Beruflich Dokumente

Kultur Dokumente

STB S19 00 Datenblatt - Scalpac - EN - v01 PDF

Hochgeladen von

Anastasia Pošarac0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

66 Ansichten2 SeitenOriginaltitel

STB-S19-00--Datenblatt_Scalpac_EN_v01 (3).pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

66 Ansichten2 SeitenSTB S19 00 Datenblatt - Scalpac - EN - v01 PDF

Hochgeladen von

Anastasia PošaracCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

scalpac

manual or semi-automatic bagging system

up to

1200

bags per

hour

highest weighing accuracy

high reliability

sturdy construction

compact design

scalpac-B scalpac-S scalpac-G

Our product portfolio has three manual

bagging systems for open-mouth bags:

Options:

SCALPAC-G, SCALPAC-B, SCALPAC-S. All three

different stainless steel designs

bagging systems are designed for up to 1200

bags per hour and only differ when it comes version with duplex net weigher

to the net weighers used. A net weigher automatic calibration

with gravity, belt or screw feeding is selected ATEX version

depending on the product to be filled.

The product is then fed to the metering unit

(gravity, belt or screw feeding system) via an

inlet chute and metered into the weighing

container. Prefabricated open-mouth bags

made from woven PP, PE or paper are

attached to the filling spout by an employee

and secured.

scalpac

manual or semi-automatic bagging system

Pneumatic clamping jaws hold the bag securely

to the bag clamp, reducing the dust generation

to a minimum. The bag is automatically clamped

via an electronic switch actuation and is

released again after filling. As soon as the bag

has been affixed, the weighed product flows

into the bag through a feed hopper. The filled

bag is transported via a conveyor belt to a bag

sealing machine, which then sews the bag shut,

heat seals it or hot-glues it, depending on the

material.

For free-flowing bulk materials, a net weigher

with gravity dosing is selected. Moderately

flowing products are fed via a belt feeder. For

fine and powdery products, the screw feeder is

best suited.

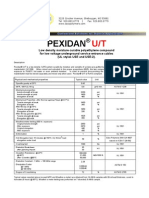

Technical data scalpac-B scalpac-S scalpac-G

Capacity 600 – 1200 bags/hour* 800 – 1200 bags/hour*

Bag placing manual

Bag type pillow bag and gusset bag

Bag material woven PP-bags, PE-bags, paper bags, jute bags

Bag width 300 – 650 mm

Bag length 400 – 1100 mm

Filling weight 5 – 80 kg

Air pressure 6 bar, constant, dry and oil free

Air consumption 12 Nl per cycle

Power supply 380 – 480 VAC, 50/60 Hz 200 – 480 VAC, 50/60 Hz

Power consumption 1,5 – 2,5 kW 3 – 9,5 kW 0,3 – 0,5 kW

*depending on product fl ow ability and operator handling time

Statec Binder GmbH

Industriestrasse 32, 8200 Gleisdorf, Austria

www.statec-binder.com Tel.: +43 3112 38 580 0, office@statec-binder.com

Das könnte Ihnen auch gefallen

- Vq40de Service ManualDokument257 SeitenVq40de Service Manualjaumegus100% (4)

- Costco Packaging Specs AddendumsDokument16 SeitenCostco Packaging Specs Addendumssaravanan_c1Noch keine Bewertungen

- Post Renaissance Architecture in EuropeDokument10 SeitenPost Renaissance Architecture in Europekali_007Noch keine Bewertungen

- SB 2500 SB 3000 Horizontal Baling Presses: WWW - Welger-Recycling - deDokument8 SeitenSB 2500 SB 3000 Horizontal Baling Presses: WWW - Welger-Recycling - deAuraNoch keine Bewertungen

- Columbia Okura 1Dokument29 SeitenColumbia Okura 1Kien Nguyen TrungNoch keine Bewertungen

- 01 STB-S19-00 - Datenblatt Nettowaage EN v03Dokument2 Seiten01 STB-S19-00 - Datenblatt Nettowaage EN v03Widhi RamadhanNoch keine Bewertungen

- Honetop-Rotary Packing Machine HT-8GDokument27 SeitenHonetop-Rotary Packing Machine HT-8GNathaniel FernandesNoch keine Bewertungen

- Innovative: Åkerlund & Rausing Tetrahedron PackageDokument6 SeitenInnovative: Åkerlund & Rausing Tetrahedron Packageravijangde10Noch keine Bewertungen

- Form Fill Seal BrochureDokument12 SeitenForm Fill Seal BrochureMuhammad Alva Budi WardhanaNoch keine Bewertungen

