Beruflich Dokumente

Kultur Dokumente

Steelwork Steelwork Continuation... Legend Metal Stud Walls: NHQC2 - CF - ST - DWG-00 - S01.03

Hochgeladen von

Ma'arif Nuzul AddibOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Steelwork Steelwork Continuation... Legend Metal Stud Walls: NHQC2 - CF - ST - DWG-00 - S01.03

Hochgeladen von

Ma'arif Nuzul AddibCopyright:

Verfügbare Formate

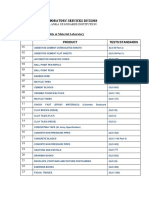

STEELWORK STEELWORK CONTINUATION...

METAL STUD WALLS LEGEND

S1. FABRICATE AND ERECT STRUCTURAL STEELWORK IN ACCORDANCE WITH AS4100-1998. S24. IMPORTED STRUCTURAL STEEL MATERIAL SW1. ALL DESIGN, WORKMANSHIP AND MATERIAL TO AS/NZS4600.

S2. PROVIDE HOLES, CLEATS AND FIXING FOR LIGHT STEEL/TIMBER FRAMING, FINISHES, ETC. SHOWN ON SW2. PROVIDE BRACING IN WALLS AS PER THE PLANS, USING PRYDA 30 X 0.8 TERM ABBREVIATION TERM ABBREVIATION

ALL STRUCTURAL STEELWORK USED ON THIS PROJECT SHALL BE COMPLIANT WITH AS4100, AND IN

ARCHITECTURAL DRAWINGS. GALVANISED STRAP BRACING OR EQUIVALENT FIXED TO THE STUD WALLS,

PARTICULAR: BOTH SIDES B/S MAXIMUM MAX

S3. THESE DRAWINGS HAVE BEEN PREPARED TO INDICATE THE STRUCTURAL INTENT. THE SHOP DETAILER IS OR NOGGING SECTIONS. FIX STRAP TO EACH STUD BY ONE (1) WAFER HEADED

- CERTIFIED MILL TEST REPORTS, OR TEST CERTIFICATES SHALL BE PROVIDED AS EVIDENCE OF BOTTOM B MINIMUM MIN

TO USE THESE DRAWINGS AS A BASIS FOR DIMENSIONAL COORDINATION WITH OTHER CONSULTANT'S SELF DRILLING METAL SCREW (4.8mm DIAMETER).

COMPLIANCE WITH THE STANDARDS REFERRED TO IN AS4100. THESE CERTIFICATES SHALL BE BLOCK WALL BW MISCELLANEOUS MISC

DRAWINGS AND IS TO PREPARE DETAILED SHOP DRAWINGS. WHERE NECESSARY, THE SHOP DETAILER IS TOP TRACK 1.15 BMT (MAY BE SLOPING)

SUBMITTED TO NORTHROP CONSULTING ENGINEERS FOR APPROVAL PRIOR TO COMMENCEMENT OF BRICK WALL BRW NEAR FACE NF

TO MAKE ASSUMPTIONS AND SUBMIT TO NORTHROP CONSULTING ENGINEERS FOR RESOLUTION. SHOP

FABRICATION.

DETAILER IS TO ALLOW TO RE-WORK SHOP DRAWINGS AS NECESSARY. FABRICATOR SHALL PREPARE CENTRALLY PLACED CENT NEAR SIDE N/S

- PROVIDE TEST CERTIFICATED FOR COMPLIANCE FOR ALL FASTENERS. THESE CERTIFICATES SHALL

SHOP DRAWINGS AND SUBMIT THEM TO THE BUILDER FOR THEIR APPROVAL. BUILDER SHALL LODGE TWO CENTRE LINE CL NOMINAL NOM

BE SUBMITTED TO NORTHROP CONSULTING ENGINEERS FOR APPROVAL PRIOR TO FABRICATION. DOUBLE STUD

HARD COPIES OF APPROVED DRAWINGS TO NORTHROP CONSULTING ENGINEERS FOR REVIEW PRIOR TO OR STEEL COLUMN CENTRES CTS NOT SHOWN ON PLAN NSOP

- FOR COLD FORMED SECTIONS A "CERTIFICATE OF CONFORMITY TO AS1163-1991" SHALL BE

FABRICATION, (ALLOW 5 WORKING DAYS FOR REVIEW). RONDO LIPPED CIRCULAR HOLLOW CHS NOT SHOWN ON NSOE

SUBMITTED TO NORTHROP CONSULTING ENGINEERS FOR APPROVAL PRIOR TO FABRICATION.

S4. TYPICAL STEELWORK CONNECTIONS (UNLESS NOTED OTHERWISE): STUDS SHOWN THUS SECTION ELEVATION

- CERTIFICATES SHALL ONLY BE ACCEPTED FROM TESTING COMPANIES ACCREDITED BY A TESTING

- COLUMN BASE PLATES: 10 BASE PLATE, 4/M16 HILTI HIT-HY200-R CHEMICAL INJECTION ANCHORS. CONCRETE CONC NOT TO SCALE NTS

AUTHORITY RECOGNISED IN AUSTRALIA, EG NATA or JAS-ANZ CERTIFIED.

