Beruflich Dokumente

Kultur Dokumente

Control of A Pneumatic Servosystem Using Fuzzy Logic

Hochgeladen von

Soare ValiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Control of A Pneumatic Servosystem Using Fuzzy Logic

Hochgeladen von

Soare ValiCopyright:

Verfügbare Formate

Control of a Pneumatic Servosystem Using Fuzzy Logic 189

CONTROL OF A PNEUMATIC

SERVOSYSTEM USING FUZZY LOGIC

Hipòlit MORENO LLAGOSTERA. Eng.

Salvador de las Heras Jimenez Dr. Eng. (Thesis Director)

Dpt. Mecánica de Fluids - UPC. Campus de TERRASSA.C/ colón 7-11

08225 TERRASSA. Barcelona

SPAIN

The servodrive analyzed here consists on a large stroke actuator of 2 meters, activated by a flow proportional

valve. The aim of the Ph.D. is to achieve a successful control of the actuator despite it having big chambers,

which has a big influence on the system response, owing to the air compressibility. For the experimental study, a

test bench has been built and a magnetorrestrictive sensor of displacement is used in order to close the loop.

Before starting the control of the system and in order to know how the pneumatic servo drive reacts, the inter-

action of the actuator and valve set has been studied by means of Bond Graph technique.

At first, the PID control was applied in pneumatic servodrives, after seeing its several problems, state control

algorithm started to be applied. The state loop control algorithm reaches a good result, however in cases where

a system parameter changes it is necessary to retune the state variable gains (position, velocity and accelera-

tion), above all in this particular case. It is here where Fuzzy Logic reasoning could be used.

Key words: Servo pneumatic drive, bond graph, state loop control, fuzzy controller.

1 INTRODUCTION

The electro-pneumatic control systems are widely applied in the industrial automation tech-

nology, especially, when action is controlled by using programmable logic controllers.

Conventionally, when a control must be optimised, we have to build up a mathematical

model, Astrom (1999) and Ogata (1996, 1998). The control performance of a traditional con-

troller fully depends on the accuracy of a known system dynamic model. The complex pneu-

matic servodrive positioning process has non-linear and time varying behaviours; thus it is

difficult to derive and identify an appropriate dynamic model for traditional controllers, Ming

(1992, 1995, 1998). Then the control system should be analysed and a controller can be

designed. It is very difficult to get an accurate and linearised mathematical model; therefore

the fuzzy control technology is applied.

As it is well known, Zadeh, Zimmermann (1991), originates the fuzzy theory in 1965. In

recent years, the control technology has been well developed and has become one of the most

successful tools in the industry. In fact, nowadays, there are several programmable logic con-

troller dealers who offer fuzzy control tools in their products..

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 190

This kind of control has been applied in the industrial world (process and automation) giving

an optimal effect, Klein (1993). The results of this application have demonstrated that the

fuzzy control shows better benefits in comparison with that those offered by other PID con-

trollers. The main advantages of the fuzzy controller are these, Sorli (1998, 1999):

• It is not necessary to build a detailed mathematical model. Despite this, in the present

work, this point is considered by means of Bond Graph Technique.

• The fuzzy controllers have a high strength and a high adjustment.

• They can operate with a high input number.

• They can be adapted easily into non-linear systems.

• The human knowledge can be easily applied.

• The process development time is relatively lower.

The essence of fuzzy logic control is that appropriate linguistic fuzzy rules are chosen, using

some decision-making process, from a rule table constructed using human control experience

and databases. In the present work the fuzzy rules are established by trial and error with the

concept of symmetry. Fuzzy set theory is employed to simulate the logic reasoning of human

beings.

Fuzzy control has been demonstrated to provide highly satisfactory results in terms of accu-

racy, repeatability and insensitivity to changes in operating conditions, Ferraresi (1990). Clas-

sic controls satisfies the requirements for stability, accuracy and rapid response; providing

that there is an optimal match between the real values of the system's physical parameters and

the values used for control design, and there is no external interference (change in load).

Advanced control techniques (e.g. optimum, robust, self tuning) requires highly sophisticated

and complex control algorithms if they are to be any effective use.

Applying fuzzy control to a continuous pneumatic positioning system is particularly advanta-

geous in terms of simplicity of design and implementation, and thus significantly reduces the

time required to develop the entire system, Ferraresi (1989, 1994). Experience shows that the

success of a fuzzy control depends on the level of knowledge concerning the positioner's

physical behaviour.

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 191

2 LAYOUT OF THE EXPERIMENTAL DEVICES

The functional pneumatic positioning system with fuzzy control is shown in figure 1. The

actuation element consists of a double-acting pneumatic rodless cylinder with bore of 40 mm,

and a stroke of 2000 mm. The cylinder is a Heavy Duty model of Norgren - Herion. The cyl-

inder chambers are connected to a flow rate proportional valve, the ISO 1 Isotron model of

Norgren (1000 Nl/min). The flow proportional valve has an internal position closed loop, an a

cutoff frequency of 80 Hz.. The system incorporates provision for varying the inertial load

acting on the actuator bore.

