Beruflich Dokumente

Kultur Dokumente

Operation Manual: Chinese Patent No (ZL 2013 2 0011912.X) DQF Series Electric Ball Valve For Silo Bottom Aeration Control

Hochgeladen von

Nova HeriOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Operation Manual: Chinese Patent No (ZL 2013 2 0011912.X) DQF Series Electric Ball Valve For Silo Bottom Aeration Control

Hochgeladen von

Nova HeriCopyright:

Verfügbare Formate

HENT 亨恩托机电

Chinese Patent No (ZL 2013 2 0011912.X)

DQF Series Electric Ball Valve for Silo Bottom

Aeration Control

(Upgrade)

Operation Manual

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

1

HENT 亨恩托机电

Content

The electric ball valve for cement homogenizing silo…………..............3

Structure of valve body…………………………………………….............3

Working principle…………………………………………………...............4

The circuit of DQF Electric ball valve ….……………………….….......... 5

The wiring of DQF Electric ball valve ………………...............................6

The dimension of DQF Electric ball valve ………………………............ 6

The Characteristics of DQF Electric Ball Valve.......................8

The Recovery Methods of DQF Electric Ball Valve......................1 0

Installing Operation of DQF Electric Ball Valve...........................1 1

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

2

HENT 亨恩托机电

The DQF Series Electric Ball Valve (Upgrade Version)

HENT brand DQF series electric ball valve have overcome the shortcoming of traditional

electromagnetic valve which usually have been damaged in diaphragm and mechanical accessory, and

it has been proved that our valve has highest reliability in high frequency working condition .

The HENT brand DQF series electric ball valve has many specifications of nominal

diameter from 15 to 150 mm standard caliber. Control voltage: 220 v, Switching speed:

0.25time/sec. and continuous action life is over one million, its life is ten times than the

traditional electromagnetic valve.

Structure of Valve Body

HENT DQF series electric ball valve is made up of in-phase electromotor, limit switch

which is imported from OMRON Company in Japan, stainless steel ball and mechanical

drive device formed by gears, Q235 steel valve body. The flange and screw thread is

manufactured in GB. And it’s compatible with traditional electromagnetic valve; so it is

convenience for replacing. The above glass window can indicate actual valve position, the

combination of electric indicator cock and control indicated lamp can reflecting valve

position of working site actually. It has a precision manufacture techniques and good

looking appearance.

Limited switch Indicator

Circuit Signal switch

board

Micro in-phase

electromotor

Relay

Hous

e

Bodyy

PTFE Seal ring

Flange

Stainless steel ball

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

3

HENT 亨恩托机电

Working Principle

When the HENT DQF series electric ball valve do not get the outer open signal, it is

keeping electric lock in full cut-off position under the effect of operating power. And the

indicator plate in full cut-off indicator position, there is no output signal (relay signal) at

electric indicator cock.

When it has been received signal, the inner relay act, and main electromotor rotating, the

little gear in transmission shaft rotating synchronously, drive the big gear and basic shaft

and stainless steel ball rotating synchronously, after 0.25 second, the valve is in full open

position. The electro-motor stopped and keeping electric lock under the action of the

limited switch. At the same time the signal indicator be touched off and acting, the signal

output and let the indicated lamp has a corresponding indicate in the control room, and

then the indicate plate is in full open indicate position.

On the opposite, when the signal disappear, the electromotor rotating to the opposite

direction. And the electromotor will stop and keeping electric lock after 0.25 second

under the action of reverse limited switch.

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

4

HENT 亨恩托机电

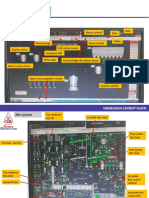

The connection diagram of DQF Motorized Ball Valve

The Outline Dimension Drawing

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

5

HENT 亨恩托机电

The outline dimension of DQF Electric ball valve

nominal Main size(mm)

Pipe thread Weight

diameter

G(inch) L I H L1 L2 (kg)

D3(mm)

15 1/2 75 13 180 185 245 10

20 3/4 80 14 200 185 245 12

25 1 90 16 205 185 245 12

32 11/4 120 20 210 185 245 12

40 11/2 150 22 215 185 245 14

50 2 175 24 225 185 245 16

The outline dimension drawing of DQF Electric ball valve

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

6

HENT 亨恩托机电

Nominal Main size(mm)

Weight

diameter

L D D1 D2 f b n-φd L1 L2 H (Kg)

D3(mm)