45°

- BEAM TO TOP OF COLUMN: CAP PLATE, 2 BOLTS TO CHANNELS, 4 BOLTS TO RHS/CHS/SHS/UB/UC. CONCRETE WALL CW OPPOSITE OPP

- UNIDENTIFIED STEEL ie. ANY STEEL THAT IS NOT ACCOMPANIED WITH EVIDENCE STATING ADDITIONAL 1-M10

- BEAM TO SIDE OF COLUMN: FIN PLATE, 2 BOLTS. COMPLIANCE WITH THE REQUIREMENT OF AS4100 SHALL ONLY BE USED STRICTLY IN CONSTRUCTION JOINT CJ OVERALL O/A

MASONRY ANCHOR BOTTOM TRACK 1.15 BMT

- BEAM TO SIDE OF BEAM: END OR FIN PLATE, 2 BOLTS. ACCORDANCE WITH CLAUSE 2.2.3 OF AS4100. DEEP/DEPTH D PARALLEL PFC

100 FROM END STUD

- COLUMNS TO TOP OF BEAM: BASE PLATE, 2 BOLTS TO CHANNELS, 4 BOLTS TO UB/UC SECTIONS. IF MATERIALS SUPPLIED AND INSTALLED ARE SUBSEQUENTLY PROVEN TO BE NON COMPLIANT WITH THE DIAMETER DIA FLANGE CHANNEL

GALVANISED 30 x 0.8 U.N.O. STRAP BRACING 1 SIDE OF WALL

- ALL ROOF & WALL BRACING: CLEAT PLATES, 2 BOLTS. SPECIFIED AUSTRALIAN STANDARDS IT SHALL BE THE CONTRACTOR'S RESPONSIBILITY AND COST TO DIAMETER INSIDE ID PLATE PL

WITH TENSIONER TYP. BEND BRACE UNDER OR OVER TRACKS

- PURLINS/WALL GIRTS: 8 CLEAT PLATES, 2 PURLIN BOLTS. UNDERTAKE NATA OR EQUIVALENT CERTIFIED TESTING TO PROVE CONFORMANCE TO THE AUSTRALIAN DIAMETER NOMINAL DN PERMANENT ACTION G

AND FIX AFTER FOLD WITH 2-4.87mm DIA SELF DRILLING

UNLESS NOTED OTHERWISE, USE: STANDARDS AND DESIGN SPECIFICATIONS. SIMILARLY ANY RECTIFICATION WORKS THAT MAY DIAMETER OUTSIDE OD (DEAD LOAD)

METAL SCREWS OR 1-M10 MASONRY ANCHOR TO CONCRETE SLAB

- 10mm BASE, CAP, GUSSET, FIN AND END PLATES. SUBSEQUENTLY BE REQUIRED TO SATISFY AUSTRALIAN CODE REQUIREMENT SHALL BE THE RESPONSIBILITY POST TENSION PT

BRACING DETAIL (NOGGINGS NOT SHOWN). DRAWING DWG

- M20 8.8/S BOLTS. (4.6/S GRADE TO BE USED FOR HOLD DOWN BOLTS). OF THE CONTRACTOR. QUANTITY QTY

EACH FACE EF

SW3. PROVIDE LIPPED AND GALVANISED WALL STUDS AS FOLLOWS U.N.O. ON DRAWINGS. RADIUS RAD

- 6mm CONTINUOUS FILLET WELDS MADE WITH E4918 MILD STEEL ELECTRODES. EACH WAY EW

- ALL WELDS SP CATEGORY. RECTANGULAR RHS

WALL TYPE SPACING (mm) MAX. HEIGHT EQUAL EQ

S5. NO PAINT ON MATING SURFACES WITH TF OR TB BOLTING UNLESS APPROVED BY NORTHROP CONSULTING HOLLOW SECTION

EQUAL ANGLE EA

ENGINEERS. INTERNAL REINFORCED CONCRETE RC

S6. TF or TB BOLTS TO BE INSTALLED WITH ONE HARDENED WASHER UNDER THE TURNED PART. PURLINS AND GIRTS 92.1 x 0.55 BMT

600 4200 EXISTING

EXPANSION JOINT

EXST

EJ

REINFORCEMENT REINF

S7. USE LOAD INDICATING WASHERS FOR ALL TB AND TF CONNECTIONS. PG1. THE SUSPENSION OF CEILINGS,SERVICES ETC FROM PURLINS AND GIRTS SHALL BE IN ACCORDANCE WITH REQUIRED REQ'D

EXTERNAL AND FAR SIDE F/S

S8. ALL BOLTS, SCREWS, HOLD DOWN BOLTS, MASONRY ANCHORS SHALL BE HOT DIP GALVANISED TO THE APPROVED METHODS DETAILED BELOW; SQUARE SQ

LINED INTERNALLY 600 3400 FAR FACE FF

AS1214-1983, AS/NZS 4534-2006, AS/NZS 4680-2006 & AS/NZS 4792-2006. NO CONNECTION SHALL 92.1 x 0.75 BMT SQUARED SHS

FINISHED FLOOR LEVEL FFL

HAVE LESS THAN 2 BOLTS. ALL BOLTS AND WASHERS SHALL BE GALVANISED. ALL HOLES SHALL BE HOLLOW SECTION

EXTERNAL AND NOT FLAT FL

2mm LARGER THAN THE BOLT DIAMETER UNLESS NOTED OTHERWISE. TOP T

LINED INTERNALLY 600 2500 GALVANISED GALV

S9. MINIMUM YIELD STRESS: TOP & BOTTOM T&B

92.1 x 0.75 BMT 600 3200 GENERAL PURPOSE GPB

- HOT ROLLED SECTIONS = 300MPa. 92.1 x 1.15 BMT TYPICAL TYP

LOAD BRACKET

- SQUARE HOLLOW SECTIONS = 350MPa. UNDER SIDE U/S

HIGH/HEIGHT H

- RECTANGULAR HOLLOW SECTIONS = 350MPa. UNEQUAL ANGLE UA

APPROVED NON-APPROVED SW4. PROVIDE NOGGINGS AT 1.6 METRES CTS MAX U.N.0. NOGGING SECTION HORIZONTAL HORIZ

- CIRCULAR HOLLOW SECTION = 250MPa. UNIVERSAL BEAM UB

SHALL BE 0.75 BMT. NOGGINGS SHALL BE MECHANICALLY FIXED TO STUDS AS IMPOSED ACTION Q

- HOT ROLLED PLATE = 250MPa. PG2. MINIMUM YIELD STRESSES OF PURLINS AND GIRTS TO BE 450MPa. UNIVERSAL COLUMN UC

PER MANUFACTURERS SPECIFICATIONS. (LIVE LOAD)

