Beruflich Dokumente

Kultur Dokumente

METALCLAD CeramAlloy CLAC PDF

Hochgeladen von

skOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

METALCLAD CeramAlloy CLAC PDF

Hochgeladen von

skCopyright:

Verfügbare Formate

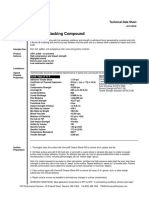

• Apply by Brush, Roller

or Flexible Applicator

• Requires No Heat

• Unlimited Shelf Life

• 100% Solids METALCLAD® CeramAlloy® CL+AC is a two component, 100% solids,

• Safe & Simple To Use liquid polymer composite used for repairing, resurfacing and coating

both damaged and new components to provide outstanding fluid flow

METALCLAD® CeramAlloy® erosion and corrosion resistance.

CL+AC is a High

When mixed, CeramAlloy® CL+AC is a viscous liquid. CeramAlloy®

Performance Polymer

CL+AC cures to a hard, ceramic-like material with an extremely smooth

Composite for resurfacing

and protecting all types of surface finish.

fluid flow equipment from

aggressive erosion and

corrosion damage.

Qualified for AFFF Stations

and high-traffic interior

passageways on U.S. Navy

vessels as detailed in

MIL-PRF-32171

Repairs & Protects...

• Heat Exchanger

Tube Sheets &

Water Boxes

• Pumps

• Valves & Pipework

• Housings & Tanks

• Cooling Towers

...and more ®

Toll Free: 888-4-ENECON (888-436-3266)

Tel: 516-349-0022 · Fax: 516-349-5522

info@enecon.com

6 Platinum Court · Medford, NY 11763-2251

Volume capacity per kg. 36 in3 / 592 cc

Surface Preparation - METALCLAD® CeramAlloy® CL+AC

Mixed density 0.061 lbs per in3 / 1.69 gm per cc

should only be applied to clean, dry and well roughened

Coverage rate per kg.

surfaces.

@ 12 - 15 mils 14 - 16 ft2 / 1.4 m2

Shelf life Indefinite 1. Remove all loose material and surface contamination and

Volume solids 100%

clean with a suitable solvent which leaves no residue on the

surface after evaporation such as acetone, MEK, isopropyl

Mixing ratio Base Activator

alcohol, etc.

By volume 3.3 1

2. Clean/roughen surface by abrasive blasting.

By weight 6 1

3. If necessary, apply moderate heat and/or allow the

component(s) to ‘leach’ to remove ingrained contaminants.

Ambient Working Machining Full Chemical

4. Thoroughly roughen surfaces by abrasive blasting to achieve

Temperature Life Light Load Mechanical Immersion a ‘white metal’ degree of cleanliness and an anchor pattern of

41oF 5 oC 4 hrs 48 hrs 96 hrs 10 days 3 mils.

o

59 F 15oC 2 hrs 24 hrs 48 hrs 5 days Note: In situations where adhesion is not desired, such as when

o

77 F 25oC 1 hr 12 hrs 24 hrs 3 days making molds and patterns or to ease future disassembly, apply

o

86 F 30oC 40 min 8 hrs 20 hrs 2 days a suitable release agent (mold release compound, paste wax,

etc.) to the appropriate surfaces.

Typical Values Test Method Mixing & Application - For your convenience, the

Compressive strength 13,500 psi 945 kg/cm2 ASTM D-695 CeramAlloy® CL+AC Base and Activator have been

Flexural strength 8,000 psi 560 kg/cm2 ASTM D-790 supplied in precisely measured quantities. Simply pour the

Izod impact strength 1.3 ft lbs/in 0.69 j/cm ASTM D-256 entire contents of the Activator container into the Base

Hardness - Shore D 85 ASTM D-2240 container and, using a spatula, putty knife or other

Taber Abrasion Resistance appropriate tool, mix thoroughly until the CeramAlloy®

CS-17 Wheel, 1000 cycles, 1 Kg Load Dry - 12.5 mm3 loss ASTM D-4060

CL+AC reaches a uniform, streak-free color.

