Beruflich Dokumente

Kultur Dokumente

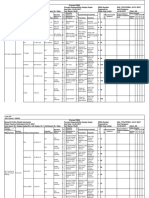

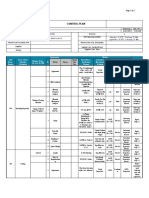

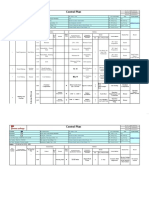

Machine Testing: Design Validation Plan and Report

Hochgeladen von

Frank Detchokul0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

54 Ansichten1 SeiteThis document is a validation plan and report for a long medical drill project. It details 4 tests to test the machine, mechanical installation, surface finish, and reliability of the drill. Each test lists acceptance criteria and responsibilities. The validation report shows the tests were completed successfully, with tight fitting and low runout for the machine and installation, visually accepted surface finish, and no vibration or damage during reliability testing. All tests passed criteria within the planned timeframes and sample sizes.

Originalbeschreibung:

Originaltitel

Test Plan

Copyright

© © All Rights Reserved

Verfügbare Formate

XLSX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document is a validation plan and report for a long medical drill project. It details 4 tests to test the machine, mechanical installation, surface finish, and reliability of the drill. Each test lists acceptance criteria and responsibilities. The validation report shows the tests were completed successfully, with tight fitting and low runout for the machine and installation, visually accepted surface finish, and no vibration or damage during reliability testing. All tests passed criteria within the planned timeframes and sample sizes.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

54 Ansichten1 SeiteMachine Testing: Design Validation Plan and Report

Hochgeladen von

Frank DetchokulThis document is a validation plan and report for a long medical drill project. It details 4 tests to test the machine, mechanical installation, surface finish, and reliability of the drill. Each test lists acceptance criteria and responsibilities. The validation report shows the tests were completed successfully, with tight fitting and low runout for the machine and installation, visually accepted surface finish, and no vibration or damage during reliability testing. All tests passed criteria within the planned timeframes and sample sizes.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Project Number SAR#3431 Design

Plan Date Validation Plan and Report

7/24/2019 Green = test passed

Project Description Long medical drill - Straits Malaysia Report Date 7/24/2019 Amber = test

Plan Author Chayoot Pungpak uncovered error

Red = test failed

Validation Plan Validation Report

Test Name Procedure Acceptence criteria Responsibility Duration Test Start Test Bundle File Pass /

Sample Size Sample Size Actual Results

Test # (hrs) Complete Fail

Machine Testing

Both flutes are formed on the tool

Grinding 2 flutes with wheel clearance No interference with the collet adaptor Gerald Tan 2 24-Jul-19 24-Jul-19 2 Pass

without any interference

Geometry after the grinding is close to the 0.3 4 um

Grind 3.2mm X 343mm brad point Run all grinding operations to achieve the

1 customer's drawing. Maximum runout of 5 Gerald Tan 2 24-Jul-19 24-Jul-19 2 Pass

tip threaded guide pin required shapr stated in the drawing.

um

No interference, not difficult to insert the 0.03

Insert the tool into the workholding Gerald Tan 2 24-Jul-19 24-Jul-19 2 Pass

tool

Mounting Integral PCA SPRG Adaptor

B32/45 WITH 70MM Spacer to FX the head Tight fit and visually accepted with rigidity Gerald Tan 1 0.1 24-Jul-19 24-Jul-19 1 Pass

stock

Enough force to clamp tool with no tool 0.03

Clamping force sliding out from the collet after apply some Gerald Tan 2 24-Jul-19 24-Jul-19 2 Pass

force to the tool

2 Mechanical installation Able to tighten the workholding to the

Tightening all screws headstock without any special tool Gerald Tan 1 0.1 24-Jul-19 24-Jul-19 1 Pass

required.

