Beruflich Dokumente

Kultur Dokumente

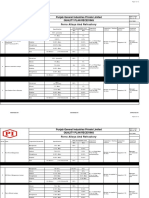

Bond Strength Testing: Test Name Principle

Hochgeladen von

rohit0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

157 Ansichten2 SeitenBond strength testing determines an adhesive's ability to remain bonded to a surface or hold two materials together under stress. There are various types of bond tests that apply forces directly to adhesives or bonded materials, including tensile, shear, and peel tests. Test results indicate the adhesive's bond strength in different stress directions or between coated surfaces and bonded substrates. Applicable standards specify procedures and equipment for bond tests of materials like metals, plastics, wood, and geosynthetics.

Originalbeschreibung:

Originaltitel

Bond Strength Testing

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenBond strength testing determines an adhesive's ability to remain bonded to a surface or hold two materials together under stress. There are various types of bond tests that apply forces directly to adhesives or bonded materials, including tensile, shear, and peel tests. Test results indicate the adhesive's bond strength in different stress directions or between coated surfaces and bonded substrates. Applicable standards specify procedures and equipment for bond tests of materials like metals, plastics, wood, and geosynthetics.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

157 Ansichten2 SeitenBond Strength Testing: Test Name Principle

Hochgeladen von

rohitBond strength testing determines an adhesive's ability to remain bonded to a surface or hold two materials together under stress. There are various types of bond tests that apply forces directly to adhesives or bonded materials, including tensile, shear, and peel tests. Test results indicate the adhesive's bond strength in different stress directions or between coated surfaces and bonded substrates. Applicable standards specify procedures and equipment for bond tests of materials like metals, plastics, wood, and geosynthetics.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Test Name Bond Strength Testing

Principle A bond test is used to determine the ability of an adhesive to remain in

contact with a surface or material while under stress or the adhesive’s

ability to hold together two materials as they are stressed. The bond

itself is tested after it has been applied and allowed to cure by either

applying a force directly to the adhesive in an attempt to remove it

from the material or by attempting to separate to materials to have

been connected to each other by the adhesive. The force is then either

steadily increased or remains constant and is applied to the bond until

it fails.

Methodology There are many different types of bond testing, but the most commonly

performed are tensile, shear and peel testing with torsional, impact,

and pull-off tests performed less often. Each bond test is used to

determine the adhesives bond strength in a given direction or under a

given type of stress. Nearly all bond testing will take one of two forms.

Either the adhesive will be applied to the surface of a material as a

type of coating and the adhesives’ bond strength is determined to be

its ability to remain in contact with the material while under stress or

the adhesive is applied between two rigid substrates and its bond

strength is determined as its ability to hold the two substrates together

while under stress.

Scope Adhesive Peel Stripping Strength of Bonds

Axially Loaded Butt Joint Test of Adhesives

Bond Strength Thermal Spray Coating Test Equipment

How to determine bond test machine requirements

Dental Adhesive & Material Tensile Adhesion Bond Strength

Bond Strength Testing of Plastics

Bond Strength Testing of Cement

Bond Strength Testing between an Adhesive and Metal

Plastic Pipe and Pipe Welds Testing

Applicable ASTM A944 Bond Strength Steel Reinforcement Rebar Test

standard

Machine

ASTM A981 Bond Strength of Steel Ground Anchors - Test

Machines

ASTM C198 Cold Bonding Refractory Mortar Test Equipment

ASTM C321 Bond Strength Mortars Test Equipment and

Solutions

ASTM D429 - Rubber to Metal Adhesion Test Equipment

ASTM D897 Tensile Strength Test Equipment for Metal to

Metal Adhesive Bonds

ASTM D903 180 degree Peel Strip Strength of Adhesive

Bonds

ASTM D905 Wood Adhesive Bonds in Shear by Compression

Loading

ASTM D1002 Lap Shear Testing for Adhesively Bonded

Metals

ASTM D3762 Adhesive-Bonded Surface Durability of

Aluminum (Wedge Test)

ASTM D4501 Block Shear Strength Testing Equipment for

Adhesive Bonds Between Rigid Substrates

ASTM D4884 Strength of Sewn or Thermally Bonded Seams

of Geotextiles

ASTM D5041 Fracture Strength in Cleavage of Adhesives in

Bonded Joints

ASTM D6496 Bonding Peel Strength Between the Top and

Bottom Layers of Needle-Punched Geosynthetic Clay Liners

ASTM D7005 Bond Strength (Ply Adhesion) of Geocomposites

ASTM F2724 Knee Dislocation Test Equipment

Das könnte Ihnen auch gefallen

- F1223 1479757-1Dokument9 SeitenF1223 1479757-1Thaweekarn ChangthongNoch keine Bewertungen

