Beruflich Dokumente

Kultur Dokumente

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Hochgeladen von

MD Shadikul Huq ShezanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Hochgeladen von

MD Shadikul Huq ShezanCopyright:

Verfügbare Formate

Page 1 of 4

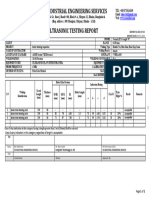

Inspection Date :26 July 2020 Report no : IES-ARBAB-UT-04

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

ULTRASONIC TEST REPORT

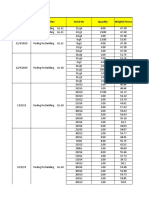

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-34 06 60 mm left ward To left 13.24 33.19 100% 66.1 A 40.00 2.31 13.00 0.24 Repair Find the defect IP,SL

Rafter Joint no -35 06 80 mm left ward To left 15.43 37.14 100% 66.1 A 90.00 3.41 15.43 0.00 Repair Find the defect IP,SL

Joint no-36 06 75 mm left ward To left 22.05 36.98 100% 66.1 A 40.00 2.45 22.05 0.00 Repair Find the defect IP,SL

Joint no-37 06 - - - - 66.1 - - - - - Accepted Satisfactory

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L = Length, a = Indication level, d = Indication

rating,

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shaharia alam Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 26/07/2020 Date: 26/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

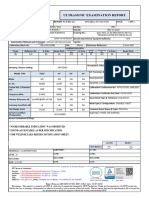

Page 2 of 4

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-38 06 - - - - 66.1 - - - - - Accepted Satisfactory

Rafter

Joint no -39 06 40 mm left ward To left 16.23 36.84 100% 66.1 A Full 3.11 16.23 0.00 Repair Find the defect IP,SL

Joint no-40 06 55 mm left ward To left 21.05 37.18 100% 66.1 A Full 2.15 21.05 0.00 Repair Find the defect IP,SL

Joint no-41 06 50 mm left ward To left 20.90 35.38 100% 66.1 A Full 3.57 24.09 0.00 Repair Find the defect IP,SL

Joint No-42 06 - - - - 66.1 - - - - Accepted Satisfactory

-

ULTRASONIC TEST REPORT

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shaharia alam Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 26/07/2020 Date: 26/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

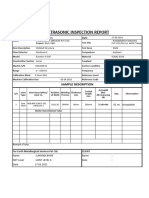

Page 3 of 4

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-43 06 - - - - 66.1 - - - - - Accepted Satisfactory

Rafter Joint no -44 06 35 mm left ward To left 23.21 38.80 100% 66.1 A Full 2.75 23.21 0.00 Repair Find the defect IP,SL

Joint no-45 06 30 mm left ward To left 21.32 38.70 100% 66.1 A Full 3.10 21.32 0.00 Repair Find the defect IP,SL

Joint no-46 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint No-47 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no -48 06 - - - - 66.1 - - - - - Accepted Satisfactory

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shaharia alam Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 26/07/2020 Date: 26/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

Page 4 of 4

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Rafter Joint No-49 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no -50 06 25 mm left ward To left 22.11 41.14 100% 66.1 A full 2.20 22.11 0.00 Repair Find the defect IP,SL

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shaharia alam Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 26/07/2020 Date: 26/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

Das könnte Ihnen auch gefallen

- Scip2 TGXDokument6 SeitenScip2 TGXKarthikeyan Ganesan100% (1)

- BestGrid EA 2.1 - (Cost $560) - For FREE - ForexCrackedDokument9 SeitenBestGrid EA 2.1 - (Cost $560) - For FREE - ForexCrackedVilayNoch keine Bewertungen

- Ir - L1904-32 17apr19-Mt (Sfjt-E)Dokument5 SeitenIr - L1904-32 17apr19-Mt (Sfjt-E)Alleyson Akin100% (1)

- Inspection Report Magnetic Particle Examination (Tupi STR)Dokument1 SeiteInspection Report Magnetic Particle Examination (Tupi STR)Jindarat Kasemsooksakul100% (1)

- Ut PWPS 001Dokument1 SeiteUt PWPS 001Goutam Kumar Deb100% (1)

- Paut 16Dokument4 SeitenPaut 16maroof mNoch keine Bewertungen

- UT ASME Report FormatDokument2 SeitenUT ASME Report Formatrifa100% (1)

- Dispersed Phase Surface Area As A Function of Drop SizeDokument3 SeitenDispersed Phase Surface Area As A Function of Drop SizegrabettyNoch keine Bewertungen

