Beruflich Dokumente

Kultur Dokumente

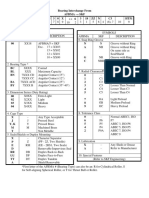

Plane Bearings: Material Indicator Shape or Series

Hochgeladen von

Juan LoaizaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Plane Bearings: Material Indicator Shape or Series

Hochgeladen von

Juan LoaizaCopyright:

Verfügbare Formate

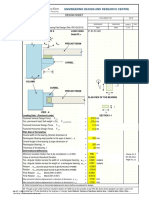

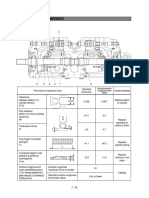

EDT Part Numbering System Revised 11/14

NA 1 G E 7 - 20-LK PLANE BEARINGS

Material Indicator

Polymer: PA, AA, NA, OE, QF, QB, FA, MA, MY, MZ * Housing only indicated as ‘1GE’ or ‘1GE-QK’.

Prefix and suffix indentifies details of assembly

Metals / metal treatments: ZA, ZF, ZN, ZQ, ZZ, Z4 or plane bearing components.

NA 1 G E 7 - 20-LK E = ER bearing

Shape or Series B = Standard flange bearings

1 = Pillow block, standard backing height C = ER flange bearing

10 = Pillow block, low backing height

L = Standard length locking sleeve

2 = Two-bolt flange, standard bolt centers

M = ER locking sleeve

6 = Two-bolt flange, small bolt pattern

3 = Three-bolt extension flange (standard) N = Extra narrow locking sleeve

23 = Three-bolt extension flange (smaller profile) DF = Double Flange, DoubleLock®

22 = Three-bolt flange (triangular) I = Self-aligning insert

32 = Three-bolt flange (round)

P = Poly-Round® Plus

4 = Four-bolt flange

O = Poly-Sphere® insert

24 = Piloted flange, four-bolt

5 = Take-up, narrow slot [PA] T = Tool, installation arbor

7 = Take-up, wide slot [ZA] T = Split collar

8 = Hanger bearing

W = Thrust washer

9 = Tapped base pillow block

NON-HOUSING HOUSING OPTIONAL HOUSING MODIFIER

NA 1 G E 7 - 20-LK U = Non-housing product G = EDT “KG” cast polymer housing (spherical ID) -CB = Cap, blind

V = Single split collar A = Stainless housing (spherical ID) -CT = Cap, thru

Housing or W =

B =

Double split collar

Polymer block bearing (straight bore)

E =

F =

Type E housing

Mild steel housing (spherical ID)

-0_ = Housing modification

-QK = QuiKlean®

Non-Housing Style L = Stainless steel split flangette housing

O = Poly-Sphere® bearing

P = Stainless steel cast housing -Q = Square bolt holes

-SM = Wider spherical radius

*Full housing P/N - 3 digits (Ex: 1GE) EX: QF 1 A E - QK 7 - 20 - LK

EDT

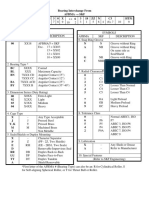

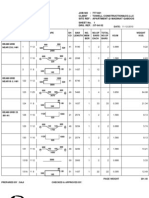

NA 1 G E 7 - 20-LK RING EDT

SIZE GROUP SPHERICAL OD

RING EDT

SIZE GROUP SPHERICAL OD

GROUP TYPE E OD’s ID

01 65mm OD x 1.35 ID

Group Size 203

204

A =

B =

1.575” / 40 mm

1.850” / 47 mm

213

214

Z =

K =

4.724” / 120 mm

4.921” / 125 mm

02

03

72mm

85mm

OD

OD

x

x

1.54

1.87

ID

ID

205 C = 2.047” / 52 mm 215 L = 5.128” / 130 mm 04 90mm OD x 2.10 ID

Dimensional interchange 206 D = 2.441” / 62 mm 216 M = 5.511” / 140 mm 05 100mm OD x 2.35 ID

