Beruflich Dokumente

Kultur Dokumente

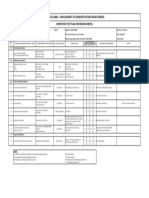

Radiographic Examination: Evaluated By: Name: Name: Name

Hochgeladen von

Trung Tinh HoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Radiographic Examination: Evaluated By: Name: Name: Name

Hochgeladen von

Trung Tinh HoCopyright:

Verfügbare Formate

Report No.

:

RADIOGRAPHIC

01 of 01

EXAMINATION Page:

Request No.:

REPORT

Project Name : Procedure No.: Job No.:

Client Name: Acceptance Standard : Place of Examination:

Item : Dwg. No.: Temperature of the object:

Tag No :

Serial No.:

Type of joint: Welding Process: Extent of Examination:

Number of repair: Surface condition :

Material Type: Weld Size (mm/inch): Date of inspection:

Material Thick( mm): Weld Thk./Reinf. Thick (mm):

X-RAY GAMMA RAY

Type : KV Current : mA Type : Ir 192 Se 75

Test Volatage : KV Current : mA Source Size :

Equipment

Focal Spot Size : mm Ug : Activity : Ci Ug :

S.O.D : mm O.F.D : mm S.O.D : mm O.F.D : mm

Exposure Time : Sec Exposure Time : Sec

Number of exposures: Number of exposures:

Number of Film in Cassette Number of Film in Cassette:

Film Type : Film Size (cm) Technique SWSI DWSI

Technique

Screen Type : Filter DWDI PANORAMIC

Density Required : Radiographic Class: IQI Position: Source Side Film side

IQI Type : IQI Wire Required: Film Processing: Manual Automatic

Imperfection Result

Weld Film Film IQI Wire

No. Welder No. Size Location Remark

Identification Location Density Visible Type ACC REJ RSH

(mm) (mm)

Total of Film 0 Films

ACC: accepted LF: Lack of Fusion LP: Lack of Penetration S.O.D.: Source to Object Distance

RSH: Reshoot BT:Burn Through ISI: Isolated Slag Inclusion O.F.D.: Object to Film Distance

REJ: Rejected CP: Cluster Porosity NSD: Non Significant Defect SWSI: Single Wall Single Image

ABBREVIATION C: Crack IU: Internal Undercut ESI: Elongated Slag Inclusion DWSI:Double Wall Single Image

P: Porosity IC: Internal Concavity EU: External Undercut DWDI:Double Wall Double Image

FM :Film Mark TI: Tungsten Inclusion N/A: Not Applicable IQI: Image Quality Indicator

ER:Excess Root EC: External concavity Ug: Geometric Unshapness

AlphaNDT Reviewed by QC Inspector Reviewed by Client Reviewed by A.I.

Evaluated by: Name: Name: Name:

Qualified:

Signature: Signature: Signature: Signature:

Date: Date: Date: Date:

Das könnte Ihnen auch gefallen

- Radio Graphic Examination Report: International GroupDokument1 SeiteRadio Graphic Examination Report: International GroupMuhammed Abo-FandoodNoch keine Bewertungen

- RT Exm Astar PDFDokument1 SeiteRT Exm Astar PDFSASINoch keine Bewertungen

- Radiographic Testing Report: EGB-S-RT-0002Dokument4 SeitenRadiographic Testing Report: EGB-S-RT-0002Tuấn ĐậuNoch keine Bewertungen

- Creep Damage and Expected Creep LifeDokument9 SeitenCreep Damage and Expected Creep LifeTrương Ngọc SơnNoch keine Bewertungen

- Advanced Inspection Methods For Wind Turbine BladesDokument25 SeitenAdvanced Inspection Methods For Wind Turbine BladesDagoberto AguilarNoch keine Bewertungen

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsVon EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNoch keine Bewertungen

- Corrosion Failures: Theory, Case Studies, and SolutionsVon EverandCorrosion Failures: Theory, Case Studies, and SolutionsNoch keine Bewertungen

- API 570 Pipeline Inspection PDFDokument1 SeiteAPI 570 Pipeline Inspection PDFKhalidMoutarajiNoch keine Bewertungen

- Catalog Tubing Inspection Probes enDokument32 SeitenCatalog Tubing Inspection Probes enMohammed Ilyas MohiuddinNoch keine Bewertungen

- VAIL-20-129-S-007 - Fitness For Service Assessment of Static Equipment - Rev. ADokument25 SeitenVAIL-20-129-S-007 - Fitness For Service Assessment of Static Equipment - Rev. Akunnar corrosionNoch keine Bewertungen

- Tube Expansion Issues & MethodsDokument4 SeitenTube Expansion Issues & MethodsSuleyman HaliciogluNoch keine Bewertungen

