Beruflich Dokumente

Kultur Dokumente

Assembly Instructions - Tube Couplings

Hochgeladen von

Er.Amritpal SinghOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Assembly Instructions - Tube Couplings

Hochgeladen von

Er.Amritpal SinghCopyright:

Verfügbare Formate

Assembly Instructions - Tube Couplings

1. Notes 2.4 Support sleeves 4. Direct assembly in the coupling 6. Checking

connecting piece

O IL

These assembly instructions describe the Connecting Tube Loosen the union nut and inspect the

piece Cutting ring Tubes with thin walls and soft tubes

two assembly methods provided for under require support sleeve (look at the table below). 4.1 Insert the tube end into the coupling material discharge. The material discharge

DIN 3859, Part 2: F OR

E connecting piece and push in must cover at least 80 % of the cutting edge

BE face.

Direct assembly in the coupling completely. During the assembly

Lightly coat the outer circumference of the

connecting piece. process, the tube must be held fully

support sleeve with lubricant (e.g. mineral-oil

Pre-assembly in the hardened inserted to prevent incorrect assembly. In this position it must still be possible to

based hydraulic oil). Then insert the sleeve E R

pre-assembly mandrel. A FT turn the cutting ring on the tube. Remove

into the tube up to the knurled section. 4.2 Screw on the union nut until there is any impurities.

All the following data were determined on tangible contact between the coupling

Use a hammer (plastic or hard rubber) to drive in

the basis of the following preconditions: connecting piece, cutting ring

the sleeve totally. In doing so, the knurled section is

Seamless steel tubes for precision and union nut.

pressed against the inner wall of the tube and pre Caution!

applications to EN 10305-1.

Corrosion protection Zink-Nickel. vents the sleeve from being displaced or falling out. 4.3 Tighten the union nut with an open-end If the collar is not raised sufficient, repeat

wrench. the assembly with greater force. Check the

For series assemblies we recommend the

Up to a tube OD 18 mm result again.

use pre-assembly equipment. The

information in the respective assembly Union nut 1 1/2 turns

instructions apply for the assembly From a tube OD 20 mm Stable material throw-up

procedures here. 1 1/4 turns

Notes:

In order for the cutting ring couplings When installing in the pipeline, hold the

to fulfil their function, observance of the coupling connecting piece with a

assembly instructions is of the greatest wrench.

Caution! importance. Incorrect handling can result in In order to ensure the prescribed number

Please observe the safety instructions for risks with respect to safety and leak tightness of turns, we recommend that marks are

installation and the recommendation on the that can under certain circumstances result made on the union nut and tube.

use of tube supports. in the complete failure of the coupling. The assembly procedure described

under 4.3 also applies to pre-assembly

in a vice.

2. Tube preparation

2.1 Minimum lengths of the straight pipe

ends must be taken into consideration 7. Final Assembly

when determining the tube lengths.

7.1 Carefully insert the tube end installed

With machine pre-assembly, the H Caution! in the coupling connecting piece

minimum lengths can be found in the Each coupling connecting piece may again into the coupling connecting

operating instructions of the respective only be used once for an initial assembly. piece in which it was installed. Then

pre-assembly equipment. If it is used several times, functional tighten the union nut strain-free by

Support sleeve required when the connection is opened often and when impairments are possible. hand.

the system is subject to intensive wear and tear (vibrations) After assembly, a visual inspection to

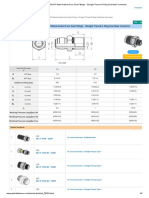

Series Tube-OD H L L check the correct assembly result is

Support sleeve deinitely required 7.1.1 Tighten the union nut with a wrench

L 06/08 31 39 Dmax Dmax absolutely crucial (see under point 6. (without extension) until a noticeable

L 10/12 33 42 Note: checking). increase in force is felt.

L 15 36 45 Tube deformations near the cutting ring approx.