A magneto restrictive analog sensor of displacement closes the loop in terms of position; this

sensor can give the speed signal also offering a high resolution. The Fuzzy Controller gener-

ates valve control signals by processing the resident program on the basis of measured mag-

nitudes. The fuzzy system consists of a National Instruments Data Acquisition Card (model

PCI 1200), the control program is run under Labview, and Labview Fuzzy Toolbox is also

used. For the control system, an electrical cupboard has been built. This rack and the pneu-

matic system are shown in figures 2a and 2b.

The rule sets and the membership functions for input and output variables are transferred to

the fuzzy processor. Rules and functions are written using the National Instruments Fuzzy

Logic Toolbox. The fuzzy inference process used by the controller is the min-max- center of

gravity method.

Transductor Magnetorestrictivo

Actuador

Carga Inercial

Consigna

CONTRO

Figure 1.- Positioning System.

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 192

Figure 2a. 2b.- Pictures of the pneumatic positioning system.

3 SYSTEM CHARACTERISATION

As explained before, the positioning system basically consists of a pneumatic actuator oper-

ated by a servovalve with a position closed-loop. Pneumatic actuator performance can be

determined at first approximation by steady state tests. The real working conditions including

coupling between actuator and proportional valve, cannot be completely achieved if the

design specifications require reduced motion times. Coupled system characteristics can only

be evaluated by performing a dynamic analysis of the system, specially dealing with short

stroke heavy loaded actuator or long stroke low loaded actuator.

Assuming the type of actuator, single or double acting, with stiff or flexible wall and suppos-

ing that the power regulation element has been chosen, the parameters that influence the

dynamics of the actuator are:

• The sizes and geometry of the chambers, defined by the linear or rotary stroke, bore

and rod, in the linear actuators.

• The type of seals and the mobile support, which exert a strong influence on friction

forces.

• The size of the regulation valve.

• The length and dimension of feeding pipes.

• The magnitude to be controlled by the actuator (force, position or velocity).

• The level of supply pressures.

• The entity of disturbances related to the controlled magnitude.

The above mentioned parameters interact in a very strong non-linear way. The servo system

performances also strongly depends on the control strategy.

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 193

Q

Ff

b

Fe

a

y

Ma Mb

Figure 3. - Drive parameters.

One of the first researchers to model the pneumatic system was Burrows (1968). In the

research work, the author suggested to feedback the state variables. Applying the first princi-

ple of thermodynamics, and the equilibrium forces, the pneumatic system is characterised as

follows:

M& V&

dPa

= γrTs a − γPa a [1]

dt Va Va

M& V&

dPb

= γrTs b − γPb b [2]

dt Vb Vb

( p a − pb )S − bvis y& − Ff − Fe = M&y& [3]

The heat transfer in the actuator models has been disdained.

Then we can express the state equations,

dy

= y& [4]

dt

F

[5]

dy& S b F

= (Pa − Pb ) − vis y& − f − e

dt M M M M

In the model taken by Backé and Ohligschläger (1990) the same formulae as Burrows, has

been taken into account considered but the heat transfer is considered. This results in the fol-

lowing state equations are given:

dP γ dV γ −1

= R( m& aTa − m& bTb ) − p + Q& [6]

dt V dt γ

dy& 1

= (A(Pa − Pb ) − bvis y& − F f − Fe ) [7]

dt M

In the research center of INSA, Tolouse (France), Prof. Scavarda (1993, 1998), bases his state

equations by considering the control signal or manipulated variable, u. Using this way, it is

possible to take a non-lineal model from Burrows'. Consequently, the state equations would

be:

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 194

x& = f ( x, u ) [8]

γrTs

dPa

= ma (u , Pa ) −

Pa A1

y& [9]

dt Va ( y ) rTs

γrTs

dPb

= mb (u, Pb ) −

Pb A2

y& [10]

dt Vb ( y ) rTs

dy

= y& [11]

dt

dy& S a

=

S b F F

Pa − b Pb − vis y& − sec − e [12]

dt M M M M M

The hypotheses considered for the construction of these models are:

- take air as a perfect gas

- homogeneous pressure and temperature in both drive chambers

- supply temperature and pressure variation, Ts, Ps, are not considered.

- kinetic energy is neglected

- valve dynamics is not considered

- air losses are not considered

- external force, Fe, is constant.

Another way to modelise the pneumatic system to obtain transfer function, is by Virvalo

(1989, 1991), considering the theoretical dynamics of the drive-valve set.

A common function transfer would be:

K qa wn2

G( s ) = [13]

s ( s + 2dwn s + wn )

2 2

Ps − 1

3Q N Pa

3∆Pn

K qa = [14]

2 Psumax A

Where the second order function represents the valve and the drive dynamic interaction and

the integrator is used to obtain the response in terms of position.

