Beruflich Dokumente

Kultur Dokumente

Pages From Mod9-6

Hochgeladen von

boeini0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

11 Ansichten2 Seitenmod7

Originaltitel

Pages from mod9-6

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenmod7

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

11 Ansichten2 SeitenPages From Mod9-6

Hochgeladen von

boeinimod7

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

NPTEL – Chemical Engineering – Chemical Engineering Design - II

Lecture 3: SAFETY MEASURES IN EQUIPMENT

DESIGN AND PRESSURE RELIEF

DEVICES

6. SAFETY MEASURES IN EQUIPMENT DESIGN

Till now we have discussed about number of safety measures for preventing or

controlling hazards. Some of these measures are significant in equipment design

problems. Here main focus is on considering equipment such as pressure vessels (i.e.

reactors, heat exchangers etc.) and the equipment which involves rotary motion

(example filters, agitators etc.). During the design stages of these items of equipment

some important safety measures need to be considered are discussed in the following

sections.

6.1 About material of construction

The selection of materials certainly involves a compromise between factors such as

strength, corrosion resistance, elasticity, toughness, wear, fatigue resistance and ease

of fabrication, as well as availability and cost. In some cases process conditions vary a

good deal, which makes the choice of material difficult. The choice of the material is

largely based on experience and even small variations in the constituents of the fluid

streams make considerable difference to the material to be used. At the design stage,

all reasonable hazards should be identified and listed, and a limit set for each variable

which can lead to such a hazard. For instance, the consequences of material failure or

deterioration should be considered, with limits for wear or corrosion being

established. To ensure safe operation a critical analysis of the process conditions and

material handled must be made.

6.2 Precautions in design and construction

It is generally known that preventing the effects of industrial accidents/hazards

necessitates, above all, a high safety standard of potentially dangerous plants. These

will vary according to the type of equipment. A properly designed piece of equipment

will have in-built safety and loss prevention features. To prevent such failures the

ideas and experience which are already available at various points in connection with

emergency measures should be incorporated. These might include, for example, unit

Joint initiative of IITs and IISc – Funded by MHRD Page 9 of 13

NPTEL – Chemical Engineering – Chemical Engineering Design - II

reliability and flexibility, ease of operations, provision for future expansion,

inspection and maintenance, emergency shutdown facility, standardization of

equipment for rapid replacement, design to withstand probable pressure and

temperature range, with facility to over pressure/temperature control etc. But at the

same time it is not possible to give the list of precautions for each and individual unit

operations, some are specified below.

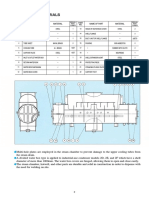

6.3 Pressure vessels

For design and construction of pressure vessel and storage tanks Indian standards

codes should be followed and vessels should be tested at 1.3 times the design pressure

(Mahajani and Umarji, 2009 ). The design should be made to keep the vessels as

simple as possible and it should not be overloaded with supplementary equipments.

Thick weld joints made on the vessel should be given special attentions. The fatigue

strength should be regularly monitored particularly if the vessel is exposed to pressure

cycling, system changes, vibrations or similar factors which are likely to create

fatigue conditions. Important point need to consider is that flange joints must be leak

proof. All pressure vessels should be provided with pressure relief devices.

6.4 Heat transfer equipments

The heat transfer equipment such as evaporator, reactors, furnaces, heat exchangers

require some type of heating which may be directly fired with the help of fuel, electric

heating, or using heat transfer media like steam or heating fluids. While designing

such equipment special precaution should be taken which would not only prevent over

heating but protect from fire and explosions this can be accomplished by different

ways.

i. Provide sufficient heating surface so that excessive rate of heat input per

unit area can be avoided

ii. In such equipments the heat absorbed by the tubes must be continuously

removed by circulating the fluids and to prevent excess temperature rise

through the liquid film heat transfer coefficient should be sufficiently high.

iii. Periodic inspection of the equipment is necessary and for that reason

sufficient numbers of inspection opening must be provided, if applicable.

iv. Provision of vent valves at all high spots in the equipment is necessary.

Joint initiative of IITs and IISc – Funded by MHRD Page 10 of 13

Das könnte Ihnen auch gefallen

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsVon EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNoch keine Bewertungen

- Mothballing Guidelines For Plant EquipmentDokument11 SeitenMothballing Guidelines For Plant EquipmentthawatchaiNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Mothballing Guidelines For Plant Equipme PDFDokument11 SeitenMothballing Guidelines For Plant Equipme PDFamarnath jagirdar100% (1)

- Experiment and Calculation of Reinforced Concrete at Elevated TemperaturesVon EverandExperiment and Calculation of Reinforced Concrete at Elevated TemperaturesBewertung: 5 von 5 Sternen5/5 (2)

- Book Reviews/Journal of Hazardous Materials 38 (1994) 329-348 339Dokument6 SeitenBook Reviews/Journal of Hazardous Materials 38 (1994) 329-348 339Carlos PerdomoNoch keine Bewertungen

- Various Considerations in Equipment Layout in The Equipment and Plot PlanDokument12 SeitenVarious Considerations in Equipment Layout in The Equipment and Plot PlanThiruvengadam100% (1)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationVon EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNoch keine Bewertungen

- 2.3 Safety and Environmental IssuesDokument4 Seiten2.3 Safety and Environmental IssuesHuy VõNoch keine Bewertungen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Cep Industrial ZohaibDokument3 SeitenCep Industrial ZohaibQamar zmanNoch keine Bewertungen

- Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationVon EverandAgeing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationNoch keine Bewertungen

- Logical Sequence ApproachDokument22 SeitenLogical Sequence ApproachV. BalasubramaniamNoch keine Bewertungen