S10. COLD FORMED SECTIONS TO CONFORM WITH: SURFACE TREATMENT OF ALL PURLINS AND GIRTS TO BE 350g/m² IN ACCORDANCE WITH AS1397-2001 UNLESS NOTED UNO

SW5. PROVIDE DOUBLE 1.15mm 'C' CHANNEL STUDS (BOXED) AND 1 EXTRA STUD INTERSECTION POINT IP

- AS/NZS 1594-2002, AS/NZS 1595-1998, AS/NZS 4600-2005 AND AS 1397-2001, AS1397, U.N.O. LAPS, BRIDGING, BRACKETS AND PURLIN BOLTS IN ACCORDANCE WITH MANUFACTURER'S OTHERWISE

AT SIDES OF OPENING. LONG/LENGTH L

AS/NZS1594 AND AS/NZS1595. INSTRUCTIONS. VERTICAL VERT

SW6. PROVIDE DOUBLE 1.15mm 'C' CHANNEL STUDS (BOXED) LENGTH VARIES LV

- MINIMUM YIELD STRESSES SECTIONS 450MPa. PG3. UNLESS OTHERWISE DETAILED FABRICATOR SHALL PROVIDE C10015 TRIMMER PURLINS ALONG WITH WIDE/WIDTH W

AT INTERMEDIATE GLAZING SECTIONS:

S11. SURFACE TREATMENT UNLESS NOTED OTHERWISE: GENERAL PURPOSE BRACKETS TO SUPPORT EDGE OF ROOF SHEETING AT ALL HIPS, VALLEYS AND

- PROTECTED FROM WEATHER = AS/NZS 2312-IZS2. PENETRATIONS.

- EXPOSED TO WEATHER = AS/NZS 2312-IZS2. PG4. UNLESS OTHERWISE DETAILED, FABRICATOR SHALL ALLOW TO PROVIDE ONE ROW OF BRIDGING FOR DOUBLE BOXED

PURLINS SPANNING UP TO 4.0m, TWO ROWS FOR PURLINS SPANNING BETWEEN 4.0m AND 8.0m AND STUD OR STEEL

2800 MAX.

- BUILT INTO THE INTERNAL SKIN OF EXTERNAL WALLS = AS/NZS 2312-IZS2.

THREE ROWS FOR SPANS GREATER THAN 8.0m INSTALLED IN ACCORDANCE WITH MANUFACTURER'S STEEL COLUMN OR COLUMN

**REFER TO PURLIN & GIRTS NOTES FOR SURFACE TREATMENT OF THESE ITEMS**

S12. UNLESS OTHERWISE DETAILED, FABRICATOR SHALL PROVIDE C100 15 TRIMMER PURLINS ALONG WITH GENERAL WRITTEN INSTRUCTIONS. DOUBLE BOXED STUD

PURPOSE BRACKETS TO SUPPORT EDGE OF ROOF SHEETING AT ALL HIPS, VALLEYS AND PENETRATIONS. PG5. PURLIN CLEATS SHALL GENERALLY BE MINIMUM 75 WIDE x 8 PLATE U.N.O. WHERE THE DISTANCE AND 1 EXTRA STUD

FIX CROSS BRACING TO PURLINS AT 3000 MAX CENTRES WITH M10 BOLTS OR M6 HOOKS. BOLTS ARE TO BETWEEN THE UNDERSIDE OF PURLIN AND THE TOP OF THE BEAM EXCEEDS 150mm THE CLEATS SHALL AT SIDES OF OPENING

S13.

BE MECHANICALLY FIXED TO PURLINS, WITH HOOKS TO BE LOOPED THROUGH THE WEB OF THE PURLINS BE MINIMUM 75 x 6 EA. UP TO A MAXIMUM HEIGHT OF 800mm.

PG6. PURLINS SHALL BE LAPPED IN ACCORDANCE WITH MANUFACTURER'S RECOMMENDATIONS UNLESS SHOWN 2500 MAX.

AND SECURED USING A NUT TO ENSURE THEY WILL NOT BECOME LOOSE DURING MOVEMENT OF THE ROOF.

ON THE DRAWINGS. HEAD AND SILL MEMBERS

ALTERNATIVELY, GALVANISED STRAP MAY BE USED TO SECURE THE BRACING. THE STRAP IS TO BE

1. UP TO 1800 SPAN - 92x1.15 'C' CHANNEL STUD

INSTALLED TO LIFT THE BRACE SUCH THAT IT IS PLUMB, WITH THE BRACE SCREW FIXED TO THE WEB OF

2. UP TO 2500 SPAN - 3x92x1.15 'C' CHANNEL STUD

THE PURLIN AT BOTH ENDS USING 2/12-14 TEKS SCREWS.

S14. ALL BURIED STEELWORK TO BE TREATED BY: SW7. UNLESS NOTED OTHERWISE, STUD WALLS SHALL BE NON LOAD BEARING.

- THE APPLICATION OF A SINGLE COAT OF INTERNATIONAL PROTECTIVE COATINGS INTERZONE 954 WORKPLACE HEALTH AND SAFETY ALLOW FOR DEFLECTION OF STUDS WITHIN TOP TRACK AT 20mm.

APPLIED TO BARE CLEAN STEEL (THICKNESS 300-400 MICRONS). APPLY TO WHOLE OF RELEVANT WHS1. THE CONTRACTOR AND ALL SUBCONTRACTORS ARE RESPONSIBLE FOR CONSTRUCTING THE WORK IN SW8. FIX BOTTOM TRACK OF BRACED PANELS TO CONCRETE FLOOR AS PER SW2.