L 18 38 48 (after driving support sleeve), can have 7.1.2 Then tighten by a further 1/4 turn. 1/4 turn

L 22/28 42 53

negative efects on the function of the

L 35/42 48 60 5. Pre-assembly in hardened

cutting ring connection. 7.2 Carefully insert the tube end installed

The deformation may not exceed Dmax pre-assembly mandrel (RAU) in the hardened pre-assembly

Series Tube-OD H L support or machine pre-assembled

S 06/08 35 44 (maximum diameter of pre-assembly The hardened pre-assembly mandrel are

mandrel (RAU) or coupling). Pre-assembly Coupling pipe end into a (new) coupling

S 10/12 37 47 mandrel (RAU) wear-resistant and permit uniform assembly connecting piece that has not yet been

S 14/16 43 54 results as they have closer tolerances. They used for assembly and tighten the

S 20 50 63 should, however, be inspected for correct union nut strain-free by hand.

S 25 54 68 dimensions after approx. 50 pre-assemblies.

S 30 58 72

3. Assembly preparation

7.2.1 Tighten the union nut with a wrench

S 38 65 82 5.1 Replace pre-assembly mandrel that are (without extension) until a noticeable

3.1 To simplify assembly, we recommend

that the thread and the taper of the no longer within the tolerances or are increase in force is felt.

L

damaged in the taper area to prevent

OI

2.2 Saw off the tube at right angles. An coupling connecting piece of the manual

angle tolerance of ± 1° is admissible. pre-assembly support are coated with incorrect assembly. 7.2.2 Then tighten by a further 1/4 turn.

Do not use tube cutters or angle lubricant. approx.

grinders. 5.2 Screw on the union nut until there is

tangible contact between the pre- 1/4 turn

3.2 Push the union nut and the

2.3 Deburr the tube ends lightly on the inside cutting ring onto the tube end. The assembly mandrel, cutting ring

and outside. Clean the tube. cutting edges of the cutting ring and union nut.

face towards the tube end.

5.3 Tighten the union nut with an open-end

wrench.

Up to a tube OD 18 mm

1 1/2 turns

CORRECT INCORRECT From a tube OD 20 mm

1 1/4 turns

ma

x. ±

1°

8. Repeat Assembly

Caution!

Tubes sawn off crooked or incorrectly –0.2

Repeat assemblies can be carried out on

deburred tubes reduce the service life Caution! the tube coupling. Tighten the union nut

and leak tightness of the connection. Caution! After each pre-assembly, a visual inspection with the same force as for the original

Use reinforcement sleeves with thin- Ensure that the progressive cutting ring is to check the correct assembly result is installation.

walled steel tubes or soft tubes of NF positioned correctly, otherwise assembly will absolutely crucial (see under point

metals (see ARMATURE Catalogue). not be correct. 6. checking).

PPT-ARMATURE AD · Kruševačka 30 · 37230 Aleksandrovac · Serbia · Phone +381(37) 3552 350 · Fax +381(37) 3552 105 · office@armature.rs · www.armature.rs

Das könnte Ihnen auch gefallen

- Warning:: P/N 1094579A Versablue Melter Coupling ReplacementDokument2 SeitenWarning:: P/N 1094579A Versablue Melter Coupling ReplacementJhonson Shut DownNoch keine Bewertungen

- RG6 Cable Mounting InstructionsDokument2 SeitenRG6 Cable Mounting InstructionsStaffan FogelbergNoch keine Bewertungen

- LT36073 0Dokument6 SeitenLT36073 0Cristian Navarro AriasNoch keine Bewertungen

- 2007 HD TouringDokument68 Seiten2007 HD TouringRod SturgeonNoch keine Bewertungen

- Instruction Sheet: WE 37 & WE46 Flexwell Waveguide Flaring and Connector AssemblyDokument2 SeitenInstruction Sheet: WE 37 & WE46 Flexwell Waveguide Flaring and Connector AssemblysamiNoch keine Bewertungen

- Crimp Instructions For Amphenol BNC Plugs: Step 1 Step 2 Step 3Dokument1 SeiteCrimp Instructions For Amphenol BNC Plugs: Step 1 Step 2 Step 3KAZIMALI25Noch keine Bewertungen

- TNC ConectorDokument2 SeitenTNC ConectorLong ComtechNoch keine Bewertungen

- Instruction Sheet: Flexwell Waveguide Flaring and Connector AssemblyDokument2 SeitenInstruction Sheet: Flexwell Waveguide Flaring and Connector AssemblysamiNoch keine Bewertungen

- Caution: Maintenance InformationDokument6 SeitenCaution: Maintenance InformationCarlos PerezNoch keine Bewertungen

- At-Sealing Replacement (GB)Dokument4 SeitenAt-Sealing Replacement (GB)George LapusneanuNoch keine Bewertungen