15 130 95 65 46 2 14 4-14 185 245 190 10

20 150 105 75 56 2 14 4-14 185 245 195 12

25 160 115 85 65 2 14 4-14 185 245 200 13

32 180 135 100 78 2 16 4-18 185 245 210 15

40 200 145 110 85 2 16 4-18 185 245 215 19

50 250 160 125 100 3 16 4-18 185 245 222.5 22

65 250 180 145 120 3 16 4-18 310 350 260 24

80 250 195 160 135 3 20 8-18 310 350 262.5 27

100 280 215 180 155 3 20 8-18 310 350 277.5 35

125 300 245 210 185 3 22 8-18 310 350 292.5 37

150 300 285 240 210 3 24 8-23 310 350 310 41

200 460 335 295 260 3 25 12-23 310 350 400 50

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

7

HENT 亨恩托机电

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

8

HENT 亨恩托机电

The Characteristics of HENT DQF Electric Ball Valve (Upgrade)

HENT DQF Series Electric Ball Valve for Silo Bottom Aeration Control is upgraded

based on invention of the national patent product in 1990. It is widely used in silo

aeration control system, particularly in cement industry, preventing material jams.

The life span is 1 million times, with the switch time 0.25s, better than the similar

imported products, which is the ideal switch valve for inflation.

Upgraded DQF Electric ball valve keeps the same advantages and has a short

switching time and better valve body, details as follow:

1. Micro synchronous motor-no burning, if jammed but no burning;

2. Stainless steel valve core and no rust. Smooth surface helps the motor turning

easily at some rating.

3. Max working temperature of PTFE Seal is 250°C. It never deforms in the normal

working temperature. PTFE seal and stainless steel core have a good sealing. Both

PTFE seal and stainless steel valve core have friction only in the turning process

and no damage and scratch on both of them. It has been proved that PTFE has a

10 year working life.

4. The Omron limit switch and relay has a 1 million time working life. According to

the aeration process, the electric ball valve has 5 years quality warranty.

5. There is no installation limit-Horizontal or vertical.

6. Using carbon steel valve body, durable, strong, smooth and beautiful shape.

7. Close/open time: 0.25 seconds (0-90 degree), to domestic and international

leading level.

8. The body with plastic safety guards is outside the terminal; Position indicator is

inside the actuator and it is easy to observe through sealed organic glass.

Protection grade: IP55.

9. Valve core is not accidentally stuck by ash and welding slag.

10. The body size is guaranteed and air volume is not losing.

As mentioned above, upgraded DQF electric ball valve is maintenance free in the first

5 year. It can turn to be another 5 year warranty time when the limit switch and relay

had been replaced.

Why the Electric Ball Valve can eliminate the air distribution valve?

The reason as follows:

1. The solenoid valve can only work 3 months in the aeration system

2. The pneumatic solenoid only work 8 months with additional air supply pipe

system to solenoid valve.

3. The solenoid valve of “o” electric ball valve malfunction frequently and randomly.

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

9

HENT 亨恩托机电

The “o” electric ball valve need air supply piping system and it also need

lubrication

4. The normal electric actuated ball valve has 8 -20 seconds switching time. The

position signal will change after 45 working days. The stem will be damaged

when the valve is installed vertically with an actuator weight. It needs 3 phase

power supply and control signal system.

5. Rotary air distributor has a high power consumption with a simply control

module. The rotary air distributor will break down once one nozzle is jammed. It

has another disadvantage of civil foundation construction.

DQF electric ball valve has a 220VAC 50HZ (Optional) power supply and control

power. The valve has a ball valve position signal with a position sensor, feeding back

to control center. The control center can know the ball valve condition timely and

accurately.

DQF electrical ball:

DN15,20,25,32,40,50,65,80,100,125,150,200;Weight:

19KG~160KG.

HENT is committed to supply high quality products to market, innovation technology

, integrity and friendly to our customers and we will make our own contribution to

building industry .

Welcome to contact us and build business relationship with us.

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

10

HENT 亨恩托机电

The Recovery Methods of HENT DQF Electric Ball Valve

1. Omron Relay is damaged,

Situation: Ball valve is still in the closed

Recovery method: Change a new

position only. The Relay has no responses after

Omron Relay;

power on. It lets the valve turn to open position

after power down.

2. Micro switch is damaged,

Situation: Position indicator in control Recovery method: Change a new

cabinet is unable to properly indicate the Micro switch;

valve switch.