- Preventing Htha Failures With The Buckeye ModelDokument2 SeitenPreventing Htha Failures With The Buckeye ModelBangkit WidayatNoch keine Bewertungen

- Potential Damage PKTDokument7 SeitenPotential Damage PKTFebri Ramdani NugrahaNoch keine Bewertungen

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDokument6 SeitenSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenNoch keine Bewertungen

- Keys To Maintenance and Repair of Coke Drums Derrick RogersDokument34 SeitenKeys To Maintenance and Repair of Coke Drums Derrick RogersNatrajiNoch keine Bewertungen

- Introduction To API 571Dokument13 SeitenIntroduction To API 571M. Nasikhun WahidinNoch keine Bewertungen

- Lloyd S Register NBIC Part 3 2017 Edition Key ChangesDokument21 SeitenLloyd S Register NBIC Part 3 2017 Edition Key ChangessreekanthsreedharaNoch keine Bewertungen

- Nuflo Mc-III Exp DatasheetDokument4 SeitenNuflo Mc-III Exp DatasheetJerrydawangNoch keine Bewertungen

- Analyses of Superheater Tube From BoilerDokument8 SeitenAnalyses of Superheater Tube From Boilerromi_hamdaniNoch keine Bewertungen

- CML Optimization FinalDokument31 SeitenCML Optimization FinalFatemeh SaadatmandNoch keine Bewertungen

- Implications of NORSOK M-650 Standard in The OffshoreDokument15 SeitenImplications of NORSOK M-650 Standard in The OffshoreBehroozNoch keine Bewertungen

- Method of Corrosion MappingDokument14 SeitenMethod of Corrosion MappingNur Abdillah SiddiqNoch keine Bewertungen

- HTHA High Temperature Hydrogen Attack Exposed SteelDokument2 SeitenHTHA High Temperature Hydrogen Attack Exposed Steelaecf_13Noch keine Bewertungen

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDokument5 SeitenSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalNoch keine Bewertungen

- CorrosionDokument57 SeitenCorrosionrahul72Noch keine Bewertungen

- What Preparation Is Required Before A Magnetic Flux Leakage (MFL) Tank Inspection Takes PlaceDokument2 SeitenWhat Preparation Is Required Before A Magnetic Flux Leakage (MFL) Tank Inspection Takes Placecal2_uniNoch keine Bewertungen

- ICDA Line 24 Multiphase Flow Modeling Report Draft 1.0Dokument27 SeitenICDA Line 24 Multiphase Flow Modeling Report Draft 1.0Pedro MarquezNoch keine Bewertungen

- 10 1016@j Ijhydene 2020 02 035Dokument9 Seiten10 1016@j Ijhydene 2020 02 035TarunNoch keine Bewertungen

- Sample RBI ReportDokument4 SeitenSample RBI ReportSyed Mahmud Habibur RahmanNoch keine Bewertungen

- ITP For Drum Screen InspectionDokument1 SeiteITP For Drum Screen InspectionkapsarcNoch keine Bewertungen

- OIL - AE - ICDA - PrA - Report - Line#26 - 02 - FINALDokument26 SeitenOIL - AE - ICDA - PrA - Report - Line#26 - 02 - FINALPedro MarquezNoch keine Bewertungen

- UT Procedure PDFDokument14 SeitenUT Procedure PDFAbhayNoch keine Bewertungen

- Phased Array Lab Exercises REV 1.0Dokument19 SeitenPhased Array Lab Exercises REV 1.0Marcus AntoniusNoch keine Bewertungen

- Corrosion Test PiecesDokument23 SeitenCorrosion Test PiecesGijoNoch keine Bewertungen

- Floormap3d MFL Tank Inspection PDFDokument4 SeitenFloormap3d MFL Tank Inspection PDFassurendran0% (1)

- Biological Treatment of Microbial Corrosion: Opportunities and ChallengesVon EverandBiological Treatment of Microbial Corrosion: Opportunities and ChallengesNoch keine Bewertungen

- Positive Material IdentificationDokument2 SeitenPositive Material IdentificationGovindKrishnanNoch keine Bewertungen

- Risk Based Inspection A Complete Guide - 2020 EditionVon EverandRisk Based Inspection A Complete Guide - 2020 EditionNoch keine Bewertungen

- NDT of PipingDokument1 SeiteNDT of PipingVu Tung LinhNoch keine Bewertungen

- Corrosion Monitoring Methods (Chevron)Dokument65 SeitenCorrosion Monitoring Methods (Chevron)Sergey KichenkoNoch keine Bewertungen

- Welding Procedure Specification (WPS) : in The Outer TubeDokument1 SeiteWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNoch keine Bewertungen