The natural frequency is calculated just considering the analogy to hydraulic systems.

2.8 ⋅ p s A12 A22

wn = ⋅( + ) [15]

3⋅ M A1 ⋅ y + V10 A2 ⋅ (l − y ) ⋅ V 20

It is noticed that the natural frequency depends on the bore position.

The models explained previously do not consider the high non-linearity system. The unidi-

rectional mechanics of the system is easily recognized in bond graph, see figure 3. Prof. de las

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 195

Heras has developed the Bond Graph used in this work, de las Heras (1997, 1999). In this

bond graph scheme three sub model have been created: the actuator, the servo valve, and the

controller. This Bond Graph is calculated by means of the 20 Sim program.

:Twall

xMEAN

actua02

fuzzy1

.. :Tin :pin :pout :Tout

FuzzyControl

valve03

..

gain_1 PUR9673

stepgen_1

:Te :pe :ps :Ts

Figure 3. - Modelization of the pneumatic positioning system in Bond Graph technique.

The actuator model considers the thermal dynamics; hence the bond graph identifies two C-

fields and two R-fields in conductance form inside the actuator model. The actuator model

considers also the behaviour of the real gases (at will), the total energy transmitted at the

ports, the stick-slip and friction forces. The simulations of the system as an open loop or and

closed loop can be acquired. For the first case, it will give response in terms of velocity and in

the other case in terms of position if a position sensor is used

The valve model considers its internal position closed loop, the hysteresis of the proportional

coil and its internal friction.

The controller model, here showed is a typical error and change in time error control. Having

one input, the position error, and one output, the control valve voltage. The linguistic vari-

ables are the position error and the error change.

Upon the completion of the physical model of the system, it is now to make some theoretical

tests. Then one of the aims of the thesis will be to contrast these results with real experiences.

The data used in the model is the real data that configures the real test bench system. In that

case a load of 5.4 kg is applied.

With this model the pneumatic system response has been studied. If a sinusoidal signal with a

variable frequency input (chirp pattern) is introduced to the system, the results given in figure

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 196

4 are obtained. For this simulation it is considered that the system is an open loop and an

input is introduced to the flow proportional valve. The response is in terms of velocity, and

the stick-slip is also considered.

As it is easy to see, the model response is not linear, because the applied model is non linear

neither. The sinusoidal input is a chirp pattern, which generates a sample according to the

following formula:

yi = A ⋅ sin((a / 2 i + b)i ), for i = 0, 1, 2, ..., n − 1 [16]

where A is amplitude, a = 2π (f 2 -f1 )/n, b = 2π f 1 , f 1 is the beginning frequency in normalised

units, f 2 is the ending frequency and n is the number of samples.

0 0

0 0

Figure 4. - Response obtained in the Bond Graph simulation with a chirp pattern Input.

One of the aims of the Ph. D. work is to obtain a real response of the pneumatic system when

a chirp pattern is introduced, in order to compare the simulation and the reality. The important

thing to determine is in which sense the non linearity of the servo drive in the Bond Graph

model, can be adjusted. The Labview software will generate this chirp pattern signal.

4 PRIMARIY TESTING.

Nowadays, the experimentation done in the Ph. D. thesis compromises of PID control, as well

as the state observer and the Fuzzy Control. In the case of the PID experiences, the tests were

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 197

done with an industrial PID of OMRON, model ES100. However, the trials made with this

controller did not give suitable results, they presented a high unsteadiness to the system

variations, and the positioning was slow, in term of severals seconds. It has to be considered

that the case explained in this work consists of a long stroke drive.

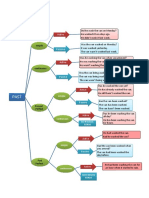

After this experimentation, the state observer was studied. In figure 5, the control scheme

used in order to close the loop in terms of positions can be seen. The Position (SP) is intro-

duced by the means of a Labview control icon, to this value the position lecture (PV) is sub-

stracted, by this way the regulation error (e) is obtained. From here, this error is treated, the

state variables (x, v, a) are feedbacked with their respective gains. By these means, the flow

proportional valve is commanded (MV).

C:\mis documentos\dades\obsestat\velierr.txt

Speed Input Speed

1

Velocitat ACH1

C:\mis documentos\dades\obsestat\spipv.txt

Position (SP)

Error (e)

Error

5.00

10.00

1

(PV) C:\mis documentos\dades\obsestat\tempsimv.txt

Position ACH0 Kx

Position Input

v

Kv

dt

Ka

P

5.00

Valve (MV)

Position

5.00

ON/OFF

Figure 5.- State control diagram in Labview.

The control algorithm presents a high and a precise response, the difficulty in this case is that

the state variable gains depends on the setpoint and the system parameters. This influence has

also been studied in order to increase the system knowledge, by this way it will be possible to

integrate the fuzzy logic in this control algorithm. The state variable gains could be scheduled

by means of a fuzzy system, in order to take the correct values for the desired positioning.

