Beruflich Dokumente

Kultur Dokumente

TDS Renderoc Plug India PDF

Hochgeladen von

Anonymous XVEucVMsEOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TDS Renderoc Plug India PDF

Hochgeladen von

Anonymous XVEucVMsECopyright:

Verfügbare Formate

Renderoc® Plug constructive solutions

Rapid setting cement based, water leak

plugging mortar

Uses

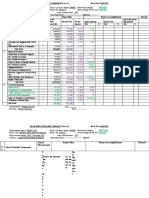

For the rapid temporary patching and plugging of concrete Heat generation characteristics : High heat output (exotherm)

segments, concrete and brick tunnel linings, sewage systems, leads to undesirably high shrinkage and consequent thermal

below ground access chambers, pipes, basements, founda- cracking. The curves below show the low heat output of Ren-

tions and mines. deroc Plug which minimises the risk of shrinkage and thermal

Advantages cracking.

Emergency water - stopping capability

Single component - only the addition of clean water is

required.

Excellent bond to the substrate

Low exotherm minimises thermal cracking

Pre-packed formulation to overcome variation in site batching

Contains no chloride admixtures.

Description

Renderoc Plug is supplied as a ready to use blend of dry pow-

Specification clauses

ders which requires only the addition of clean water at site to

produce a highly consistent, rapid setting mortar which is easy Water stopping mortar

to apply in many difficult conditions. The material is based The water stopping mortar shall be Renderoc Plug, a single

on a blend of cements, graded aggregates, special fillers and component cement based product to which only the site -addi-

chemical additives which control the rate of set and minimise tion of clean water shall be permitted. It must be chloride free

the risk of thermal cracking. and shall have a low exotherm to minimise thermal cracking.

Technical support Application instructions

Fosroc offers a comprehensive range of high performance, high Preparation

quality concrete repair and construction products. In addition,

Areas to be patched should be cut back to a depth of 15mm

Fosroc offers technical support service to specifiers, end us-

and given a good mechanical key. Feather edges must not be

ers and contractors, as well as on-site technical assistance in

allowed. Surface should be brushed clean to remove loose

locations all over the country.

material, dust and laitance. Grease, slime or mould growth

Design criteria should be removed by steam cleaning or high pressure water

Renderoc Plug can be applied to horizontal, vertical or overhead jetting. A proprietary degreasing agent should be used for

surface at a wide range of thickness. Generally, the volume removal of light oil or grease contamination.

of mixed material used in a single application is restricted to To seal leaks, crack openings must be chased out to approxi-

that which can be applied by trowel or gloved hand. Thicker mately 20mm. The chase should always be undercut to avoid

sections can be built up in layers. If any doubt arises about leaving a V-section. All loose material and debris should be

the nature of the substrate, consult the local Fosroc office for removed.

further information.

Mixing

Properties

Renderoc Plug should be added to clean water in the follow-

Initial set time Approx. 1 - 2 mins. at 300C ing proportions :

Note : Set times will be extended when mixed or applied at One part clean water : 3 parts Renderoc Plug ( measured by

lower temperatures. volume ).

Compressive strength : 25N/mm2 @ 28 days @ 300C Mix to a stiff consistency in a suitable container using a trowel

Renderoc Plug

or gloved hand. Due to the rapid set characteristics of the

product, only prepare a quantity of mortar which can be placed

within the prescribed set time.

page 1 of 2

Renderoc® Plug

Precautions

Health & Safety

Application

Renderoc Plug contains cement powders which, when mixed or

Trowel apply or hand-knead the mixed mortar in place, ensuring

become damp, release alkalis which can be harmful to the skin.

maximum contact with the substrate before the material sets.

During use, avoid inhalation of dust and contact with skin and

If being used to plug running water, Renderoc Plug should be

eyes. Wear suitable protective clothing, gloves, eye protection

used and held in place until the initial set is reached.

and respiratory protective equipment. The use of barrier creams

Cleaning provide additional skin protection. In case of contact with skin,

Renderoc Plug should be removed from tools, equipment and rinse with plenty of clean water, then cleanse with soap and

mixers with clean water prior to the initial set. Cured material water. In case of contact with eyes, rinse immediately with

can only be removed mechanically. plenty of clean water and seek medical advice. If swallowed,

seek medical attention immediately - do not induce vomitting.

Limitations

Fire

Renderoc Plug should not be used when the temperature is

below 10 0C and falling. Renderoc Plug is non-flammable.

