Beruflich Dokumente

Kultur Dokumente

The Material For Fittings IS0

Hochgeladen von

Nisarg PandyaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Material For Fittings IS0

Hochgeladen von

Nisarg PandyaCopyright:

Verfügbare Formate

cO A 234/A 234M

cOitstituteslion-conformance with this specification. In case of composition of the Grade in Table 1 and the mechanical properties of the .

Grade in Table 2. Heat treatment shall be in accordance with Section 7. All

a conflict between the requirements of this specification and

Specification A 960, this specification shall prevail. caps machined from bar stock shall be examined by liquid penetrant or

magnetic particle in accordance with S52 or S53 in Specification A 960.

5. Materials

6.2 All welds including welds in tubular products from

5.1 The J,llaterial for fittings shall consist of killed steel,

which fittings are made shall be (1) made by welders, welding

forgings, bars, plates, seamless or fusion-welded tubular prod- operators, and welding procedures qualified under the provi-

uctswith filler metal added and shall conform to the chemical

sions of ASME Section IX, (2) heat treated in accordance with

requirements of Table 1. Unless otherwise specified for carbon

Se~tion 7 of this specification, and (3) radiographically exam-

steelplates, the steel may be made to either coarse grain or fine

ined throughout the entire length of each weld in accordance

grainpractice. Grade WP9 shall be made to fine grain practice.

with Article 2, ASME Section V with acceptance limits in

5.2 A statting material specification that specifically re-

accordance with Paragraph UW-51 of ASME Section VIII,

quires the addition of any elllment beyond those listed for the

Division 1 of the ASME Boiler & Pressure Vessel Code. In

materials in Table 1 for the Ilpplicable grade of material is not

on, place of radiographic examination, welds may be ultrasonically

permitted. This does not preclude the use of deoxidizers or the

;er- examined in accordance with Appendix 12 of Section VIII. Th~

Isi-

judicious use of element~ for grain size control.

6. Manufacture

NDE of welds in Grades WPB, WPC, WPl, WPll Class

WPll Class 2, WPll Class 3, WP12 Class 1, WP12 Class 2,

l;

llts

6.1 Forgib.g or shaping operations may be performed by andWPR may beperformedeither prior to or after forming.

hammering, ! pressing, piCfrdng, extruding, upsetting, rolling, NDE of welds in Grades WP5, WP9, WP91, WP911, WP22

for bending, fusion welding,' machining, or by a combination of Class I, and WP22 Class 3 shall be done after forming.

twoor mord of tIi~~"bperations. The forming procedure shall 6.3 Personnel performing NDE examinations shall be quali-

beso applied that it will not produce injurious imperfections in fied in accordance with SNT-TC-IA.

the fittings. 6.4 The welded joints of the fittings shall be finished in

jed

NOTE I-Fittings NPS-4 and under may be machined from hot-forged accordance with the requirements of Paragraph UW-35 ( a) of

IWS

or rolled, cold-sized, and straightened bar stock having the chemical ASME Section VIII, Division I.

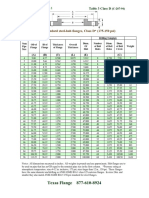

TABLE 1 Chemical Requirements

0.50

1.00

0.60max

0.50-1.00

0.010

0.040

1.90-2.60

1.00-1.50

8.0-10.0

0.050

0.40-1.06

0.030

0.058 0.045

0.030

max

4.0-6.0

0.30-0.60

0,30-0.60

0.30-0.60

0.040

0.020

Chromium

0.045

0.80-1.25

0,045

0;20-0.50

8.0-9.5

0.30-0.80

0.050

0,10-0.50

Sulfur,

0,10

0.40

0.10

0.040 0.15

max max

00.05-0.15

0.05-0.20

0.28

mill

min 0.20 max are maximum

0.08-0.12

0,P.II-l.06

0.30-0.90

.05-0,20

0.01i0

Carbon

0.30

Manganese

Q.p.ll-l.0a

O,OIla IT\l!x

0.351T\l\x Silicon unless otherwise indicated. Composition, %

NOTE I-All requirements PhosphO-

WPl1CLI

WP9CLI,

WP5CLI,

WP22Cll,

:'WPR

NOTE

Grade 2-Where

and an ellipsis (... ) appears in this table, there is no requirement.