MEMBER, TOP COAT IF REQUIRED BY ARCHITECT FOR VISUAL APPEARANCE. ACCORDANCE WITH THE WORK HEALTH AND SAFETY (WHS) ACT 2011; WHS REGULATIONS 2011; FOR ALL OTHER FIXINGS REFER TO MANUFACTURERS SPECIFICATION.

OR RELEVANT CODES OF PRACTICE, AUSTRALIAN STANDARDS AND OTHER REGULATORY REQUIREMENTS. SW9. TOP PLATES SHALL BE FIXED TO THE UNDERSIDE OF THE SLAB UNLESS

- THE APPLICATION OF HDG AS SPECIFIED IN S11 ABOVE FOLLOWED BY AN APPLICATION OF TWO NOTED OTHERWISE. SHOT FIX RONDO DEFLECTION HEAD TRACKS TO THE

VERIFIER: -

THE PRINCIPLE CONTRACTOR MUST INFORM ALL STAKEHOLDERS, INCLUDING NORTHROP, OF NEW

COATS OF INTERNATIONAL PROTECTIVE COATINGS INTERPLUS 1180 (EACH COAT 150-250 MICRONS) HAZARDS IDENTIFIED IN THE COURSE OF PLANNING AND UNDERTAKING THE WORKS. UNDERSIDE OF SLABS/BEAMS.

WHERE BURIED IN THE GROUND. WHS2. DURING THE DESIGN OF THE STRUCTURE NORTHROP HAS IDENTIFIED RESIDUAL HAZARDS RELATING TO

THEN THE DESIGN OF THE STRUCTURAL WORKS THAT WE CONSIDER TO BE UNUSUAL OR NON-TYPICAL.

- CONCRETE ENCASE STEELWORK WITH MASS CONCRETE (MINIMUM 75mm COVER TO STEELWORK). HAZARDS WHICH ARE NORMAL WORKPLACE HAZARDS, ARE TO BE MANAGED BY PERSONS IN CONTROL FIRE PROTECTION OF STEELWORK

S15. STEELWORK TO BE CONCRETE ENCASED FOR FIRE RATING PURPOSES SHALL BE FREE FROM ALL LOOSE OF THE WORKPLACE THROUGH A WHS SYSTEM TO MANAGE THE NORMAL HAZARDS ASSOCIATED WITH FP1. PROVIDE FIRE PROTECTION TO ALL PERMANENT STRUCTURAL STEEL MEMBERS AND CONNECTIONS.

RUST, LOOSE MILL SCALE, DIRT, OIL, GREASE, ETC. AND REINFORCED WITH SL41 FABRIC OR EQUIVALENT CONSTRUCTION, USE AND MAINTENANCE OF THE STRUCTURE. THE RESIDUAL HAZARDS IDENTIFIED ON REFER TO MCD FIRE ENGINEERING REPORT FOR REQUIRED FRLs.

BLACK IRON WIRE, 3mm DIA. THE NORTHROP DRAWINGS ARE NOT AN ENTIRE ASSESSMENT OF HAZARDS, AND DO NOT RELIEVE FP2. REINSTATE ANY FIRE PROTECTION REMOVED FROM EXISTING STRUCTURAL STEELWORK.

S16. BOLT SYMBOLS: OTHER PARTIES OR STAKEHOLDERS OF THE THEIR RESPONSIBILITY UNDER THE WHS ACT 2011, WHS FP3. INSTALL FIRE PROTECTION MATERIALS IN ACCORDANCE WITH THE MANUFACTURER'S WRITTEN

- 4.6/S = GRADE 4.6 BOLT / SNUG TIGHTENED. REGULATIONS 2011, AND THE CODE OF PRACTICE FOR SAFE DESIGN OF STRUCTURES. SPECIFICATIONS.

- 8.8/S = GRADE 8.8 BOLT / SNUG TIGHTENED. WHS3. TEMPORARY BRACING AND SUPPORT OF STRUCTURE IS THE RESPONSIBILITY OF THE CONTRACTOR AND FP4. PROVIDE CERTIFICATION OF FIRE PROTECTION ON COMPLETION.

- 8.8/TF = GRADE 8.8 BOLT / FULLY TENSIONED FRICTION TYPE (USE LOAD INDICATOR WASHERS). SHALL BE MAINTAINED DURING ALL STAGES OF CONSTRUCTION.

JOB MANAGER: JL

- 8.8/TB = GRADE 8.8 BOLT / FULLY TENSIONED BEARING TYPE (USE LOAD INDICATOR WASHERS).

WHS4. RESIDUAL HAZARDS ARE SHOWN ON THE NORTHROP DRAWINGS.

S17. THE CONTRACTOR SHALL SUPPLY WRITTEN CERTIFICATION TO THE STRUCTURAL ENGINEER PRIOR TO THE

IDENTIFIED BY:

ERECTION OF ANY STRUCTURAL STEEL STATING THAT THE BOLTS PROPOSED TO BE USED COMPLY WITH S1

AS/NZS 1252-1996. HIGH STRENGTH BOLTS (8.8) ARE NOT TO BE WELDED.

S18. THE FABRICATION AND ERECTION OF THE STRUCTURAL STEEL WORK SHALL BE SUPERVISED BY A

QUALIFIED PERSON EXPERIENCED IN SUCH SUPERVISION, IN ORDER TO ENSURE THAT ALL REQUIREMENTS

S19.

OF THE DESIGN ARE MET.

ALL MEMBERS SHALL BE SUPPLIED IN SINGLE LENGTHS. SPLICES SHALL ONLY BE PERMITTED IN

GREENSTAR

LOCATIONS SHOWN ON THE STRUCTURAL DRAWINGS.

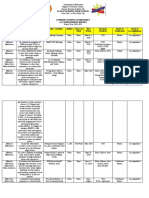

S20. ALL BUTT WELDS SHALL BE COMPLETE PENETRATION BUTT WELDS CATEGORY SP TO AS1554.1-2004 U.N.O 13.2 1 point is available TBC: Requirement of the

THE EXTENT ON NON-DESTRUCTIVE WELD EXAMINATION SHALL BE AS NOTED BELOW: Engineered 1 (high risk) where at least 95% of ESD Master Specification. 3

Wood... all engineered wood... ...