- Astm 1717Dokument21 SeitenAstm 1717Emmanuel100% (2)

- Astm G151Dokument15 SeitenAstm G151Testing TeamNoch keine Bewertungen

- F1440 1479757-1Dokument6 SeitenF1440 1479757-1Thaweekarn ChangthongNoch keine Bewertungen

- Astm Density d1505-03Dokument7 SeitenAstm Density d1505-03KASHIKA THAPA100% (1)

- Param XLW (PC) Auto Tensile Tester: ProfessionalDokument3 SeitenParam XLW (PC) Auto Tensile Tester: ProfessionalAamirMalik100% (1)

- Composition of Anorganic Bone For Surgical ImplantsDokument4 SeitenComposition of Anorganic Bone For Surgical ImplantsGustavo SuarezNoch keine Bewertungen

- E 96 - e 96M - 15Dokument13 SeitenE 96 - e 96M - 15ruben carcamoNoch keine Bewertungen

- Iso 14243 1 2002 FR PDFDokument8 SeitenIso 14243 1 2002 FR PDFRobe01Noch keine Bewertungen

- D 1415 - 88 R99 - Rde0mtu - PDFDokument5 SeitenD 1415 - 88 R99 - Rde0mtu - PDFGyna SHNoch keine Bewertungen

- Resistência Ao Rasgo (Elmendorf) - ASTM D1424-96Dokument8 SeitenResistência Ao Rasgo (Elmendorf) - ASTM D1424-96raissaNoch keine Bewertungen

- Understanding ESCRDokument9 SeitenUnderstanding ESCRimru2Noch keine Bewertungen

- ASTM D570.water Absorbtion-2010 PDFDokument4 SeitenASTM D570.water Absorbtion-2010 PDFticaruedaNoch keine Bewertungen

- Astm D 3767Dokument8 SeitenAstm D 3767jackie wang100% (1)

- E145-94 Standard Specification For Gravity-Convection and Forced-Ventilation OvensDokument2 SeitenE145-94 Standard Specification For Gravity-Convection and Forced-Ventilation OvensLê Duy ThăngNoch keine Bewertungen

- F1044 1479757-1Dokument5 SeitenF1044 1479757-1Thaweekarn ChangthongNoch keine Bewertungen

- F1536 1479757-1Dokument5 SeitenF1536 1479757-1Thaweekarn ChangthongNoch keine Bewertungen

- F1800 1479757-1Dokument6 SeitenF1800 1479757-1Thaweekarn ChangthongNoch keine Bewertungen

- Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureDokument2 SeitenLinear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperaturePyone Ei ZinNoch keine Bewertungen

- Astm F2579 - 10Dokument11 SeitenAstm F2579 - 10Bia NogueiraNoch keine Bewertungen

- Iso 06721-1-2011Dokument28 SeitenIso 06721-1-2011Ha Linh VuNoch keine Bewertungen

- Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureDokument2 SeitenLinear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureStevenf2002Noch keine Bewertungen

- Astm G176 PDFDokument9 SeitenAstm G176 PDFJohnny VargasNoch keine Bewertungen

- Astm d1434 1982 - CompressDokument12 SeitenAstm d1434 1982 - CompressManish Kumar SinghNoch keine Bewertungen

- ASTM D3578 Rubber GloveDokument5 SeitenASTM D3578 Rubber GloveSofiaProtopsalti100% (3)

- Standard Specification For Tensile Testing Machines For Textiles'Dokument8 SeitenStandard Specification For Tensile Testing Machines For Textiles'prateekNoch keine Bewertungen

- Mil STD 3010Dokument60 SeitenMil STD 3010Program ManagerNoch keine Bewertungen

- Rubber: ASTM D412 Tensile Properties of Vulcanized Rubber and Thermoplastic ElastomersDokument2 SeitenRubber: ASTM D412 Tensile Properties of Vulcanized Rubber and Thermoplastic ElastomersPrabhakar KambleNoch keine Bewertungen