207 E = 2.835” / 72 mm 217 N = 5.905” / 150 mm 06 120mm OD x 2.65 ID

208 F = 3.150” / 80 mm 218 O = 6.299” / 160 mm 07 125mm OD x 3.14 ID

209 G = 3.346” / 85 mm 219 P = 6.693” / 170 mm 08 145mm OD x 3.70 ID

210 H = 3.543” / 90 mm 220 Q = 7.480” / 190 mm 09 175mm OD x 4.20 ID

211 I = 3.937” / 100 mm 221 R = 7.874” / 200 mm 10 195mm OD x 4.70 ID

212 J = 4.331” / 110 mm 11 212mm OD x 5.20 ID

O = Standard part 2 = Poly-Round® Plus with Double Flange DoubleLock® sleeve

NA 1 G E 7 - 20-LK C = Custom part 3 = Poly-Round® narrow, no locking sleeve (with or without housing)

H = Hardened steel 4 = Poly-Round® narrow and locking sleeve (with or without housing)

Modifier M = Mild steel

Q = Square bolt hole

5 = Poly-Round® in housing (no locking sleeve)

7 = Poly-Round® with locking sleeve (with or without housing)

T = Split 8 = Ball bearing in housing

6 = 316 Stainless steel components 9 = ALL-ROUND® Supreme bearing (with or without housing)

P = Poly-Round® Plus assembly

Inches in 16th’s (Ex: 1-1/4” = 20/16 → 20) OPTIONAL MODIFIER (EX: QF 1 A E - QK 7 - 20 - LK)

NA 1 G E 7 - 20-LK OR

Fractions (Ex: 1-1/4”) -04 = 0.6 Longer locking sleeve -HT = High temperature

-04-LK = 0.6 Longer sleeve, DoubleLock® -HTV = High temp, fixed end

Shaft/ID Size Metric with “M” or “mm” suffix -LK = KleenCap® DoubleLock® -HTE = High temp, expansion end

(Ex: 20M OR 20mm) -LC = DoubleLock® (Obsolete, now LK or MC) -OS = Oven series

(indicated as “x” in the catalog) -MC = DoubleLock®

EX: 4Y1GE8-20GX

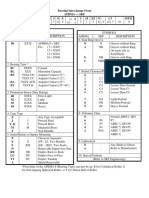

4Y205-16GX BALL BEARINGS

Ball Bearing Material Ball Bearing Style BB Ring Size OR Housing Modifier - Shaft Lubricant Modifier

4 400 stainless Y set-screw (also B) For inserts - refer to Blank if bearing only G - Food grade

Group Size section above Not an assembly size Grease Y - High temp food grade

X Standard

in

16ths F - Food grade (-55° to 200°)

*For assemblies - use mounted; ball J, B, P - Miscellaneous food

3 300 stainless U wide eccentric (also A) 3-digit Housing part number 8

bearing in housing Z Shield

Solid lube grades

- polymer C - Food grade non-corrosive

5 NC steel E narrow eccentric Example: K, R - High temperature O Open

6 52100 steel 0 unmounted 205 group / ring size E, D - Industrial grades B Bare

Solid lube

W, M, T, V - Various

temperature

7 alloy F flanged unmounted 1GE housing style V Vacuum grade

- graphite ranges

SM Wider unit

360-574-7294 FAX 360-574-3834 edtcorp.com edtsales@edtcorp.com PN-1

EDT Split bearing assembly part numbers

A split locking sleeve has two (2) DoubleLock®

collars in order to stay round.

A standard Poly-Round® insert does not space

the two collars far enough outside of the stainless

X housing to allow full wear of a Poly-Round®

bearing (longevity due to a thick bearing wall is

one of the advantages of Poly-Round® bearings.

To remedy this, split housings must be mated with a symmetrical

style of Poly-Round®, designated as ‘OS.’ An OS Poly-Round®

allows a thrust surface on both sides of the housing that, even with

significant wear over time, should not intersect the housing.