- RADIOGRAPHIC OR ULTRASONIC EXAMINATION SHALL BE TO AS/NZS 1554.1-2004, AS 2177-2006

DESIGNED: MK

AND AS2207-2007 AS APPROPRIATE.

20.1 1 point is available TBC: Credit requirements

S21. GROUT ALL STEEL BASES BY DRY PACKING USING GROUT WHICH IS NON-SHRINK AND HAS A MINIMUM

Structural 1 (high risk) where 95% of the should be met if HY 3

COMPRESSIVE STRENGTH AT 7 DAYS OF 40MPa. and... building’s steel (by mas... sources steel from...

S22. PROVIDE SEAL PLATES TO THE ENDS OF ALL HOLLOW SECTIONS, WITH 'BREATHER' HOLES IF MEMBERS

ARE TO BE HOT DIP GALVANISED.

1 point is available Achieved: Requirements

S23. THESE DRAWINGS MAY NOT IDENTIFY ALL SECONDARY STEELWORK ELEMENTS THAT ARE REQUIRED FOR

25/06/2020 11:49:52 AM

20.2 Timber 1 (high risk) where at least 95% (by of the ESD Master 1

SUPPORT, FIXING AND FINISHING OF GLAZING, CLADDING AND LINING. THE TENDERER IS RESPONSIBLE FOR

cost) of all timber used... Specification. Typical...

THE INCLUSION OF SUCH STEELWORK ELEMENTS TO THE EXTENT REQUIRED ON THE ARCHITECT'S

DRAWINGS.

20.3 1 point is available Achieved: Refer to the

Permanent 1 (high risk) where 90% (by cost) of ESD Master Specification 1

Project Status

Formwork,... all permanent formwork... for product requiremen...

DRAWN: MH

AMMENDMENTS STRUC, CIVIL PROJECT NORTH

ALL SETOUT TO ARCHITECT'S DRAWINGS. NORTHROP ENGINEERS PERUMAL PEDAVOLI ARCHITECTS

A

REV

JL

BY DATE

09.08.19 50% ISSUE

DESCRIPTION

DIMENSIONS TO BE VERIFIED WITH ARCHITECT AND (02) 9241 4188 T: 02 9291 0000

WEB: www.pp-a.com.au

CATHERINE FIELD PS SCALE 1 : 1 @ A1

B JL 17.09.19 ISSUED FOR SCHEMATIC DESIGN

BUILDER BEFORE COMMENCING SHOP DRAWINGS OR MECH, ELEC Nominated Architect:

DRAWN CHECKED VERIFIED DATE

C JL 18.12.19 75% ISSUE SITE WORK. NORTHROP ACCEPTS NO RESPONSIBILITY STEENSEN VARMING

(02) 9967 2200

Vince Pedavoli NSW reg No.5045 NEW HIGH QUALITY CLASSROOMS MH JL - 25.06.20

D JL 20.12.19 ISSUED FOR DETAILED DESIGN FOR THE USABILITY, COMPLETENESS OR SCALE OF

E JL 24.01.20 REVISED FOR DETAILED DESIGN DRAWINGS TRANSFERRED ELECTRONICALLY. Sydney HYD DRAWING NAME DRAWING NUMBER REVISION

DRAWINGS NOT TO BE USED FOR CONSTRUCTION WOOLACOTTS

F JL 20.03.20 REVISED FOR DETAIL DESIGN

Level 11, 345 George Street, Sydney, N.S.W. 2000 (02) 8241 9900 STRUCTURAL SPECIFICATION - SHEET 3 PROJECT CODE SCH. REF. DISC. TYPE SERIES#

G

G JL 25.06.20 ISSUED FOR CROWN CERTIFICATE UNLESS VERIFICATION SIGNATURE HAS BEEN ADDED

Ph (02) 9241 4188 Email: sydney@northrop.com.au FIRE LANDSCAPING

THE COPYRIGHT OF THIS DRAWING REMAINS WITH

NORTHROP CONSULTING ENGINEERS PTY LTD

ABN 81 094 433 100 MCD FIRE ENGINEERING

(04) 2392 2745

TAYLOR BRAMMER LANDS. ARCH.

(02) 9387 8855

NHQC2 - CF - ST - DWG-00_S01.03

Das könnte Ihnen auch gefallen

- Shear in Inclined WebsDokument2 SeitenShear in Inclined WebsjologscresenciaNoch keine Bewertungen

- Heat Transfer Lab AssignmentDokument5 SeitenHeat Transfer Lab AssignmentChristyNoch keine Bewertungen

- How Hydraulic Valve Lifters WorkDokument1 SeiteHow Hydraulic Valve Lifters WorkSanket Sabale100% (1)

- General Construction NotesDokument1 SeiteGeneral Construction NotesjanelleNoch keine Bewertungen

- Pipe Support - Type 3Dokument17 SeitenPipe Support - Type 3Angelique SutantoNoch keine Bewertungen

- Book - Advanced Steel Structures, Fire and Fatigue Design - by W LuDokument118 SeitenBook - Advanced Steel Structures, Fire and Fatigue Design - by W LuAbbes ChakchoukNoch keine Bewertungen

- Design Mega Columns-N-M ImperialDokument27 SeitenDesign Mega Columns-N-M Imperialtuanna2000Noch keine Bewertungen

- Chapter 4 - Bending & Shear Capacity - 4.3.2Dokument2 SeitenChapter 4 - Bending & Shear Capacity - 4.3.2NIBEDITA DEYNoch keine Bewertungen

- Hot Rolled Steel ConnectionsDokument16 SeitenHot Rolled Steel ConnectionsakhileshgojeNoch keine Bewertungen

