Beruflich Dokumente

Kultur Dokumente

Electronic Controller For The Intelligent Management of A Compressor Room From 2 To 4 Devices

Hochgeladen von

Емил Гаврилов0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

36 Ansichten2 SeitenOriginaltitel

LOGIK104_GB

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

36 Ansichten2 SeitenElectronic Controller For The Intelligent Management of A Compressor Room From 2 To 4 Devices

Hochgeladen von

Емил ГавриловCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

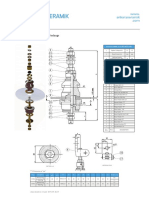

104 Electronic controller for the intelligent management

of a compressor room from 2 to 4 devices

LOGIK 104/15 Pressure control from 03 ÷ 13 Bar

LOGIK 104/30 Pressure control from 13 ÷ 29 Bar

LOGIK 104/50 Pressure control from 29 ÷ 48 Bar

LOGIK104 is an electronic controller able to manage up to four compressors monitoring the air pressure,

the system status and the room temperature.

The Logik104 technology, studied for reacting immediately to the variations of the working pressure,

it allows to have a constant pressure on the line saving the energy and guaranteeing maximum

functionality to the system. Logik104 is easy to install and to set, it can pilot compressors of different

capacities, different factories and equipped with electromechanical or electronic controllers.

It shows by lighting led the possible failures of the compressors.

Display LCD – VDF

for visualization in real time of:

- pressure of start / stop

- working pressure

- room temperature

- the next hour of ON compressor

- the next hour of OFF compressor

Showing led for status compressors:

- ON

- OFF

- IN MAINTENANCE

- IN ALARM

Easy to set by keyboard

Real time clock for setting

the hours of start / stop of

the compressors

Box IP 64

Easy assemblage to wall

Via Garibaldi, 83A - 20054 Nova Milanese (MI) Italy

telefono +39/0362/3700.1 - fax +39/0362/370030

www.logikacontrol.it

104 TECHNICAL FEATURES

LOGIK 104/15 • Operating temperature: 0 ÷ 50 °C with 90% RH, non condensing.

LOGIK 104/30 • Storage temperature: -20 ÷ +70 °C

• Power supply: 230 V.c.a ± 10% 50÷60 Hz.

LOGIK 104/50

• Inputs and outputs via terminal-blocks board and outputs via core hitches

• No.5 function key: ON - OFF - INC. - DEC. - ENTER

• No.4 switches to select operation compressor in Maintenance / Working mode

• No.1 dip-switch to select the compressor capacities in Manual / Automatic setting

• Visualizations by display LCD - VDF with 20 digits x 2 rows for:

- visualization in real time of:

Start/Stop pressure, working pressure, room temperature, next hour of ON/OFF compressors, total working hours for every

single compressor, maintenance timer for every single compressor, alarms

- setting under password of:

Start/Stop pressure, minimum and maximum pressure alarm, minimum and maximum temperature alarm, timer of ON/OFF

on 3 levels for every day of the week, maintenance timer for every single compressor

• No.1 input for temperature probe PT1000 with working range –20 ÷ +80 °C, resolution 1°C

• No.1 input 4 ÷ 20 m.A. for pressure transducer to check the working pressure with range:

Logik104/15 = 0÷15 bar, Logik104/30 = 0÷30 bar, Logik104/50 = 0÷50 bar

• No.1 real time clock with buffer battery

• No.1 non-volatile memory to store data set, compressor status, alarms

• No.1 serial output RS232 for connection with GSM unit or PC for super vision program

• No.4 green led for showing working mode of compressors

• No.4 red led for showing alarms and/or maintenance compressors

• No.4 opto-isolated inputs for survey status compressor, input 12/24-110-230 V.a.c.

• No.5 outputs via relay 8(2) A. 250V.c.a. to pilot: compressors, alarm output

• The electronic controller switches in OFF with micro interruptions of power supply grater than 400 m.sec.

• Weight: 2 kgs.

The Logik104 controller equipment is provided with:

• No.1 temperature probe PT1000 for air temperature check with range -20 ÷ +80 °C, resolution 1°C,

precision ± 0.5°C, cable in silicone rubber, length 4 mt.

• No.1 pressure transducer 4÷20 m.A. to check the working pressure with operating range:

Logik104/15 = 0÷15 bar, Logik104/30 = 0÷30 bar, Logik104/50 = 0÷50 bar

• Window™ application for remote control (super vision and tele assistance)

On request the controller is provided with:

• No.1 GSM unit

Via Garibaldi, 83A - 20054 Nova Milanese (MI) Italy

telefono +39/0362/3700.1 - fax +39/0362/370030

www.logikacontrol.it

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Logik16: Handbook Electronic Controller Logika Control S.R.LDokument20 SeitenLogik16: Handbook Electronic Controller Logika Control S.R.LЕмил Гаврилов100% (5)

- Logik16: Handbook Electronic Controller Logika Control S.R.LDokument20 SeitenLogik16: Handbook Electronic Controller Logika Control S.R.LЕмил Гаврилов100% (5)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Sparet Parts V3F80Dokument44 SeitenSparet Parts V3F80Edgar Flores100% (2)

- ELET 2101 Lab Manual 5Dokument16 SeitenELET 2101 Lab Manual 5hal jordanNoch keine Bewertungen

- 1 KV 250 A 3150 Din 42530 67 3370221Dokument2 Seiten1 KV 250 A 3150 Din 42530 67 3370221Yigit SarıkayaNoch keine Bewertungen

- Xe 90 70 R-SeriesDokument140 SeitenXe 90 70 R-SeriesЕмил ГавриловNoch keine Bewertungen

- Xe 90 70 R-SeriesDokument140 SeitenXe 90 70 R-SeriesЕмил ГавриловNoch keine Bewertungen