In all split assembly part numbers, it is necessary to

indicate with ‘T’ which component(s) are spliT

Housing p/n is #AC-SPLIT

Insert is _ _IUCT-C-OS

Locking sleeve is ZALUCT-16-OS (or ZALUCT-16-OS-04 if extra length is needed for

shaft expansion)

Examples of Part Numbering options

QF2ACT7T-16T Indicates housing, insert, and locking sleeve are split

QF2ACT7T-16 Indicates housing and insert are split, but locking sleeve is 1-piece

QF2ACT7-16 Indicates split housing with 1-piece insert and 1 piece set-screw locking

sleeve

NA2ACT5T-16 Indicates ss split 2-bolt with split Poly-Round® and no sleeve (5 assembly) for 1" shaft

Assembly considerations

You can have a split housing with a 1-piece or split Poly-Round®

You can have a split Poly-Round® with a 1-piece or split sleeve

You can NOT have a split sleeve without having a split housing and split bearing

You MUST have a split housing and a split bearing in order to use a split sleeve

You can NOT use a split sleeve with a 1-piece Poly-Round®

You can NOT use a split Poly-Round® with a 1-piece housing

You can use a split Poly-Round® without a locking sleeve (…5T), but the shaft material and surface finish MAY

compromise the longevity of the Poly-Round® (won’t be as long lived as running with a sleeve). Operating

without a locking sleeve is not a Poly-Round® failure and therefore not an EDT warranty issue.

Note: For high load applications: choose Poly-Sphere® bearings instead of Poly-Round® inserts.

Poly-Sphere® maximizes load capacity of the polymer because the OD is almost entirely

supported by the stainless housing, versus the OS style where only the major OD is supported

by the housing.

PN-2 edtcorp.com edtsales@edtcorp.com FAX 360-574-3834 360-574-7294

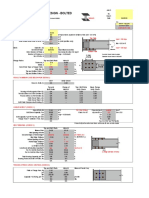

EDT Ball Bearing Part Numbering System

Ball Bearing Bearing or

Material Ball Bearing Style Housing Size Modifier Shaft Lubricant* Modifier

Bearing Size

Blank

4 400 stainless Y Set screw Examples: only (not in G Food grade Grease X Standard

assembly) 16ths

EPL†

3 300 stainless U Wide eccentric (also A) 205 Ring size F Food grade (-55° to 200°F) Z Shield

8 Mounted EPL†

5 NC steel E Narrow eccentric 1GE Housing group ball bearing J,B,P Other food grade designations O Open

in housing

EPL†

6 52100 steel 0 Unmounted C Food grade non-corrosive SM Wider unit

(Refer to

charts below) EPL†

Food grade hi temp

7 Alloy F Flanged unmounted K (-25° to 350°F)

B Set screw, commodity E Industrial grades EPL†

Temp -250° to +250°F

A Wide eccentric, commodity W EGL‡

(vacuum grades available, “V”)

Temp +32° to +450°F

M EGL‡

(vacuum grades available, “V”)

Temp +40° to +650°F

T EGL‡

(vacuum grades available, “V”)

*Lubricants listed as food grade †

EPL: EDT polymer lube ‡

EGL: EDT graphite lube

are designated H1

For more information about EDT solid lubricants see the next page.

Housing Shape / Housing Material Group /

Profile Indicators Indicators Size Indicators

Indicators Housing styles Indicators Housing material Spherical Size: EDT

Ball Bearing Ball Bearing OD Group

1 Pillow block G Polymer; EDT “KG” Ring Size Housing ID Size

2 2-Bolt flange A Stainless 304/316 201, 202, 203 1.575” / 40mm A

3 3-Bolt, extension F Cast iron 204 1.850” / 47mm B

4 4-Bolt P Cast stainless 205 2.047” / 52mm C

5 Take-up, narrow E Type E stainless 206 2.441” / 62mm D

6 2-Bolt flange, small bolt pattern 207 2.835” / 72mm E

7 Take-up, wide 208 3.150” / 80mm F

8 Hanger 209 3.346” / 85mm G

9 Tapped base pillow block 210 3.543” / 90mm H

10 Pillow block, low backing height 211 3.937” / 100mm I

22 3-Bolt, triangular 212 4.331” / 110mm J

23 3-Bolt, extension, smaller profile 214 4.921” / 125mm K

24 4-Bolt, piloted 215 5.128” / 130mm L

32 3-Bolt, round

Additional Sizes (not available in SS)