- Designing Property Drainage SystemsDokument287 SeitenDesigning Property Drainage SystemsUsama TahirNoch keine Bewertungen

- Chemical Anchoring ChemSet Reo502Dokument2 SeitenChemical Anchoring ChemSet Reo502James MizziNoch keine Bewertungen

- Corrsion AssessmentDokument27 SeitenCorrsion Assessmentanilsmg09Noch keine Bewertungen

- 3S Structural Engineering Design Manual - Revision 5Dokument74 Seiten3S Structural Engineering Design Manual - Revision 5Lampard ChenNoch keine Bewertungen

- Asphalt Plug JointDokument103 SeitenAsphalt Plug JointMahmood MuftiNoch keine Bewertungen

- Design Guidelines For Bridge Size CulvertsDokument28 SeitenDesign Guidelines For Bridge Size Culvertsعصام السامرائي100% (1)

- HSFG Bolt PDFDokument6 SeitenHSFG Bolt PDFSatish PawarNoch keine Bewertungen

- B.o.Q of Baste Shelga BridgeDokument12 SeitenB.o.Q of Baste Shelga BridgeAhmed BakrNoch keine Bewertungen

- Iwozizcfyr Oaqøhv Ikbi (Fo'Ks"K LGK Dkax LFGR) Fof'Kf"V: HKKJRH EkudDokument38 SeitenIwozizcfyr Oaqøhv Ikbi (Fo'Ks"K LGK Dkax LFGR) Fof'Kf"V: HKKJRH EkudPratik KharmateNoch keine Bewertungen

- Finite Element Analysis of Piping Vibration With Guided SupportsDokument12 SeitenFinite Element Analysis of Piping Vibration With Guided SupportsPatranNoch keine Bewertungen

- DSR 2010-11 Pipes RatesDokument140 SeitenDSR 2010-11 Pipes RatesDeepthy VasavanNoch keine Bewertungen

- Design Example of Pipe Rack StructureDokument16 SeitenDesign Example of Pipe Rack StructureJimit PayNoch keine Bewertungen

- Con 1303Dokument8 SeitenCon 1303chef100% (1)

- Bridge & Flyover DrainageDokument1 SeiteBridge & Flyover DrainageSantoso100% (1)

- Analysis of Large Bracing Connections Designs For Heavy ConstructionDokument25 SeitenAnalysis of Large Bracing Connections Designs For Heavy Constructiondaniel.j.mccarthyNoch keine Bewertungen

- Civil Engineering, Water & Wastewater, Earthquake, Railways (3538 Titles) PDFDokument148 SeitenCivil Engineering, Water & Wastewater, Earthquake, Railways (3538 Titles) PDFTomasz CzNoch keine Bewertungen

- ETCulvert V2 Brochure Web PDFDokument2 SeitenETCulvert V2 Brochure Web PDFjorgesalinasengNoch keine Bewertungen

- Approved List of Bridge Bearing SuppliersDokument9 SeitenApproved List of Bridge Bearing Supplierskarunamoorthi_p2209Noch keine Bewertungen

- Laboratory Services Division: Sri Lanka Standards InstitutionDokument4 SeitenLaboratory Services Division: Sri Lanka Standards InstitutionAbcNoch keine Bewertungen

- Anchor Bolt Design Per ACI-318-11 Crane Beam DesignDokument3 SeitenAnchor Bolt Design Per ACI-318-11 Crane Beam DesignJenny Cecilia Ureña ZuriNoch keine Bewertungen

- Technical Data Sheet For HSA Stud Anchor Technical Information ASSET DOC 2027424Dokument22 SeitenTechnical Data Sheet For HSA Stud Anchor Technical Information ASSET DOC 2027424aldert_pathNoch keine Bewertungen

- 5.13 Open-Web Steel JoistsDokument1 Seite5.13 Open-Web Steel JoistsaccullNoch keine Bewertungen

- CEM Part VI Chap 5 Pt2Dokument84 SeitenCEM Part VI Chap 5 Pt2raly1Noch keine Bewertungen

- Vibrating Wire Piezometer - Product DetailsDokument2 SeitenVibrating Wire Piezometer - Product DetailsR Shyam SainiNoch keine Bewertungen

- Eurocode 3 - Design of Steel Structures - Part 6 - Crane Supporting StructuresDokument37 SeitenEurocode 3 - Design of Steel Structures - Part 6 - Crane Supporting StructuresErmal RulaNoch keine Bewertungen

- Is 16088 2012Dokument26 SeitenIs 16088 2012kishor150688Noch keine Bewertungen

- MAURER Spherical BearingsDokument9 SeitenMAURER Spherical BearingsTiago Carvalho100% (1)

- Calculating Length of Reinforcing BarsDokument3 SeitenCalculating Length of Reinforcing BarsswarluNoch keine Bewertungen

- DPP Installation of 02 Nos Deep Tube Well P&DDokument27 SeitenDPP Installation of 02 Nos Deep Tube Well P&DMahfuzur RahmanNoch keine Bewertungen

- Circular Precastconcrete Manholes PDFDokument13 SeitenCircular Precastconcrete Manholes PDFBalaji NaikNoch keine Bewertungen

- 80MT Weigh Bridge SpecificationsDokument3 Seiten80MT Weigh Bridge SpecificationsCao Van PhongNoch keine Bewertungen

- STAADPro V8i Verification ManualDokument176 SeitenSTAADPro V8i Verification ManualjasimabdNoch keine Bewertungen

- Revised Estimate Draft 24-12-2021Dokument100 SeitenRevised Estimate Draft 24-12-2021Reenu CherianNoch keine Bewertungen

- Volume-I Part II SpecificationDokument118 SeitenVolume-I Part II SpecificationHiren DesaiNoch keine Bewertungen