Storage

Shelf life

Renderoc plug has a shelf life of 6 months if kept in a dry store

in the original, unopened bags.

Important note :

Fosroc products are guaranteed against defective materials and manufacture and are sold

subject to its standard terms and conditions of sale, copies of which may be obtained on

request. Whilst Fosroc endeavours to ensure that any advice, recommendation specification

or information it may give is accurate and correct, it cannot, because it has no direct or

continuous control over where or how its products are applied, accept any liability either

Fosroc Chemicals directly or indirectly arising from the use of its products whether or not in accordance with

any advice, specification, recommendation or information given by it.

(India) Pvt. Ltd.

Head Office telephone fax e-mail

“Sapthagiri Palace”, No.38,

II & III Floor, 12th Cross, ++91 80-42521900 ++91 80-23551510 enquiryindia@fosroc.com

CBI Road, Ganganagar North,

Bangalore 560 024

Regional Offices

Chennai Mumbai Noida Kolkata

No. 26(old no.33), 1st Floor, 1401/1402, 14th Floor, D-166 Sector 10 304, Jodhpur Park

1st Street Postal Colony, A-Wing’The Great Eastern Summit’ Dist. Gautam Budha Nagar, Kolkata 700 068

West Mambalam, Sector-15, CBD, Belapur Noida, Ph:033-65343188

Chennai 600 033. Navi Mumbai 400 614 UP 201 301 Fax: 033-2499-0280

Ph: 044-24899949-94 Ph: 022-43406800-04 Ph:0120-4270620-21

Fax: 044-24896641 Fax: 022-27562423 Fax: 0120-4270622

www.fosroc.com

page 2 of 2 INDIA/2014/0408/A

Das könnte Ihnen auch gefallen

- Renderoc PlugDokument2 SeitenRenderoc PlugMansoor AliNoch keine Bewertungen

- Creative Resin: Easy techniques for contemporary resin artVon EverandCreative Resin: Easy techniques for contemporary resin artNoch keine Bewertungen

- Renderoc PlugDokument3 SeitenRenderoc Plugtalatzahoor100% (1)

- Renderoc SMDokument2 SeitenRenderoc SMMas DaffiNoch keine Bewertungen

- Renderoc SM - 230624 - 220802Dokument3 SeitenRenderoc SM - 230624 - 220802Amar PutraNoch keine Bewertungen

- Renderoc RsxtraDokument4 SeitenRenderoc RsxtraBalasubramanian AnanthNoch keine Bewertungen

- Fosroc Renderoc FC TDSDokument2 SeitenFosroc Renderoc FC TDSm.basim.technitalNoch keine Bewertungen

- Renderoc SDokument2 SeitenRenderoc SMansoor AliNoch keine Bewertungen

- Renderoc PlugDokument2 SeitenRenderoc PlugmilanbrasinaNoch keine Bewertungen

- Renderoc MPRDokument2 SeitenRenderoc MPRtalatzahoorNoch keine Bewertungen

- Renderoc CSDokument2 SeitenRenderoc CSAnonymous XVEucVMsENoch keine Bewertungen

- Renderoc CS: Single Part, Non Shrink, Cementitious, Crack Sealer For Plaster, Masonry and ConcreteDokument2 SeitenRenderoc CS: Single Part, Non Shrink, Cementitious, Crack Sealer For Plaster, Masonry and ConcreteAnonymous XVEucVMsENoch keine Bewertungen

- Renderoc Plaster PDFDokument1 SeiteRenderoc Plaster PDFNarutojane BorutoNoch keine Bewertungen

- Renderoc PlasterDokument1 SeiteRenderoc PlasterNarutojane BorutoNoch keine Bewertungen

- Fosroc Renderoc S: Constructive SolutionsDokument2 SeitenFosroc Renderoc S: Constructive SolutionsVincent JavateNoch keine Bewertungen

- Renderoc CS: Single Part, Non Shrink, Cementitious, Crack Sealer For Plaster, Masonry and ConcreteDokument2 SeitenRenderoc CS: Single Part, Non Shrink, Cementitious, Crack Sealer For Plaster, Masonry and Concreteharish babu aluruNoch keine Bewertungen

- Renderoc HSDokument2 SeitenRenderoc HSAdnan JadoonNoch keine Bewertungen

- Renderoc SP40: Constructive SolutionsDokument2 SeitenRenderoc SP40: Constructive SolutionsSathiyaseelan SubramaniNoch keine Bewertungen