- Mil PRF 28800FDokument88 SeitenMil PRF 28800FVinayNoch keine Bewertungen

- Recovery of Microorganisms From Skin Using The Cup Scrub TechniqueDokument3 SeitenRecovery of Microorganisms From Skin Using The Cup Scrub TechniqueEric GozzerNoch keine Bewertungen

- HDT 3-6 Vicat GB-AP911-06Dokument6 SeitenHDT 3-6 Vicat GB-AP911-06Diego Fernado AvendañoNoch keine Bewertungen

- Water Vapor Transmission of Materials: Standard Test Methods ForDokument12 SeitenWater Vapor Transmission of Materials: Standard Test Methods Formailtorubal2573Noch keine Bewertungen

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Dokument2 SeitenPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaNoch keine Bewertungen

- F648 1889433-1Dokument8 SeitenF648 1889433-1Kandido AcaNoch keine Bewertungen

- Galling Resistance of Materials: Standard Test Method ForDokument4 SeitenGalling Resistance of Materials: Standard Test Method ForKarin Soldatelli Borsato100% (1)

- Astm D412 Testing FixtureDokument3 SeitenAstm D412 Testing Fixturesimbua72Noch keine Bewertungen

- Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesDokument8 SeitenBurst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesraulNoch keine Bewertungen

- Crack Bridging Ability of Liquid-Applied Waterproofing MembraneDokument3 SeitenCrack Bridging Ability of Liquid-Applied Waterproofing Membranesabaris ksNoch keine Bewertungen

- Conditioning Plastics For TestingDokument4 SeitenConditioning Plastics For TestingROHITNoch keine Bewertungen

- A Comparison of Laboratory Abrasion and Field Wear ResultsDokument11 SeitenA Comparison of Laboratory Abrasion and Field Wear ResultschrisnnnNoch keine Bewertungen

- Standard Test Method For Strength Properties of Tissue Adhesives in Lap-Shear by Tension LoadingDokument6 SeitenStandard Test Method For Strength Properties of Tissue Adhesives in Lap-Shear by Tension Loadingגבריאל קליןNoch keine Bewertungen

- ASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodDokument9 SeitenASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodAndre Rodriguez Spirim100% (1)

- Astm d747 Pdqv6897Dokument5 SeitenAstm d747 Pdqv6897Nayth Andres GalazNoch keine Bewertungen

- Astm D4000 2004 PDFDokument19 SeitenAstm D4000 2004 PDFHARSHANoch keine Bewertungen

- ASTM D1000 10 Standard Test Methods For Pressure Sensitive Adhesive Coated Tapes Used ForDokument20 SeitenASTM D1000 10 Standard Test Methods For Pressure Sensitive Adhesive Coated Tapes Used ForsasikumareNoch keine Bewertungen

- Astm E2347Dokument5 SeitenAstm E2347aminNoch keine Bewertungen

- FLTM BP 101-01 Rubber Ozone ResistanceDokument10 SeitenFLTM BP 101-01 Rubber Ozone ResistanceFrancesco VignaliNoch keine Bewertungen

- D2990 01Dokument20 SeitenD2990 01alifaramarzNoch keine Bewertungen

- ASTM D 3354-96 Standard Test Method For Blocking Load of Plastic Film by The Parallel Plate MethodDokument5 SeitenASTM D 3354-96 Standard Test Method For Blocking Load of Plastic Film by The Parallel Plate MethodFahmi Ramadhan PutraNoch keine Bewertungen

- Tearing Strength of Fabrics by Trapezoid Procedure: Standard Test Method ForDokument7 SeitenTearing Strength of Fabrics by Trapezoid Procedure: Standard Test Method ForMaqsoodUlHassanChaudharyNoch keine Bewertungen

- Impact Attenuation of Playing Surface Systems and Materials: Standard Test Method ForDokument6 SeitenImpact Attenuation of Playing Surface Systems and Materials: Standard Test Method ForElif SarıoğluNoch keine Bewertungen

- E2141-06 EC Durability Test Method PDFDokument13 SeitenE2141-06 EC Durability Test Method PDFavik6294846Noch keine Bewertungen

- Tensile Bond TestDokument14 SeitenTensile Bond TestPanneer SelvamNoch keine Bewertungen

- ASTM C272 Water Absorption of Core Materials For Sandwich PDFDokument4 SeitenASTM C272 Water Absorption of Core Materials For Sandwich PDFSílvio Xavier SantosNoch keine Bewertungen