Set runout on spacer, collet adaptor and tool Set-up time is not over 45 minute Gerald Tan 1 24-Jul-19 24-Jul-19 1 0.5 Pass

0.8

blank and check using a dial guage. Runout maximum of 4 um Gerald Tan 2 24-Jul-19 24-Jul-19 2 2 um Pass

No visual interferance with the pop-up

Installation pop-up steady Gerald Tan 1 0.3 24-Jul-19 24-Jul-19 1 Pass

steady

3 Surface Finish Visual inspection of the surface finish Visually accepted surface condition Gerald Tan 2 1 24-Jul-19 24-Jul-19 2 No unappealing surface finish Pass

4 No vibration or damage to the A-Axis and No vibration, the workhold still

Run a-axis forward and backward 360 degree remain rigid

Reliability the workholding remain intact to the Gerald Tan 1 5 25-Jul-19 25-Jul-19 1

and stop for 1 second. Repeat for 5 hours

headstock

Total 6.3

495689242.xlsx 1 of 1 10/20/2020

Das könnte Ihnen auch gefallen

- Playing With Pop-Ups - The Art of Dimensional, Moving Paper DesignsDokument147 SeitenPlaying With Pop-Ups - The Art of Dimensional, Moving Paper DesignsSara100% (4)

- Etech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingDokument4 SeitenEtech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingMadan PrakashNoch keine Bewertungen

- National Football League FRC 2000 Sol SRGBDokument33 SeitenNational Football League FRC 2000 Sol SRGBMick StukesNoch keine Bewertungen

- PFMEA SampleDokument24 SeitenPFMEA SamplePk Nimiwal67% (3)

- CP20200804-A Model Control Plan - FoundationsDokument6 SeitenCP20200804-A Model Control Plan - Foundationsmanno200Noch keine Bewertungen

- Fmea CastingDokument8 SeitenFmea CastingSuraj RawatNoch keine Bewertungen

- Extra - Relative PronounsDokument4 SeitenExtra - Relative PronounsFrank Detchokul100% (1)

- Machining PFMEADokument8 SeitenMachining PFMEASuraj RawatNoch keine Bewertungen

- Casting CPDokument2 SeitenCasting CPSuraj RawatNoch keine Bewertungen

- Fmea CastingDokument4 SeitenFmea CastingSuraj RawatNoch keine Bewertungen

- Check List AlimakDokument2 SeitenCheck List Alimakmaria elena100% (4)

- DIT Test CertificateDokument4 SeitenDIT Test CertificateMoshoeu Makofane100% (1)

- Anexo 05 - Process Planning Review v1.5 Nov2014Dokument20 SeitenAnexo 05 - Process Planning Review v1.5 Nov2014Neumar NeumannNoch keine Bewertungen

- SecuritizationDokument46 SeitenSecuritizationHitesh MoreNoch keine Bewertungen

- Control Plan & FMEADokument13 SeitenControl Plan & FMEAAmit LuniaNoch keine Bewertungen

- QAF12 Process Audit Rev 09Dokument4 SeitenQAF12 Process Audit Rev 09ukavathekarNoch keine Bewertungen

- HSE WEEKLY REPORT Februari Week Ke 13Dokument19 SeitenHSE WEEKLY REPORT Februari Week Ke 13richo naiborhuNoch keine Bewertungen

- Data StructuresDokument4 SeitenData StructuresBenjB1983Noch keine Bewertungen

- Control Plan Ingersol RandDokument2 SeitenControl Plan Ingersol Randrgrao85Noch keine Bewertungen

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsDokument4 SeitenControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- Standard Operation ProcedureDokument3 SeitenStandard Operation ProcedureAnand KesarkarNoch keine Bewertungen

- Union Test Prep Nclex Study GuideDokument115 SeitenUnion Test Prep Nclex Study GuideBradburn Nursing100% (2)

- Espree I Class Korr3Dokument22 SeitenEspree I Class Korr3hgaucherNoch keine Bewertungen

- System QSB First Step Fast Response PDFDokument19 SeitenSystem QSB First Step Fast Response PDFPrabagarane RamachandranNoch keine Bewertungen

- Seabank Statement 20220726Dokument4 SeitenSeabank Statement 20220726Alesa WahabappNoch keine Bewertungen

- Inspection Test Plan For Eot CraneDokument4 SeitenInspection Test Plan For Eot CraneBikash ShreshthaNoch keine Bewertungen

- Green Belt ProjectDokument24 SeitenGreen Belt ProjectEl Mostafa El KourdiNoch keine Bewertungen

- DFo 2 1Dokument15 SeitenDFo 2 1Donna HernandezNoch keine Bewertungen

- QAV-2 Step-3 Audit Check Sheet PDFDokument5 SeitenQAV-2 Step-3 Audit Check Sheet PDFRajNoch keine Bewertungen

- CHECK LIST Lighting FixtureDokument5 SeitenCHECK LIST Lighting FixtureKham NguyenNoch keine Bewertungen