- D3230 19 PDFDokument7 SeitenD3230 19 PDFalexanderNoch keine Bewertungen

- On Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitDokument17 SeitenOn Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitAzmi Mohammed NorNoch keine Bewertungen

- Welding Procedure SpecificationDokument2 SeitenWelding Procedure SpecificationSAKDA MAPRADITKULNoch keine Bewertungen

- 9.Mb21 5f Externally Finned TubesDokument4 Seiten9.Mb21 5f Externally Finned Tubesyulianus_srNoch keine Bewertungen

- Corrosion ManagementDokument6 SeitenCorrosion Managementnaren57Noch keine Bewertungen

- Understanding API SIRE Reading 1 Part 2 of 2Dokument54 SeitenUnderstanding API SIRE Reading 1 Part 2 of 2glazetmNoch keine Bewertungen

- Drill String InspectionsDokument13 SeitenDrill String Inspectionsamin peyvandNoch keine Bewertungen

- Esab, Ok 309L (29.12.16)Dokument1 SeiteEsab, Ok 309L (29.12.16)RodrigoNoch keine Bewertungen

- CRA Material PDFDokument114 SeitenCRA Material PDFsenthil_kr100% (3)

- Avoiding 5 Common Pitfalls ofDokument4 SeitenAvoiding 5 Common Pitfalls ofRiccardo CozzaNoch keine Bewertungen

- Inspection RoleDokument18 SeitenInspection Rolesribd9128Noch keine Bewertungen

- DVS 2207-3Dokument12 SeitenDVS 2207-3gura9054Noch keine Bewertungen

- FfsDokument2 SeitenFfsKmt_AeNoch keine Bewertungen

- Asset Intelligence Report - A Primer On High Temperature Hydrogen AttackDokument9 SeitenAsset Intelligence Report - A Primer On High Temperature Hydrogen AttackVajid MadathilNoch keine Bewertungen

- 06189G FrontmatterDokument11 Seiten06189G FrontmatterEd Marti100% (1)

- ATTAR - Gamma Exposure Calculator and RT CalculationsDokument2 SeitenATTAR - Gamma Exposure Calculator and RT CalculationsVishnuGK100% (1)

- NDT Technqiue Selection For TubesDokument14 SeitenNDT Technqiue Selection For TubesTrung Tinh HoNoch keine Bewertungen

- Metallic DepositsDokument2 SeitenMetallic DepositsTrung Tinh HoNoch keine Bewertungen

- OD CrackDokument1 SeiteOD CrackTrung Tinh HoNoch keine Bewertungen

- Typical Tube Defects: NDE Associates, IncDokument1 SeiteTypical Tube Defects: NDE Associates, IncTrung Tinh HoNoch keine Bewertungen

- Ect SurfaceDokument3 SeitenEct SurfaceTrung Tinh HoNoch keine Bewertungen

- Taekyung Lee, Chong Soo Lee: Fatigue & Plasticity Lab., Dept. of Materials Science and Engineering, POSTECHDokument12 SeitenTaekyung Lee, Chong Soo Lee: Fatigue & Plasticity Lab., Dept. of Materials Science and Engineering, POSTECHTrung Tinh Ho100% (1)

- Acceptance Levels For Internal Imperfections in Steel Plate, Strip and Wide Flats, Based On Ultrasonic TestingDokument14 SeitenAcceptance Levels For Internal Imperfections in Steel Plate, Strip and Wide Flats, Based On Ultrasonic TestingTrung Tinh HoNoch keine Bewertungen

- DNVGL RU SHIP Pt4Ch6Dokument118 SeitenDNVGL RU SHIP Pt4Ch6Trung Tinh HoNoch keine Bewertungen

- Offshore Installation Operations (VMO Standard Part 2-4) : DNV-OS-H204Dokument37 SeitenOffshore Installation Operations (VMO Standard Part 2-4) : DNV-OS-H204Trung Tinh HoNoch keine Bewertungen

- SAW Flux StorageDokument2 SeitenSAW Flux StorageTrung Tinh HoNoch keine Bewertungen

- DNVGL RU SHIP Pt2Ch4Dokument132 SeitenDNVGL RU SHIP Pt2Ch4Trung Tinh HoNoch keine Bewertungen

- DNVGL Os C401Dokument133 SeitenDNVGL Os C401Trung Tinh Ho78% (9)

- Certification Memo From ASNTDokument4 SeitenCertification Memo From ASNTTrung Tinh HoNoch keine Bewertungen

- Energy Conversion ProcessesDokument15 SeitenEnergy Conversion Processesimamsakroni048Noch keine Bewertungen

- Static ElectricityDokument10 SeitenStatic ElectricityJohn MillerNoch keine Bewertungen