Before reaching this point, the fuzzy control has been studied, taking as fuzzy variables the

error (e) and the change in time error (de). The controller structure is the usual in fuzzy con-

trollers, in figure 6 it is reflected how it is controlled in the Labview program. For this con-

troller the Labview fuzzy control toolbox has been used.

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 198

C:\mis documentos\dades\fuzzy\errorde\velierr.txt

de

Error (%) C:\mis documentos\dades\fuzzy\errorde\spipv.txt

Position (SP) 10.00

5.00 e de

C:\mis documentos\dades\fuzzy\errorde\tempsimv.txt

Error (e)

1

(PV)

Position ACH0 Valve (MV)

Position Input Position

5.00

Figure 6. - Fuzzy e, de control in Labview.

For this control a response for a 5 V step is shown in figure 7. This step corresponds to 50%

of the pneumatic drive stroke; in this case it is 1 meter. In the figure it is possible to see the

process variable (PV) evolution and the manipulated variable (MV) faced with the setpoint

signal. From this result the response time can be observed, next to a 1 second. It can be appre-

ciated that the speed is almost constant, seeing that the PV presents an evolution that corre-

sponds to a straight with a constant slope. The average speed in the case shown is 1 meter per

second.

Step Response

10 5

8 3

SP; PV (Volts)

MV (Volts)

6 1

4 -1

2 -3

0 -5

0 5 10 15 20 25

Time (s)

SP (Volts) PV (Volts) MV (Volts)

Figure 7. - Step Response of Fuzzy e, de control.

At present, it is proceeded to the realisation of a system control by the means of the state

observer. The structure used corresponds to that of the figure 5, but in the actual case a fuzzy

algorithm parameterises the state variable gains. With this, the steadiness of the state observer

controller with a high response along with the fuzzy logic adaptation is competed for. The

control algorithm final structure is shown in figure 8, for this controller it has not been possi-

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 199

ble to obtain good results up to this moment, as it is necessary to increase the system

knowledge for this kind of control structure.

Speed Input Speed

1

Speed ACH1

Position (SP)

Error (e) Error (%)

5.00

10.00

1

(PV)

Position ACH0 Kx

Position Input

v

Kv

dt

a

Ka

5.00

Valve (MV)

Position

5.00

ON/OFF

Figure 8. - State Fuzzy control diagram in Labview.

5 CONCLUSIONS AND FURTHER STUDIES

In conclusion, it is important to make evident the great potential that fuzzy logic has to offer,

such as the need for the mathematical model. However high system knowledge is necessary to

improve the performance of the controlled servodrive. Another point to consider is also the

easy integration of the fuzzy logic in traditional control algorithm, as it is shown in this work.

Another advantage that the fuzzy logic offers is that an autotuning algorithm can be applied to

the system, by the means of this reasoning. In this way, the system can learn the control

parameters to take, Backé and Klein (1990). With this point it is possible to save the experi-

mentation for the controller tuning.

Considering these the further studies of the thesis will be the experimental characterisation of

the pneumatic servodrive. After this the results will be compared with those of the Bond

Graph. With this, the influence of the control to the closed loop will be seen and studied.

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 200

6 ACKNOWLEDGEMENTS

In this research work we have the support of the NORGREN Company.

7 REFERENCES

Astrom K., Häglund T. (1999) PID Controllers Theory, Design and Tuning. Library of

Congress Cataloguing-in-Publication Data.

Burrows C.R., Webb C.R. (1968) Simulation of an On - Off Pneumatic Servomechanism.

Automatic Control Group.

De las Heras S., Codina E. (1997). Modelización de sistemas fluidos mediante Bondgraph.

CBS, S.A. Terrassa.

Ferraresi C., Velardocchia M.. (1988) Posizionatore Pneumatico con Controllo Elettrico.

Oleodinamica. Pneumatica. Italy.

Ferraresi C., Raparelli T., Velardocchia M. (1990). Studio della Stabilità e della Prontezza

di Sistemi di Posizionamento Pneumatici. X Congresso Nazionale dell'Associazione Italiana

de meccatronica.

Ferraresi Carlo, Giraudo P., Quaglia G. (1994) Non Conventional Adaptive Control of a

Servopneumatic Unit for Vertical Load Positioning. Proceedings of the 46th National Confer-

ence on Fluid Power.

Kagawa T., Ohligschläger O. (1990) Simultionsmodel für Pneumatische Zylinderantriebe.

Olhydraulik und Pneumatik.

Klein A., Backé W. (1992) An Intelligent Optimisation of State Loop Controller with Fuzzy-

Set-Logic. Circuit, components and system design. 5th Bath In.

Klein A. (1993) Employment of fuzzy Logic for Controller Adaption in fluid Power Cylinder

Actuators. European Journal of Fluid Power, Noc.

Ming-Chang S., Tseng S. I. (1995) Identification and position Control of a Servo Penumatic

Cylinder. Control Eng. Practice, 3.