- Isir - (00003)Dokument1 SeiteIsir - (00003)ducthangspktNoch keine Bewertungen

- In-Process Inspection Report For Infant Incubator Parts9Dokument1 SeiteIn-Process Inspection Report For Infant Incubator Parts9Hilario AlinabonNoch keine Bewertungen

- Transformer 3Dokument77 SeitenTransformer 3Abhinav TewariNoch keine Bewertungen

- TR-22004-L-Mtl - Test Report On TV Knob StickerDokument2 SeitenTR-22004-L-Mtl - Test Report On TV Knob StickerAshraaf aushiNoch keine Bewertungen

- Control Plan - 608 2RS C3Dokument28 SeitenControl Plan - 608 2RS C3trandangbkNoch keine Bewertungen

- Amo-Ep-Bcpm-302373-Inspect Protection Sleeve: Name Initials Name InitialsDokument11 SeitenAmo-Ep-Bcpm-302373-Inspect Protection Sleeve: Name Initials Name InitialsIvan MauricioNoch keine Bewertungen

- Lembar 1Dokument1 SeiteLembar 1saepudin 40Noch keine Bewertungen

- APPI-VAL-005 Validation of Control Measure Effectiveness of Standard Stripping Pin of Die Cut ProcessDokument3 SeitenAPPI-VAL-005 Validation of Control Measure Effectiveness of Standard Stripping Pin of Die Cut Processmonik manuelNoch keine Bewertungen

- APPI-VAL-004 Validation of Control Measure Effectiveness of Standard Size of Glue ApplicatorDokument3 SeitenAPPI-VAL-004 Validation of Control Measure Effectiveness of Standard Size of Glue Applicatormonik manuelNoch keine Bewertungen

- Project Dry Docking Rampdoor Ali-7 Dan Ali-8: Progress ReportDokument1 SeiteProject Dry Docking Rampdoor Ali-7 Dan Ali-8: Progress Reportrianto arung payungNoch keine Bewertungen

- Potential Failure Mode and Effect Analysis (Process Fmea) : Opn - NoDokument1 SeitePotential Failure Mode and Effect Analysis (Process Fmea) : Opn - Noprasad sapareNoch keine Bewertungen

- Target Product Safety & Facility Audit December - PA3 - 2022.Dokument2 SeitenTarget Product Safety & Facility Audit December - PA3 - 2022.Hizkia Angga HendrayanaNoch keine Bewertungen

- 2953 Thrad TightDokument6 Seiten2953 Thrad TightRohit QualityNoch keine Bewertungen

- In-Process Inspection Report For Infant Incubator PartsDokument1 SeiteIn-Process Inspection Report For Infant Incubator PartsHilario AlinabonNoch keine Bewertungen

- GM Casting CPDokument3 SeitenGM Casting CPSuraj RawatNoch keine Bewertungen

- Control Plan FormatDokument1 SeiteControl Plan FormatMagesh WaranNoch keine Bewertungen

- In-Process Inspection Report For Infant Incubator PartsDokument4 SeitenIn-Process Inspection Report For Infant Incubator PartsHilario AlinabonNoch keine Bewertungen

- DFMEA PosterDokument1 SeiteDFMEA PosterRishikesh GunjalNoch keine Bewertungen

- QAV-2 Step-5 Audit Check Sheet PDFDokument6 SeitenQAV-2 Step-5 Audit Check Sheet PDFRajNoch keine Bewertungen

- 7 QC Tools - TrainingDokument27 Seiten7 QC Tools - TrainingRadhika GuptaNoch keine Bewertungen

- Problem Investigation ReportDokument2 SeitenProblem Investigation ReportShaheenNoch keine Bewertungen

- Hypermesh ChecklistDokument2 SeitenHypermesh Checklistvdmoorthy123Noch keine Bewertungen

- Check Sheet I QCDokument4 SeitenCheck Sheet I QCEri ParihahNoch keine Bewertungen

- FMEA For PROFILE Unit-II 2Dokument3 SeitenFMEA For PROFILE Unit-II 2Hitarth_dhamsaniaNoch keine Bewertungen

- For Receving Gauges - Master Sample: Gauge Callibration Work InstructionsDokument1 SeiteFor Receving Gauges - Master Sample: Gauge Callibration Work InstructionsAnkur Gupta100% (1)

- J59K Readiness Checklist-Updated Progress 21-12-2022Dokument1 SeiteJ59K Readiness Checklist-Updated Progress 21-12-2022wadie606 dzglobalNoch keine Bewertungen

- WI QA 14 PIug GaugesDokument1 SeiteWI QA 14 PIug GaugesAnkur Gupta100% (1)