EDT

Group

Ring Size Spherical OD Size

213 4.724” / 120mm Z

216 5.511” / 140mm M

217 5.905” / 150mm N

218 6.299” / 160mm O

219 6.693” / 170mm P

220 7.480” / 190mm Q

221 7.874” / 200mm R

360-574-7294 FAX 360-574-3834 edtcorp.com edtsales@edtcorp.com PN-3

Radial Poly-Round® Part Numbering Guide

OE 6200 ________ RPR Part Number Examples

Material identifier Industry part # Any modifier Radial Poly-Round ®

OE6200RPR

Ref: Material (EDT assign) OEF691/6RPR

Selection Chart QFR6-2RPR

(See chart above)

FOR MORE INFORMATION, REFER TO THE UNMOUNTED RADIAL BEARINGS CATALOG SECTION

Type E and RPB Part Numbering Guide

Housing Style

Polymer material for 1=2 Bolt Pillow Block Shaft Size

Poly-Sphere® bearing Type E / RPB Group Size

4=4-Bolt 1-1/8" thru 5" (in 16th) and

NA 14=4 Bolt Pillow Block metric sizes (ie 85m)

Part Numbering

QF 24=Piloted 4-Bolt

Explanation

QF 1 E 8 -55

Sleeve Indicator

Indicates Split Housing Material Indicates Split T=Split Sleeve

Poly-Sphere® E=SS Housing Housing -LKV = DoubleLock® with collar

T=Split G=Polymer Housing T=Split -LKE = DoubleLock® expansion (w/o collar)

"T" is optional when the component is spliT (available SS ONLY) BLANK = Double Flange DoubleLock®

FOR MORE INFORMATION, REFER TO THE TYPE E CATALOG SECTION

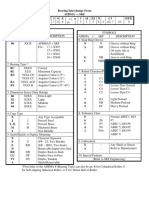

EDT Solid Lubricants

Food-Grade

EDT Solid Lube Solid Lubricant ‘Food grade’ lubricants are rated H-1 (incidental food contact) Color Operating

PN Indicator Type Temperature

Food grade oil- permeated polymer solid lube utilizing high performance synthetic lubricants. Formulated to withstand and inhibit

-55°F to 200°F

F EPL corrosion in most food-processing environments that involve moisture and wash-down, performs equally well in similar industrial white

(-48°C to 93°C)

applications. Low temp to -55°F (-48°C).

Food grade oil-permeated polymer solid lube utilizing high performance synthetic lubricants. Same kinds of food-processing and -65°F to 200°F

B EPL white

industrial applications as F lube (withstand moisture, corrosion inhibitors) with low temp to -65°F (-54°C) (-54°C to 93°C)

Food grade oil-permeated polymer solid lube utilizing high performance synthetic lubricants. Moisture resistance and corrosion -25°F to 350°F

K EPL white

inhibitors like F lube, with the ability to operate in high temps to 350°F (176°C) (-32°C to 176°C)

Food grade oil-permeated polymer solid lubricant utilizing high performance synthetic lubricants. Designed to resist moisture, with -33°F to 350°F

C EPL white

more aggressive resistance to cleaners including strong oxidizers (elements that are high pH.) High temp stability to 350°F (176°C) (-36°C to 176°C)

Food grade graphite-based solid lube resistance to most chemicals (wide pH range, except extreme pH.) Unaffected by moisture,

-150°F to 250°F

W EGL radiation and UV resistant. Wide temperature range -150°F to 250°F. Low friction. Inert nature of graphite can be useful in wide black

(-101°C to 121°C)

range of applications. EGL is brittle and impact may accelerate loss of the lube. Vacuum grade available: WV.

Food grade graphite based solid lubricant designed to operate within the range of most high temperature processing applications,

250°F to 450°F

M EGL from 250°F to 450°F including submerged in oil & other liquids, in ovens and fryers. UV- and radiation- resistant. Low friction. black

(121°C to 232°C)

Hardness of lube can be advantageous with abrasion. EGLs are brittle, M is more brittle than W. Vacuum grade available: MV.