- Air Reciver Vessel-1 (Compressor Unit-2)Dokument5 SeitenAir Reciver Vessel-1 (Compressor Unit-2)MD Shadikul Huq ShezanNoch keine Bewertungen

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Dokument1 Seite75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNoch keine Bewertungen

- Design Journeys Through Complex Systems Tools PostersDokument41 SeitenDesign Journeys Through Complex Systems Tools PostersAmerika SanchezNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument3 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument4 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Industrial Engineering Services: Ultrasonic Test ReportDokument2 SeitenIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument3 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Gpti Qicl J931 Mut 041Dokument3 SeitenGpti Qicl J931 Mut 041uselessinstaid52Noch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument4 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Gpti Qicl 032Dokument2 SeitenGpti Qicl 032uselessinstaid52Noch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- UT ReportDokument1 SeiteUT ReportAmit HasanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- 1-UT-Pot Shell 588Dokument2 Seiten1-UT-Pot Shell 588Azhar GulzarNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNoch keine Bewertungen

- Gpti Qicl J931 Mut 004Dokument3 SeitenGpti Qicl J931 Mut 004uselessinstaid52Noch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument3 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- CPP HT Pipeline ReportDokument301 SeitenCPP HT Pipeline ReportAbdulkaderNoch keine Bewertungen

- Ut ProcedureDokument2 SeitenUt ProcedureJJ WeldingNoch keine Bewertungen

- Gpti Qicl J931 Mut 019Dokument3 SeitenGpti Qicl J931 Mut 019uselessinstaid52Noch keine Bewertungen

- Phased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateDokument1 SeitePhased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateshervinyNoch keine Bewertungen

- A-Star Testing & Inspection (S) Pte LTD No 5, Soon Lee Street #03-37 - Pioneer Point Singapore 627607 - Tel: +65 62616162 / +65 62616169Dokument8 SeitenA-Star Testing & Inspection (S) Pte LTD No 5, Soon Lee Street #03-37 - Pioneer Point Singapore 627607 - Tel: +65 62616162 / +65 62616169Hari KarthickNoch keine Bewertungen

- UT REport For Nornal Probe Shah CementDokument1 SeiteUT REport For Nornal Probe Shah CementMD Shadikul Huq ShezanNoch keine Bewertungen

- Industrial Engineering Services: Ultrasonic Test ReportDokument2 SeitenIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNoch keine Bewertungen

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Dokument1 SeiteUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNoch keine Bewertungen

- CB-043 Mpi Exp-02 Apr 2024Dokument1 SeiteCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNoch keine Bewertungen

- Gpti Qicl J931 Mut 002Dokument2 SeitenGpti Qicl J931 Mut 002uselessinstaid52Noch keine Bewertungen

- ACS GW 24 001 AR029 Gose Neck ThreadDokument1 SeiteACS GW 24 001 AR029 Gose Neck Threadarehmanmirza1990Noch keine Bewertungen

- CAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Dokument3 SeitenCAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Komang Triwahyudi100% (1)

- Ut Report - 018 - Fab Tech Abudhabi LLC 19.04.2018Dokument2 SeitenUt Report - 018 - Fab Tech Abudhabi LLC 19.04.2018ADOBEENoch keine Bewertungen

- MT RSDokument37 SeitenMT RSdeari nur azisNoch keine Bewertungen

- RTCLNT 142111 Wa 44Dokument1 SeiteRTCLNT 142111 Wa 44Mitul KapadiaNoch keine Bewertungen

- Amir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)Dokument3 SeitenAmir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)sumit singhNoch keine Bewertungen

- UT PLTU BTG Turbine 1-DikonversiDokument2 SeitenUT PLTU BTG Turbine 1-DikonversiWawan KurniawanNoch keine Bewertungen

- Content 20240115185834Dokument2 SeitenContent 20240115185834BLY YEDEKPA NOEL BENITONoch keine Bewertungen

- Int'L NDT Services: Magnetic Particle Examination ReportDokument3 SeitenInt'L NDT Services: Magnetic Particle Examination Reportsarsan nedumkuzhiNoch keine Bewertungen

- Liquid PenetrantDokument2 SeitenLiquid PenetrantabdiNoch keine Bewertungen

- Industrial Engineering Services: Ultrasonic Test ReportDokument2 SeitenIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNoch keine Bewertungen

- Bis-Dk-Rt-1049 - Ip2022-CeDokument2 SeitenBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNoch keine Bewertungen

- Industrial Engineering Services: Ultrasonic Test ReportDokument2 SeitenIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNoch keine Bewertungen