- SES eDokument1 SeiteSES erizky randaNoch keine Bewertungen

- Mercruiser Mechanical Trim Actuator Installation - 846063A1Dokument7 SeitenMercruiser Mechanical Trim Actuator Installation - 846063A1JeffNoch keine Bewertungen

- Grinnell Mechanical Products Figure 61 Flange Adapter For Joining Copper Tubing (CTS) Installation / Assembly InstructionsDokument2 SeitenGrinnell Mechanical Products Figure 61 Flange Adapter For Joining Copper Tubing (CTS) Installation / Assembly InstructionsMina MagdyNoch keine Bewertungen

- Two Brothers Exhaust System InstallDokument2 SeitenTwo Brothers Exhaust System InstallShinobiNoch keine Bewertungen

- IM&OM - PC-AR - enDokument12 SeitenIM&OM - PC-AR - enzodenapeNoch keine Bewertungen

- I & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDokument11 SeitenI & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDanel GonzalezNoch keine Bewertungen

- Vciom 06062 enDokument4 SeitenVciom 06062 enJoeNoch keine Bewertungen

- (Student) T3 FastenerDokument23 Seiten(Student) T3 FastenerZAMEER AKRAM ABDUL WAHABNoch keine Bewertungen

- Crimping Die Assemblies 58166 - For Shielded Data Link (SDL) ConnectorsDokument5 SeitenCrimping Die Assemblies 58166 - For Shielded Data Link (SDL) ConnectorszavabossNoch keine Bewertungen

- Rosso 1 Eng 2019Dokument40 SeitenRosso 1 Eng 2019vladatanNoch keine Bewertungen

- 5600 Shifter ServiceDokument1 Seite5600 Shifter ServiceMichaelRMilaniNoch keine Bewertungen

- Multipole Low Voltage: Cable Assembly InstructionsDokument3 SeitenMultipole Low Voltage: Cable Assembly Instructionsbo cephusNoch keine Bewertungen

- 8 Er H L HU UH UH L L UH H H H U: 1/ Single-Strand Unit (1F13/1F15)Dokument3 Seiten8 Er H L HU UH UH L L UH H H H U: 1/ Single-Strand Unit (1F13/1F15)Huy Nguyen VanNoch keine Bewertungen

- Samiflex en Product CatalogDokument16 SeitenSamiflex en Product CatalogFitsum TadesseNoch keine Bewertungen

- On-Center Compliant Contacts Reference Guide REV ADokument5 SeitenOn-Center Compliant Contacts Reference Guide REV AAlainckv MaligadNoch keine Bewertungen

- Broschyr 7 Eng PDFDokument16 SeitenBroschyr 7 Eng PDFNebojša JovanovićNoch keine Bewertungen

- Fischer Connectors Cable Assembly Instructions Core Series Multipole Low Voltage 107Dokument4 SeitenFischer Connectors Cable Assembly Instructions Core Series Multipole Low Voltage 107jeannotlusiku1Noch keine Bewertungen

- Stainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Dokument5 SeitenStainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Utada HikaruNoch keine Bewertungen

- Installation Instruction No. 132101F/02.2008 Seik 14, 24, 34Dokument5 SeitenInstallation Instruction No. 132101F/02.2008 Seik 14, 24, 34Sonia Noval LlorianNoch keine Bewertungen

- Assembly Instruction Vossringm GBDokument1 SeiteAssembly Instruction Vossringm GBshunmugaNoch keine Bewertungen

- 9K688NDokument7 Seiten9K688NHelar Armejo VasquezNoch keine Bewertungen

- Installation Instructions: Product DescriptionDokument4 SeitenInstallation Instructions: Product DescriptionHữu Khánh NguyễnNoch keine Bewertungen

- B 8086 Dfe 0Dokument2 SeitenB 8086 Dfe 0Ginés Ballesteros SorianoNoch keine Bewertungen

- Size Chart O'RingsDokument57 SeitenSize Chart O'Ringscygnus marine panamaNoch keine Bewertungen

- Instruction Guide Combiflex Crimping ToolDokument2 SeitenInstruction Guide Combiflex Crimping ToolAE,110 KV KanjikodeNoch keine Bewertungen

