Beruflich Dokumente

Kultur Dokumente

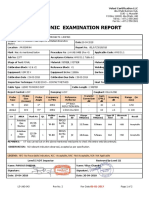

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Hochgeladen von

MD Shadikul Huq ShezanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Hochgeladen von

MD Shadikul Huq ShezanCopyright:

Verfügbare Formate

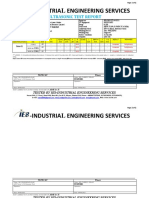

Page 1 of 4

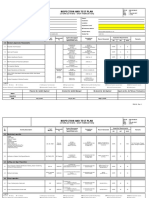

Inspection Date :26 July 2020 Report no : IES-ARBAB-UT-03

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

ULTRASONIC TEST REPORT

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-05 06 - - - - 66.1 - - - - - Accepted Satisfactory,

After Recheck

Rafter Joint no -06 06 - - - - 66.1 - - - - - Accepted Satisfactory,

After Recheck

Joint no-07 06 - - - - 66.1 - - - - - Accepted Satisfactory,

After Recheck

Joint no-08 06 - - - - 66.1 - - - - - Accepted Satisfactory,

After Recheck

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L = Length, a = Indication level, d = Indication

rating,

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shaharia alam Name: Engr.Salman

IES: ASNT Level –II (UT,MT,DPT,VT) Arbab -Engineer

Signature: Signature:

Date: 26/07/2020 Date: 26/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

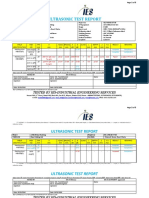

Page 2 of 4

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-13 06 - - - - 66.1 - - - - - Accepted Satisfactory,

Rafter After Recheck

Joint no -15 06 - - - - 66.1 - - - - - Accepted Satisfactory,

After Recheck

Joint no-16 06 - - - - 66.1 - - - - - Accepted Satisfactory,

After Recheck

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L = Length, a = Indication level, d = Indication

rating,

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shaharia alam Name: Engr.Salman

IES: ASNT Level –II (UT,MT,DPT,VT) Arbab -Engineer

Signature: Signature:

Date: 26/07/2020 Date: 26/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

Page 3 of 4

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-35 06 - - - - 66.1 - - - - - Accepted Satisfactory,

Rafter After Recheck

Joint No-36 06 - - - - 66.1 - - - - - Accepted Satisfactory,

After Recheck

Joint no -39 06 - - - - 66.1 - - - - - Accepted Satisfactory,

After Recheck

Joint no-40 06 - - - - 66.1 - - - - - Accepted Satisfactory,

After Recheck

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L = Length, a = Indication level, d = Indication

rating,

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shaharia alam Name: Engr.Salman

IES: ASNT Level –II (UT,MT,DPT,VT) Arbab -Engineer

Signature: Signature:

Date: 26/07/2020 Date: 26/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

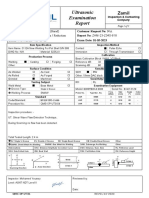

Page 4 of 4

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shaharia alam Name: Engr.Salman

IES: ASNT Level –II (UT,MT,DPT,VT) Arbab -Engineer

Signature: Signature:

Date: 26/07/2020 Date: 26/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

Das könnte Ihnen auch gefallen

- JIS-B0252-1996-Limit Gauges For Metric Fine Screw ThreadsDokument154 SeitenJIS-B0252-1996-Limit Gauges For Metric Fine Screw Threadsfatimah100% (4)

- Linear IC Applications: A Designer's HandbookVon EverandLinear IC Applications: A Designer's HandbookBewertung: 4 von 5 Sternen4/5 (1)

- P-WPS 135 - Mag (S355JR)Dokument9 SeitenP-WPS 135 - Mag (S355JR)Tarun PatelNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument4 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument3 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Arbab Polypack UT Inspection ReportDokument4 SeitenArbab Polypack UT Inspection ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNoch keine Bewertungen

- Industrial Engineering Services: Ultrasonic Test ReportDokument2 SeitenIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNoch keine Bewertungen

- Ultrasonic Test ReportDokument3 SeitenUltrasonic Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic inspection reportDokument1 SeiteUltrasonic inspection reportMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Inspection ReportDokument1 SeiteUltrasonic Inspection ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument3 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Offshore Wind Farm Jacket Inspection ReleaseDokument2 SeitenOffshore Wind Farm Jacket Inspection ReleasejeswinNoch keine Bewertungen

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDokument2 SeitenInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNoch keine Bewertungen