- Renderoc Rsxtra: Rapid Setting Repair ConcreteDokument4 SeitenRenderoc Rsxtra: Rapid Setting Repair ConcretekalidindivenkatarajuNoch keine Bewertungen

- Renderoc S: Polymer Modified Structural Grade Repair MortarDokument3 SeitenRenderoc S: Polymer Modified Structural Grade Repair Mortarmyke_0101Noch keine Bewertungen

- Renderoc TG: Trowel Grade Cementitous Repair MortarDokument2 SeitenRenderoc TG: Trowel Grade Cementitous Repair Mortarmohammad khabibNoch keine Bewertungen

- Nitobond TMDokument2 SeitenNitobond TMVincent JavateNoch keine Bewertungen

- Renderoc FC TDSDokument3 SeitenRenderoc FC TDSZaid AqeelNoch keine Bewertungen

- TEC-030100.2-MET-DoR-002-Fosroc1A-Renderoc FC (Fairing Coat) (1 Component Polymer Modifyied CementitiousDokument4 SeitenTEC-030100.2-MET-DoR-002-Fosroc1A-Renderoc FC (Fairing Coat) (1 Component Polymer Modifyied CementitiousEli MatucadNoch keine Bewertungen

- Elastomeric Waterproofing: Resin Powder Grey Powder WhiteDokument2 SeitenElastomeric Waterproofing: Resin Powder Grey Powder WhiteUpulHettiarachchiNoch keine Bewertungen

- TDS Hydroproof Xtra India2Dokument2 SeitenTDS Hydroproof Xtra India2Sameehu TVNoch keine Bewertungen

- Renderoc S2Dokument4 SeitenRenderoc S2chandelsinghNoch keine Bewertungen

- sHOTPATCH 10 v3 PDFDokument2 SeitensHOTPATCH 10 v3 PDFAnkita Baban GavadeNoch keine Bewertungen

- Renderoc BF2: Design CriteriaDokument2 SeitenRenderoc BF2: Design CriteriaShyam SinghNoch keine Bewertungen

- RCT-ConRep FR MortarDokument2 SeitenRCT-ConRep FR MortarfahadNoch keine Bewertungen

- Dr. Fixit Dampguard 145 1 PDFDokument3 SeitenDr. Fixit Dampguard 145 1 PDFvbadsNoch keine Bewertungen

- Fosroc Renderoc LA: Constructive SolutionsDokument2 SeitenFosroc Renderoc LA: Constructive SolutionsshahidNoch keine Bewertungen

- Renderoc RGDokument4 SeitenRenderoc RGvenkatasuri999Noch keine Bewertungen

- Fosroc Dekguard S TDSDokument3 SeitenFosroc Dekguard S TDSManoharan RNoch keine Bewertungen

- 7 Renderoc SP30Dokument4 Seiten7 Renderoc SP30samueltee212Noch keine Bewertungen

- TERRACO WeathercoatDokument4 SeitenTERRACO WeathercoatAkhilNoch keine Bewertungen

- Renderoc HSDokument2 SeitenRenderoc HSMansoor AliNoch keine Bewertungen

- Renderoc Plug: Uses SpecificationDokument2 SeitenRenderoc Plug: Uses SpecificationVenkata RaoNoch keine Bewertungen

- DR Fixit Pidifin 2KDokument3 SeitenDR Fixit Pidifin 2KAsif AhmadNoch keine Bewertungen

- Fosroc Renderoc Putty: Cement Based Polymer Rich Putty For Wall and CeilingDokument2 SeitenFosroc Renderoc Putty: Cement Based Polymer Rich Putty For Wall and CeilingVincent JavateNoch keine Bewertungen

- Renderoc PuttyDokument2 SeitenRenderoc PuttyVincent JavateNoch keine Bewertungen

- Renderoc LAXtraDokument2 SeitenRenderoc LAXtrajaga67Noch keine Bewertungen

- TDS Hydroproof Xtra IndiaDokument2 SeitenTDS Hydroproof Xtra IndiaJoeNoch keine Bewertungen

- Renderoc FCXtra SubmittalDokument35 SeitenRenderoc FCXtra SubmittalAjit Singh Rathore100% (1)

- 12 Renderoc SkimcoatDokument3 Seiten12 Renderoc SkimcoatdodsbusinessNoch keine Bewertungen