- Live Testing - Take 5 Rev EDokument2 SeitenLive Testing - Take 5 Rev EVicky JiNoch keine Bewertungen

- Control Plan: FG 260 As Per IS 210: 2009Dokument24 SeitenControl Plan: FG 260 As Per IS 210: 2009Suraj RawatNoch keine Bewertungen

- NDT-FRM-038 1.5 Profile Radiography ReportDokument22 SeitenNDT-FRM-038 1.5 Profile Radiography ReportDEBJYOTI SENGUPTANoch keine Bewertungen

- QAV-2 Step-4 Audit Check Sheet PDFDokument5 SeitenQAV-2 Step-4 Audit Check Sheet PDFRajNoch keine Bewertungen

- Field Assessment Form (Safety)Dokument2 SeitenField Assessment Form (Safety)Subash Kr. ThakurNoch keine Bewertungen

- Oshcom Mar 2021 Rev 02Dokument50 SeitenOshcom Mar 2021 Rev 02RaDaCa CabsNoch keine Bewertungen

- 8d Report Ajax Fiori Stopper PinDokument4 Seiten8d Report Ajax Fiori Stopper PinVengadesh MNoch keine Bewertungen

- Emi Catalog LR 1 1 - Compressed 1Dokument40 SeitenEmi Catalog LR 1 1 - Compressed 1CADTDDNoch keine Bewertungen

- Inspection Plan - Link Plate - (Am-2 Chain)Dokument3 SeitenInspection Plan - Link Plate - (Am-2 Chain)pradeepasalunkeNoch keine Bewertungen

- In-Process Inspection Report For Infant Incubator Parts2Dokument2 SeitenIn-Process Inspection Report For Infant Incubator Parts2Hilario AlinabonNoch keine Bewertungen

- Crown Gaskets Pvt. LTD.: Pre-Feasibility StudyDokument2 SeitenCrown Gaskets Pvt. LTD.: Pre-Feasibility StudyTrivesh SharmaNoch keine Bewertungen

- BackgroundDokument3 SeitenBackgroundFrank DetchokulNoch keine Bewertungen

- Issue Log: Project Title Date Prepared Issue ID Type Issue Description Priority Impact On ObjectivesDokument1 SeiteIssue Log: Project Title Date Prepared Issue ID Type Issue Description Priority Impact On ObjectivesFrank DetchokulNoch keine Bewertungen

- SAR5558 - Auto loading from CPX to MX7 conceptDokument6 SeitenSAR5558 - Auto loading from CPX to MX7 conceptFrank DetchokulNoch keine Bewertungen

- E4695 - Shipping InfoDokument3 SeitenE4695 - Shipping InfoFrank DetchokulNoch keine Bewertungen

- All About Project Scope: Simply Put, Scope Is The Size of The Project. But There's More To It Than That!Dokument7 SeitenAll About Project Scope: Simply Put, Scope Is The Size of The Project. But There's More To It Than That!Frank DetchokulNoch keine Bewertungen

- 1.0 General Information: Reporting Period: Study CodeDokument7 Seiten1.0 General Information: Reporting Period: Study CodeFrank DetchokulNoch keine Bewertungen

- Business Case Review: BI and The Portfolio: Improving Annual PlanningDokument2 SeitenBusiness Case Review: BI and The Portfolio: Improving Annual PlanningFrank DetchokulNoch keine Bewertungen

- Lesson Learned RegisterDokument20 SeitenLesson Learned RegisterFrank DetchokulNoch keine Bewertungen

- Confidential - For Internal Use OnlyDokument2 SeitenConfidential - For Internal Use OnlyFrank DetchokulNoch keine Bewertungen

- Sales Report - #2.octDokument6 SeitenSales Report - #2.octFrank DetchokulNoch keine Bewertungen

- GD&T Rule 1 & 2Dokument1 SeiteGD&T Rule 1 & 2Frank DetchokulNoch keine Bewertungen

- CCA Certificate Java Level 1Dokument1 SeiteCCA Certificate Java Level 1Frank DetchokulNoch keine Bewertungen

- Week 2 17-06-17Dokument3 SeitenWeek 2 17-06-17Frank DetchokulNoch keine Bewertungen

- Pronoun 2Dokument1 SeitePronoun 2Frank DetchokulNoch keine Bewertungen

- Polibrid 705 Proposal For IPDokument13 SeitenPolibrid 705 Proposal For IPFrank DetchokulNoch keine Bewertungen