3. Valve core is jammed, Recovery method: Remove flange

Situation: The valve core continues not opening and clean the impurity particles on

or closing after turning to a certain positions. the valve core. Then, reinstall the

flange.

4.Resistance is damaged,

Recovery method: Change a new

Situation: Micro synchronous motor shakes and

resistance;

does not operate well.

5. Electrical network is in trouble; Recovery method: Recheck

Situation: Do not work properly. electrical network(the circuit

board and supporting circuit)

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

11

HENT 亨恩托机电

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

12

HENT 亨恩托机电

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

13

HENT 亨恩托机电

Zhejiang HENT Electromechanical Engineering Co., Ltd.

Tel:+86 571 23230606 +86 571 23230707 Fax:+86 571 23230707 ext.7017 Mobile:+86 13306518261 Wang Yongliang

14

Das könnte Ihnen auch gefallen

- Training Basic HydraulicsDokument50 SeitenTraining Basic Hydraulicssalicurri88% (8)

- Esp IndexDokument70 SeitenEsp IndexAhemadNoch keine Bewertungen

- 345BDokument2 Seiten345BHector Valles100% (1)

- Schneider M258 User ManualDokument158 SeitenSchneider M258 User ManualPuneethNoch keine Bewertungen

- Esp eDokument40 SeitenEsp eVijayakumarVageesanNoch keine Bewertungen

- ESPDokument15 SeitenESPlrpatraNoch keine Bewertungen

- High Pressure ProcessingDokument29 SeitenHigh Pressure ProcessingZohaib ArshadNoch keine Bewertungen

- SCADADokument57 SeitenSCADAkailasamvv100% (1)

- GTDokument122 SeitenGTAnand Patel100% (1)

- Programming Guide 11/2002 Edition: Fundamentals SINUMERIK 840D/840Di/810DDokument504 SeitenProgramming Guide 11/2002 Edition: Fundamentals SINUMERIK 840D/840Di/810Dfigaro1234Noch keine Bewertungen

- Airlocks PPT 2005-02-18 DGLDokument35 SeitenAirlocks PPT 2005-02-18 DGLAndrey ScholdeaNoch keine Bewertungen

- SinomaDokument52 SeitenSinomansprasad88Noch keine Bewertungen

- Electrical Control SystemsDokument9 SeitenElectrical Control SystemsM.IBRAHEEMNoch keine Bewertungen

- Screw Compressor: Controller Operating ManualDokument24 SeitenScrew Compressor: Controller Operating Manuallucas100% (2)

- Manual Solar Controler SR868C8Dokument44 SeitenManual Solar Controler SR868C8Pedro PereiraNoch keine Bewertungen

- F193-Flow Control Gate PDFDokument449 SeitenF193-Flow Control Gate PDFDilshad Ahmed100% (2)

- Sd119 ManualDokument2 SeitenSd119 ManualVictor PatsiNoch keine Bewertungen

- UM10724G00Dokument377 SeitenUM10724G00TuanBi Le100% (1)

- Comet - Glands 2023 List PriceDokument2 SeitenComet - Glands 2023 List PriceNIRALI PRAJAPATINoch keine Bewertungen

- 7 Quality Management and Control of Cement Production - Ó+ Í - + - +ÝËÙ+ÏÍãDokument88 Seiten7 Quality Management and Control of Cement Production - Ó+ Í - + - +ÝËÙ+ÏÍãNova HeriNoch keine Bewertungen

- Chapter 1Dokument56 SeitenChapter 1Surbhi JainNoch keine Bewertungen

- Beumer Autopac 3000 en PDFDokument2 SeitenBeumer Autopac 3000 en PDFYhane Hermann BackNoch keine Bewertungen

- Pneumax Fittings Accessories CatalogDokument32 SeitenPneumax Fittings Accessories CatalogBryan Brito100% (1)

- PDFDokument19 SeitenPDFGabriel Bolívar100% (1)

- F43-Obajana Line 3-PM-04 - Clinker ProductionDokument109 SeitenF43-Obajana Line 3-PM-04 - Clinker ProductionYhane Hermann BackNoch keine Bewertungen

- PC010501 0313 0914 en Viking ProductCatalogue Detection MR PDFDokument348 SeitenPC010501 0313 0914 en Viking ProductCatalogue Detection MR PDFJiNoch keine Bewertungen

- 6105-S5 Controller e PDFDokument110 Seiten6105-S5 Controller e PDFnicoanday80% (5)