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDokument2 SeitenInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNoch keine Bewertungen

- Gpti Qicl 032Dokument2 SeitenGpti Qicl 032uselessinstaid52Noch keine Bewertungen

- 1-UT-Pot Shell 588Dokument2 Seiten1-UT-Pot Shell 588Azhar GulzarNoch keine Bewertungen

- Content 20240115185834Dokument2 SeitenContent 20240115185834BLY YEDEKPA NOEL BENITONoch keine Bewertungen

- CPP HT Pipeline ReportDokument301 SeitenCPP HT Pipeline ReportAbdulkaderNoch keine Bewertungen

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDokument2 SeitenInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNoch keine Bewertungen

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDokument2 SeitenInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNoch keine Bewertungen

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDokument2 SeitenInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNoch keine Bewertungen

- Liquid Penetrant Test: Visual Inspection Results: Additional DetailsDokument4 SeitenLiquid Penetrant Test: Visual Inspection Results: Additional DetailsWisüttisäk PeäröönNoch keine Bewertungen

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDokument2 SeitenInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNoch keine Bewertungen

- C-0659 R08-CR-RCD - Rev.B - Dimensional Inspection Record Form For Compressor RotorDokument4 SeitenC-0659 R08-CR-RCD - Rev.B - Dimensional Inspection Record Form For Compressor RotorHimanyu RafiqNoch keine Bewertungen

- South Yoloten Gas Field Development Turkmenistan: Daily Welding ReportDokument2 SeitenSouth Yoloten Gas Field Development Turkmenistan: Daily Welding ReportOctavian PanteaNoch keine Bewertungen

- Inspection Release for Jacket Leg CoatingDokument2 SeitenInspection Release for Jacket Leg CoatingjeswinNoch keine Bewertungen

- BC MT 1688-0000Dokument84 SeitenBC MT 1688-0000Tuấn ĐậuNoch keine Bewertungen

- Liquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Dokument4 SeitenLiquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Riesky FirdyanNoch keine Bewertungen

- Gpti Qicl J931 Mut 041Dokument3 SeitenGpti Qicl J931 Mut 041uselessinstaid52Noch keine Bewertungen

- Customer Specific Formatting and Validation ReportDokument1 SeiteCustomer Specific Formatting and Validation ReportHarjeet SinghNoch keine Bewertungen

- Pt. Gintam Tehnik: InspeksiDokument4 SeitenPt. Gintam Tehnik: Inspeksirizky youlandaNoch keine Bewertungen

- Ut Report - 018 - Fab Tech Abudhabi LLC 19.04.2018Dokument2 SeitenUt Report - 018 - Fab Tech Abudhabi LLC 19.04.2018ADOBEENoch keine Bewertungen

- MAGNETIC PARTICLE INSPECTION REPORT FINDINGSDokument163 SeitenMAGNETIC PARTICLE INSPECTION REPORT FINDINGSNico Achmad ZulviansyahNoch keine Bewertungen

- Int'L NDT Services: Magnetic Particle Examination ReportDokument3 SeitenInt'L NDT Services: Magnetic Particle Examination Reportsarsan nedumkuzhiNoch keine Bewertungen

- Ilovepdf MergedDokument8 SeitenIlovepdf MergedSagar SharmaNoch keine Bewertungen

- PIPELINEMAN NO.2876Dokument3 SeitenPIPELINEMAN NO.2876Hussein HishamNoch keine Bewertungen

- Coupler Plate DP TestDokument1 SeiteCoupler Plate DP Testshindemitesh17Noch keine Bewertungen

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDokument2 SeitenInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNoch keine Bewertungen

- SEIP For 089-H-002Dokument7 SeitenSEIP For 089-H-002Thinh NguyenNoch keine Bewertungen

- Water Tank ItpDokument5 SeitenWater Tank ItpHgagselim SelimNoch keine Bewertungen

- Sac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API TanksDokument14 SeitenSac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API Tankshusnain aliNoch keine Bewertungen

- After Cooler InspectionAE3Dokument1 SeiteAfter Cooler InspectionAE3boy qsiNoch keine Bewertungen

- ACS GW 24 001 AR029 Gose Neck ThreadDokument1 SeiteACS GW 24 001 AR029 Gose Neck Threadarehmanmirza1990Noch keine Bewertungen

- Shazadabagh - Control Cable ScheduleDokument83 SeitenShazadabagh - Control Cable ScheduleAnkur SangwanNoch keine Bewertungen

- WELDING MACHINE ChecklistDokument1 SeiteWELDING MACHINE Checklistsakthi venkatNoch keine Bewertungen