- D 1582 - 98 Rde1oditotgDokument2 SeitenD 1582 - 98 Rde1oditotgMarceloNoch keine Bewertungen

- Adhesion Testing, Adhesive TestingDokument3 SeitenAdhesion Testing, Adhesive TestingLabthinkchinaNoch keine Bewertungen

- D4896Dokument6 SeitenD4896Phillip TaiNoch keine Bewertungen

- Materials Testing 1Dokument58 SeitenMaterials Testing 1Vanvan BitonNoch keine Bewertungen

- Astm d7234Dokument1 SeiteAstm d7234Juan Manuel RodriguezNoch keine Bewertungen

- 16.0 Grade Wise Chemical CompositionDokument29 Seiten16.0 Grade Wise Chemical CompositionrohitNoch keine Bewertungen

- Production: Punjab General Industries Private Limited Plot 149-150, - Sector-24, Faridabad, Haryana-121005Dokument2 SeitenProduction: Punjab General Industries Private Limited Plot 149-150, - Sector-24, Faridabad, Haryana-121005rohitNoch keine Bewertungen

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DateDokument1 SeiteAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DaterohitNoch keine Bewertungen

- Iso 9001-2015Dokument1 SeiteIso 9001-2015rohitNoch keine Bewertungen

- As Per ISO 9001:2015 & IATF 16949:2016: Formula For Calculation of Liquidus TempratureDokument1 SeiteAs Per ISO 9001:2015 & IATF 16949:2016: Formula For Calculation of Liquidus TempraturerohitNoch keine Bewertungen

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DateDokument1 SeiteAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DaterohitNoch keine Bewertungen

- 11.0 Raw Material SpecificationDokument6 Seiten11.0 Raw Material SpecificationrohitNoch keine Bewertungen

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Dokument3 SeitenMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNoch keine Bewertungen

- 14.0grade Wise Scrap Charge Mix.Dokument8 Seiten14.0grade Wise Scrap Charge Mix.rohitNoch keine Bewertungen

- Pgil Master Ferro Alloy and Refrac ListDokument12 SeitenPgil Master Ferro Alloy and Refrac ListrohitNoch keine Bewertungen

- Creep Testing: Test Name PrincipleDokument2 SeitenCreep Testing: Test Name PrinciplerohitNoch keine Bewertungen

- Co-Efficient of Friction TestingDokument1 SeiteCo-Efficient of Friction TestingrohitNoch keine Bewertungen

- The Lee Company Industrial Microhydraulics Group - Quality ManualDokument65 SeitenThe Lee Company Industrial Microhydraulics Group - Quality Manualrohit100% (1)

- Weigh Balance Calibration CertificateDokument1 SeiteWeigh Balance Calibration Certificaterohit100% (3)

- Quality Manual Pgi-Ml-Qm: As Per IS / ISO / IEC 17025: 2017Dokument25 SeitenQuality Manual Pgi-Ml-Qm: As Per IS / ISO / IEC 17025: 2017rohit100% (6)

- Work Instructions Marking Machine (E9-P123)Dokument1 SeiteWork Instructions Marking Machine (E9-P123)rohitNoch keine Bewertungen

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Dokument3 SeitenMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNoch keine Bewertungen

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDokument1 SeiteSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNoch keine Bewertungen

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDokument1 SeiteSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNoch keine Bewertungen

- Detecting Susceptibility To Intergranular Attack in Austenitic Stainless SteelsDokument20 SeitenDetecting Susceptibility To Intergranular Attack in Austenitic Stainless SteelsrohitNoch keine Bewertungen

- Optimization of Continuous Casting Process in Steel Manufacturing IndustryDokument5 SeitenOptimization of Continuous Casting Process in Steel Manufacturing IndustryrohitNoch keine Bewertungen

- Job ResponsibilityDokument34 SeitenJob Responsibilityrohit100% (1)

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDokument1 SeiteSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNoch keine Bewertungen

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDokument1 SeiteSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNoch keine Bewertungen

- High-Temperature Quality of Accelerated SpheroidizDokument10 SeitenHigh-Temperature Quality of Accelerated SpheroidizrohitNoch keine Bewertungen

- China Email ListDokument3 SeitenChina Email ListRosie Brown40% (5)

- Biologic and Biophysical Technologies. FINALDokument28 SeitenBiologic and Biophysical Technologies. FINALRafael Miguel MallillinNoch keine Bewertungen