Ming-Chang S., Tsung-Wei L. (1998). On-line Learning Neural Fuzzy Control the Position

of a Pneumatic Cylinder. International Conference on Advanced Mechatronics.

Ming-Chang S., Huang Yu-Fenf. (1992). Pneumatic Servo-Cylinder Position Control Using

a Self-Tuning Controller. JSME International Journal, 35. . pp 247-254.

Ogata K. (1998). Ingeniería de Control Moderna. Prentice Hall.

Ogata K. (1996) .Sistemas de Control en Tiempo Discreto. Prentice Hall.

Scavarda S.. Lin X. (1993). Linearized Analysis of an Electropneumatic Servovalve/Long

Pneumatic Actuator Assembly Using Bond Graph. Proc IEEE INT Conf on Systems Man and

Cybenetics, 1.

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Control of a Pneumatic Servosystem Using Fuzzy Logic 201

Scavarda S., Sesmat S., Thommaset D. (1998). Controllo di Inseguimiento per un Sistema

Elettropneumatico di Posizionamento. Oleodinamica Pneumatica.

Sorli M., Gastaldi L., Codina E., De las Heras S. (1999). Dynamic Analysis of Pneumatic

Actuators. Journal SIMPRA.

Sorli M., Gastaldi L (1998). Modellazione d'Attuatori Pneumatici. Oleodinamica Pneu-

matica.

Virvalo T. (1989). Designing a Pneumatic Positionc Servo System. Power International.

Virvalo T., Mäkinen E. (1991). A Combined Pressure and Velocity Control of an Electro

Pneumatic Receiver. The 2nd. Tampere Int. Conference on Fluid Power.

Virvalo T. (1991). The Use of Linear Model in Design of Electropneumatic Servo System.

The 2nd Tampere Int. Conference on Fluid Power.

Zimmermann H. J. (1991). Fuzzy Set Theory and its Aplications second edition. Kluwer

Academic Publishers.

Proc. of 1st FPNI-PhD Symp. Hamburg 2000, pp. 189-201

Das könnte Ihnen auch gefallen

- Q2 Grade 7 Music DLL Week 1Dokument8 SeitenQ2 Grade 7 Music DLL Week 1Wilson de Gracia100% (2)

- Workshop Little Red Reading HoodDokument5 SeitenWorkshop Little Red Reading HoodLoraine OrtegaNoch keine Bewertungen

- Accurate Pneumatic Control with Fuzzy Gain SchedulingDokument4 SeitenAccurate Pneumatic Control with Fuzzy Gain SchedulingkahvumidragaispeciNoch keine Bewertungen

- Adaptive Fuzzy Controller: Application To The Control of The Temperature of A Dynamic Room in Real TimeDokument18 SeitenAdaptive Fuzzy Controller: Application To The Control of The Temperature of A Dynamic Room in Real TimeLittle ChickNoch keine Bewertungen

- Positioning System with Proportional Pressure RegulatorsDokument6 SeitenPositioning System with Proportional Pressure RegulatorsFawaz PartoNoch keine Bewertungen

- Internal Combustion EngineDokument6 SeitenInternal Combustion EngineMohammad UmairNoch keine Bewertungen

- WWW - Unlock PDF - Com 952928Dokument23 SeitenWWW - Unlock PDF - Com 952928Davidleonardo GalindoNoch keine Bewertungen

- Refference CheckDokument5 SeitenRefference CheckQuyết Nguyễn CôngNoch keine Bewertungen

- Position Feedback Dynamic Surface Control For Pneumatic Actuator Position Servo System PDFDokument11 SeitenPosition Feedback Dynamic Surface Control For Pneumatic Actuator Position Servo System PDFRAUL ALEXANDER ABANTO CUBASNoch keine Bewertungen

- Moving Horizon Model Based Control in The Presence of Feedback NoiseDokument3 SeitenMoving Horizon Model Based Control in The Presence of Feedback NoiseATSNoch keine Bewertungen

- Electrical Power and Energy Systems: A. Khodabakhshian, R. HooshmandDokument8 SeitenElectrical Power and Energy Systems: A. Khodabakhshian, R. HooshmandNabin AdhikariNoch keine Bewertungen

- Real Time Application of Ants Colony Optimization: Dr.S.M.Girirajkumar Dr.K.Ramkumar Sanjay Sarma O.VDokument13 SeitenReal Time Application of Ants Colony Optimization: Dr.S.M.Girirajkumar Dr.K.Ramkumar Sanjay Sarma O.VKarthik BalajiNoch keine Bewertungen

- Air Pressure Control Via Sliding Mode Approach Using An On/off Solenoid ValveDokument5 SeitenAir Pressure Control Via Sliding Mode Approach Using An On/off Solenoid ValveMuhammad RidwanNoch keine Bewertungen

- Stephan 1991Dokument13 SeitenStephan 1991mero zghloulNoch keine Bewertungen

- An Itae Optimal Sliding Mode Controller For Systems With Control Signal and Velocity LimitationsDokument9 SeitenAn Itae Optimal Sliding Mode Controller For Systems With Control Signal and Velocity LimitationsMIKS DARKNoch keine Bewertungen