- Ram Connection V8i Crack Free Download: Click Here To Get FileDokument2 SeitenRam Connection V8i Crack Free Download: Click Here To Get FileMichael LumauigNoch keine Bewertungen

- DPR For Bus Park 2078-1-17Dokument236 SeitenDPR For Bus Park 2078-1-17Sailesh BudhathokiNoch keine Bewertungen

- Institute For Steel Development & Growth (Insdag)Dokument1 SeiteInstitute For Steel Development & Growth (Insdag)VAVINoch keine Bewertungen

- Ruidp Sor 2013 PDFDokument520 SeitenRuidp Sor 2013 PDFJayesh KabraNoch keine Bewertungen

- Slab Design One-WayDokument8 SeitenSlab Design One-WayEmil ParangueNoch keine Bewertungen

- Annex 8.3 - Culvert ProposalDokument6 SeitenAnnex 8.3 - Culvert ProposalParamitaDanaNoch keine Bewertungen

- Jersey Barrier DrawingDokument1 SeiteJersey Barrier DrawingShams Khattak100% (1)

- Data Sheet Dramix Steel Fiber 3D - 8060BG (Findotek) - 2Dokument1 SeiteData Sheet Dramix Steel Fiber 3D - 8060BG (Findotek) - 2Didi SutriadiNoch keine Bewertungen

- 2395 CH 15Dokument19 Seiten2395 CH 15abdülkadir cebeciNoch keine Bewertungen

- IHHA 2013 - FunkwalDokument10 SeitenIHHA 2013 - FunkwalMd. Shiraz JinnathNoch keine Bewertungen

- BoqDokument24 SeitenBoqDilshad AhemadNoch keine Bewertungen

- 22a - Simply Supported Crawl BeamDokument22 Seiten22a - Simply Supported Crawl BeamMbalekelwa MpembeNoch keine Bewertungen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Structural Analysis 1: Statically Determinate StructuresVon EverandStructural Analysis 1: Statically Determinate StructuresNoch keine Bewertungen

- Design of 33 SQM HousingDokument1 SeiteDesign of 33 SQM HousingDJNoch keine Bewertungen

- E. Formworks: (Structural)Dokument1 SeiteE. Formworks: (Structural)Nonoy Justiniane-Giray JrNoch keine Bewertungen

- 38 Evans Street, Fairfield Heights (Structure Set)Dokument6 Seiten38 Evans Street, Fairfield Heights (Structure Set)patel nikunj rNoch keine Bewertungen

- Weight by Drawing Sheet: RevisionDokument1 SeiteWeight by Drawing Sheet: RevisionOseni MomoduNoch keine Bewertungen

- Design Criteria: Reinforcing SteelDokument12 SeitenDesign Criteria: Reinforcing SteelALL-ROUNDER CIVIL ENGINEERS ENGLISHNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- DCM-GU-CH-03-A Appendix A - Workface Plan Template (Electrical)Dokument3 SeitenDCM-GU-CH-03-A Appendix A - Workface Plan Template (Electrical)Ma'arif Nuzul AddibNoch keine Bewertungen

- Field Installation Work PackageDokument28 SeitenField Installation Work PackageMa'arif Nuzul AddibNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- 1 C-C13 1 C-C14 1 C-C15: REV Sheet Structural Details Custom Steel FramesDokument1 Seite1 C-C13 1 C-C14 1 C-C15: REV Sheet Structural Details Custom Steel FramesMa'arif Nuzul AddibNoch keine Bewertungen

- GA1 - 3D VIEW - Rev 0Dokument1 SeiteGA1 - 3D VIEW - Rev 0Ma'arif Nuzul AddibNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- P 391-1 Warning of Hot Surfaces: January 2007Dokument3 SeitenP 391-1 Warning of Hot Surfaces: January 2007Ma'arif Nuzul AddibNoch keine Bewertungen

- Project Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsDokument1 SeiteProject Specification C02817261026 - 2804101 - 0002614 PT OKI Pulp & Paper MillsMa'arif Nuzul AddibNoch keine Bewertungen

- M502-CH-1 - CHUTE - Rev.0Dokument1 SeiteM502-CH-1 - CHUTE - Rev.0Ma'arif Nuzul AddibNoch keine Bewertungen

- Gojek RegisterDokument1 SeiteGojek RegisterMa'arif Nuzul AddibNoch keine Bewertungen

- Bolt LiBNBNstDokument1 SeiteBolt LiBNBNstAboMuhmadSr.Noch keine Bewertungen

- M502 - Part List #14.04.2021Dokument4 SeitenM502 - Part List #14.04.2021Ma'arif Nuzul AddibNoch keine Bewertungen

- Main Workshop A2b - Assembly - List - Rev A #05.11.2021Dokument3 SeitenMain Workshop A2b - Assembly - List - Rev A #05.11.2021Ma'arif Nuzul AddibNoch keine Bewertungen

- Bolt LiBNBNstDokument1 SeiteBolt LiBNBNstAboMuhmadSr.Noch keine Bewertungen

- M502 - Assembly List #14.04.2021Dokument1 SeiteM502 - Assembly List #14.04.2021Ma'arif Nuzul AddibNoch keine Bewertungen

- MAIN WORKSHOP A2B - Part - List - REV A #05.11.2020Dokument6 SeitenMAIN WORKSHOP A2B - Part - List - REV A #05.11.2020Ma'arif Nuzul AddibNoch keine Bewertungen

- 4102-G1-4 - BEAM - Rev.1Dokument1 Seite4102-G1-4 - BEAM - Rev.1Ma'arif Nuzul AddibNoch keine Bewertungen

- 4102-G1-3 - GALLERY - Rev.1Dokument1 Seite4102-G1-3 - GALLERY - Rev.1Ma'arif Nuzul AddibNoch keine Bewertungen

- Main Workshop A2b - Assembly - List - Rev A #05.11.2021Dokument3 SeitenMain Workshop A2b - Assembly - List - Rev A #05.11.2021Ma'arif Nuzul AddibNoch keine Bewertungen