- Instruction Sheet Is Js1615: - Style Number Js1615Bn:: Package ContentsDokument3 SeitenInstruction Sheet Is Js1615: - Style Number Js1615Bn:: Package Contentsdayshift5Noch keine Bewertungen

- Cellpack Contrax Joints PDFDokument4 SeitenCellpack Contrax Joints PDFAmit BhatiaNoch keine Bewertungen

- Epp 0407-10-01Dokument6 SeitenEpp 0407-10-01galicruNoch keine Bewertungen

- Csti - HDLDDokument6 SeitenCsti - HDLDQuang Kien NguyenNoch keine Bewertungen

- Contactor 3TS47, 3TS48: Operating InstructionsDokument7 SeitenContactor 3TS47, 3TS48: Operating Instructionsemilce RiveraNoch keine Bewertungen

- A4 LDDokument1 SeiteA4 LDOmar Molina100% (1)

- Butterfly Valve For Mixing StationDokument3 SeitenButterfly Valve For Mixing StationMech MallNoch keine Bewertungen

- Mahula de PeçasDokument411 SeitenMahula de PeçasRUBSONMOTANoch keine Bewertungen

- Havana Semi Flush Fitting InstructionsDokument2 SeitenHavana Semi Flush Fitting InstructionsMuratNoch keine Bewertungen

- Para-Flex Couplings: Includes ATEX Certified Couplings Instruction ManualDokument4 SeitenPara-Flex Couplings: Includes ATEX Certified Couplings Instruction Manualrrobles011Noch keine Bewertungen

- 2-3/4" Perforating Shock Absorber Assembly ProceduresDokument10 Seiten2-3/4" Perforating Shock Absorber Assembly ProceduresCuenta InformacionNoch keine Bewertungen

- Assembly Instruction - REAN Stage BoxDokument2 SeitenAssembly Instruction - REAN Stage BoxGladys TseNoch keine Bewertungen

- Freno Warner 1Dokument4 SeitenFreno Warner 1javier castilloNoch keine Bewertungen

- Flexible Hose Ins.+Test.Dokument3 SeitenFlexible Hose Ins.+Test.Filip NikolevskiNoch keine Bewertungen

- Tomahawk: D-RegionDokument8 SeitenTomahawk: D-RegionSSS999Noch keine Bewertungen

- Series: Insert FittingsDokument7 SeitenSeries: Insert FittingsDiogo CarameloNoch keine Bewertungen

- clmt0365 0211Dokument2 Seitenclmt0365 0211manuel paredesNoch keine Bewertungen

- ETP Shaft BushingDokument2 SeitenETP Shaft Bushingeng_moh04Noch keine Bewertungen

- Operating Instructions: Nose & Ear Hair TrimmerDokument2 SeitenOperating Instructions: Nose & Ear Hair TrimmerMohamed HassanNoch keine Bewertungen

- INSTRUCTIONS-Fixed VersionDokument4 SeitenINSTRUCTIONS-Fixed VersionKrakaNoch keine Bewertungen

- Instruction Sheet Is-Da9010 Style Number: Da9010Ib: Package ContentsDokument3 SeitenInstruction Sheet Is-Da9010 Style Number: Da9010Ib: Package Contentsdayshift5Noch keine Bewertungen

- Tyco Electronic RJ45 ConnectorDokument17 SeitenTyco Electronic RJ45 Connectorafiq danialNoch keine Bewertungen

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationVon EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationBewertung: 4 von 5 Sternen4/5 (1)

- YJT 01240803VCR Metal Gasket Face Seal Fittings - Straight Thread O-Ring Seal Male ConnectorDokument3 SeitenYJT 01240803VCR Metal Gasket Face Seal Fittings - Straight Thread O-Ring Seal Male ConnectorEr.Amritpal SinghNoch keine Bewertungen

- YJT 01241103VCR Metal Gasket Face Seal Fittings - Reducing Adapter PDFDokument3 SeitenYJT 01241103VCR Metal Gasket Face Seal Fittings - Reducing Adapter PDFEr.Amritpal SinghNoch keine Bewertungen

- YJT 01241002VCR Metal Gasket Face Seal Fittings - Male Reducing UnionDokument3 SeitenYJT 01241002VCR Metal Gasket Face Seal Fittings - Male Reducing UnionEr.Amritpal SinghNoch keine Bewertungen