- 07 - Competence Cement PM 280Dokument12 Seiten07 - Competence Cement PM 280Yhane Hermann BackNoch keine Bewertungen

- 16 50061-Mr-003-Zk-lst-02 Bill of Instrument Installed MaterialDokument4 Seiten16 50061-Mr-003-Zk-lst-02 Bill of Instrument Installed MaterialPhucChuVanNoch keine Bewertungen

- Wa0001 PDFDokument25 SeitenWa0001 PDFMuntandwe georgeNoch keine Bewertungen

- Design of Main GirderDokument58 SeitenDesign of Main GirderovikbasuNoch keine Bewertungen

- Annex 2 Equipment Specification Alt50Dokument279 SeitenAnnex 2 Equipment Specification Alt50MKPashaPashaNoch keine Bewertungen

- Ac-Dc KilnsDokument10 SeitenAc-Dc KilnsPrateek SinghNoch keine Bewertungen

- SFF PerformanceDokument17 SeitenSFF PerformanceVijay BhanNoch keine Bewertungen

- Ok Mill Interlock ListDokument1 SeiteOk Mill Interlock ListVijay BhanNoch keine Bewertungen

- SC37-SM-26052022 R0-Recomm Spare Parts For WFDokument5 SeitenSC37-SM-26052022 R0-Recomm Spare Parts For WFValipireddy NagarjunNoch keine Bewertungen

- Ef ElexDokument28 SeitenEf ElexAnonymous yF1z4oNoch keine Bewertungen

- 2.4 Solid Fuel Handling SystemDokument29 Seiten2.4 Solid Fuel Handling SystemNind's Chef100% (1)

- Group Alpha (Widy, Yoga, Fadly) - FMEA - ManRisk - MK3L 2019Dokument3 SeitenGroup Alpha (Widy, Yoga, Fadly) - FMEA - ManRisk - MK3L 2019Widy Abe Wibisono100% (1)

- Baghouse 130218005547 Phpapp01Dokument54 SeitenBaghouse 130218005547 Phpapp01Vishal HiremathNoch keine Bewertungen

- 2010 CatalogDokument21 Seiten2010 CatalogMar SolNoch keine Bewertungen

- Dol Starter DrawingDokument1 SeiteDol Starter DrawingSavant SinghNoch keine Bewertungen

- Hammer Crusher DesignDokument45 SeitenHammer Crusher DesignmubashirNoch keine Bewertungen

- Milltronics MFA 4p en-USDokument57 SeitenMilltronics MFA 4p en-USRavenShieldXNoch keine Bewertungen

- Thermowell CatalogDokument24 SeitenThermowell CatalogMANTCRUZNoch keine Bewertungen

- Combined PDFDokument22 SeitenCombined PDFThafer MajeedNoch keine Bewertungen

- Operating Instruction ROTOCEM - ENDokument81 SeitenOperating Instruction ROTOCEM - ENLuis MecNoch keine Bewertungen

- 03mill SlidesDokument21 Seiten03mill SlidesNael El SayyadNoch keine Bewertungen

- 531GS155Dokument7 Seiten531GS155Valipireddy NagarjunNoch keine Bewertungen

- Thesis "Power Generation From Waste Heat in Cement Plants - Application in Lafarge Volos Plant"Dokument81 SeitenThesis "Power Generation From Waste Heat in Cement Plants - Application in Lafarge Volos Plant"Nguyen Dang Binh ThanhNoch keine Bewertungen

- Weighfeeder DetailsDokument4 SeitenWeighfeeder DetailsAnonymous p4GdtQpNoch keine Bewertungen

- Operation and Maintenance Manual: Belt DiverterDokument38 SeitenOperation and Maintenance Manual: Belt DiverterTinTunNaingNoch keine Bewertungen

- Flsmidth Pvt. LTDDokument36 SeitenFlsmidth Pvt. LTDValipireddy NagarjunNoch keine Bewertungen

- 90.25772-BLMS GDC-051 As BuiltDokument26 Seiten90.25772-BLMS GDC-051 As BuiltValipireddy Nagarjun100% (1)

- Abb Tzidc PositionerDokument90 SeitenAbb Tzidc PositionerMARI SHANKARNoch keine Bewertungen

- ROTALIGN-Ultra Operating-Instructions ALI-209.855!01!09 2.06 GDokument165 SeitenROTALIGN-Ultra Operating-Instructions ALI-209.855!01!09 2.06 GDon Freeman100% (1)