- Fuzzy Control of Ac InductionDokument6 SeitenFuzzy Control of Ac Inductionapi-19667371100% (1)

- Research Article Expert Control of Mine Hoist Control SystemDokument8 SeitenResearch Article Expert Control of Mine Hoist Control SystemNehal ANoch keine Bewertungen

- Modeling of Heavy Duty Electrohydraulic ManipulatorDokument10 SeitenModeling of Heavy Duty Electrohydraulic Manipulatoraenas984363Noch keine Bewertungen

- Effect of adaptation gain in MRAC controlled systemsDokument6 SeitenEffect of adaptation gain in MRAC controlled systemskkaytugNoch keine Bewertungen

- An Aeroload SimulatorDokument71 SeitenAn Aeroload SimulatorNikunj AgarwalNoch keine Bewertungen

- Sensorless DTC of induction motor with sliding mode controllersDokument20 SeitenSensorless DTC of induction motor with sliding mode controllersMuhammad UmarNoch keine Bewertungen

- Construction and Analysis of PID, Fuzzy and Predictive Controllers in Flow SystemDokument7 SeitenConstruction and Analysis of PID, Fuzzy and Predictive Controllers in Flow SystemLuigi FreireNoch keine Bewertungen

- 2013 2014 Report1Dokument64 Seiten2013 2014 Report1Christian Gonzalez ArandaNoch keine Bewertungen

- A Generalized Predictive Force Controller For Electropneumatic CylindersDokument6 SeitenA Generalized Predictive Force Controller For Electropneumatic CylindersEngr Nayyer Nayyab MalikNoch keine Bewertungen

- High Performance Position Control of Permanent Magnet Synchronous DrivesDokument11 SeitenHigh Performance Position Control of Permanent Magnet Synchronous DrivesdjoodjooNoch keine Bewertungen

- p311 PDFDokument9 Seitenp311 PDFmohammad naseemNoch keine Bewertungen

- Trajectory Tracking For The Magnetic Ball Levitation System Via Exact Feedforward Linearisation and GPI ControlDokument12 SeitenTrajectory Tracking For The Magnetic Ball Levitation System Via Exact Feedforward Linearisation and GPI ControlChe ItoNoch keine Bewertungen

- A New Engineering Method For Fuzzy Reliability Analysis of Surge Detection and Isolation in Centrifugal CompressorDokument6 SeitenA New Engineering Method For Fuzzy Reliability Analysis of Surge Detection and Isolation in Centrifugal CompressorMohamed HamedNoch keine Bewertungen

- IMC Based Automatic Tuning Method For PID Controllers in A Smith Predictor ConfigurationDokument10 SeitenIMC Based Automatic Tuning Method For PID Controllers in A Smith Predictor ConfigurationAnonymous WkbmWCa8MNoch keine Bewertungen

- Pressure Control in Production LineDokument10 SeitenPressure Control in Production LineIJRASETPublicationsNoch keine Bewertungen

- Synergetic ControlDokument13 SeitenSynergetic Controlrostamkola1229Noch keine Bewertungen

- Electronics 09 01494 With CoverDokument45 SeitenElectronics 09 01494 With CoverMarcel NicolaNoch keine Bewertungen

- Mechanical Systems and Signal Processing: Syuan-Yi Chen, Sheng-Sian GongDokument18 SeitenMechanical Systems and Signal Processing: Syuan-Yi Chen, Sheng-Sian GongKurnia Pangeran EmpUztNoch keine Bewertungen

- Back-EMF Sensorless Control Algorithm For High Dynamics Performances PMSMDokument9 SeitenBack-EMF Sensorless Control Algorithm For High Dynamics Performances PMSMSaranji GuruNoch keine Bewertungen

- Design and Tuning of A Ratio ControllerDokument13 SeitenDesign and Tuning of A Ratio ControllerEzgi CoşkunNoch keine Bewertungen

- Autonomous Power SystemDokument14 SeitenAutonomous Power SystemgagagagNoch keine Bewertungen

- Control Theory - WikipediaDokument15 SeitenControl Theory - WikipediaDAVID MURILLONoch keine Bewertungen

- Model Refrence Adaptive Control Presentation by RishiDokument63 SeitenModel Refrence Adaptive Control Presentation by RishiRishi Kant Sharma100% (5)

- Automatic Tuning and Adaptation For Pid Controllers - A SurveyDokument16 SeitenAutomatic Tuning and Adaptation For Pid Controllers - A SurveyTwistiesFifie FafauNoch keine Bewertungen

- China PaperDokument7 SeitenChina PaperCarl EncarnacionNoch keine Bewertungen

- 1 s2.0 S1474667017354435 MainDokument6 Seiten1 s2.0 S1474667017354435 MainLokesh HRNoch keine Bewertungen

