Beruflich Dokumente

Kultur Dokumente

New Oil Cooler For 11 Engines: Background

Hochgeladen von

joaojitoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

New Oil Cooler For 11 Engines: Background

Hochgeladen von

joaojitoCopyright:

Verfügbare Formate

Technical

1

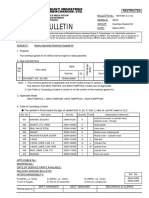

TI 1-95 01 21 GT/B/F/M/U

information

en

SI 1-92 12 21 GT/B

New oil cooler for 11 engines

Background

There have been complaints about the current

oil cooler due to leakage.

Changes made

A series of modifications have been made to the

oil cooler over the last few years.

The following is a brief history of modifications

made.

Oil cooler 350 061 was replaced in May 1992

by oil cooler, part number 1 300 004, which had

a completely new design.

Due to quality problems with this cooler, the

earlier cooler (part No. 350 061) was reintro- Part No. Part No.

duced in November 1992, but with a new part 1 300 004 350 061

number (1 350 909). This is a so-called collec- 528 211

tive number, which means that identical parts 1 318 933

have different part numbers. In this case, there 1 350 909

are two different part numbers:

350 061 and 528 211.

The above change was made from the following

engine numbers:

Scania Södertälje 5 330 340

Scania Nederland 4 089 346

For DTC11, the new design of oil cooler was

not introduced, but it retained the part number

1 318 933.

In January 1994, an oil cooler with part number

1 362 222 (part No. 1 362 274 for DTC11) was

introduced which has reinforced edge plates

(wall thickness increased from 1.25 mm

to 2 mm).

The above change was made from the following

engine numbers:

Part No.

Scania Södertälje 5 338 104 1 362 222

Scania Nederland 4 094 110 1 362 274

© Scania CV AB (504) 1995 1

During the spring of 1994, a heat-treated oil 2 mm

cooler housing was also successively intro-

duced to prevent wear between housing and

O-ring. The heat-treated oil cooler housing has

a cast-in part number, while the untreated one

has the part number stamped.

In May 1994, oil cooler 1 368 735

(1 368 795 for DTC11) was introduced, on

which the following has been done:

1. O-ring groove in oil cooler + extra O-ring.

2. Protective grease under end plate.

3. Improved surface quality on inside of oil

cooler housing beside O-ring positions.

01_1202

The above change was made from the following

engine numbers: Part No.

1 368 735

Scania Södertälje 5 340 311

1 368 795

Scania Nederland 4 096 022

In November 1994, oil cooler 1 368 736

(1 370 897 for DTC11, 1 369 743 classed) was

introduced, to which the following changes

have been made:

1. Rubber has been vulcanized to the underside

of the end plates.

2. O-ring groove + extra O-ring have been

withdrawn.

The above change was made from the following

engine numbers:

Scania Södertälje 5 344 386

Scania Nederland 4 098 626

01_1203

Part No.

1 368 736

1 370 892

1 369 743

2 © Scania CV AB TI 1-95 01 21 GT/B/F/M/U en

What to do in the case of leak

In terms of function and quality, the last two changes are identical. For oil coolers

with part number 350 061 and 1 362 222, it is possible, as a preventative measure

and in the case of leakage, to change to vulcanized end plates and oil cooler housing

with better material quality.

IMPORTANT. A protective layer of grease should be applied between O-ring and

end plate.

For oil coolers with part numbers 528 211, 1 300 004, 1 318 933 and 1 326 274,

no component spare parts are available and these must be completely changed.

Parts for rebuild

Designation Part No. before change Part No. after change

Oil cooler housing 265 795 265 795

End plate 243 796 or 1 361 664 1 370 746*

Protective grease - 814 240

* End plates with vulcanized rubber.