- Scip2 TGXDokument6 SeitenScip2 TGXKarthikeyan Ganesan100% (1)

- Report UT CS From 21Dokument112 SeitenReport UT CS From 21daemsalNoch keine Bewertungen

- Checklist For Rock Bolts PDFDokument4 SeitenChecklist For Rock Bolts PDFImran FarooqNoch keine Bewertungen

- Digital Micro-Ohm MeterDokument2 SeitenDigital Micro-Ohm MeterjamilNoch keine Bewertungen

- HAJ-AR-UDR-001 Rev.0 - 1.08.2023Dokument4 SeitenHAJ-AR-UDR-001 Rev.0 - 1.08.2023divakar.panigrahiNoch keine Bewertungen

- Gpti Qicl J931 Mut 002Dokument2 SeitenGpti Qicl J931 Mut 002uselessinstaid52Noch keine Bewertungen

- Report 1 Paut Sts 409Dokument12 SeitenReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- Water Tank ItpDokument5 SeitenWater Tank Itptuan mai vanNoch keine Bewertungen

- Client:: Olectra Greentech LTDDokument1 SeiteClient:: Olectra Greentech LTDnareshNoch keine Bewertungen

- Gpti Qicl J931 Mut 004Dokument3 SeitenGpti Qicl J931 Mut 004uselessinstaid52Noch keine Bewertungen

- Ultrasonic Testing Report Summary for Rooppur Nuclear Power Plant Butt JointsDokument3 SeitenUltrasonic Testing Report Summary for Rooppur Nuclear Power Plant Butt JointsMD Shadikul Huq ShezanNoch keine Bewertungen

- MD - Akibur Sheikh PT Test ReportDokument2 SeitenMD - Akibur Sheikh PT Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

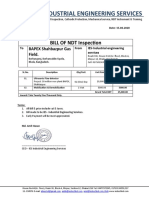

- BILL OF NDT Inspection: To From IES-Industrial Engineering ServicesDokument2 SeitenBILL OF NDT Inspection: To From IES-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- MD - Akibur Sheikh WQTDokument2 SeitenMD - Akibur Sheikh WQTMD Shadikul Huq ShezanNoch keine Bewertungen

- IES-Hydraulic Test ReportDokument4 SeitenIES-Hydraulic Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- IES-Industrial Engineering Services for NDT, Cathodic Protection, and Mechanical ServicesDokument1 SeiteIES-Industrial Engineering Services for NDT, Cathodic Protection, and Mechanical ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Sujan Das PT Test ReportDokument2 SeitenSujan Das PT Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Sujan Das WQTDokument2 SeitenSujan Das WQTMD Shadikul Huq ShezanNoch keine Bewertungen

- UT REport For Nornal Probe Shah CementDokument1 SeiteUT REport For Nornal Probe Shah CementMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- IES-Hydraulic Test ReportDokument4 SeitenIES-Hydraulic Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Heder Boiler Room Hydrolic TestDokument5 SeitenHeder Boiler Room Hydrolic TestMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic inspection reportDokument1 SeiteUltrasonic inspection reportMD Shadikul Huq ShezanNoch keine Bewertungen

- Ies-Industrial Engineering Services: Ultrasonoic Thickness Gauge ReportDokument1 SeiteIes-Industrial Engineering Services: Ultrasonoic Thickness Gauge ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Boiler UTG Seperation Wall Burner SideDokument2 SeitenBoiler UTG Seperation Wall Burner SideMD Shadikul Huq ShezanNoch keine Bewertungen

- Ies-Industrial Engineering Services: Hydraulic Test ReportDokument7 SeitenIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test ReportDokument3 SeitenUltrasonic Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Inspection ReportDokument1 SeiteUltrasonic Inspection ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Help For Report ShezanDokument5 SeitenHelp For Report ShezanMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Inspection ReportDokument1 SeiteUltrasonic Inspection ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Date Description Serial No Quantity Weight/ PecessDokument12 SeitenDate Description Serial No Quantity Weight/ PecessMD Shadikul Huq ShezanNoch keine Bewertungen

- Tested by Ies-Industrial Engineering Services: Data and Test SpecimenDokument7 SeitenTested by Ies-Industrial Engineering Services: Data and Test SpecimenMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Inspection ReportDokument1 SeiteUltrasonic Inspection ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Inspection ReportDokument1 SeiteUltrasonic Inspection ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- MailDokument1 SeiteMailMD Shadikul Huq ShezanNoch keine Bewertungen