- TDS Renderoc FC Saudi ArabiaDokument3 SeitenTDS Renderoc FC Saudi ArabiaMohammad ArslanNoch keine Bewertungen

- DR Fixit Pidifin 2K Dec 19Dokument3 SeitenDR Fixit Pidifin 2K Dec 19Nav Nirman Con SpecialitiesNoch keine Bewertungen

- TDS Renderoc CF India2Dokument2 SeitenTDS Renderoc CF India2AL RawaqNoch keine Bewertungen

- d2) Epilux218 4267Dokument2 Seitend2) Epilux218 4267Syed FaridNoch keine Bewertungen

- Bostik Boscolastic Rev1Dokument2 SeitenBostik Boscolastic Rev1decenabuilders2016Noch keine Bewertungen

- 112 DR Fixit Pidifin 2kDokument3 Seiten112 DR Fixit Pidifin 2kreshmitapallaNoch keine Bewertungen

- Renderoc BF2Dokument2 SeitenRenderoc BF2milanbrasinaNoch keine Bewertungen

- Dekguard CVCFDCDokument2 SeitenDekguard CVCFDCTarek TarekNoch keine Bewertungen

- 66210-76110-76115 Weathercoat GP. Water ProofingDokument2 Seiten66210-76110-76115 Weathercoat GP. Water ProofingUpulHettiarachchiNoch keine Bewertungen

- Dr. Fixit Raincoat Waterproof CoatingDokument3 SeitenDr. Fixit Raincoat Waterproof CoatingsudhakarrrrrrNoch keine Bewertungen

- Fosroc Renderoc FC: Constructive SolutionsDokument4 SeitenFosroc Renderoc FC: Constructive Solutionsraahul_nNoch keine Bewertungen

- Renderoc PlugDokument2 SeitenRenderoc Plug0410636Noch keine Bewertungen

- IS 516-Part-5 Sec 1-2018 (UPV)Dokument18 SeitenIS 516-Part-5 Sec 1-2018 (UPV)Anonymous XVEucVMsENoch keine Bewertungen

- IS 1199-Part 2-2018Dokument24 SeitenIS 1199-Part 2-2018Anonymous XVEucVMsENoch keine Bewertungen

- Renderoc CSDokument2 SeitenRenderoc CSAnonymous XVEucVMsENoch keine Bewertungen

- Conbextra EBG (M) : Epoxy Resin Bearing GroutDokument3 SeitenConbextra EBG (M) : Epoxy Resin Bearing GroutAnonymous XVEucVMsENoch keine Bewertungen

- Masterflow 928T: Cementitious High Strength Non-Shrink Precision GroutDokument2 SeitenMasterflow 928T: Cementitious High Strength Non-Shrink Precision GroutAnonymous XVEucVMsENoch keine Bewertungen

- Sikadur - 42 HES (IN) : 3-Part, High Performance, Pourable Epoxy Grouting SystemDokument4 SeitenSikadur - 42 HES (IN) : 3-Part, High Performance, Pourable Epoxy Grouting SystemAnonymous XVEucVMsENoch keine Bewertungen

- Effect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventDokument8 SeitenEffect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventMega MustikaningrumNoch keine Bewertungen

- Calculation Condensation StudentDokument7 SeitenCalculation Condensation StudentHans PeterNoch keine Bewertungen

- Site Quality ManualDokument376 SeitenSite Quality ManualsNoch keine Bewertungen

- Hydrogen Production From The Air: Nature CommunicationsDokument9 SeitenHydrogen Production From The Air: Nature CommunicationsdfdffNoch keine Bewertungen

- SSN Melaka SMK Seri Kota 2021 Annual Training Plan: Athletes Name Training ObjectivesDokument2 SeitenSSN Melaka SMK Seri Kota 2021 Annual Training Plan: Athletes Name Training Objectivessiapa kahNoch keine Bewertungen

- Microbial Communities From Arid Environments On A Global Scale. A Systematic ReviewDokument12 SeitenMicrobial Communities From Arid Environments On A Global Scale. A Systematic ReviewAnnaNoch keine Bewertungen

- E3sconf 2F20187307002Dokument4 SeitenE3sconf 2F20187307002Nguyễn Thành VinhNoch keine Bewertungen

- CRM McDonalds ScribdDokument9 SeitenCRM McDonalds ScribdArun SanalNoch keine Bewertungen

- Analyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioDokument12 SeitenAnalyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioLukas ArenasNoch keine Bewertungen