TI 1-95 01 21 GT/B/F/M/U en © Scania CV AB 3

Das könnte Ihnen auch gefallen

- Tid 0000108 01 PDFDokument1 SeiteTid 0000108 01 PDFjoaojitoNoch keine Bewertungen

- Ti 01-06 01 11 en Technical Information: BackgroundDokument4 SeitenTi 01-06 01 11 en Technical Information: BackgroundRuanNoch keine Bewertungen

- New Valve Mechanism For Unit Injectors: BackgroundDokument2 SeitenNew Valve Mechanism For Unit Injectors: BackgroundjoaojitoNoch keine Bewertungen

- Changes: Ti 01-07 02 17 en-GB Technical InformationDokument3 SeitenChanges: Ti 01-07 02 17 en-GB Technical InformationRuanNoch keine Bewertungen

- Комплекты прокладок DeutzDokument13 SeitenКомплекты прокладок DeutzЛеонид БеркоNoch keine Bewertungen

- Gasket Set Compact Engines 2Dokument13 SeitenGasket Set Compact Engines 2ibrahim salemNoch keine Bewertungen

- Changed Bearing On Clutch Lever For Pull-Type ClutchDokument1 SeiteChanged Bearing On Clutch Lever For Pull-Type ClutchjoaojitoNoch keine Bewertungen

- Background Production Solution: Ti 01-07 03 19 en Technical InformationDokument2 SeitenBackground Production Solution: Ti 01-07 03 19 en Technical InformationRuanNoch keine Bewertungen

- Dust Cover Under The Fan: BackgroundDokument2 SeitenDust Cover Under The Fan: BackgroundjoaojitoNoch keine Bewertungen

- Lubrication For Throttle Linkage: BackgroundDokument2 SeitenLubrication For Throttle Linkage: BackgroundjoaojitoNoch keine Bewertungen

- TR019937011693 - en - PDF Coolant Pump Installation Instruction & RepairDokument5 SeitenTR019937011693 - en - PDF Coolant Pump Installation Instruction & Repairibrahim salemNoch keine Bewertungen

- Advisory: Subject: Na295 Compressor End SealingDokument3 SeitenAdvisory: Subject: Na295 Compressor End SealingMarcelo OrdóñezNoch keine Bewertungen

- Service InformationDokument4 SeitenService InformationMarcelo GiussaniNoch keine Bewertungen

- M18 061 eDokument3 SeitenM18 061 eFalgon IslamNoch keine Bewertungen

- Wheel Install 16x7.5 ET31Dokument10 SeitenWheel Install 16x7.5 ET31Oleg FedchenkoNoch keine Bewertungen

- MG Rover Group: Model/Derivative: No: Date: DRIVE Bulletins UpdateDokument4 SeitenMG Rover Group: Model/Derivative: No: Date: DRIVE Bulletins Updateanon_941221142Noch keine Bewertungen

- New Setting Solenoid Bearing in EDC Injection Pump and Various PartsDokument5 SeitenNew Setting Solenoid Bearing in EDC Injection Pump and Various PartsjoaojitoNoch keine Bewertungen

- EngineRotary EditedDokument32 SeitenEngineRotary EditedNamit GuptaNoch keine Bewertungen

- Service PartsDokument8 SeitenService PartsYankonde ChisenseNoch keine Bewertungen

- Service Information: 1 - Clutch Cylinder 2 - Spacer Flange 3 - ScrewDokument2 SeitenService Information: 1 - Clutch Cylinder 2 - Spacer Flange 3 - ScrewMarcelo GiussaniNoch keine Bewertungen

- Tid 0000052 01 PDFDokument1 SeiteTid 0000052 01 PDFjoaojitoNoch keine Bewertungen

- Tid 0000039 01 PDFDokument4 SeitenTid 0000039 01 PDFjoaojitoNoch keine Bewertungen

- Service InformationDokument2 SeitenService InformationMarcelo GiussaniNoch keine Bewertungen