IgS, Molybdenum Nickel Copper Others

0.15 max 0.40 max 0.40 max Vanadium 0.08 max

COlumbium 0.02 max

0.15 max 0.40 max 0.40 max Vanadium 0.08 max

Columbium 0.02 max

0.44-0.65 )

uc- 0.44-0.65 '

0.44-0.65

0.44-0.65

0.87-1.13

0.44-0.65

1 to 0.90-1.10

)Ie-

1.60-2.24 0.75-1.25

jer. 0.85-1.05 0.40 max ... Vanadium 0.18-0.25

}60 Columbium 0.06-0.10

Nitrogen 0.03-0.07

Aluminum 0.04 max

'WP911 0.09-0.13 0.30-0.60 0.020 0.010 0.10-0.50 8.5-10.5 0.90-1.10 0.40 max ... Vanadium 0.18-0.25

Columbium 0.060-0.10

Nitrogen 0.04-0.09

NY Aluminum 0.04 max

Boron 0.0003-0.006

ings Tungsten 0.90-1.10

A When fittingS are of welded construction, the grade and ma,rking symbol shown above shall be supplemented by letter W.

gate , B Fittings mad~ from bar or plate may have 0.35 max carbon.

fj c Fittings made from forgings may have 0.35 max carbon and 0.35 max silicon with no minimum.

D For each reduCtion of 0.Q1.% below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted, up to a

maximumof 1.35 %.

EThe sum of Copper, Nickel, Chromium, and Molybdenum shall not exceed 1.00 %.

FThe sum of Chromium and Molybdenum shall not exceed 0.32 %.

127

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- FlangesDokument5 SeitenFlangesNisarg PandyaNoch keine Bewertungen

- WIC Role of InspectorDokument19 SeitenWIC Role of InspectorNisarg PandyaNoch keine Bewertungen

- Buoyancy Per Unit LengthDokument4 SeitenBuoyancy Per Unit LengthNisarg PandyaNoch keine Bewertungen

- BS137991974 PDFDokument1 SeiteBS137991974 PDFNisarg PandyaNoch keine Bewertungen

- BS137991974 PDFDokument1 SeiteBS137991974 PDFNisarg PandyaNoch keine Bewertungen

- Asme ptc2 4Dokument1 SeiteAsme ptc2 4Nisarg PandyaNoch keine Bewertungen

- Asme ptc2 7Dokument1 SeiteAsme ptc2 7Nisarg PandyaNoch keine Bewertungen

- QW 482 Suggested Format For Welding ProcedureDokument1 SeiteQW 482 Suggested Format For Welding ProcedureNisarg PandyaNoch keine Bewertungen

- Asme ptc2 5Dokument1 SeiteAsme ptc2 5Nisarg PandyaNoch keine Bewertungen

- Asme mfc-1m PDFDokument37 SeitenAsme mfc-1m PDFNisarg PandyaNoch keine Bewertungen

- Asme Fap-1 PDFDokument34 SeitenAsme Fap-1 PDFNisarg PandyaNoch keine Bewertungen

- 6 Designation: Parallel Pipe Thread ISO 7/1-Rp 1 Taper Pipe Thread ISO 711-Rc 1 Always Taper Pipe Thread ISO 7/ L-R 1Dokument1 Seite6 Designation: Parallel Pipe Thread ISO 7/1-Rp 1 Taper Pipe Thread ISO 711-Rc 1 Always Taper Pipe Thread ISO 7/ L-R 1Nisarg PandyaNoch keine Bewertungen

- QW 482 Suggested Format For Welding ProcedureDokument1 SeiteQW 482 Suggested Format For Welding ProcedureNisarg PandyaNoch keine Bewertungen

- AWWA Standard Steel-Hub Flanges, Class D (175-150 Psi) : Texas Flange 877-610-8924Dokument1 SeiteAWWA Standard Steel-Hub Flanges, Class D (175-150 Psi) : Texas Flange 877-610-8924Nisarg PandyaNoch keine Bewertungen

- AWWA Standard Steel-Ring Flanges, Class B (86 Psi)Dokument1 SeiteAWWA Standard Steel-Ring Flanges, Class B (86 Psi)Nisarg PandyaNoch keine Bewertungen

- Evaluating UT E 317 94Dokument1 SeiteEvaluating UT E 317 94Nisarg PandyaNoch keine Bewertungen

- Evaluating UT E 317 94Dokument1 SeiteEvaluating UT E 317 94Nisarg PandyaNoch keine Bewertungen

- GST15!16!17-Bad Debt Relief RecoverDokument10 SeitenGST15!16!17-Bad Debt Relief RecoverDaud Farook IINoch keine Bewertungen

- Modeling, Control and Simulation of A Chain Link Statcom in Emtp-RvDokument8 SeitenModeling, Control and Simulation of A Chain Link Statcom in Emtp-RvBožidar Filipović-GrčićNoch keine Bewertungen