H-10 Wheel, 1000 cycles, 1 Kg Load Wet - 160.6 mm3 loss ASTM D-4060

Tensile Shear Adhesion Apply the mixed material to the prepared surface using a

Steel 4000 psi 280 kg/cm2 ASTM D-1002 stiff-bristled brush, applicator or roller. As a guide, an even

Aluminum 2500 psi 175 kg/cm2 ASTM D-1002

thickness of approximately 12-15 mils per coat should be

Copper 3000 psi 210 kg/cm2 ASTM D-1002 obtained. A minimum two coat application is required.

Stainless steel 4100 psi 287 kg/cm2 ASTM D-1002 Overcoating should ideally be performed when the

Surface resistivity 15

1 x 10 ohms ASTM D-257 previously applied coat is just surface tacky; and certainly

Volume resistivity 1 x 1015 ohm/cm ASTM D-257 within 8 hours of the previous coat.

Dielectric constant 7.5 ASTM D-150

Dielectric strength 652 volts/mil ASTM D-115 Health & Safety - Every effort is made to insure that

Breakdown voltage 6.1 Kv ASTM D-115 ENECON® products are as simple and safe to use as

possible. Normal industry standards and practices for

Acetic acid (0-10%) . . . . . . . . EX Methyl alcohol . . . . . . . . . . G housekeeping, cleanliness and personal protection should

Acetic acid (10-20%) . . . . . . . G Methyl ethyl ketone . . . . . . . . G be observed.

Acetone . . . . . . . . . . . . . . G Nitric acid (0-10%) . . . . . . . . EX Please refer to the detailed SAFETY DATA SHEET (SDS)

Aviation fuel . . . . . . . . . . . . EX Nitric acid (10-20%) . . . . . . . . G supplied with the material (also available on request) for

Butyl alcohol . . . . . . . . . . . EX Phosphoric acid (0-5%) . . . . . . EX more information.

Calcium chloride . . . . . . . . . EX Phosphoric acid (5-10%) . . . . . G

Crude oil . . . . . . . . . . . . . EX Potassium chloride . . . . . . . . EX

Diesel fuel . . . . . . . . . . . . . EX Propyl alcohol . . . . . . . . . . . EX Cleaning Equipment - Wipe excess material from tools

Ethyl alcohol . . . . . . . . . . . G Sodium chloride . . . . . . . . . . EX immediately. Use acetone, MEK, isopropyl alcohol or similar

Gasoline . . . . . . . . . . . . . EX Sodium hydroxide . . . . . . . . . EX solvent as needed.

Heptane . . . . . . . . . . . . . . EX Sulfuric acid (0-10%) . . . . . . . EX

Hydrochloric acid (0-10%) . . . . . EX Sulfuric acid (10-20%) . . . . . . G Technical Support - The ENECON® engineering team is

Hydrochloric acid (10-20%) . . . . G Toluene . . . . . . . . . . . . . . G

always available to provide technical support and

Kerosene . . . . . . . . . . . . . EX Xylene . . . . . . . . . . . . . . EX

EX - Suitable for most applications including immersion. assistance. For guidance on difficult application procedures

G - Suitable for intermittent contact, splashes, etc. or for answers to simple questions, call your local

ENECON® Fluid Flow Systems Specialist or the ENECON®

Engineering Center.

All information contained herein is based on long term testing in our

®

laboratories as well as practical field experience and is believed to be reliable

and accurate. No condition or warranty is given covering the results from use of

our products in any particular case, whether the purpose is disclosed or not,

and we cannot accept liability if the desired results are not obtained.

Copyright © 2018 by ENECON® Corporation. All rights reserved. No part of this work may be

reproduced or used in any form or by any means - graphic, electronic or mechanical

including photocopying, recording, taping or information storage and retrieval systems -

without written permission of ENECON® Corporation.

Printed in the USA

February, 2018

Das könnte Ihnen auch gefallen

- METALCLAD CeramAlloy CPAC PDFDokument2 SeitenMETALCLAD CeramAlloy CPAC PDFskNoch keine Bewertungen

- Metalclad Ceramalloy Cp+Ac: Toll Free: 888-4-ENECON (888-436-3266)Dokument2 SeitenMetalclad Ceramalloy Cp+Ac: Toll Free: 888-4-ENECON (888-436-3266)mrchardNoch keine Bewertungen

- METALCLAD DurAlloy™Dokument2 SeitenMETALCLAD DurAlloy™Romie AntonoNoch keine Bewertungen