- JMC BulkicebaggerDokument2 SeitenJMC BulkicebaggerHangga Atna WijayaNoch keine Bewertungen

- Innovative Packtech Machines - CatalogueDokument8 SeitenInnovative Packtech Machines - CatalogueDj Spark IndiaNoch keine Bewertungen

- Moba Maxipack EN v01Dokument4 SeitenMoba Maxipack EN v01PedroNoch keine Bewertungen

- Intertec Maquinas para Su Empresa28Dokument1 SeiteIntertec Maquinas para Su Empresa28Alberto VELOSA ROANoch keine Bewertungen

- ELIDA Products CatalogueDokument37 SeitenELIDA Products CatalogueAbhishek AgarwalNoch keine Bewertungen

- Your Palletizing SolutionDokument8 SeitenYour Palletizing SolutionKien Nguyen TrungNoch keine Bewertungen

- Bucket Elevator 1 4.09.30 AmDokument2 SeitenBucket Elevator 1 4.09.30 AmMananjay Kumar SinghNoch keine Bewertungen

- Newte Bag Palletizing 3Dokument4 SeitenNewte Bag Palletizing 3Kien Nguyen TrungNoch keine Bewertungen

- AD Star Bags QualityDokument18 SeitenAD Star Bags QualityKhizzar IshaqueNoch keine Bewertungen

- Wilpat Andes Bio-Pellets Sn101415-3Dokument52 SeitenWilpat Andes Bio-Pellets Sn101415-3Cristian Godoy VargasNoch keine Bewertungen

- Bulk Bag Fillers: Avalon Engineering LTDDokument3 SeitenBulk Bag Fillers: Avalon Engineering LTDmanoj983@gmail.comNoch keine Bewertungen

- Sanovo - Automation For EggsDokument7 SeitenSanovo - Automation For EggsAleksandrs AkuleckisNoch keine Bewertungen

- Fortuna Brochure - World of Fortuna Eng BakeryDokument20 SeitenFortuna Brochure - World of Fortuna Eng BakeryAndrea HernandezNoch keine Bewertungen

- Sw-Pl1 Vertical Weighing Packaging System: 1. ApplicationDokument8 SeitenSw-Pl1 Vertical Weighing Packaging System: 1. ApplicationAlvaro DiazNoch keine Bewertungen

- Alfa Laval Astepo Combibox: Compact Cartoning System For Use in The Food and Beverage IndustriesDokument2 SeitenAlfa Laval Astepo Combibox: Compact Cartoning System For Use in The Food and Beverage IndustriesJosefina DiasNoch keine Bewertungen

- User's Manual: Register Your Product and Get Support atDokument16 SeitenUser's Manual: Register Your Product and Get Support atnelson gonzalezNoch keine Bewertungen

- Terra 3308-50Dokument1 SeiteTerra 3308-50José AlvaradoNoch keine Bewertungen

- Pexidan Ut Saco 0510Dokument2 SeitenPexidan Ut Saco 0510Eddy BrentonNoch keine Bewertungen

- Bulk Bag Filler Brochure WWDokument8 SeitenBulk Bag Filler Brochure WWTran Anh LeNoch keine Bewertungen

- Dession Quotation For Coffee Powder Packing Machine DS-520DZ From Kenny (2022.11.16)Dokument8 SeitenDession Quotation For Coffee Powder Packing Machine DS-520DZ From Kenny (2022.11.16)aura maria ubeda gadeaNoch keine Bewertungen

- Sealed Air Polska System Papierowych Opakowan Amortyzujacych System Papierowych Opakowan Amortyzujacych 593294Dokument8 SeitenSealed Air Polska System Papierowych Opakowan Amortyzujacych System Papierowych Opakowan Amortyzujacych 593294Srikanth VankamamidiNoch keine Bewertungen

- Presto Lift General Catalog PDFDokument36 SeitenPresto Lift General Catalog PDFlalit PatilNoch keine Bewertungen

- Wilcraft Full Product CatalogueDokument256 SeitenWilcraft Full Product CatalogueR.s. Sudarshanan SridharanNoch keine Bewertungen

- As/As-V Sealcut: Pouchmaking Machine For The Automatic Production of Flat and Gusseted PouchesDokument6 SeitenAs/As-V Sealcut: Pouchmaking Machine For The Automatic Production of Flat and Gusseted PouchesillaNoch keine Bewertungen