- Inspection and Test Plan: ISO 9001: 2008 CERTIFIEDDokument1 SeiteInspection and Test Plan: ISO 9001: 2008 CERTIFIEDFrank DetchokulNoch keine Bewertungen

- TETP1610122 - Euro ChemDokument1 SeiteTETP1610122 - Euro ChemFrank DetchokulNoch keine Bewertungen

- Long-Term Disability Coverage: Total Expense Total Saving Total Income Net (Income - Expense)Dokument2 SeitenLong-Term Disability Coverage: Total Expense Total Saving Total Income Net (Income - Expense)Frank DetchokulNoch keine Bewertungen

- PE MELCs Grade 3Dokument4 SeitenPE MELCs Grade 3MARISSA BERNALDONoch keine Bewertungen

- Mosharaf HossainDokument2 SeitenMosharaf HossainRuhul RajNoch keine Bewertungen

- Owners Manual Air Bike Unlimited Mag 402013Dokument28 SeitenOwners Manual Air Bike Unlimited Mag 402013David ChanNoch keine Bewertungen

- Google Tools: Reggie Luther Tracsoft, Inc. 706-568-4133Dokument23 SeitenGoogle Tools: Reggie Luther Tracsoft, Inc. 706-568-4133nbaghrechaNoch keine Bewertungen

- Product Manual 26086 (Revision E) : EGCP-2 Engine Generator Control PackageDokument152 SeitenProduct Manual 26086 (Revision E) : EGCP-2 Engine Generator Control PackageErick KurodaNoch keine Bewertungen

- CS8CHP EletricalDokument52 SeitenCS8CHP EletricalCristian ricardo russoNoch keine Bewertungen

- Frellwits Swedish Hosts FileDokument10 SeitenFrellwits Swedish Hosts FileAnonymous DsGzm0hQf5Noch keine Bewertungen

- EAC Inquiry SDCDokument9 SeitenEAC Inquiry SDCThe Sustainable Development Commission (UK, 2000-2011)Noch keine Bewertungen

- SABRE MK-3 CFT Gel SpecDokument1 SeiteSABRE MK-3 CFT Gel Specseregio12Noch keine Bewertungen

- Lab Report SBK Sem 3 (Priscilla Tuyang)Dokument6 SeitenLab Report SBK Sem 3 (Priscilla Tuyang)Priscilla Tuyang100% (1)

- Product NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Dokument14 SeitenProduct NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Paras ShardaNoch keine Bewertungen

- Komunikasi Sebagai Piranti Kebijakan Bi: Materi SESMABI Mei 2020Dokument26 SeitenKomunikasi Sebagai Piranti Kebijakan Bi: Materi SESMABI Mei 2020syahriniNoch keine Bewertungen

- Dreaded Attack - Voyages Community Map Rules v1Dokument2 SeitenDreaded Attack - Voyages Community Map Rules v1jNoch keine Bewertungen

- Individual Career Plan: DIRECTIONS: Answer The Following Questions in Paragraph Form (3-4 Sentences) Per QuestionDokument2 SeitenIndividual Career Plan: DIRECTIONS: Answer The Following Questions in Paragraph Form (3-4 Sentences) Per Questionapi-526813290Noch keine Bewertungen

- Walking in Space - Lyrics and Chord PatternDokument2 SeitenWalking in Space - Lyrics and Chord Patternjohn smithNoch keine Bewertungen

- Predator U7135 ManualDokument36 SeitenPredator U7135 Manualr17g100% (1)

- Bcci ScandalDokument6 SeitenBcci ScandalNausaf AhmedNoch keine Bewertungen

- EVOM ManualDokument2 SeitenEVOM ManualHouston WhiteNoch keine Bewertungen

- Kosher Leche Descremada Dairy America Usa Planta TiptonDokument2 SeitenKosher Leche Descremada Dairy America Usa Planta Tiptontania SaezNoch keine Bewertungen

- Practical Modern SCADA Protocols. DNP3, 60870.5 and Related SystemsDokument4 SeitenPractical Modern SCADA Protocols. DNP3, 60870.5 and Related Systemsalejogomez200Noch keine Bewertungen

- Editan - Living English (CD Book)Dokument92 SeitenEditan - Living English (CD Book)M Luthfi Al QodryNoch keine Bewertungen

- C4 Vectors - Vector Lines PDFDokument33 SeitenC4 Vectors - Vector Lines PDFMohsin NaveedNoch keine Bewertungen