- DuralloyDokument2 SeitenDuralloyAlfred GomoeliaNoch keine Bewertungen

- Outstanding Chemical Resistance Apply by Brush, - Roller or Spray Unlimited Shelf Life - 100% Solids - Simple To Use - DurableDokument2 SeitenOutstanding Chemical Resistance Apply by Brush, - Roller or Spray Unlimited Shelf Life - 100% Solids - Simple To Use - DurableAlfred GomoeliaNoch keine Bewertungen

- Chemclad SC PDFDokument2 SeitenChemclad SC PDFskNoch keine Bewertungen

- Plastic Steel Putty (A) : Technical Data SheetDokument3 SeitenPlastic Steel Putty (A) : Technical Data SheetsanjayNoch keine Bewertungen

- Flexiclad Er PDFDokument2 SeitenFlexiclad Er PDFVincent AndiNoch keine Bewertungen

- Product Specification Sheet Belzona 1111Dokument2 SeitenProduct Specification Sheet Belzona 1111Quy RomNoch keine Bewertungen

- Epoxy Sealer SP810Dokument2 SeitenEpoxy Sealer SP810melvinkorahNoch keine Bewertungen

- Technical Data Sheet: DescriptionDokument4 SeitenTechnical Data Sheet: Descriptionerode els erodeNoch keine Bewertungen

- Belzona 1821: Product Specification SheetDokument2 SeitenBelzona 1821: Product Specification SheetAlex BravoNoch keine Bewertungen

- Technical Data: Plastic Steel Putty (A)Dokument4 SeitenTechnical Data: Plastic Steel Putty (A)francisNoch keine Bewertungen

- Belzona 1121: Product Specification SheetDokument2 SeitenBelzona 1121: Product Specification SheetQuy RomNoch keine Bewertungen

- Floropoxy 4700 TdsDokument3 SeitenFloropoxy 4700 TdsCarlos Rojas HandalNoch keine Bewertungen

- BELZONA 1111 Product Specification SheetDokument2 SeitenBELZONA 1111 Product Specification SheetMohamed NouzerNoch keine Bewertungen

- High Performance Backing Compound: Technical Data SheetDokument2 SeitenHigh Performance Backing Compound: Technical Data SheetNiku SamarthNoch keine Bewertungen

- High Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationDokument4 SeitenHigh Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationChandresh M SachdevNoch keine Bewertungen

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDokument2 SeitenLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNoch keine Bewertungen

- Bronze Putty: Technical Data SheetDokument2 SeitenBronze Putty: Technical Data SheetSharad ShahNoch keine Bewertungen

- Transocean - C5-M Typical Coating SystemDokument2 SeitenTransocean - C5-M Typical Coating SystemMuhammad Nu'manNoch keine Bewertungen

- Bipigard Coaltar Finish PDFDokument2 SeitenBipigard Coaltar Finish PDFKhirod KroutNoch keine Bewertungen

- Plasite 4100 PDS-3Dokument5 SeitenPlasite 4100 PDS-3Linnie McleodNoch keine Bewertungen

- AbraSphere PulvDokument2 SeitenAbraSphere PulverikaNoch keine Bewertungen

- TDS - PPro Wearing Compound - 012221S1Dokument3 SeitenTDS - PPro Wearing Compound - 012221S1Isabelo AbaoNoch keine Bewertungen

- Plastic Steel 5 Minute PuttyDokument3 SeitenPlastic Steel 5 Minute PuttyDivyanshu GuptaNoch keine Bewertungen

- Technical Data: Plastic Steel 5-Minute Putty (SF)Dokument4 SeitenTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNoch keine Bewertungen

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDokument2 SeitenWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNoch keine Bewertungen

- ENG Siliconizer RC200 TDSDokument2 SeitenENG Siliconizer RC200 TDSPedro PaulinoNoch keine Bewertungen

- Bipigard Coaltar FinishDokument2 SeitenBipigard Coaltar FinishKhirod Krout100% (1)

- NSF 61 PaintDokument2 SeitenNSF 61 Paintraviraj londheNoch keine Bewertungen

- Monneli Epofloor E250 - DOC - TECHNICAL - MAP - en - 963Dokument3 SeitenMonneli Epofloor E250 - DOC - TECHNICAL - MAP - en - 963Maha MuflehNoch keine Bewertungen