Food grade graphite based solid lubricant designed to operate within the range of industrial- and some food- processing

450°F to 650°F

T EGL applications, from 450°F to 650°F; intermittently to 900°F is feasible. Abrasion-, radiation- and UV- resistant. Low friction. EGLs are black

(232°C to 343°C)

brittle, T more brittle than M. Vacuum grade available: TV.

Note: solid lubricants reduce the maximum speed and load capacity of bearings

PN-4 edtcorp.com edtsales@edtcorp.com FAX 360-574-3834 360-574-7294

Das könnte Ihnen auch gefallen

- 2006 - LIVRO - Epoxy Adhesive Formulations PDFDokument554 Seiten2006 - LIVRO - Epoxy Adhesive Formulations PDFÉrica Rodrigues100% (2)

- PQC - Typical Details of Rigid Pavement Drawing - 22!03!2021-ModelDokument1 SeitePQC - Typical Details of Rigid Pavement Drawing - 22!03!2021-ModelLalit Choudhary100% (1)

- Injection Mold Design DetailsDokument43 SeitenInjection Mold Design DetailsKen100% (1)

- Material Equivalent STD PDFDokument1 SeiteMaterial Equivalent STD PDFANIL100% (1)

- Design Sheet: View A Load Case= Nodal ID = α F F F Precast BeamDokument5 SeitenDesign Sheet: View A Load Case= Nodal ID = α F F F Precast BeamGanesh PrabuNoch keine Bewertungen

- Pile Cap Design OriDokument14 SeitenPile Cap Design OriHoihogo Hoi100% (1)

- AFBMA Bearing InterchangeDokument1 SeiteAFBMA Bearing Interchangejaviervb100% (1)

- AISC-34 Gusset PlateDokument4 SeitenAISC-34 Gusset PlateMartin Cristobal CupitayNoch keine Bewertungen

- Pneumatic StructuresDokument9 SeitenPneumatic StructuresMaitreyi YellapragadaNoch keine Bewertungen

- Design of Bolted Gusset Base OF COLUMN (FOR HEAVELY LOADED COLUMS)Dokument5 SeitenDesign of Bolted Gusset Base OF COLUMN (FOR HEAVELY LOADED COLUMS)Uttam Raj SutraveNoch keine Bewertungen

- Aisc 34Dokument4 SeitenAisc 34AlaaBadwyNoch keine Bewertungen

- Pre Qualified Weld DesginationDokument33 SeitenPre Qualified Weld DesginationSumit patilNoch keine Bewertungen

- End Plate Conn. To Hollow Col. EC2Dokument26 SeitenEnd Plate Conn. To Hollow Col. EC2Raymond SabadoNoch keine Bewertungen

- Column W10x49 2L6x4x1/2 BraceDokument4 SeitenColumn W10x49 2L6x4x1/2 BraceDario Federico Noguez GonzalézNoch keine Bewertungen

- Iso 19598 2016Dokument9 SeitenIso 19598 2016相鸣宇50% (2)

- AFBMA To SKF Bearing Interchange PDFDokument1 SeiteAFBMA To SKF Bearing Interchange PDFaazznovskyNoch keine Bewertungen

- AISC LRFD Moment Connections BoltedDokument531 SeitenAISC LRFD Moment Connections BoltedManoj JaiswalNoch keine Bewertungen

- 2020 06 Data Sheet KHS-T Wafer BodyDokument4 Seiten2020 06 Data Sheet KHS-T Wafer BodypeterNoch keine Bewertungen

- AFBMA Bearing Interchange PDFDokument1 SeiteAFBMA Bearing Interchange PDFvandoNoch keine Bewertungen

- AFBMA Bearing Interchange PDFDokument1 SeiteAFBMA Bearing Interchange PDFaazznovskyNoch keine Bewertungen

- AFBMA Bearing InterchangeDokument1 SeiteAFBMA Bearing InterchangevandoNoch keine Bewertungen

