

- Microwave Trouble Shooting ManualDokument35 SeitenMicrowave Trouble Shooting ManualAde NugroxxNoch keine Bewertungen

- DWS2510.02 - Auxiary Drive SpecificationDokument11 SeitenDWS2510.02 - Auxiary Drive SpecificationCorneNoch keine Bewertungen

- Abb High Voltage Bushing Wells For Pad Mounted Distribution Transformers R5Dokument9 SeitenAbb High Voltage Bushing Wells For Pad Mounted Distribution Transformers R5Eko SusantoNoch keine Bewertungen

- Ont Axle 2 PDFDokument34 SeitenOnt Axle 2 PDFFrezgi BirhanuNoch keine Bewertungen

- Rehana ShoudhDokument13 SeitenRehana ShoudhRehana TahasildarNoch keine Bewertungen

- ARGUS - Movement Detectors - MTN565219Dokument2 SeitenARGUS - Movement Detectors - MTN565219fahmi1987Noch keine Bewertungen

- Fuel Injection Pump and PipingDokument2 SeitenFuel Injection Pump and PipingWilheam MamaniNoch keine Bewertungen