- Ies-Industrial Engineering Services: BILL OF NDT InspectionDokument1 SeiteIes-Industrial Engineering Services: BILL OF NDT InspectionMD Shadikul Huq ShezanNoch keine Bewertungen

- Satr-W-2020Dokument1 SeiteSatr-W-2020Joni Carino SuniNoch keine Bewertungen

- Metals and How To Weld ThemDokument1 SeiteMetals and How To Weld ThemJack JohnsonNoch keine Bewertungen

- Cold-Formed Member Joint DesignDokument15 SeitenCold-Formed Member Joint DesignmabuhamdNoch keine Bewertungen

- Malz Grup KaynakDokument43 SeitenMalz Grup KaynakÜmit Uçak100% (1)

- STPB740Dokument12 SeitenSTPB740Antônio Rafael BatistaNoch keine Bewertungen

- PG 1200-350 Combo Parts ManualDokument54 SeitenPG 1200-350 Combo Parts ManualAlfiya Anam100% (1)

- Stud Bolt Length For UploadDokument1 SeiteStud Bolt Length For UploadDan PastorNoch keine Bewertungen

- IS 456:2000 Cement Content Limitations for Concrete Exposed to Sulphate AttackDokument1 SeiteIS 456:2000 Cement Content Limitations for Concrete Exposed to Sulphate Attacksharath1199Noch keine Bewertungen

- F Number in AWS D1.6Dokument1 SeiteF Number in AWS D1.6kapsarcNoch keine Bewertungen

- Asme B31.3 2020Dokument4 SeitenAsme B31.3 2020Tuugii OtgooNoch keine Bewertungen

- Filler Metal Selection Guide: Cronacast-211 Ni-Rod-55Dokument9 SeitenFiller Metal Selection Guide: Cronacast-211 Ni-Rod-55Vijaya BaraniNoch keine Bewertungen

- Matching Bolt Nut GradeDokument3 SeitenMatching Bolt Nut GradehidexNoch keine Bewertungen

- Miscellaneous Adaptors: Metric Niples BSPT BSPT NPTF NPTFDokument22 SeitenMiscellaneous Adaptors: Metric Niples BSPT BSPT NPTF NPTFРома БлошенкоNoch keine Bewertungen

- Mig WeldDokument47 SeitenMig Weldravindra_jivaniNoch keine Bewertungen

- WPS Format For Asme Ix - Wps - Gtaw SmawDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- Cement & Concrete Composites: Effects of Low-Calcium Fly Ash, Limestone, and Dolomitic LimestoneDokument8 SeitenCement & Concrete Composites: Effects of Low-Calcium Fly Ash, Limestone, and Dolomitic LimestoneIsha PatelNoch keine Bewertungen

- CDC 83301200C BR3B8 Storage Module PartsDokument73 SeitenCDC 83301200C BR3B8 Storage Module PartsAlexandru Daniel BuleuNoch keine Bewertungen

- Advanced Welding Process PDFDokument3 SeitenAdvanced Welding Process PDFbusiness singhNoch keine Bewertungen

- Understanding TIG Welding Process, Its Advantages and LimitationsDokument5 SeitenUnderstanding TIG Welding Process, Its Advantages and LimitationsRao MaazNoch keine Bewertungen

- Online Price List for Welding Codes and StandardsDokument2 SeitenOnline Price List for Welding Codes and StandardsSebastian RajeshNoch keine Bewertungen

- WC-477 - Gas Metal Arc Welding (GMAW) Modes of Transfer PDFDokument1 SeiteWC-477 - Gas Metal Arc Welding (GMAW) Modes of Transfer PDFNathanLaertePiaiNoch keine Bewertungen

- 25 Q Uiii AwtDokument5 Seiten25 Q Uiii Awtsachin rajputNoch keine Bewertungen

- Satr-W-2008 Atyb TRDokument6 SeitenSatr-W-2008 Atyb TRDeo MNoch keine Bewertungen

- WedingDokument75 SeitenWedingSrinivasan MuthuvelNoch keine Bewertungen

- RS 002 July 2014 (Welder Test Run Sheet Asep W)Dokument1 SeiteRS 002 July 2014 (Welder Test Run Sheet Asep W)Muhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- Design of Welded ConnectionsDokument51 SeitenDesign of Welded Connectionscutefrenzy100% (1)

- Weld Procedure SpecificationDokument3 SeitenWeld Procedure SpecificationJorge Valdera100% (1)

- ESL Welder BroucherDokument1 SeiteESL Welder BroucheresltrichyseoNoch keine Bewertungen