- AFBMA Bearing Interchange PDFDokument1 SeiteAFBMA Bearing Interchange PDFfabian aguilarNoch keine Bewertungen

- AFBMA Bearing Interchange PDFDokument1 SeiteAFBMA Bearing Interchange PDFAkhyar HidayatNoch keine Bewertungen

- AFBMA Bearing InterchangeDokument1 SeiteAFBMA Bearing InterchangevandoNoch keine Bewertungen

- AFBMA Bearing Interchange PDFDokument1 SeiteAFBMA Bearing Interchange PDFRigeNoch keine Bewertungen

- AFBMA Bearing InterchangeDokument1 SeiteAFBMA Bearing InterchangeantonNoch keine Bewertungen

- AFBMA To SKF PDFDokument1 SeiteAFBMA To SKF PDFaazznovskyNoch keine Bewertungen

- Nomenclatura SKFDokument1 SeiteNomenclatura SKFJuan José MeroNoch keine Bewertungen

- AFBMA To SKF PDFDokument1 SeiteAFBMA To SKF PDFaazznovskyNoch keine Bewertungen

- Conversion AFBMA - To - SKFDokument1 SeiteConversion AFBMA - To - SKFGABRIEL MATTOSNoch keine Bewertungen

- AFBMA To SKF PDFDokument1 SeiteAFBMA To SKF PDFrfriosEPNoch keine Bewertungen

- AFBMA To SKFDokument1 SeiteAFBMA To SKFfahrian05Noch keine Bewertungen

- NGK Resistor Covers Decoding EnglishDokument3 SeitenNGK Resistor Covers Decoding EnglishKostiantyn UsenkoNoch keine Bewertungen

- Air Cylinder: Are Added To The Mounting TypesDokument124 SeitenAir Cylinder: Are Added To The Mounting Typesjakalae5263Noch keine Bewertungen

- Bearing Nomenclature Housing NomenclatureDokument7 SeitenBearing Nomenclature Housing NomenclatureRajmohan KushwahaNoch keine Bewertungen

- X2FS140Dokument1 SeiteX2FS140Bahram BandeshahNoch keine Bewertungen

- LINK BELT Yatakli Rulman Uygulama KilavuzuDokument38 SeitenLINK BELT Yatakli Rulman Uygulama Kilavuzugizem.kilicNoch keine Bewertungen

- Product Risk Matrix DivCDokument13 SeitenProduct Risk Matrix DivCSamuel CamachoNoch keine Bewertungen

- Catalogo 2Dokument84 SeitenCatalogo 2carteauNoch keine Bewertungen

- Toyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p048Dokument1 SeiteToyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p048sơn forkliftNoch keine Bewertungen

- Ca2 ZDokument105 SeitenCa2 ZAde RachmanNoch keine Bewertungen

- PSI Flange Isolation Ordering Guide/Work Sheet: RubberDokument1 SeitePSI Flange Isolation Ordering Guide/Work Sheet: RubberVíctor PonteNoch keine Bewertungen

- AISC 34 Gusset PlateDokument4 SeitenAISC 34 Gusset PlateAnonymous 5ZwT2C2BTANoch keine Bewertungen

- AISC 13ed LRFD Bolted Moment Connections Post r4Dokument504 SeitenAISC 13ed LRFD Bolted Moment Connections Post r4Amresh KumarNoch keine Bewertungen

- 2018-2020 Yamaha mt-07 CAP4Dokument93 Seiten2018-2020 Yamaha mt-07 CAP4Ernesto Capdepon CarvajalNoch keine Bewertungen

- Hande AxleDokument43 SeitenHande Axleeman haghshenasNoch keine Bewertungen

- High-Performance External Gear Pump Azpb: FeaturesDokument4 SeitenHigh-Performance External Gear Pump Azpb: FeaturesMichail ArmitageNoch keine Bewertungen

- Bearing Nomenclature: Type of Bearing and Their CodeDokument2 SeitenBearing Nomenclature: Type of Bearing and Their CodeRajNoch keine Bewertungen