- Alpha Beta Gamma Nuclear Decay Activity SheetDokument10 SeitenAlpha Beta Gamma Nuclear Decay Activity SheetArlo RivasNoch keine Bewertungen

- Thermosensitive Sol-Gel Reversible HydrogelsDokument15 SeitenThermosensitive Sol-Gel Reversible HydrogelsnunipostNoch keine Bewertungen

- Measurement of Fluorescence Quantum YieldsDokument4 SeitenMeasurement of Fluorescence Quantum YieldsChaudhary Mandeep Singh Dalal100% (1)

- SS SamplingValveBrochureDokument12 SeitenSS SamplingValveBrochureJOBRAN SofienNoch keine Bewertungen

- Shell and Tube Heat ExchangerDokument18 SeitenShell and Tube Heat ExchangertatvaNoch keine Bewertungen

- What Is Polymer Chemistry?Dokument8 SeitenWhat Is Polymer Chemistry?ハジャ 咲良Noch keine Bewertungen

- Materi Aplikasi Reaksi RedoksDokument28 SeitenMateri Aplikasi Reaksi Redokszaharo putriNoch keine Bewertungen

- ACTIFLO® ProcessDokument6 SeitenACTIFLO® ProcesscartagliNoch keine Bewertungen

- Jadual 1 Menunjukkan Takat Lebur Dan Takat Didih Bagi Bahan X, Y Dan ZDokument41 SeitenJadual 1 Menunjukkan Takat Lebur Dan Takat Didih Bagi Bahan X, Y Dan ZWati AtiNoch keine Bewertungen

- Silva2019 Article OptimizationOfLycopeneExtractiDokument11 SeitenSilva2019 Article OptimizationOfLycopeneExtractilunosicaNoch keine Bewertungen

- Ssab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99Dokument1 SeiteSsab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99Agustin FloresNoch keine Bewertungen

- Geodynanics PerforatingCatalog - 05152020Dokument224 SeitenGeodynanics PerforatingCatalog - 05152020McSOLA ONoch keine Bewertungen

- Pit Iagi37 Sdg043 Lambok Full Paper Gas Geochemistry Final PDFDokument12 SeitenPit Iagi37 Sdg043 Lambok Full Paper Gas Geochemistry Final PDFakun cadanganNoch keine Bewertungen

- MMMM Co Located Show Exhibtor List 2022Dokument12 SeitenMMMM Co Located Show Exhibtor List 2022Aamir SaleemNoch keine Bewertungen

- Tangential Flow Filtration BasicsDokument19 SeitenTangential Flow Filtration BasicsKarthik VijayakumarNoch keine Bewertungen

- Experience With Lined and Clad PipelinesDokument17 SeitenExperience With Lined and Clad Pipelinesjoni Mart Sitio100% (1)

- Steam BookDokument66 SeitenSteam Bookdekate_manoj100% (1)

- DocDokument6 SeitenDocapi-287506055Noch keine Bewertungen

- Explanation Text - Reading Comprehensive - Text 1 To 3Dokument4 SeitenExplanation Text - Reading Comprehensive - Text 1 To 3DEA ANNNoch keine Bewertungen

- Absroption Unit in Dilute Nitric Acid ProductionDokument8 SeitenAbsroption Unit in Dilute Nitric Acid ProductionFateh HakeemNoch keine Bewertungen

- 1.8 Gas Well Testing PDFDokument3 Seiten1.8 Gas Well Testing PDFHATEMNoch keine Bewertungen

- A A 52524aDokument4 SeitenA A 52524amuhammed emin akgülNoch keine Bewertungen

- The Chemistry of Cooking and Cleaning - Ellen RichardsDokument106 SeitenThe Chemistry of Cooking and Cleaning - Ellen RichardsSandra Mian100% (2)

- Hostacom M2 U08 100000Dokument16 SeitenHostacom M2 U08 100000javierutnNoch keine Bewertungen

- As 1221 Hose-ReelsDokument2 SeitenAs 1221 Hose-ReelsDo BuiNoch keine Bewertungen

- Identification of The Best Model and Parameters For T-Y-X Equilibrium Data of Ethanol-Water MixtureDokument7 SeitenIdentification of The Best Model and Parameters For T-Y-X Equilibrium Data of Ethanol-Water MixtureMeghana SNoch keine Bewertungen

- SEJ446 Final Report 2014Dokument43 SeitenSEJ446 Final Report 2014Busiku SilengaNoch keine Bewertungen

- Water: Methods For Stabilization of Food Systems by Control of Water ActivityDokument1 SeiteWater: Methods For Stabilization of Food Systems by Control of Water ActivityFood & HealthNoch keine Bewertungen