- On-Highway: Donaldson Endurance Air Filters Will Go Twice The Distance!Dokument2 SeitenOn-Highway: Donaldson Endurance Air Filters Will Go Twice The Distance!Емил ГавриловNoch keine Bewertungen

- IchillDokument40 SeitenIchillluis andres HerreraNoch keine Bewertungen

- Easytronic Iii Manual: ServiceDokument12 SeitenEasytronic Iii Manual: ServiceЕмил Гаврилов33% (3)

- Thermozorb Heatless Regenerative Air Dryer: TZ22 - TZ903Dokument2 SeitenThermozorb Heatless Regenerative Air Dryer: TZ22 - TZ903Емил ГавриловNoch keine Bewertungen

- Engine Lube and Hydraulic Oil Analysis ProgramDokument8 SeitenEngine Lube and Hydraulic Oil Analysis ProgramЕмил ГавриловNoch keine Bewertungen

- Thermozorb Heatless Regenerative Air Dryer: TZ22 - TZ142Dokument2 SeitenThermozorb Heatless Regenerative Air Dryer: TZ22 - TZ142Емил ГавриловNoch keine Bewertungen

- TZ TZ Dryer 22135834Dokument8 SeitenTZ TZ Dryer 22135834Емил ГавриловNoch keine Bewertungen

- D12IN-D480IN Refrigerated Dryers - Manual - EngDokument89 SeitenD12IN-D480IN Refrigerated Dryers - Manual - EngЕмил ГавриловNoch keine Bewertungen

- Compressor Elements PDFDokument102 SeitenCompressor Elements PDFЕмил ГавриловNoch keine Bewertungen

- Vacuum Packaging Manual New KorDokument44 SeitenVacuum Packaging Manual New KorSameer KhanNoch keine Bewertungen

- 2020 FinalDokument3 Seiten2020 FinalBen ChouNoch keine Bewertungen

- 1SDA100467R1 xt5s 630 Ekip Dip Ls I in 630 4p F FDokument4 Seiten1SDA100467R1 xt5s 630 Ekip Dip Ls I in 630 4p F Fccssaa123Noch keine Bewertungen

- Service Manual: Super-Sonic™ 22Dokument24 SeitenService Manual: Super-Sonic™ 22Jura Zdravnik100% (1)

- MCQ For Power ElectronicsDokument16 SeitenMCQ For Power ElectronicsNabil Ahmed Ali ElhadyNoch keine Bewertungen

- Mars Off Grid Solar Power SystemDokument20 SeitenMars Off Grid Solar Power SystemEben KinaboNoch keine Bewertungen

- 1.-SEMIKRON DataSheet RT380MDokument2 Seiten1.-SEMIKRON DataSheet RT380MvaleriaNoch keine Bewertungen

- L 2 Ohm's Law: Resistance in Circuit Resistance in ParallelDokument3 SeitenL 2 Ohm's Law: Resistance in Circuit Resistance in ParallelCho Wing SoNoch keine Bewertungen

- 3500/15 AC and DC Power Supplies: DatasheetDokument8 Seiten3500/15 AC and DC Power Supplies: DatasheetArthur BastosNoch keine Bewertungen

- JOB SHEET IngDokument8 SeitenJOB SHEET IngariespotterNoch keine Bewertungen

- UD Cable Selection R4Dokument35 SeitenUD Cable Selection R4tonetNoch keine Bewertungen

- Topical Test Chapter 18: AC Circuits Section A: Objective (10 Marks)Dokument4 SeitenTopical Test Chapter 18: AC Circuits Section A: Objective (10 Marks)Wong Chai YenNoch keine Bewertungen

- T/C Extension Cable, FR-KX-G-VVAMSR-1P-1.5SQ: Details of Components CharacteristicsDokument1 SeiteT/C Extension Cable, FR-KX-G-VVAMSR-1P-1.5SQ: Details of Components CharacteristicsDat NguyenNoch keine Bewertungen

- Signat Audio Folder 08Dokument16 SeitenSignat Audio Folder 08Sérgio Marques0% (1)

- Burglar Alarm Design Project SummaryDokument15 SeitenBurglar Alarm Design Project SummaryAhmed M H Al-YousifNoch keine Bewertungen

- Codigos de Error Samsung PDFDokument18 SeitenCodigos de Error Samsung PDFOscar LinoNoch keine Bewertungen

- SS GT4DBDokument10 SeitenSS GT4DBed salvador ap GarayNoch keine Bewertungen

- Poop GPTDokument312 SeitenPoop GPTPatrick Ian BernardNoch keine Bewertungen

- AbstractDokument4 SeitenAbstractMohamed IbrahemNoch keine Bewertungen

- LICODokument16 SeitenLICOAmrNoch keine Bewertungen

- El509 6KG6Dokument2 SeitenEl509 6KG6Diego García MedinaNoch keine Bewertungen

- Auxiliary Power Supplies: Aps6A, Aps10ADokument4 SeitenAuxiliary Power Supplies: Aps6A, Aps10AJosé Alberto Ayala SantosNoch keine Bewertungen

- Tabela Avel Reles 2018Dokument12 SeitenTabela Avel Reles 2018Ricardo RosárioNoch keine Bewertungen

- Projeyardim 1Dokument4 SeitenProjeyardim 1Victor SerranoNoch keine Bewertungen

- EVO1ST TDS n.05 June 2020Dokument1 SeiteEVO1ST TDS n.05 June 2020William EmmanuelNoch keine Bewertungen

- MCB and FuseDokument78 SeitenMCB and Fuseraghu myNoch keine Bewertungen

- Metering CT Burden CalculationDokument1 SeiteMetering CT Burden Calculationlalitendu jenaNoch keine Bewertungen