- Talking SwedishDokument32 SeitenTalking Swedishdiana jimenezNoch keine Bewertungen

- Contractions 29.01Dokument1 SeiteContractions 29.01Katita la OriginalNoch keine Bewertungen

- Ra 9293 Amending Ra 7836Dokument2 SeitenRa 9293 Amending Ra 7836vonoblesseNoch keine Bewertungen

- Peter Zumthor - Thinking Architecture PDFDokument33 SeitenPeter Zumthor - Thinking Architecture PDFDiana Sterian73% (11)

- Motivation MBADokument31 SeitenMotivation MBAAkshitaNoch keine Bewertungen

- Pico Power: A Boon For Rural Electrification: Rajat KapoorDokument8 SeitenPico Power: A Boon For Rural Electrification: Rajat KapoorBamNoch keine Bewertungen

- Different Strategies in TeachingDokument12 SeitenDifferent Strategies in TeachingCris MolinaNoch keine Bewertungen

- Tamang GrammarDokument12 SeitenTamang Grammarsoftdina100% (1)

- The Lion and The Boar Story EnglishDokument2 SeitenThe Lion and The Boar Story EnglishKemal AmarullahNoch keine Bewertungen

- 1.2 Introduction To PHP - PHP KeywordsDokument12 Seiten1.2 Introduction To PHP - PHP KeywordsOvie Nur FaizahNoch keine Bewertungen

- Math Studies Financial MathsDokument7 SeitenMath Studies Financial MathsGirish MishraNoch keine Bewertungen

- Ksiidc and KssidcDokument13 SeitenKsiidc and KssidckasperNoch keine Bewertungen

- Installing Hyperledger Fabric and Composer: Ser/latest/installing/development-To Ols - HTMLDokument13 SeitenInstalling Hyperledger Fabric and Composer: Ser/latest/installing/development-To Ols - HTMLVidhi jainNoch keine Bewertungen

- Hindu Succession-Male & FemaleDokument14 SeitenHindu Succession-Male & FemaleKumar MangalamNoch keine Bewertungen

- Ap Government Imperial PresidencyDokument2 SeitenAp Government Imperial Presidencyapi-234443616Noch keine Bewertungen

- List of All Run Commands For WindowsDokument10 SeitenList of All Run Commands For Windowsdixityog100% (1)

- PEOPLE v. ROBERTO QUIACHON Y BAYONADokument11 SeitenPEOPLE v. ROBERTO QUIACHON Y BAYONAMarkNoch keine Bewertungen

- MAPEH Q4 ScriptDokument4 SeitenMAPEH Q4 Scriptcharice maanoNoch keine Bewertungen

- Checklist-Telephone - Mobile ExpenseDokument2 SeitenChecklist-Telephone - Mobile ExpenseMichelle Domanacal UrsabiaNoch keine Bewertungen

- Global Strategy 3rd Edition Peng Solutions ManualDokument16 SeitenGlobal Strategy 3rd Edition Peng Solutions ManualJenniferThompsonxergb100% (13)

- Strength of Materials Aug 5 2017Dokument16 SeitenStrength of Materials Aug 5 2017MikaellaTeniolaNoch keine Bewertungen

- Rawson Homes Duplex DesignsDokument16 SeitenRawson Homes Duplex DesignsJhondy TibubosNoch keine Bewertungen

- People Vs SB - Paredes - Ex Post FactoDokument2 SeitenPeople Vs SB - Paredes - Ex Post FactoMara Aleah CaoileNoch keine Bewertungen

- Enzyme Kinetics Principles and MethodsDokument268 SeitenEnzyme Kinetics Principles and MethodsCarlos Carinelli100% (4)

- Job Board Week WhituDokument5 SeitenJob Board Week WhituAnonymous MZh1KUUXNoch keine Bewertungen

- (EN) Google Developer Policy - September 1, 2021Dokument56 Seiten(EN) Google Developer Policy - September 1, 2021JimmyNoch keine Bewertungen

- Buchanan, KeohaneDokument34 SeitenBuchanan, KeohaneFlorina BortoșNoch keine Bewertungen

- E5170s-22 LTE CPE - Quick Start Guide - 01 - English - ErP - C - LDokument24 SeitenE5170s-22 LTE CPE - Quick Start Guide - 01 - English - ErP - C - LNelsonNoch keine Bewertungen