- YJT 01241001VCR Metal Gasket Face Seal Fittings - Male UnionDokument3 SeitenYJT 01241001VCR Metal Gasket Face Seal Fittings - Male UnionEr.Amritpal SinghNoch keine Bewertungen

- Technical Handbook Parker PDFDokument64 SeitenTechnical Handbook Parker PDFNemoz Zr100% (1)

- YJT 01240802VCR Metal Gasket Face Seal Fittings - Male NPT Bulkhead ConnectorDokument3 SeitenYJT 01240802VCR Metal Gasket Face Seal Fittings - Male NPT Bulkhead ConnectorEr.Amritpal SinghNoch keine Bewertungen

- 1CF43 Female Metric L - Swivel 90° Elbow (24° Cone With O-Ring) ISO 12151-2 - SWEDokument1 Seite1CF43 Female Metric L - Swivel 90° Elbow (24° Cone With O-Ring) ISO 12151-2 - SWEEr.Amritpal SinghNoch keine Bewertungen

- DIN-2353 Metrics - Hose and Fittings SourceDokument18 SeitenDIN-2353 Metrics - Hose and Fittings SourceEr.Amritpal SinghNoch keine Bewertungen

- Mask EngDokument1 SeiteMask EngDheeraj GoyalNoch keine Bewertungen

- Jic Hydraulic Fittings Size ChartDokument5 SeitenJic Hydraulic Fittings Size ChartEr.Amritpal SinghNoch keine Bewertungen

- GB - T 3733 (B) - 200824° Cone Connectors - Straight Thread, Type BDokument3 SeitenGB - T 3733 (B) - 200824° Cone Connectors - Straight Thread, Type BEr.Amritpal SinghNoch keine Bewertungen

- Global Presence. Local Expertise.: Product CatalogueDokument402 SeitenGlobal Presence. Local Expertise.: Product CatalogueEr.Amritpal SinghNoch keine Bewertungen

- GB - T 3746 - 200824° Cone Connectors - Union CrossDokument3 SeitenGB - T 3746 - 200824° Cone Connectors - Union CrossEr.Amritpal SinghNoch keine Bewertungen

- DIN 2353 - 2013non-Soldering Compression Fittings With Cylindrical Screw-In Pins Form A or B According To DIN 3852-1, DIN 3852-2Dokument3 SeitenDIN 2353 - 2013non-Soldering Compression Fittings With Cylindrical Screw-In Pins Form A or B According To DIN 3852-1, DIN 3852-2Er.Amritpal SinghNoch keine Bewertungen

- Four Easy Steps To Identify Hydraulic Threads - Parker HannifinDokument6 SeitenFour Easy Steps To Identify Hydraulic Threads - Parker HannifinEr.Amritpal SinghNoch keine Bewertungen

- DIN 2353 - 2013non-Soldering Compression Fittings With Cutting Ring For Screwed Connections With Tapered Screw-In Spigot Form C According To DIN 3852-1 and DIN 3852-2Dokument3 SeitenDIN 2353 - 2013non-Soldering Compression Fittings With Cutting Ring For Screwed Connections With Tapered Screw-In Spigot Form C According To DIN 3852-1 and DIN 3852-2Er.Amritpal SinghNoch keine Bewertungen

- Poster Corona Ad Eng PDFDokument1 SeitePoster Corona Ad Eng PDFSubhasis SarkarNoch keine Bewertungen

- 2d Checklist PDFDokument1 Seite2d Checklist PDFEr.Amritpal SinghNoch keine Bewertungen

- Self 3D Checklist For Designer/EngineerDokument1 SeiteSelf 3D Checklist For Designer/EngineerEr.Amritpal SinghNoch keine Bewertungen

- Self 3D Checklist For Designer/EngineerDokument1 SeiteSelf 3D Checklist For Designer/EngineerEr.Amritpal SinghNoch keine Bewertungen

- 2d Checklist PDFDokument1 Seite2d Checklist PDFEr.Amritpal SinghNoch keine Bewertungen

- Do - 026 - s2023 (Item 624 Roadway Lighting)Dokument13 SeitenDo - 026 - s2023 (Item 624 Roadway Lighting)QWERTY YUYUPNoch keine Bewertungen

- Panasonic TC-P42X5 Service ManualDokument74 SeitenPanasonic TC-P42X5 Service ManualManager iDClaimNoch keine Bewertungen