- Name:-Ebrahim Abd EL-Hadi Ebrahim Section: - 1 Department: - Mechatronics (4 Year)Dokument22 SeitenName:-Ebrahim Abd EL-Hadi Ebrahim Section: - 1 Department: - Mechatronics (4 Year)Ebrahim Abd El HadyNoch keine Bewertungen

- Amalgamod Ultralight - 14U 104HP Folding Case - User GuideDokument2 SeitenAmalgamod Ultralight - 14U 104HP Folding Case - User GuideScappinNoch keine Bewertungen

- Masina de Cusut Saci - GK35-6ADokument3 SeitenMasina de Cusut Saci - GK35-6AIonescuTeodoraNoch keine Bewertungen

- Automatic Form-Fill-Seal Machine For Packaging of Liquid Products E.G. Fresh Milk, Fruit Juices, Water, Cooking Oil and Ghee EtcDokument2 SeitenAutomatic Form-Fill-Seal Machine For Packaging of Liquid Products E.G. Fresh Milk, Fruit Juices, Water, Cooking Oil and Ghee EtcAdil ArifNoch keine Bewertungen

- Digital W.chair PlatformDokument2 SeitenDigital W.chair PlatformSuhaimi RostiNoch keine Bewertungen

- Samwoo Catalogue 2012Dokument24 SeitenSamwoo Catalogue 2012quyNoch keine Bewertungen

- Blood Bags (JTP)Dokument7 SeitenBlood Bags (JTP)arthisoundaryaNoch keine Bewertungen

- Web Chiossi SpeedyT 2023 - Rev01 - ENGDokument2 SeitenWeb Chiossi SpeedyT 2023 - Rev01 - ENGTrung Hieu NguyenNoch keine Bewertungen

- Price List For Lab EquipmentDokument77 SeitenPrice List For Lab Equipmentsouvik5000100% (1)

- Bagging System: Chrono-Weigh E 25-G/E 55-G Reliable Net WeighersDokument4 SeitenBagging System: Chrono-Weigh E 25-G/E 55-G Reliable Net WeighersAlderine KuswardhaniNoch keine Bewertungen

- Juicemaster Professional Mod. 42.6Dokument2 SeitenJuicemaster Professional Mod. 42.6Anonymous snSfklbI8pNoch keine Bewertungen

- Mountainsilos enDokument2 SeitenMountainsilos enXabi LamelasNoch keine Bewertungen

- BagMizer 400CC Manual de OperaciónDokument16 SeitenBagMizer 400CC Manual de OperaciónFrancisco LópezNoch keine Bewertungen

- ITW Stretch Wrapper Octopus - 1800-2800 - S-SFTS Data SheetDokument4 SeitenITW Stretch Wrapper Octopus - 1800-2800 - S-SFTS Data Sheetarun kumarNoch keine Bewertungen

- TAEHWA Encapsulation SystemsDokument8 SeitenTAEHWA Encapsulation SystemsAdrian NovelNoch keine Bewertungen

- Con BeltDokument52 SeitenCon BeltNaeemSiddiquiNoch keine Bewertungen

- TrituradoraDokument12 SeitenTrituradoraMarco Antonio Fuenzalida PinoNoch keine Bewertungen

- Bagging SystemDokument1 SeiteBagging SystemshrinkfilmNoch keine Bewertungen

- General Brochure AVAPACDokument37 SeitenGeneral Brochure AVAPACmarciojunkNoch keine Bewertungen

- Staying Ahead of The CurveDokument8 SeitenStaying Ahead of The CurvehimanshuNoch keine Bewertungen

- JMB-8000 Aseptic Brick Carton Filling Machine For 200-350mlDokument4 SeitenJMB-8000 Aseptic Brick Carton Filling Machine For 200-350mlkanon77Noch keine Bewertungen

- Ei Machinery Pvt. LTD: Manufacturer of End of Line Packing Machinery and Conveyor AutomationDokument6 SeitenEi Machinery Pvt. LTD: Manufacturer of End of Line Packing Machinery and Conveyor AutomationyogiprathmeshNoch keine Bewertungen

- Orwak Power 3420 - enDokument2 SeitenOrwak Power 3420 - enBranko KakucaNoch keine Bewertungen

- Tiger Offshore Catalog LowresDokument64 SeitenTiger Offshore Catalog LowresRafaelNoch keine Bewertungen

- Series FTS : Sack Closing MachinesDokument2 SeitenSeries FTS : Sack Closing MachinesliviuppNoch keine Bewertungen

- BW Intergrated SystemsDokument2 SeitenBW Intergrated SystemsKien Nguyen TrungNoch keine Bewertungen