- Carbozinc 859Dokument2 SeitenCarbozinc 859Khemaraj PathNoch keine Bewertungen

- Strongcoat ConductiveDokument83 SeitenStrongcoat ConductiveAhmed AssafNoch keine Bewertungen

- 323+ Data SheetDokument5 Seiten323+ Data SheetSergioNoch keine Bewertungen

- Masteremaco P 5000: Single Component, Cement Based, Multi-Use, Bonding and Active Protective PrimerDokument2 SeitenMasteremaco P 5000: Single Component, Cement Based, Multi-Use, Bonding and Active Protective PrimerMuhammad Fadhil ImansyahNoch keine Bewertungen

- Carboguard 1209: Selection & Specification DataDokument4 SeitenCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Urethane Coating 165 PWDokument2 SeitenUrethane Coating 165 PWANIBALLOPEZVEGANoch keine Bewertungen

- F13 - Carboguard 893-Zn PDS 10-09Dokument2 SeitenF13 - Carboguard 893-Zn PDS 10-09naveenbaskaran1989Noch keine Bewertungen

- Florgard SL: Self Levelling Epoxy Based FlooringDokument3 SeitenFlorgard SL: Self Levelling Epoxy Based FlooringRavi KantNoch keine Bewertungen

- 3M Scotchkote Epoxy Primer GP220 - Rev2Dokument2 Seiten3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanNoch keine Bewertungen

- Quakebond J300Sr: The Infrastructure InnovatorsDokument2 SeitenQuakebond J300Sr: The Infrastructure Innovatorskhoirul ramadhanNoch keine Bewertungen

- Technical Data Sheet: Epoguard EnamelDokument3 SeitenTechnical Data Sheet: Epoguard Enameltrường phạmNoch keine Bewertungen

- AbraSphere 400Dokument2 SeitenAbraSphere 400erikaNoch keine Bewertungen

- Mastertop 1240: Epoxy Based High Strength Mortar Flooring SystemDokument2 SeitenMastertop 1240: Epoxy Based High Strength Mortar Flooring Systemdilshad khanNoch keine Bewertungen

- Carboguard 893: Selection & Specification DataDokument5 SeitenCarboguard 893: Selection & Specification DataQuy RomNoch keine Bewertungen

- Tds Al Jazeera Epoxy SealerDokument2 SeitenTds Al Jazeera Epoxy Sealermena ashrafNoch keine Bewertungen

- Carboguard 890 PDSDokument5 SeitenCarboguard 890 PDScrisNoch keine Bewertungen

- Belzona 1321: Product Specification SheetDokument2 SeitenBelzona 1321: Product Specification Sheetmehdi kamaliNoch keine Bewertungen

- Tds Aluminium Liquid SheetDokument2 SeitenTds Aluminium Liquid SheetRonnalyn TorresNoch keine Bewertungen

- Tuffkote: Epigard Epoxy Finish Bipigard Cte XLDokument2 SeitenTuffkote: Epigard Epoxy Finish Bipigard Cte XLSHATABDI- DELNoch keine Bewertungen

- Basf Mastertop 1240 Tds PDFDokument2 SeitenBasf Mastertop 1240 Tds PDFHari HaranNoch keine Bewertungen

- Carboguard 890 GF PDSDokument2 SeitenCarboguard 890 GF PDSfazeel mohammedNoch keine Bewertungen

- Epicon ARG: Technical DatasheetDokument3 SeitenEpicon ARG: Technical DatasheetBogdanBNoch keine Bewertungen

- 2 Ardacolor Xtrem Easy - EN - TMDokument2 Seiten2 Ardacolor Xtrem Easy - EN - TMAngelo Carlo MalabananNoch keine Bewertungen

- Carboguard 893 PDSDokument5 SeitenCarboguard 893 PDSUtomoNoch keine Bewertungen

- Crusher Backing: Technical InformationDokument1 SeiteCrusher Backing: Technical InformationjohnNoch keine Bewertungen

- Detailers Dictionary Volume 2: The Industry StandardVon EverandDetailers Dictionary Volume 2: The Industry StandardNoch keine Bewertungen

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Von EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Noch keine Bewertungen