- Spare Parts Catalog: 9 S 1115 TD Otosan Material Number: 1324.032.018Dokument70 SeitenSpare Parts Catalog: 9 S 1115 TD Otosan Material Number: 1324.032.018Jhon MechanicNoch keine Bewertungen

- TCD2015 PDFDokument67 SeitenTCD2015 PDFRosa ChNoch keine Bewertungen

- Generator Bearing ServiceDokument10 SeitenGenerator Bearing ServiceMustafa A.W100% (1)

- Engine Rotary Motor MazdaDokument32 SeitenEngine Rotary Motor Mazdastripy101100% (1)

- Rear DifferentialDokument15 SeitenRear DifferentialCarlos VelázquezNoch keine Bewertungen

- Multi DCTF: Dual Clutch Transmission (DCT) Fluid Dry DCT and Wet DCT TechnosyntheseDokument2 SeitenMulti DCTF: Dual Clutch Transmission (DCT) Fluid Dry DCT and Wet DCT TechnosyntheseCarlos JuniorNoch keine Bewertungen

- Scania P, G, R, T Series Workshop Manual - Removing The Retarder Part 2Dokument8 SeitenScania P, G, R, T Series Workshop Manual - Removing The Retarder Part 2lilik sukristiantoNoch keine Bewertungen

- 02 1K2K 03Dokument3 Seiten02 1K2K 03Francisco Wilson Bezerra FranciscoNoch keine Bewertungen

- Fag Imported Bearings MRP 2018Dokument28 SeitenFag Imported Bearings MRP 2018SHAMPA SINHAROYNoch keine Bewertungen

- 924S-86 To 88 Parts ListDokument0 Seiten924S-86 To 88 Parts ListMelissa Cargill PernellNoch keine Bewertungen

- Service PartsDokument6 SeitenService Partsslam9Noch keine Bewertungen

- Motul Multi HFDokument2 SeitenMotul Multi HFMariosNoch keine Bewertungen

- Tra 026Dokument7 SeitenTra 026Trọng Nghĩa VõNoch keine Bewertungen

- Turbocharger NR 12 / S - Introduction of Splash Oil Cooling Modification of Locating BearingDokument3 SeitenTurbocharger NR 12 / S - Introduction of Splash Oil Cooling Modification of Locating BearingmariodalNoch keine Bewertungen

- T Z40eDokument5 SeitenT Z40earness22Noch keine Bewertungen

- Lateral Vibrations in The Powertrain: BackgroundDokument2 SeitenLateral Vibrations in The Powertrain: BackgroundjoaojitoNoch keine Bewertungen

- Troubleshooting (Musso & Korando)Dokument23 SeitenTroubleshooting (Musso & Korando)francisca19100% (1)

- Splitter Oil InjestionDokument2 SeitenSplitter Oil InjestionJHON JAMES VILLEGAS SANCHEZNoch keine Bewertungen

- New Bushing For Springs: BackgroundDokument2 SeitenNew Bushing For Springs: BackgroundjoaojitoNoch keine Bewertungen

- 212-10153208 - APL-6324 - 31-03-2021 Eje TRASERODokument26 Seiten212-10153208 - APL-6324 - 31-03-2021 Eje TRASEROLucas ScioscioliNoch keine Bewertungen

- Description: GB232 - Gearbox, Body AluminiumDokument2 SeitenDescription: GB232 - Gearbox, Body AluminiumMehedi HasanNoch keine Bewertungen

- Main Bearing Desing Update Man BWDokument21 SeitenMain Bearing Desing Update Man BWMiroslaw LabudaNoch keine Bewertungen

- Service Bulletin: Subject Model Applied Date Region 1. SummaryDokument2 SeitenService Bulletin: Subject Model Applied Date Region 1. SummaryXuân Quang PhạmNoch keine Bewertungen

- Service InformationDokument2 SeitenService InformationMarcelo GiussaniNoch keine Bewertungen