- Location: Mill: Sagar Cement, Jajpur Jcpl/Inst/Cl MillDokument15 SeitenLocation: Mill: Sagar Cement, Jajpur Jcpl/Inst/Cl MillValipireddy NagarjunNoch keine Bewertungen

- DR290Dokument63 SeitenDR290DineshNoch keine Bewertungen

- 800xa 5.1 Ac 800m Controller Data SheetDokument4 Seiten800xa 5.1 Ac 800m Controller Data Sheetrmsr_7576100% (1)

- HNC 8 System Commissioning Manual Grinding System v2.4 PDFDokument80 SeitenHNC 8 System Commissioning Manual Grinding System v2.4 PDFSam eagle goodNoch keine Bewertungen

- High Pressure ProcessingDokument18 SeitenHigh Pressure ProcessingTanuj BansalNoch keine Bewertungen

- Gss25qsta Ss ManualDokument112 SeitenGss25qsta Ss ManualathapaNoch keine Bewertungen

- Saimo 6105 Belt Feeder IntegratorDokument72 SeitenSaimo 6105 Belt Feeder IntegratorMuhammad AndiNoch keine Bewertungen

- Platform Load Cell, PWS Type 10 ... 700 KGDokument4 SeitenPlatform Load Cell, PWS Type 10 ... 700 KGSohail AhmedNoch keine Bewertungen

- Smartcon 4000Dokument20 SeitenSmartcon 4000செல்வமாரியப்பன் சீனிவாசன்Noch keine Bewertungen

- Load Cell ActuatorsDokument2 SeitenLoad Cell Actuatorssandeep100% (1)

- 90.25771-SFF-001 As BuiltDokument45 Seiten90.25771-SFF-001 As BuiltValipireddy NagarjunNoch keine Bewertungen

- GA-15-18-and-22-Parts List-5-6Dokument2 SeitenGA-15-18-and-22-Parts List-5-6RE musicNoch keine Bewertungen

- SMGQ2Dokument10 SeitenSMGQ2CarlosNoch keine Bewertungen

- Eq 215Dokument9 SeitenEq 215Jože StajnkoNoch keine Bewertungen

- 9 Application of Cement - ÓÁ-Ë Ë+Dokument22 Seiten9 Application of Cement - ÓÁ-Ë Ë+Nova HeriNoch keine Bewertungen

- Discharge Device: Nantong Yawei Machinery Manufacture Co., LTDDokument8 SeitenDischarge Device: Nantong Yawei Machinery Manufacture Co., LTDNova HeriNoch keine Bewertungen

- Shut-Off Manual (Pneu) Size 500x500Dokument12 SeitenShut-Off Manual (Pneu) Size 500x500Nova HeriNoch keine Bewertungen

- 8 Energy Saving and Environmental Protection in Cement Production - Ó + - ËÙ+À ÚDokument15 Seiten8 Energy Saving and Environmental Protection in Cement Production - Ó + - ËÙ+À ÚNova HeriNoch keine Bewertungen

- 8 Energy Saving and Environmental Protection in Cement Production - Ó + - ËÙ+À ÚDokument15 Seiten8 Energy Saving and Environmental Protection in Cement Production - Ó + - ËÙ+À ÚNova HeriNoch keine Bewertungen

- 1 Basic Knowledge of Cement Production Technics - Ó+ Ñêi+ Í - ÂDokument19 Seiten1 Basic Knowledge of Cement Production Technics - Ó+ Ñêi+ Í - ÂNova HeriNoch keine Bewertungen

- 2 Process Flow of Production Line in China United Cement Lunan Corporation - Íð - + ÑêiDokument5 Seiten2 Process Flow of Production Line in China United Cement Lunan Corporation - Íð - + ÑêiNova HeriNoch keine Bewertungen

- 9 Application of Cement - ÓÁ-Ë Ë+Dokument22 Seiten9 Application of Cement - ÓÁ-Ë Ë+Nova HeriNoch keine Bewertungen

- Checklist Patrol Crusher, Storage&proportionDokument10 SeitenChecklist Patrol Crusher, Storage&proportionNova HeriNoch keine Bewertungen

- 1 Basic Knowledge of Cement Production Technics - Ó+ Ñêi+ Í - ÂDokument19 Seiten1 Basic Knowledge of Cement Production Technics - Ó+ Ñêi+ Í - ÂNova HeriNoch keine Bewertungen

- 2 Process Flow of Production Line in China United Cement Lunan Corporation - Íð - + ÑêiDokument5 Seiten2 Process Flow of Production Line in China United Cement Lunan Corporation - Íð - + ÑêiNova HeriNoch keine Bewertungen