- ITmk3 TechnologyDokument8 SeitenITmk3 Technologyferozcan100% (1)

- Knan, Knaf, Onan, OnafDokument2 SeitenKnan, Knaf, Onan, Onafponnarasu8250% (2)

- Monthly ReportDokument15 SeitenMonthly ReportMae Ann GonzalesNoch keine Bewertungen

- Sub Sec 1 To 9Dokument7 SeitenSub Sec 1 To 9khan4luvNoch keine Bewertungen

- Dr. Fixit RaincoatDokument2 SeitenDr. Fixit RaincoatnivasshaanNoch keine Bewertungen

- Cat Casseforme UKDokument12 SeitenCat Casseforme UKMilan UljarevicNoch keine Bewertungen

- Printing On Proteinic FabricsDokument10 SeitenPrinting On Proteinic FabricsDÃljït Sīñgh100% (1)

- Clay Treatment of Fuel White PaperDokument3 SeitenClay Treatment of Fuel White PaperGiuliano Castellani CiodaroNoch keine Bewertungen

- Arinc 600 Series: Rack & Panel Rectangular ConnectorsDokument48 SeitenArinc 600 Series: Rack & Panel Rectangular Connectorstousif111Noch keine Bewertungen

- Alulight Datasheets En2006Dokument8 SeitenAlulight Datasheets En2006DaniNoch keine Bewertungen

- Crown Cork & SealDokument8 SeitenCrown Cork & Sealtconn8276100% (1)

- Energies 13 00610 v2 PDFDokument25 SeitenEnergies 13 00610 v2 PDFIsmail ŞahbazNoch keine Bewertungen

- 1.ehs Hydro Unit Eu Ib Db68-07003a-03 en 20181219Dokument62 Seiten1.ehs Hydro Unit Eu Ib Db68-07003a-03 en 20181219ion tNoch keine Bewertungen

- "Strength and Analysis of Basalt Fibre in Concrete": Project Seminar OnDokument29 Seiten"Strength and Analysis of Basalt Fibre in Concrete": Project Seminar OnArsam Haq100% (1)

- Tripura University (A Central University) : Material Science & Engineering M. Tech 2 Semester Session-2020-2021Dokument16 SeitenTripura University (A Central University) : Material Science & Engineering M. Tech 2 Semester Session-2020-2021Abhijit RoyNoch keine Bewertungen

- JDokument36 SeitenJmaizansofiaNoch keine Bewertungen

- FlorosparticDokument3 SeitenFlorosparticCarlos Rojas HandalNoch keine Bewertungen

- RT3 Straight BladeDokument34 SeitenRT3 Straight Bladecamohunter71Noch keine Bewertungen

- Bosch Catalog - Edition 2014Dokument456 SeitenBosch Catalog - Edition 2014longtrandang5867Noch keine Bewertungen

- Caleb Catalogue DiscspringDokument5 SeitenCaleb Catalogue DiscspringsantoshNoch keine Bewertungen

- Operation & Maintenance of Plug Valves PDFDokument5 SeitenOperation & Maintenance of Plug Valves PDFعزت عبد المنعمNoch keine Bewertungen

- PV 1303Dokument10 SeitenPV 1303tufantasma100% (2)

- Elective Course (2) - Composite Materials MET 443Dokument16 SeitenElective Course (2) - Composite Materials MET 443يوسف عادل حسانينNoch keine Bewertungen

- Material Reconciliation - PDF REVISEDDokument32 SeitenMaterial Reconciliation - PDF REVISEDSrinivasan RanganathanNoch keine Bewertungen

- Clg855h (Gcic t2) Service Manual 202007002-EnDokument642 SeitenClg855h (Gcic t2) Service Manual 202007002-EnRicky Safira zahiraNoch keine Bewertungen

- Oxidation ChemGuideDokument17 SeitenOxidation ChemGuideShopneel MHNoch keine Bewertungen

- What Really Happens To The Plastic You Throw Away?: Emma Bryce - TED-EdDokument1 SeiteWhat Really Happens To The Plastic You Throw Away?: Emma Bryce - TED-EdJennefer Gudao AranillaNoch keine Bewertungen

- Finish Machine Presentation - July12-1Dokument28 SeitenFinish Machine Presentation - July12-1MehtaMilanNoch keine Bewertungen