- Alarm Installation V3Dokument18 SeitenAlarm Installation V3Momik BahmansonNoch keine Bewertungen

- IB-300 - RE 4S - Modification in Front Hub Pivot PinDokument2 SeitenIB-300 - RE 4S - Modification in Front Hub Pivot PinKiara GirónNoch keine Bewertungen

- Cirrus Design SR20-2Dokument1 SeiteCirrus Design SR20-2Jonatan BernalNoch keine Bewertungen

- Cx,,vel.12as 2331 TDDokument81 SeitenCx,,vel.12as 2331 TDClaudemiro CostaNoch keine Bewertungen

- M.I.L. On DTC p1349 - Vvti Actuator T-Eg009-03Dokument4 SeitenM.I.L. On DTC p1349 - Vvti Actuator T-Eg009-03Omar Aguilar100% (1)

- 9802/6220 B1-3-1 Tank, Diesel Fuel & FittingsDokument2 Seiten9802/6220 B1-3-1 Tank, Diesel Fuel & FittingsGarcia CruzNoch keine Bewertungen

- E 993 KatalogDokument488 SeitenE 993 KatalogGigi DuruNoch keine Bewertungen

- GM 009 04Dokument2 SeitenGM 009 04Marco Soto CallejaNoch keine Bewertungen

- E02F Spare Part CatalogueDokument21 SeitenE02F Spare Part CatalogueErick JaitaNoch keine Bewertungen

- GarrettDokument96 SeitenGarrettdurmotz100% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesVon EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNoch keine Bewertungen

- Tid 0000209 01 PDFDokument5 SeitenTid 0000209 01 PDFjoaojitoNoch keine Bewertungen

- Repair and Reinforcement of Engine Frame N113: BackgroundDokument1 SeiteRepair and Reinforcement of Engine Frame N113: BackgroundjoaojitoNoch keine Bewertungen

- Tid 0000342 01 PDFDokument3 SeitenTid 0000342 01 PDFjoaojitoNoch keine Bewertungen

- Faulty Relay Causing Faults in Electrical Equipment: BackgroundDokument1 SeiteFaulty Relay Causing Faults in Electrical Equipment: BackgroundjoaojitoNoch keine Bewertungen

- Tid 0000336 01 PDFDokument1 SeiteTid 0000336 01 PDFjoaojitoNoch keine Bewertungen

- Tid 0000205 01 PDFDokument1 SeiteTid 0000205 01 PDFjoaojitoNoch keine Bewertungen

- Earthing Fault On Vehicles With ELC Causes Strange BehaviourDokument1 SeiteEarthing Fault On Vehicles With ELC Causes Strange BehaviourjoaojitoNoch keine Bewertungen

- Tid 0000376 01 PDFDokument1 SeiteTid 0000376 01 PDFjoaojitoNoch keine Bewertungen

- Gas Engine OSC11 G03: Air - Fuel Ratio (LambdaDokument2 SeitenGas Engine OSC11 G03: Air - Fuel Ratio (LambdajoaojitoNoch keine Bewertungen

- Improved Fuel Pipe Connection For The Auxiliary Heater: BackgroundDokument2 SeitenImproved Fuel Pipe Connection For The Auxiliary Heater: BackgroundjoaojitoNoch keine Bewertungen

- Fuel Contaminated Coolant in Engines With Unit Injectors: BackgroundDokument1 SeiteFuel Contaminated Coolant in Engines With Unit Injectors: BackgroundjoaojitoNoch keine Bewertungen

- Cover For Door Emergency Opening Knob: BackgroundDokument1 SeiteCover For Door Emergency Opening Knob: BackgroundjoaojitoNoch keine Bewertungen

- Lateral Vibrations in The Powertrain: BackgroundDokument2 SeitenLateral Vibrations in The Powertrain: BackgroundjoaojitoNoch keine Bewertungen