- Heavy Duty Apron Feeder PDFDokument2 SeitenHeavy Duty Apron Feeder PDFNova HeriNoch keine Bewertungen

- ScenchDokument4 SeitenScenchKoteswara RaoNoch keine Bewertungen

- Display ABB: CO2 SystemDokument5 SeitenDisplay ABB: CO2 SystemNova HeriNoch keine Bewertungen

- Refractory Dan Belt Conveyor ListDokument32 SeitenRefractory Dan Belt Conveyor ListNova HeriNoch keine Bewertungen

- Greenid Rotary Kiln Feb 2018.Dokument8 SeitenGreenid Rotary Kiln Feb 2018.Nova HeriNoch keine Bewertungen

- CMD Kiln Drive Performance PDFDokument3 SeitenCMD Kiln Drive Performance PDFNova HeriNoch keine Bewertungen

- Apron Feeder: Made in IndonesiaDokument4 SeitenApron Feeder: Made in IndonesiaBayu EkosaputroNoch keine Bewertungen

- CMD Kiln Drive PerformanceDokument3 SeitenCMD Kiln Drive PerformanceNova HeriNoch keine Bewertungen

- Hitachi Printer: Technical Manual Ink Jet Printer For Industrial MarkingDokument188 SeitenHitachi Printer: Technical Manual Ink Jet Printer For Industrial MarkingAnh Lê VănNoch keine Bewertungen

- Relay M 8 HDokument2 SeitenRelay M 8 HgeorgeNoch keine Bewertungen

- Mitsubishi 89 Wiring-DiagDokument91 SeitenMitsubishi 89 Wiring-DiagDinesh JayasekaraNoch keine Bewertungen

- DVR1610 enDokument83 SeitenDVR1610 enDo Chanh TrungNoch keine Bewertungen

- Terminal Program at orDokument2 SeitenTerminal Program at orsanflo7Noch keine Bewertungen

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument36 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768frankkenny ramirez gutierreNoch keine Bewertungen

- JUMO Di 308: Digital IndicatorDokument76 SeitenJUMO Di 308: Digital IndicatorKharlaSotoNoch keine Bewertungen

- ECP 11-0003 Testing and Commissioning Guidance NotesDokument48 SeitenECP 11-0003 Testing and Commissioning Guidance NotesKhalidNoch keine Bewertungen

- CDV62Dokument2 SeitenCDV62KIRUBANESANNoch keine Bewertungen

- Features:: Modules and Devices Are Powered Wiring DiagramDokument3 SeitenFeatures:: Modules and Devices Are Powered Wiring DiagramMatt StubblefieldNoch keine Bewertungen

- Instructions Manual Te808silverDokument100 SeitenInstructions Manual Te808silverMiguel Angel Pavon Carbonell100% (1)

- Model: K3063i: Specialize in Electric Power TestingDokument3 SeitenModel: K3063i: Specialize in Electric Power Testingrey chicoNoch keine Bewertungen

- ZHF XPXN 0SB39 Omi 001-1Dokument29 SeitenZHF XPXN 0SB39 Omi 001-1Online 4-lifeNoch keine Bewertungen

- Manual 800 3310 IB 09MC1Dokument199 SeitenManual 800 3310 IB 09MC1Jeremias StraussNoch keine Bewertungen

- MTL BarriersDokument36 SeitenMTL BarriersNavneet Singh100% (1)

- Fs10 R, RN Spec (Sp330c)Dokument5 SeitenFs10 R, RN Spec (Sp330c)theloniussherekNoch keine Bewertungen

- Eac 805Dokument1 SeiteEac 805Charles TineoNoch keine Bewertungen

- BernardDokument20 SeitenBernardandy131078Noch keine Bewertungen

- Noark Product CatalogueDokument86 SeitenNoark Product CatalogueTapelea Cristian100% (3)

- Altistart 01 - ATS01N209QNDokument6 SeitenAltistart 01 - ATS01N209QNkarimNoch keine Bewertungen

- MFAC ManualDokument19 SeitenMFAC ManualAlpesh PatelNoch keine Bewertungen

- Notifier Nfs2 3030Dokument8 SeitenNotifier Nfs2 3030Reginald D. De GuzmanNoch keine Bewertungen

- DS1120Dokument4 SeitenDS1120Hoc chung khoan MIEN PHINoch keine Bewertungen