- Adaptive Speed Control For Permanent-Magnet Synchronous Motor System With Variations of Load InertiaDokument10 SeitenAdaptive Speed Control For Permanent-Magnet Synchronous Motor System With Variations of Load InertiaRawaz Hama Aziz H.KarimNoch keine Bewertungen

- Backstepping Control of Wind TunnelDokument10 SeitenBackstepping Control of Wind TunnellamuelNoch keine Bewertungen

- Control Steam Turbine Combined Cycle Power Plant Based On Soft ComputingDokument6 SeitenControl Steam Turbine Combined Cycle Power Plant Based On Soft Computingleanhhai1080Noch keine Bewertungen

- New StylesDokument4 SeitenNew StylesKarimPrinceAddoNoch keine Bewertungen

- Control Systems for Drones and AUVs in High WindsDokument28 SeitenControl Systems for Drones and AUVs in High Windshw606Noch keine Bewertungen

- Archive of SID: Dynamic Controllers Design For STATCOMDokument7 SeitenArchive of SID: Dynamic Controllers Design For STATCOMRajaavikhram YohanandhanNoch keine Bewertungen

- Watt's Speed Governor ForDokument18 SeitenWatt's Speed Governor ForMuhammad Tayyab YousafzaiNoch keine Bewertungen

- 07 Chapter 2Dokument23 Seiten07 Chapter 2Anonymous 2vaaNbDvNoch keine Bewertungen

- Slotine Li Tac 88Dokument9 SeitenSlotine Li Tac 88Linh Chi NguyenNoch keine Bewertungen

- HF 5 Energies-12-03645Dokument26 SeitenHF 5 Energies-12-03645Duy TínhNoch keine Bewertungen

- ControlDokument43 SeitenControlaramNoch keine Bewertungen

- Analytical Tuning Method For Cascade Control System Via Multi-Scale Control SchemeDokument26 SeitenAnalytical Tuning Method For Cascade Control System Via Multi-Scale Control SchemeFelipe BravoNoch keine Bewertungen

- Steam Turbine Governing Systems and Electronic Governor Retrofit by Josephs. Lamberson and Jack ReedDokument8 SeitenSteam Turbine Governing Systems and Electronic Governor Retrofit by Josephs. Lamberson and Jack ReedEr Mahendra KeshriNoch keine Bewertungen

- Robust Fuzzy Fault Detection and Isolation Approach Applied To Surge in Centrifugal Compressor Modeling and ControlDokument25 SeitenRobust Fuzzy Fault Detection and Isolation Approach Applied To Surge in Centrifugal Compressor Modeling and Controlmehdipoor33Noch keine Bewertungen

- Control System NotesDokument2 SeitenControl System NotesAkshata PachhapurkarNoch keine Bewertungen

- Robust Continuous Sliding Mode Control For Manipulator PMSM Trajectory Tracking System Under Time-Varying Uncertain DisturbancesDokument15 SeitenRobust Continuous Sliding Mode Control For Manipulator PMSM Trajectory Tracking System Under Time-Varying Uncertain DisturbancesJuan Camilo Alarcon JaramilloNoch keine Bewertungen

- New Results On The Synthesis of PID Controllers: Guillermo J. Silva, Aniruddha Datta, and S. P. BhattacharyyaDokument12 SeitenNew Results On The Synthesis of PID Controllers: Guillermo J. Silva, Aniruddha Datta, and S. P. Bhattacharyyadebasishmee5808Noch keine Bewertungen

- Approximately Time-Optimal Fuzzy Control of Two-Tank System: Thomas Heckenthaler and Sebastian EngellDokument7 SeitenApproximately Time-Optimal Fuzzy Control of Two-Tank System: Thomas Heckenthaler and Sebastian EngellVaghela ChintanNoch keine Bewertungen

- Nature-Inspired Optimization Algorithms for Fuzzy Controlled Servo SystemsVon EverandNature-Inspired Optimization Algorithms for Fuzzy Controlled Servo SystemsNoch keine Bewertungen

- Instrument Technology: Telemetering and Automatic ControlVon EverandInstrument Technology: Telemetering and Automatic ControlNoch keine Bewertungen

- Service Manual Acer Aspire 5520 5220 SeriesDokument114 SeitenService Manual Acer Aspire 5520 5220 SeriesAlVaPi100% (1)

- IRF644ADokument7 SeitenIRF644ASoare ValiNoch keine Bewertungen

- Digital Signal Processing in VLSIDokument612 SeitenDigital Signal Processing in VLSIFlor Kaliope Lomeli DablantesNoch keine Bewertungen

- Technics SA410 RecDokument7 SeitenTechnics SA410 RecSoare Vali100% (1)

- Wikipedia'Nin Turkce GrameriDokument25 SeitenWikipedia'Nin Turkce GrameriΚυπριανός ΚυπριανούNoch keine Bewertungen

- Importance of EnglishDokument3 SeitenImportance of Englishsksatishkumar7Noch keine Bewertungen