- Tid 0000220 01 PDFDokument1 SeiteTid 0000220 01 PDFjoaojitoNoch keine Bewertungen

- Plate Wear and Starting Gear On GR801 and GR/GRS900 (Series 3 and 4)Dokument2 SeitenPlate Wear and Starting Gear On GR801 and GR/GRS900 (Series 3 and 4)joaojitoNoch keine Bewertungen

- Modification of Air Suspension (4 Series) : BackgroundDokument3 SeitenModification of Air Suspension (4 Series) : BackgroundjoaojitoNoch keine Bewertungen

- Tid 0000110 01 PDFDokument1 SeiteTid 0000110 01 PDFjoaojitoNoch keine Bewertungen

- The New EBS Control Unit Does Not Work With SLD: BackgroundDokument1 SeiteThe New EBS Control Unit Does Not Work With SLD: BackgroundjoaojitoNoch keine Bewertungen

- Improved Vertical Exhaust System: BackgroundDokument7 SeitenImproved Vertical Exhaust System: BackgroundjoaojitoNoch keine Bewertungen

- Tid 0000058 01 PDFDokument3 SeitenTid 0000058 01 PDFjoaojitoNoch keine Bewertungen

- Fault Types For Unit Injectors: Faults That Do Not Generate Fault CodesDokument1 SeiteFault Types For Unit Injectors: Faults That Do Not Generate Fault CodesjoaojitoNoch keine Bewertungen

- Tid 0000221 01 PDFDokument1 SeiteTid 0000221 01 PDFjoaojitoNoch keine Bewertungen

- Trouble Shooting and Action Against "Extra" Speed Limiter On P3Dokument1 SeiteTrouble Shooting and Action Against "Extra" Speed Limiter On P3joaojitoNoch keine Bewertungen

- Bushing Kit For Front Axle AM/AMA56, AM/AMA61 and AM70: Service Kit, Part No 1 355 387Dokument2 SeitenBushing Kit For Front Axle AM/AMA56, AM/AMA61 and AM70: Service Kit, Part No 1 355 387joaojitoNoch keine Bewertungen

- Adjusting Throttle Reduction For Articulated Bus Idling Speed For Elgas Generation 3Dokument1 SeiteAdjusting Throttle Reduction For Articulated Bus Idling Speed For Elgas Generation 3joaojitoNoch keine Bewertungen

- New Fuel Filter For Engines With Unit Injectors: BackgroundDokument2 SeitenNew Fuel Filter For Engines With Unit Injectors: BackgroundjoaojitoNoch keine Bewertungen

- Air Bellows Chafing Against Crossmember: BackgroundDokument2 SeitenAir Bellows Chafing Against Crossmember: BackgroundjoaojitoNoch keine Bewertungen

- Replacing The Cab Tilt Pump: ItemsDokument1 SeiteReplacing The Cab Tilt Pump: ItemsjoaojitoNoch keine Bewertungen

- Aditya Academy Syllabus-II 2020Dokument7 SeitenAditya Academy Syllabus-II 2020Tarun MajumdarNoch keine Bewertungen

- Electronic Diversity Visa ProgrambDokument1 SeiteElectronic Diversity Visa Programbsamkimari5Noch keine Bewertungen

- Does Adding Salt To Water Makes It Boil FasterDokument1 SeiteDoes Adding Salt To Water Makes It Boil Fasterfelixcouture2007Noch keine Bewertungen

- Title: Smart Monitoring & Control of Electrical Distribution System Using IOTDokument27 SeitenTitle: Smart Monitoring & Control of Electrical Distribution System Using IOTwaleed HaroonNoch keine Bewertungen

- Determinant of Nurses' Response Time in Emergency Department When Taking Care of A PatientDokument9 SeitenDeterminant of Nurses' Response Time in Emergency Department When Taking Care of A PatientRuly AryaNoch keine Bewertungen