- Main Workshop A2b - Assembly - List - Rev A #05.11.2021Dokument3 SeitenMain Workshop A2b - Assembly - List - Rev A #05.11.2021Ma'arif Nuzul AddibNoch keine Bewertungen

- 4102-SPB-2 - SPILLAGE BUCKET - Rev.1Dokument1 Seite4102-SPB-2 - SPILLAGE BUCKET - Rev.1Ma'arif Nuzul AddibNoch keine Bewertungen

- 4102-G1-4 - BEAM - Rev.1Dokument1 Seite4102-G1-4 - BEAM - Rev.1Ma'arif Nuzul AddibNoch keine Bewertungen

- 4102-G1-1 - GALLERY - Rev.1Dokument1 Seite4102-G1-1 - GALLERY - Rev.1Ma'arif Nuzul AddibNoch keine Bewertungen

- Leoline Installation and MaintenanceDokument8 SeitenLeoline Installation and MaintenanceFloorkitNoch keine Bewertungen

- La Paz National High SchoolDokument19 SeitenLa Paz National High SchoolBon Ivan FirmezaNoch keine Bewertungen

- Pathological Anatomy IntroDokument27 SeitenPathological Anatomy IntroJoiya KhanNoch keine Bewertungen

- Ableism - What It Is and Why It Matters To EveryoneDokument28 SeitenAbleism - What It Is and Why It Matters To Everyonellemma admasNoch keine Bewertungen

- Summary of Germ LayersDokument2 SeitenSummary of Germ Layersaichiii.bearNoch keine Bewertungen

- Psicologia BuenisimoDokument6 SeitenPsicologia BuenisimoSophieNoch keine Bewertungen

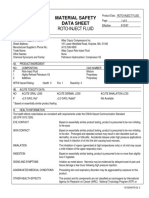

- Material Safety Data Sheet Roto-Inject FluidDokument5 SeitenMaterial Safety Data Sheet Roto-Inject FluidQuintana JoseNoch keine Bewertungen

- Standardization 1 PDFDokument7 SeitenStandardization 1 PDFmazharul HasanNoch keine Bewertungen

- Flight School BundleDokument43 SeitenFlight School BundleyoyoNoch keine Bewertungen

- EVK203/EVK213/EVK223/EVK233/EVK253: Digital Thermostats For Ventilated Refrigerating UnitsDokument2 SeitenEVK203/EVK213/EVK223/EVK233/EVK253: Digital Thermostats For Ventilated Refrigerating UnitsMihai BordeianuNoch keine Bewertungen

- Modelling The Effects of Condensate Banking On High CGR ReservoirsDokument11 SeitenModelling The Effects of Condensate Banking On High CGR ReservoirslikpataNoch keine Bewertungen

- Lesson 5: Prejudice and StereotypesDokument31 SeitenLesson 5: Prejudice and StereotypesZeynep SulaimankulovaNoch keine Bewertungen

- Job Description - Director of AdvancementDokument1 SeiteJob Description - Director of AdvancementCanterburyCambridgeNoch keine Bewertungen

- Final Workshop Report On Value Addition and AgroprocessingDokument31 SeitenFinal Workshop Report On Value Addition and AgroprocessingBett K. BernardNoch keine Bewertungen

- Arma 2018 047Dokument7 SeitenArma 2018 047Lígia BrumNoch keine Bewertungen

- Job Satisfaction and Professional Ethics Practices in Public SectorDokument13 SeitenJob Satisfaction and Professional Ethics Practices in Public SectorMuhammad NafeesNoch keine Bewertungen

- Grade 10 Chemistry Week 1Dokument3 SeitenGrade 10 Chemistry Week 1Nikoli MajorNoch keine Bewertungen

- Subject: Invitation To Join As "Resource Speaker" On Our Seminar On Fire Prevention and Safety ConsciousnessDokument6 SeitenSubject: Invitation To Join As "Resource Speaker" On Our Seminar On Fire Prevention and Safety ConsciousnessRjay CadaNoch keine Bewertungen

- Stern TubesDokument8 SeitenStern Tubesweesweekwee8652Noch keine Bewertungen

- Production of AcetaldehydeDokument124 SeitenProduction of AcetaldehydeAdilaAnbreen80% (5)

- Leonard Peikoff-Introduction To LogicDokument20 SeitenLeonard Peikoff-Introduction To Logicbursa07Noch keine Bewertungen

- Connection Manual: BNP-B2203D (ENG)Dokument122 SeitenConnection Manual: BNP-B2203D (ENG)Allison CarvalhoNoch keine Bewertungen

- VW Golf 8 Variant WD EngDokument664 SeitenVW Golf 8 Variant WD EngLakhdar BouchenakNoch keine Bewertungen

- Ashin Tejaniya: Questions & Answers WithDokument241 SeitenAshin Tejaniya: Questions & Answers WithharioNoch keine Bewertungen

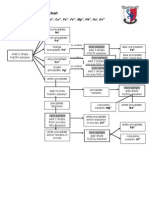

- Testing For Cations Flow ChartDokument2 SeitenTesting For Cations Flow Chartapi-252561013Noch keine Bewertungen

- Targets: Chris Paul P. Pagaoa, LPT, Msc. Biology - InstructorDokument4 SeitenTargets: Chris Paul P. Pagaoa, LPT, Msc. Biology - InstructorVince RetutaNoch keine Bewertungen

- INSTITUTO CAMBRIDGE de Cultura Inglesa - EXÁMENES 2020: Kids 1Dokument3 SeitenINSTITUTO CAMBRIDGE de Cultura Inglesa - EXÁMENES 2020: Kids 1Mel DeniseNoch keine Bewertungen

- Kmartinez Draft Research PaperDokument14 SeitenKmartinez Draft Research Paperapi-273007806Noch keine Bewertungen