- Chapter 1 Section 6 Spoon Feeding BasicsDokument9 SeitenChapter 1 Section 6 Spoon Feeding Basicskenneth mayaoNoch keine Bewertungen

- 19.-Solid Waste TreatmentDokument108 Seiten19.-Solid Waste TreatmentShaira Dale100% (1)

- Di SilvioDokument47 SeitenDi SilviomaryroseengNoch keine Bewertungen

- Turbo Lab 1Dokument10 SeitenTurbo Lab 1Seng SoonNoch keine Bewertungen

- Peritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionDokument10 SeitenPeritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionAjeng SuparwiNoch keine Bewertungen

- Field Study 1-Act 5.1Dokument5 SeitenField Study 1-Act 5.1Mariya QuedzNoch keine Bewertungen

- Mechanical Interview Questions and Answers - Fluid MechanicsDokument2 SeitenMechanical Interview Questions and Answers - Fluid MechanicsannukiitNoch keine Bewertungen

- ЗОШИТ для ДЗ №2 Microsoft WordDokument44 SeitenЗОШИТ для ДЗ №2 Microsoft WordдимаNoch keine Bewertungen

- Pulse Oximetry CircuitDokument19 SeitenPulse Oximetry Circuitنواف الجهنيNoch keine Bewertungen

- Principles in Biochemistry (SBK3013)Dokument3 SeitenPrinciples in Biochemistry (SBK3013)Leena MuniandyNoch keine Bewertungen

- Reviewer Crim 3 FinalsDokument6 SeitenReviewer Crim 3 FinalsMaria Rafaella P. DadoNoch keine Bewertungen

- Security Officer Part Time in Orange County CA Resume Robert TalleyDokument2 SeitenSecurity Officer Part Time in Orange County CA Resume Robert TalleyRobertTalleyNoch keine Bewertungen

- DIABETES MELLITUS BensonDokument14 SeitenDIABETES MELLITUS BensonNixon KeyaNoch keine Bewertungen

- Achai, Sydney Jill S. GE 15 - SIM - ULOcDokument13 SeitenAchai, Sydney Jill S. GE 15 - SIM - ULOcSydney AchaiNoch keine Bewertungen

- XII Biology Practicals 2020-21 Without ReadingDokument32 SeitenXII Biology Practicals 2020-21 Without ReadingStylish HeroNoch keine Bewertungen

- Kidney Diet DelightsDokument20 SeitenKidney Diet DelightsArturo Treviño MedinaNoch keine Bewertungen

- Doppler EffectDokument47 SeitenDoppler EffectLouies UngriaNoch keine Bewertungen

- Myasthenia Gravis DiseaseDokument14 SeitenMyasthenia Gravis Diseaseapi-482100632Noch keine Bewertungen

- General Method For Cable Sizing - Electrical Installation GuideDokument10 SeitenGeneral Method For Cable Sizing - Electrical Installation Guidebhaskar_dandapathakNoch keine Bewertungen

- TOCDokument14 SeitenTOCAthirah HattaNoch keine Bewertungen

- Life Everlasting 2021001Dokument11 SeitenLife Everlasting 2021001realangelinemylee2020721001Noch keine Bewertungen

- MCQ Questions For Class 10 Science Periodic Classification of Elements With AnswersDokument30 SeitenMCQ Questions For Class 10 Science Periodic Classification of Elements With AnswersAymen WaelNoch keine Bewertungen

- Switchyard Equipments, Switching Schmes & LayoutsDokument66 SeitenSwitchyard Equipments, Switching Schmes & LayoutsPraveen Kumar88% (17)

- Solar Grass Cutter MachDokument21 SeitenSolar Grass Cutter MachAnonymous I13s99Noch keine Bewertungen

- Plumbing Design Calculation - North - Molino - PH1 - 5jun2017Dokument5 SeitenPlumbing Design Calculation - North - Molino - PH1 - 5jun2017Jazent Anthony RamosNoch keine Bewertungen

- CV TemplateDokument5 SeitenCV TemplateLopezDistrict FarmersHospitalNoch keine Bewertungen

- Medical-Surgical Nursing Assessment and Management of Clinical Problems 9e Chapter 23Dokument5 SeitenMedical-Surgical Nursing Assessment and Management of Clinical Problems 9e Chapter 23sarasjunkNoch keine Bewertungen

- Real Time EvaluationDokument3 SeitenReal Time Evaluationأيوب علاءNoch keine Bewertungen