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Chimneys Selection, Design and Engineering (BASED ON EN 1992-1-1, EN 1993-3-2, EN 1443, EN 13084-PARTS 1, 2, 4, 5, 6, 7 AND 8)Dokument34 SeitenChimneys Selection, Design and Engineering (BASED ON EN 1992-1-1, EN 1993-3-2, EN 1443, EN 13084-PARTS 1, 2, 4, 5, 6, 7 AND 8)skNoch keine Bewertungen

- Engineering Standard for Refractory SystemsDokument25 SeitenEngineering Standard for Refractory SystemszsmithNoch keine Bewertungen

- Onshore Ancillary Steel Structures: Dep SpecificationDokument19 SeitenOnshore Ancillary Steel Structures: Dep Specificationsk100% (4)

- Thermo-Lag 3000-P PDS PDFDokument7 SeitenThermo-Lag 3000-P PDS PDFskNoch keine Bewertungen

- Heating, Ventilation and Air Conditioning For Plant BuildingsDokument48 SeitenHeating, Ventilation and Air Conditioning For Plant Buildingssk50% (4)

- Carbothane 133 HB PDS PDFDokument5 SeitenCarbothane 133 HB PDS PDFskNoch keine Bewertungen

- Chemclad SC PDFDokument2 SeitenChemclad SC PDFskNoch keine Bewertungen

- World Class: Integrity & Maintenance SolutionsDokument2 SeitenWorld Class: Integrity & Maintenance SolutionsskNoch keine Bewertungen

- Technowrap H.A. Resin (Part A) PDFDokument6 SeitenTechnowrap H.A. Resin (Part A) PDFskNoch keine Bewertungen

- ICR Gulf Brochure PDFDokument2 SeitenICR Gulf Brochure PDFskNoch keine Bewertungen

- Technowrap H.A. Hardener (Part B) PDFDokument6 SeitenTechnowrap H.A. Hardener (Part B) PDFskNoch keine Bewertungen

- Technowrap 2K PDFDokument1 SeiteTechnowrap 2K PDFskNoch keine Bewertungen

- Technowrap 2K Cloth CS PDFDokument2 SeitenTechnowrap 2K Cloth CS PDFskNoch keine Bewertungen

- Plural Component XP70 Graco MachineDokument8 SeitenPlural Component XP70 Graco MachineskNoch keine Bewertungen

- Loctite SDS PDFDokument15 SeitenLoctite SDS PDFskNoch keine Bewertungen

- Certificates For Belzona 1391 & Belzona 1511 PDFDokument2 SeitenCertificates For Belzona 1391 & Belzona 1511 PDFskNoch keine Bewertungen

- Material Safety Data SheetDokument4 SeitenMaterial Safety Data SheetskNoch keine Bewertungen

- Avme Export-04.09.19Dokument5.350 SeitenAvme Export-04.09.19skNoch keine Bewertungen

- Enviroline 405HTR+wp+eng PDFDokument12 SeitenEnviroline 405HTR+wp+eng PDFskNoch keine Bewertungen

- Details of AbrasivesDokument6 SeitenDetails of AbrasivesskNoch keine Bewertungen

- Details of AbrasivesDokument6 SeitenDetails of AbrasivesskNoch keine Bewertungen

- Enviroline 2405 Application Guidelines: Protective Coatings Technical SupportDokument12 SeitenEnviroline 2405 Application Guidelines: Protective Coatings Technical SupportskNoch keine Bewertungen

- Duqm Refinery RAM ChecklistDokument8 SeitenDuqm Refinery RAM ChecklistskNoch keine Bewertungen

- Garnet SpecificationDokument2 SeitenGarnet SpecificationskNoch keine Bewertungen

- Abrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaDokument1 SeiteAbrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaskNoch keine Bewertungen

- Duqm Refinery RAM ChecklistDokument8 SeitenDuqm Refinery RAM ChecklistskNoch keine Bewertungen

- Garnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsDokument1 SeiteGarnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsskNoch keine Bewertungen

- Heat 4e Chap02 LectureDokument48 SeitenHeat 4e Chap02 LectureAbdul MohsinNoch keine Bewertungen

- How Objects Are Discovered and Monitored in Operations ManagerDokument2 SeitenHow Objects Are Discovered and Monitored in Operations ManagerAkhilesh NandanwarNoch keine Bewertungen