- Consent CertificateDokument5 SeitenConsent Certificatedhanu2399Noch keine Bewertungen

- Assignment Nutrition and HydrationDokument17 SeitenAssignment Nutrition and Hydrationmelencio olivasNoch keine Bewertungen

- Existensive Happiness by AristotleDokument2 SeitenExistensive Happiness by AristotleIan Robert Roa NovalNoch keine Bewertungen

- MelatoninaDokument32 SeitenMelatoninaCodrut GeorgescuNoch keine Bewertungen

- Capstone-ModDokument25 SeitenCapstone-ModMohammad Ryyan PumbagulNoch keine Bewertungen

- Quarterly Progress Report FormatDokument7 SeitenQuarterly Progress Report FormatDegnesh AssefaNoch keine Bewertungen

- Hippocrates OathDokument6 SeitenHippocrates OathSundary FlhorenzaNoch keine Bewertungen

- Assignment 2: Loan Submission For Equipment FinanceDokument6 SeitenAssignment 2: Loan Submission For Equipment FinanceIT'S SIMPLENoch keine Bewertungen

- Cranial Electrotherapy Stimulator (C.E.S.) Earlobe Stimulator, Pocket-Transportable, 9VDokument1 SeiteCranial Electrotherapy Stimulator (C.E.S.) Earlobe Stimulator, Pocket-Transportable, 9VemiroNoch keine Bewertungen

- Reading Assignment Nuclear ChemistryDokument2 SeitenReading Assignment Nuclear Chemistryapi-249441006Noch keine Bewertungen

- The Power of PositivityDokument5 SeitenThe Power of PositivityYorlenis PintoNoch keine Bewertungen

- Technology For Teaching and Learning 2 OBE SyllabusDokument9 SeitenTechnology For Teaching and Learning 2 OBE Syllabusjesreel canalNoch keine Bewertungen

- MSU-Iligan Institute of TechnologyDokument5 SeitenMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDONoch keine Bewertungen

- TDS Shell Spirax s6 Gxme 75w-80Dokument2 SeitenTDS Shell Spirax s6 Gxme 75w-80rstec pyNoch keine Bewertungen

- Ecg Quick Guide PDFDokument7 SeitenEcg Quick Guide PDFansarijavedNoch keine Bewertungen

- Science 9-Quarter 2-Module-3Dokument28 SeitenScience 9-Quarter 2-Module-3Mon DyNoch keine Bewertungen

- Arann Magazine, Issue 1-2-Online VersionDokument36 SeitenArann Magazine, Issue 1-2-Online VersionmujismileNoch keine Bewertungen

- AppendicitisDokument7 SeitenAppendicitisTim LuoNoch keine Bewertungen

- #1 - The World'S Oldest First GraderDokument6 Seiten#1 - The World'S Oldest First GraderTran Van ThanhNoch keine Bewertungen

- Group 7 Worksheet No. 1 2Dokument24 SeitenGroup 7 Worksheet No. 1 2calliemozartNoch keine Bewertungen

- Wa0016Dokument3 SeitenWa0016Vinay DahiyaNoch keine Bewertungen

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- Piping Engineering Leadership for Process Plant ProjectsVon EverandPiping Engineering Leadership for Process Plant ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Well Integrity for Workovers and RecompletionsVon EverandWell Integrity for Workovers and RecompletionsBewertung: 5 von 5 Sternen5/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- An Applied Guide to Water and Effluent Treatment Plant DesignVon EverandAn Applied Guide to Water and Effluent Treatment Plant DesignBewertung: 5 von 5 Sternen5/5 (4)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlVon EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlBewertung: 4 von 5 Sternen4/5 (4)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingVon EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNoch keine Bewertungen

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideVon EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideBewertung: 2 von 5 Sternen2/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Advanced Production Decline Analysis and ApplicationVon EverandAdvanced Production Decline Analysis and ApplicationBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesVon EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesBewertung: 4 von 5 Sternen4/5 (2)

- A New Approach to HAZOP of Complex Chemical ProcessesVon EverandA New Approach to HAZOP of Complex Chemical ProcessesNoch keine Bewertungen

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen

- The Perfumed Pages of History: A Textbook on Fragrance CreationVon EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationBewertung: 4 von 5 Sternen4/5 (1)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersVon EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsVon EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottBewertung: 4 von 5 Sternen4/5 (6)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsVon EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNoch keine Bewertungen