- Industrial Engineering Services: Ultrasonic Test ReportDokument2 SeitenIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNoch keine Bewertungen

- Int-Aim-231861 MT 06-08-23Dokument4 SeitenInt-Aim-231861 MT 06-08-23Joshua ClaytonNoch keine Bewertungen

- WFT-0001 (2378680) Jan 02 Ico-Corp-Mpt-5002 MpiDokument1 SeiteWFT-0001 (2378680) Jan 02 Ico-Corp-Mpt-5002 MpiApichai ZankerNoch keine Bewertungen

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADokument1 SeiteUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNoch keine Bewertungen

- WFT-0005 (2378695) Jan 02 Ico-Corp-Mpt-5002 MpiDokument1 SeiteWFT-0005 (2378695) Jan 02 Ico-Corp-Mpt-5002 MpiApichai ZankerNoch keine Bewertungen

- 1 23.03.2021 Powermech Services PVT - LTD Ut ReportDokument1 Seite1 23.03.2021 Powermech Services PVT - LTD Ut Reportearth metallurgical services pvt.ltd.Noch keine Bewertungen

- Radiography OfferDokument1 SeiteRadiography OfferRavi patelNoch keine Bewertungen

- Doosan Power Systems Indai PVT Limited: System CalibrationDokument3 SeitenDoosan Power Systems Indai PVT Limited: System CalibrationBalkishan DyavanapellyNoch keine Bewertungen

- (LRJRL : Sree Sai Not ServicesDokument2 Seiten(LRJRL : Sree Sai Not ServicesNiranjan KumarNoch keine Bewertungen

- Sievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportDokument1 SeiteSievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportAvijit DebnathNoch keine Bewertungen

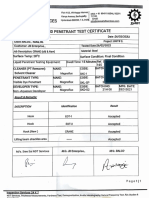

- MD - Akibur Sheikh PT Test ReportDokument2 SeitenMD - Akibur Sheikh PT Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Sujan Das WQTDokument2 SeitenSujan Das WQTMD Shadikul Huq ShezanNoch keine Bewertungen

- IES PadDokument1 SeiteIES PadMD Shadikul Huq ShezanNoch keine Bewertungen

- Sujan Das PT Test ReportDokument2 SeitenSujan Das PT Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- 30-11-2021 UT ReportDokument3 Seiten30-11-2021 UT ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- MD - Akibur Sheikh WQTDokument2 SeitenMD - Akibur Sheikh WQTMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ies-Industrial Engineering Services: Hydraulic Test ReportDokument7 SeitenIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Heder 02 Hydrolic Test Dyeing Floor DistributionDokument4 SeitenHeder 02 Hydrolic Test Dyeing Floor DistributionMD Shadikul Huq ShezanNoch keine Bewertungen

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDokument2 SeitenMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- UT REport For Nornal Probe Shah CementDokument1 SeiteUT REport For Nornal Probe Shah CementMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument1 SeiteUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Heder Boiler Room Hydrolic TestDokument5 SeitenHeder Boiler Room Hydrolic TestMD Shadikul Huq ShezanNoch keine Bewertungen

- Tested by Ies-Industrial Engineering Services: Data and Test SpecimenDokument7 SeitenTested by Ies-Industrial Engineering Services: Data and Test SpecimenMD Shadikul Huq ShezanNoch keine Bewertungen

- Date Description Serial No Quantity Weight/ PecessDokument12 SeitenDate Description Serial No Quantity Weight/ PecessMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument3 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDokument2 SeitenUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Ies-Industrial Engineering Services: Ultrasonic Thickness Test ReportDokument3 SeitenIes-Industrial Engineering Services: Ultrasonic Thickness Test ReportMD Shadikul Huq ShezanNoch keine Bewertungen

- Help For Report ShezanDokument5 SeitenHelp For Report ShezanMD Shadikul Huq ShezanNoch keine Bewertungen

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDokument2 SeitenMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDokument2 SeitenMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDokument2 SeitenMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDokument2 SeitenMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Air Reciver Vessel-2 (Compressor Unit-2)Dokument5 SeitenAir Reciver Vessel-2 (Compressor Unit-2)MD Shadikul Huq ShezanNoch keine Bewertungen

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDokument2 SeitenMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDokument2 SeitenMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNoch keine Bewertungen

- Account Statement For Account:3869000100750616: Branch DetailsDokument4 SeitenAccount Statement For Account:3869000100750616: Branch DetailsUddeshya SrivastavaNoch keine Bewertungen

- CR - Secrets Manager With KMSDokument4 SeitenCR - Secrets Manager With KMSrahul.psNoch keine Bewertungen