- Mathematical Communication Ability and Curiosity Attitude Through Problem Based Learning and Cognitive Conflict Strategy Based On Academic Level: A Study in Number TheoryDokument17 SeitenMathematical Communication Ability and Curiosity Attitude Through Problem Based Learning and Cognitive Conflict Strategy Based On Academic Level: A Study in Number TheoryGlobal Research and Development ServicesNoch keine Bewertungen

- Speech Production Models Blur Phonology and Phonetics BoundaryDokument12 SeitenSpeech Production Models Blur Phonology and Phonetics BoundaryEslam El HaddadNoch keine Bewertungen

- RESEARCH VARIABLES; Conceptualization; AND OperationalizationDokument19 SeitenRESEARCH VARIABLES; Conceptualization; AND OperationalizationNuwasasira BrianNoch keine Bewertungen

- Descriptive TextDokument14 SeitenDescriptive TextAl - KautsarNoch keine Bewertungen

- WowwDokument22 SeitenWowwMirela Cojocaru StetcoNoch keine Bewertungen

- English Language Teaching: Past and Present MethodsDokument31 SeitenEnglish Language Teaching: Past and Present MethodsKalfanyNoch keine Bewertungen

- Educ 293 Annotated RRL 2Dokument9 SeitenEduc 293 Annotated RRL 2Kenjie EneranNoch keine Bewertungen

- OpenStax Effective Reading and Notetaking GuideDokument9 SeitenOpenStax Effective Reading and Notetaking GuideseattlechazNoch keine Bewertungen

- Blog 1Dokument2 SeitenBlog 1api-330219476Noch keine Bewertungen

- All Past Tenses Active and Passive Mind Map Classroom Posters Grammar Drills Grammar Guides Wo - 57410Dokument1 SeiteAll Past Tenses Active and Passive Mind Map Classroom Posters Grammar Drills Grammar Guides Wo - 57410Tyas RenadaNoch keine Bewertungen

- Understanding M & EDokument42 SeitenUnderstanding M & ELeoncio LumabanNoch keine Bewertungen

- Emotional State and Affective Commitment Towards WorksDokument6 SeitenEmotional State and Affective Commitment Towards WorksDanica MadeloNoch keine Bewertungen

- English Writing Skills Class 11 ISCDokument8 SeitenEnglish Writing Skills Class 11 ISCAnushka SwargamNoch keine Bewertungen

- Ch02 PPTDokument14 SeitenCh02 PPTMdeeq AbdullahiNoch keine Bewertungen

- Cambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationDokument12 SeitenCambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationOmar shady100% (1)

- Entrep Behavior Chapter 8Dokument15 SeitenEntrep Behavior Chapter 8LauriLeighQuevadaZumárragaNoch keine Bewertungen

- Module 13 Ethics Truth and Reason Jonathan PascualDokument5 SeitenModule 13 Ethics Truth and Reason Jonathan PascualKent brian JalalonNoch keine Bewertungen

- Meena Ketheswaranathan Lesson PlanDokument3 SeitenMeena Ketheswaranathan Lesson Planapi-508167920Noch keine Bewertungen

- Lesson Plan in Science 6 4 Quarter: Kagawaran NG Edukasyon Sangay NG Lungsod NG DabawDokument2 SeitenLesson Plan in Science 6 4 Quarter: Kagawaran NG Edukasyon Sangay NG Lungsod NG DabawEmmanuel Nicolo TagleNoch keine Bewertungen

- Ai Robocom: Mick G.D. Remmerswaal March 18, 2020Dokument11 SeitenAi Robocom: Mick G.D. Remmerswaal March 18, 2020Mick RemmerswaalNoch keine Bewertungen

- Barbara Johnsons Critical Difference A RDokument4 SeitenBarbara Johnsons Critical Difference A Roliviu petrescuNoch keine Bewertungen

- Wood - Neal.2009. The Habitual Consumer PDFDokument14 SeitenWood - Neal.2009. The Habitual Consumer PDFmaja0205Noch keine Bewertungen

- Gumaca National High School's Daily Math Lesson on Quadratic EquationsDokument4 SeitenGumaca National High School's Daily Math Lesson on Quadratic EquationsArgel Panganiban DalwampoNoch keine Bewertungen

- STENIUS, Erik - Wittgenstein's Tractatus. A Critical Exposition of Its Main Lines of ThoughtsDokument250 SeitenSTENIUS, Erik - Wittgenstein's Tractatus. A Critical Exposition of Its Main Lines of ThoughtsJuan ErlleNoch keine Bewertungen

- Computer: 01 Hour and A HalfDokument3 SeitenComputer: 01 Hour and A HalfMohammedBaouaisseNoch keine Bewertungen

- Dr. Ramon de Santos National High School learning activity explores modal verbs and nounsDokument3 SeitenDr. Ramon de Santos National High School learning activity explores modal verbs and nounsMark Jhoriz VillafuerteNoch keine Bewertungen