- Bearing Nomenclature: Type of Bearing and Their CodeDokument2 SeitenBearing Nomenclature: Type of Bearing and Their CodeRajNoch keine Bewertungen

- Double Ball ValveDokument5 SeitenDouble Ball ValveValmac ServicesNoch keine Bewertungen

- Bolts Non-Structural (A-307) A325 A449 A490 Rivets (Obsolete)Dokument40 SeitenBolts Non-Structural (A-307) A325 A449 A490 Rivets (Obsolete)claudio perez prietoNoch keine Bewertungen

- Compression Members 2Dokument31 SeitenCompression Members 2Nicole Reyes100% (1)

- Chapter 3 Steel 23-24Dokument66 SeitenChapter 3 Steel 23-24nyankyalps5Noch keine Bewertungen

- Chelsea 870 Series: Ten Bolt Powershift P.T.ODokument2 SeitenChelsea 870 Series: Ten Bolt Powershift P.T.Oayman akrabNoch keine Bewertungen

- ReleiDokument16 SeitenReleistarostrugaNoch keine Bewertungen

- C5BA03 How To Order MOVSDokument1 SeiteC5BA03 How To Order MOVSIgor PNoch keine Bewertungen

- Pressure Uessel and Piping CadesDokument9 SeitenPressure Uessel and Piping CadesJoão Paulo VissottoNoch keine Bewertungen

- Thermocouples High TemperatureDokument2 SeitenThermocouples High TemperatureEliasNoch keine Bewertungen

- EG-Series-HIWIN CatalogDokument17 SeitenEG-Series-HIWIN CatalogLoc HuynhNoch keine Bewertungen

- Series: Intrinsically Safe ValvesDokument1 SeiteSeries: Intrinsically Safe ValvesAndi FebriantoNoch keine Bewertungen

- SKILLS BasePlate EN PDFDokument82 SeitenSKILLS BasePlate EN PDFandibolNoch keine Bewertungen

- Group 2 Major Component: 1. Main PumpDokument7 SeitenGroup 2 Major Component: 1. Main PumpHậu MinhNoch keine Bewertungen

- Column W10x49 2L6x4x1/2 BraceDokument4 SeitenColumn W10x49 2L6x4x1/2 Bracek.m.ariful islamNoch keine Bewertungen

- Products & Die ListDokument25 SeitenProducts & Die ListShabanaNoch keine Bewertungen

- Consolidated Bearing Cylindrical Roller BearingDokument80 SeitenConsolidated Bearing Cylindrical Roller BearingJuan LoaizaNoch keine Bewertungen

- Timken Spherical Roller Bearing Solid-Block Housed UnitsDokument6 SeitenTimken Spherical Roller Bearing Solid-Block Housed UnitsEdi GuarnizoNoch keine Bewertungen

- Solid Block HU CatalogDokument184 SeitenSolid Block HU CatalogOrta GonzalezNoch keine Bewertungen

- SAF Housed Unit Catalog 1Dokument126 SeitenSAF Housed Unit Catalog 1Noche de EstrellasNoch keine Bewertungen

- Catalogo Equivalencias Chumaceras PDFDokument180 SeitenCatalogo Equivalencias Chumaceras PDFC.Z. InsignaresNoch keine Bewertungen

- SRB Steel Auxilary Covers PDFDokument6 SeitenSRB Steel Auxilary Covers PDFJuan LoaizaNoch keine Bewertungen

- SRB Steel Auxilary Covers PDFDokument6 SeitenSRB Steel Auxilary Covers PDFJuan LoaizaNoch keine Bewertungen

- Catalogo Equivalencias Chumaceras PDFDokument180 SeitenCatalogo Equivalencias Chumaceras PDFC.Z. InsignaresNoch keine Bewertungen

- Drymortar BasicsDokument17 SeitenDrymortar Basicsoffice.rotaqoNoch keine Bewertungen

- ASTM A276-05aDokument7 SeitenASTM A276-05aNadhiraNoch keine Bewertungen

- Designed: Checked:: North Luzon Expressway Project Leighton Contractors / Maunsell / DCCDDokument2 SeitenDesigned: Checked:: North Luzon Expressway Project Leighton Contractors / Maunsell / DCCDDan PeckleyNoch keine Bewertungen