- Chronos WeighingDokument4 SeitenChronos WeighingIrene ThenNoch keine Bewertungen

- Family Handyman Whole House Storage & OrganizingVon EverandFamily Handyman Whole House Storage & OrganizingFamily HandymanNoch keine Bewertungen

- Knots: An Illustrated Practical Guide to the Essential Knot Types and their UsesVon EverandKnots: An Illustrated Practical Guide to the Essential Knot Types and their UsesNoch keine Bewertungen

- Fce Use of English 1 Teacher S Book PDFDokument2 SeitenFce Use of English 1 Teacher S Book PDFOrestis GkaloNoch keine Bewertungen

- ABBindustrialdrives Modules en RevBDokument2 SeitenABBindustrialdrives Modules en RevBMaitry ShahNoch keine Bewertungen

- Springs: All India Distributer of NienhuisDokument35 SeitenSprings: All India Distributer of NienhuisIrina DroliaNoch keine Bewertungen

- 02 CT311 Site WorksDokument26 Seiten02 CT311 Site Worksshaweeeng 101Noch keine Bewertungen

- Capgemini - 2012-06-13 - 2012 Analyst Day - 3 - Michelin - A Better Way ForwardDokument12 SeitenCapgemini - 2012-06-13 - 2012 Analyst Day - 3 - Michelin - A Better Way ForwardAvanish VermaNoch keine Bewertungen

- Fin Accounting IFRS 2e Ch13Dokument62 SeitenFin Accounting IFRS 2e Ch13Nguyễn Vinh QuangNoch keine Bewertungen

- SHS G11 Reading and Writing Q3 Week 1 2 V1Dokument15 SeitenSHS G11 Reading and Writing Q3 Week 1 2 V1Romeo Espinosa Carmona JrNoch keine Bewertungen

- SL Generator Ultrasunete RincoDokument2 SeitenSL Generator Ultrasunete RincoDariaNoch keine Bewertungen

- 5045.CHUYÊN ĐỀDokument8 Seiten5045.CHUYÊN ĐỀThanh HuyềnNoch keine Bewertungen

- Scoring Rucric Lecture Eassess2.docx NewDokument6 SeitenScoring Rucric Lecture Eassess2.docx NewMaica Ann Joy SimbulanNoch keine Bewertungen

- BAMDokument111 SeitenBAMnageswara_mutyalaNoch keine Bewertungen

- Gobekli TepeDokument2 SeitenGobekli TepeCarl Feagans100% (1)

- Clinical Skills TrainingDokument12 SeitenClinical Skills TrainingSri Wahyuni SahirNoch keine Bewertungen

- MSCM Dormitory Housing WEB UpdateDokument12 SeitenMSCM Dormitory Housing WEB Updatemax05XIIINoch keine Bewertungen

- Tata NanoDokument25 SeitenTata Nanop01p100% (1)

- Lecture 19 Code Standards and ReviewDokument27 SeitenLecture 19 Code Standards and ReviewAdhil Ashik vNoch keine Bewertungen

- Consumer Protection ActDokument34 SeitenConsumer Protection ActshikhroxNoch keine Bewertungen

- Leather PuppetryDokument8 SeitenLeather PuppetryAnushree BhattacharyaNoch keine Bewertungen

- E Voting PPT - 1Dokument11 SeitenE Voting PPT - 1madhu100% (2)

- Joomag 2020 06 12 27485398153Dokument2 SeitenJoomag 2020 06 12 27485398153Vincent Deodath Bang'araNoch keine Bewertungen

- Diagnosis ListDokument1 SeiteDiagnosis ListSenyorita KHayeNoch keine Bewertungen

- Monitor 14sepDokument2 SeitenMonitor 14sepabhaymvyas1144Noch keine Bewertungen

- Fertilisation and PregnancyDokument24 SeitenFertilisation and PregnancyLopak TikeNoch keine Bewertungen

- PDF BrochureDokument50 SeitenPDF BrochureAnees RanaNoch keine Bewertungen

- Chapter 5 - Principle of Marketing UpdateDokument58 SeitenChapter 5 - Principle of Marketing UpdateKhaing HtooNoch keine Bewertungen

- 6int 2008 Dec ADokument6 Seiten6int 2008 Dec ACharles_Leong_3417Noch keine Bewertungen

- Population Second TermDokument2 SeitenPopulation Second Termlubna imranNoch keine Bewertungen

- Unit 1 Bearer PlantsDokument2 SeitenUnit 1 Bearer PlantsEmzNoch keine Bewertungen