- Underfloor Wheelset Lathe: Operating / Maintenance ManualDokument84 SeitenUnderfloor Wheelset Lathe: Operating / Maintenance ManualMinh Canh100% (1)

- White Paper c11 737101Dokument13 SeitenWhite Paper c11 737101Aleksandar PopovicNoch keine Bewertungen

- N-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDDokument9 SeitenN-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDAnonymous p1ig0zX6p0Noch keine Bewertungen

- Alpha Eritrean Engineers Community's Magazine (October's Issue)Dokument8 SeitenAlpha Eritrean Engineers Community's Magazine (October's Issue)meharigrwNoch keine Bewertungen

- IGCSE Topical Past Papers PhysicsDokument64 SeitenIGCSE Topical Past Papers PhysicsHubert DMelloNoch keine Bewertungen

- Is 2705 PDFDokument17 SeitenIs 2705 PDFArijit Das100% (2)

- Prescolite Akt4 WH Specsheet 13Dokument2 SeitenPrescolite Akt4 WH Specsheet 13James HohensteinNoch keine Bewertungen

- Database Normalization Is The Process of Organizing The Fields and Tables of A Relational Database To Minimize RedundancyDokument2 SeitenDatabase Normalization Is The Process of Organizing The Fields and Tables of A Relational Database To Minimize RedundancyStan DitonaNoch keine Bewertungen

- Pilot Operated Safety Relief ValvesDokument6 SeitenPilot Operated Safety Relief ValvesfabioNoch keine Bewertungen

- Vend RegDokument49 SeitenVend RegProcaeHexdofNoch keine Bewertungen

- Non Conventional Machining PDFDokument55 SeitenNon Conventional Machining PDFMarthande100% (1)

- 2012 JBLM MILCON Tacoma Chamber of Commerce Oct2012Dokument13 Seiten2012 JBLM MILCON Tacoma Chamber of Commerce Oct2012Brackett427Noch keine Bewertungen

- 1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualDokument3 Seiten1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualBobbi Jo Bach-Oachs50% (2)

- Rotary EvaporatorDokument3 SeitenRotary EvaporatorDaryl ChianNoch keine Bewertungen

- Review of Antenna Designs for India's Regional Navigation Satellite SystemDokument9 SeitenReview of Antenna Designs for India's Regional Navigation Satellite SystemkhyatichavdaNoch keine Bewertungen

- Planning - THERM - Timber - H-I - H-V - 2016 (RAICO)Dokument542 SeitenPlanning - THERM - Timber - H-I - H-V - 2016 (RAICO)AnrStukNoch keine Bewertungen

- Face Recognization and Detection System For Attendance.Dokument39 SeitenFace Recognization and Detection System For Attendance.Deepanshu Sharma33% (3)

- Local buckling classificationDokument10 SeitenLocal buckling classificationHaya BakerNoch keine Bewertungen

- Heliobond GI WE3Dokument24 SeitenHeliobond GI WE3jarodzeeNoch keine Bewertungen

- Komatsu SAA6D114E-3D Engine ManualDokument634 SeitenKomatsu SAA6D114E-3D Engine ManualLuzioNetoNoch keine Bewertungen

- Hager Protection Devices TechnicalDokument70 SeitenHager Protection Devices TechnicalerreagaaNoch keine Bewertungen

- Lifetime Extension Steam TurbineDokument10 SeitenLifetime Extension Steam Turbineramakantinamdar100% (1)

- RCP-15 Drilling Fluid Agitator Parts ListDokument5 SeitenRCP-15 Drilling Fluid Agitator Parts ListwaleedNoch keine Bewertungen

- Commsys 2 2012 4Dokument47 SeitenCommsys 2 2012 4AnuNoch keine Bewertungen

- Eiac RQ Ib 004Dokument25 SeitenEiac RQ Ib 004esivaks2000100% (1)

- Price ListDokument2 SeitenPrice ListCHeng SOngco TAlosigNoch keine Bewertungen

- Cal Val Refile ValveDokument1 SeiteCal Val Refile Valvesourav samadderNoch keine Bewertungen

- Silent Sound TechnologyDokument22 SeitenSilent Sound TechnologyPurnima K100% (2)