- Volumes by Sections Using Prismoidal FormulasDokument4 SeitenVolumes by Sections Using Prismoidal FormulasfaizalprbwNoch keine Bewertungen

- Digital Marketing 101 - QuizDokument54 SeitenDigital Marketing 101 - QuizAsep Andi0% (2)

- HL Paper1Dokument15 SeitenHL Paper1Soham MishraNoch keine Bewertungen

- Speaker JBLCtrl24C ManualDokument19 SeitenSpeaker JBLCtrl24C ManualalexmilarNoch keine Bewertungen

- Sae J1040Dokument21 SeitenSae J1040amir sadighiNoch keine Bewertungen

- Toaz - Info English Department Action Plan Sy 2020 2021 PR - C8db047a46a43415432d2d1276Dokument9 SeitenToaz - Info English Department Action Plan Sy 2020 2021 PR - C8db047a46a43415432d2d1276Jhonalyn Toren-Tizon Longos100% (1)

- Syllabus:: Unit-3: Classes, Inheritance, Exceptions, Packages and InterfacesDokument56 SeitenSyllabus:: Unit-3: Classes, Inheritance, Exceptions, Packages and InterfacesabcNoch keine Bewertungen

- Plagiarism Lesson Plan BeginnerDokument4 SeitenPlagiarism Lesson Plan Beginnerdv vargasNoch keine Bewertungen

- 2024 Beijing Institute of Technology Admission Books For International StudentsDokument34 Seiten2024 Beijing Institute of Technology Admission Books For International StudentsToni MengNoch keine Bewertungen

- Argosy Professional Ethics Class FAQsDokument38 SeitenArgosy Professional Ethics Class FAQsDavid Moore, PhD CDP100% (1)

- Juan Dela Cruz: UP Mindanao Security Personnel ProfileDokument4 SeitenJuan Dela Cruz: UP Mindanao Security Personnel ProfileinvictuslorenzoNoch keine Bewertungen

- UNIT 1 Solved Quiz Operations ResearchDokument5 SeitenUNIT 1 Solved Quiz Operations Researchzohaib100% (1)

- FinalRevisedChapter1 4ForIAAS (RAMIREZ)Dokument113 SeitenFinalRevisedChapter1 4ForIAAS (RAMIREZ)jhona dobladaNoch keine Bewertungen

- Dermacryl: Product DescriptionDokument2 SeitenDermacryl: Product DescriptionAbdelmuneimNoch keine Bewertungen

- Spleeter A Fast and Efficient Music Source SeparatDokument4 SeitenSpleeter A Fast and Efficient Music Source SeparatZekeriya AkbabaNoch keine Bewertungen

- Grammarly Score and Plagiarism Check PercentageDokument24 SeitenGrammarly Score and Plagiarism Check PercentageSABS RIDES AND LIFENoch keine Bewertungen

- En 9 8 001 BSP HoseDokument11 SeitenEn 9 8 001 BSP HosePaulo YorgosNoch keine Bewertungen

- The Greatest Inventions in The Past 1000 YearsDokument2 SeitenThe Greatest Inventions in The Past 1000 YearsRosario CabarrubiasNoch keine Bewertungen

- Design of Helical Antenna With Balun at 2.2 GHZ IJERTV7IS010118Dokument3 SeitenDesign of Helical Antenna With Balun at 2.2 GHZ IJERTV7IS010118Euvannisa JasminNoch keine Bewertungen

- NTCC Mep QCDD 001 r0 ReceivedDokument441 SeitenNTCC Mep QCDD 001 r0 ReceivedIbrahim A. HameedNoch keine Bewertungen

- CC ZG522 Ec-2r First Sem 2023-2024Dokument12 SeitenCC ZG522 Ec-2r First Sem 2023-20242023mt03587Noch keine Bewertungen

- Abeer-Reem ProgrammingDokument8 SeitenAbeer-Reem ProgrammingruxlixNoch keine Bewertungen

- Pore-Water Pressures Defined Using A Finite Element AnalysisDokument5 SeitenPore-Water Pressures Defined Using A Finite Element AnalysisPuspa ChandNoch keine Bewertungen

- GK420 GT800 Datasheet ENG APAC EnglishDokument2 SeitenGK420 GT800 Datasheet ENG APAC EnglishMarino FroesNoch keine Bewertungen

- Lesson 5 Managing Text Flow 742780943 (Yeah Good Day)Dokument37 SeitenLesson 5 Managing Text Flow 742780943 (Yeah Good Day)Ahmed El IssawiNoch keine Bewertungen