- AP8 Q4 Ip9 V.02Dokument7 SeitenAP8 Q4 Ip9 V.02nikka suitadoNoch keine Bewertungen

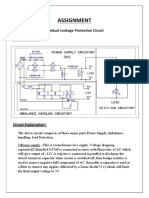

- Assignment: Residual Leakage Protection Circuit Circuit DiagramDokument2 SeitenAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaNoch keine Bewertungen

- Banking Ombudsman 58Dokument4 SeitenBanking Ombudsman 58Sahil GauravNoch keine Bewertungen

- 06 SAP PM Level 1 Role Matrix Template SampleDokument5 Seiten06 SAP PM Level 1 Role Matrix Template SampleRiteshSinhmar100% (1)

- Class 12 Physics Derivations Shobhit NirwanDokument6 SeitenClass 12 Physics Derivations Shobhit Nirwanaastha.sawlaniNoch keine Bewertungen

- HRM Practices in NepalDokument22 SeitenHRM Practices in NepalBodhiNoch keine Bewertungen

- E7d61 139.new Directions in Race Ethnicity and CrimeDokument208 SeitenE7d61 139.new Directions in Race Ethnicity and CrimeFlia Rincon Garcia SoyGabyNoch keine Bewertungen

- Work Energy Power SlidesDokument36 SeitenWork Energy Power Slidessweehian844100% (1)

- Cause Analysis For Spun Pile Crack and BrokenDokument11 SeitenCause Analysis For Spun Pile Crack and BrokenRony LesbtNoch keine Bewertungen

- AYUMJADokument1 SeiteAYUMJASoumet Das SoumetNoch keine Bewertungen

- Course Outline ENTR401 - Second Sem 2022 - 2023Dokument6 SeitenCourse Outline ENTR401 - Second Sem 2022 - 2023mahdi khunaiziNoch keine Bewertungen

- Meta100 AP Brochure WebDokument15 SeitenMeta100 AP Brochure WebFirman RamdhaniNoch keine Bewertungen

- Industrial ReportDokument52 SeitenIndustrial ReportSiddharthNoch keine Bewertungen

- English For Academic and Professional Purposes - ExamDokument3 SeitenEnglish For Academic and Professional Purposes - ExamEddie Padilla LugoNoch keine Bewertungen

- 1994 Manual de Taller Bronco, Econoline, F-Series PDFDokument208 Seiten1994 Manual de Taller Bronco, Econoline, F-Series PDFOscar Cruz100% (1)

- Jurnal Job DescriptionDokument13 SeitenJurnal Job DescriptionAji Mulia PrasNoch keine Bewertungen

- SDS ERSA Rev 0Dokument156 SeitenSDS ERSA Rev 0EdgarVelosoCastroNoch keine Bewertungen

- Department of Ece, Adhiparasakthi College of Engineering, KalavaiDokument31 SeitenDepartment of Ece, Adhiparasakthi College of Engineering, KalavaiGiri PrasadNoch keine Bewertungen

- Halloween EssayDokument2 SeitenHalloween EssayJonathan LamNoch keine Bewertungen

- Abilash - Subramanian CV - 003 PDFDokument4 SeitenAbilash - Subramanian CV - 003 PDFAbilash SubramanianNoch keine Bewertungen

- Uniform Motion WorksheetDokument8 SeitenUniform Motion Worksheetnikhil patro100% (1)

- Chapter 2 HydrateDokument38 SeitenChapter 2 HydrateTaha Azab MouridNoch keine Bewertungen

- 5.0008786 Aluminum GrapheneDokument11 Seiten5.0008786 Aluminum GrapheneBensinghdhasNoch keine Bewertungen

- Job Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeDokument16 SeitenJob Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeNaveen KumarNoch keine Bewertungen

- Prediction of Compressive Strength of Research PaperDokument9 SeitenPrediction of Compressive Strength of Research PaperTaufik SheikhNoch keine Bewertungen