- FreehcpDemo4 2AHJDokument3 SeitenFreehcpDemo4 2AHJOriana Palencia Finol100% (1)

- PDS - Sika MonoTop-412 MYDokument4 SeitenPDS - Sika MonoTop-412 MYNorlizawati YusofNoch keine Bewertungen

- Flat Oval Duct and Fittings PDFDokument15 SeitenFlat Oval Duct and Fittings PDFolivaresjhonNoch keine Bewertungen

- 3 Information Series The Welding of Stainless Steel MaterialDokument6 Seiten3 Information Series The Welding of Stainless Steel MaterialRamzi BEN AHMEDNoch keine Bewertungen

- Experimental Study of Polypropylene Fiber-Reinforced ConcreteDokument14 SeitenExperimental Study of Polypropylene Fiber-Reinforced Concreteprajwal ursNoch keine Bewertungen

- Waste Recycling in Malaysia: Problems and Prospects: Mohd Nasir HassanDokument9 SeitenWaste Recycling in Malaysia: Problems and Prospects: Mohd Nasir HassanRed Jagung FishNoch keine Bewertungen

- RD257581 (Parent RD 159179) - HOL22 BULK - YIG-06614Dokument14 SeitenRD257581 (Parent RD 159179) - HOL22 BULK - YIG-06614Phương Thanh TrịnhNoch keine Bewertungen

- DEGALAN 66 02 N eDokument2 SeitenDEGALAN 66 02 N echungyang.gohNoch keine Bewertungen

- Conclusion Results and Discussion: Enhancement of Bio-Plastic Using Eggshells and Chitosan On Potato Starch BasedDokument1 SeiteConclusion Results and Discussion: Enhancement of Bio-Plastic Using Eggshells and Chitosan On Potato Starch BasedAbigail Marie Therese FuentesNoch keine Bewertungen

- Laboratory Activities 4, 5 and 6Dokument10 SeitenLaboratory Activities 4, 5 and 6REX IAN BONGALESNoch keine Bewertungen

- CERT SAE 4340 180mm 8.195mtDokument1 SeiteCERT SAE 4340 180mm 8.195mtMiguel AychasiNoch keine Bewertungen

- Microstructural Examination of Ceramic MaterialDokument16 SeitenMicrostructural Examination of Ceramic MaterialRudrang ChauhanNoch keine Bewertungen

- Dawood Rebar CoDokument32 SeitenDawood Rebar Cocbala_2006Noch keine Bewertungen

- Fixing GIB PlasterboardDokument4 SeitenFixing GIB PlasterboardLucas RibeiroNoch keine Bewertungen

- Microporous WikiDokument2 SeitenMicroporous WikiIris BalcarceNoch keine Bewertungen

- Chapter 4Dokument6 SeitenChapter 4Zaw Min TunNoch keine Bewertungen

- PP PE PE-RT PPR High Speed Extrusion Line 16-63mm Benk Machinery Co LTDDokument7 SeitenPP PE PE-RT PPR High Speed Extrusion Line 16-63mm Benk Machinery Co LTDazeez engNoch keine Bewertungen

- Wear Behavior of Graphene-Reinforced Alumina-Silicon Carbide Whisker NanocompositeDokument11 SeitenWear Behavior of Graphene-Reinforced Alumina-Silicon Carbide Whisker NanocompositeTanzil ZaidiNoch keine Bewertungen

- Chapter 2 PRDokument8 SeitenChapter 2 PRKatsuki HashimotoNoch keine Bewertungen

- Astm A615 A615m 20Dokument4 SeitenAstm A615 A615m 20arieNoch keine Bewertungen

- BGMs in Mine Construction Breul McilwraithDokument8 SeitenBGMs in Mine Construction Breul Mcilwraithconsultor9010Noch keine Bewertungen

- AGILIA High Strength Floor Screed DatasheetDokument6 SeitenAGILIA High Strength Floor Screed Datasheetiask5275Noch keine Bewertungen