- Nidcmxa 2Dokument10 SeitenNidcmxa 2Fuzail AyazNoch keine Bewertungen

- Carrier - Handbook of Air Conditioning System Design (Part 1)Dokument162 SeitenCarrier - Handbook of Air Conditioning System Design (Part 1)Jonathan Castro96% (93)

- Pocket Guide to Preventing Process Plant Materials Mix-upsVon EverandPocket Guide to Preventing Process Plant Materials Mix-upsNoch keine Bewertungen

- Construction Safety (Summer 2018-19)Dokument25 SeitenConstruction Safety (Summer 2018-19)Necklal SoniNoch keine Bewertungen

- Fatigue Assessment in Light Water Reactors for Long Term Operation: Good Practices and Lessons LearnedVon EverandFatigue Assessment in Light Water Reactors for Long Term Operation: Good Practices and Lessons LearnedNoch keine Bewertungen

- Is 8091.2008 - Safe Plant LayoutDokument20 SeitenIs 8091.2008 - Safe Plant LayoutPrakash Kumar KumarNoch keine Bewertungen

- Guidance On Safety Requirements For Hot Forging G5!26!10!15!0021Dokument24 SeitenGuidance On Safety Requirements For Hot Forging G5!26!10!15!0021abdul basitNoch keine Bewertungen

- Ped StarterDokument19 SeitenPed Starterjasons92Noch keine Bewertungen

- Combined Cooling, Heating and Power: Decision-Making, Design and OptimizationVon EverandCombined Cooling, Heating and Power: Decision-Making, Design and OptimizationNoch keine Bewertungen

- Compressor - Safety Instruction SheetsDokument14 SeitenCompressor - Safety Instruction Sheetsnox noxNoch keine Bewertungen

- Handbook of Adhesive Bonded Structural RepairVon EverandHandbook of Adhesive Bonded Structural RepairBewertung: 5 von 5 Sternen5/5 (1)

- Fail-Safe Designs 1Dokument4 SeitenFail-Safe Designs 1Karthi KeyanNoch keine Bewertungen

- Lay-Up of BoilersDokument68 SeitenLay-Up of Boilerseric100% (3)

- Advanced Temperature Measurement and Control, Second EditionVon EverandAdvanced Temperature Measurement and Control, Second EditionNoch keine Bewertungen

- Ped StarterDokument19 SeitenPed Starterfeihung2012Noch keine Bewertungen

- Comparison ASME and PEDDokument19 SeitenComparison ASME and PEDManjadi MaverickNoch keine Bewertungen

- Process STD 601Dokument13 SeitenProcess STD 601madx44100% (1)

- Industrial Plant LayoutDokument18 SeitenIndustrial Plant Layoutamit singhNoch keine Bewertungen

- Chemcial - Design Considerations For Petrochemical Plant - ASSE ArticleDokument6 SeitenChemcial - Design Considerations For Petrochemical Plant - ASSE ArticleTerry A. WaldropNoch keine Bewertungen

- Safety Training ProgramDokument30 SeitenSafety Training ProgramShivaniNoch keine Bewertungen

- Engineering Design For Process SafetyDokument6 SeitenEngineering Design For Process Safetytoalok4723Noch keine Bewertungen

- Design of Pressure Vessel For Improvement of A System in A Process UnitDokument8 SeitenDesign of Pressure Vessel For Improvement of A System in A Process UnitTJPRC PublicationsNoch keine Bewertungen

- Processes 09 02177 v2Dokument11 SeitenProcesses 09 02177 v2man alamNoch keine Bewertungen

- Guidance On Safety Requirements For Hot Forging: April 2018Dokument25 SeitenGuidance On Safety Requirements For Hot Forging: April 2018HarryNoch keine Bewertungen

- Belt Conveyor Project 03-07-2013Dokument57 SeitenBelt Conveyor Project 03-07-2013Shashikala Kollipara0% (1)

- Fachartikel ICR 2018 11 VDZ Kiln Maintenance enDokument3 SeitenFachartikel ICR 2018 11 VDZ Kiln Maintenance en이상길Noch keine Bewertungen

- Loc ProcessDokument76 SeitenLoc Processuserscribd2011Noch keine Bewertungen

- Kafco 2Dokument16 SeitenKafco 2jpr220022Noch keine Bewertungen

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentDokument21 SeitenShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajNoch keine Bewertungen

- Operating Manual - FP3 - UK - Revision 1Dokument29 SeitenOperating Manual - FP3 - UK - Revision 1benakiaNoch keine Bewertungen

- RLA in High Temp Zones of Power Plant ComponentsDokument7 SeitenRLA in High Temp Zones of Power Plant ComponentsEzhil Vendhan PalanisamyNoch keine Bewertungen

- Asset Inspection and Maintenance Management System On LNG FacilityDokument40 SeitenAsset Inspection and Maintenance Management System On LNG FacilityAbu Faiz100% (1)

- Carrier Handbook Part 1Dokument162 SeitenCarrier Handbook Part 1Tanveer100% (3)

- Safe Operation of Kilns, Furnaces & Driers: A Tool Kit For BusinessDokument23 SeitenSafe Operation of Kilns, Furnaces & Driers: A Tool Kit For BusinessAdewaleNoch keine Bewertungen

- CHP 2... Safety in Pressure System (Controllable Units)Dokument56 SeitenCHP 2... Safety in Pressure System (Controllable Units)kira ENTERTAINMENT100% (2)

- Code of Practice For The Installation of Remedial Damp Proof Courses in Masonry WallsDokument13 SeitenCode of Practice For The Installation of Remedial Damp Proof Courses in Masonry Wallsalex_3_15Noch keine Bewertungen

- Safety Issues On DryerDokument5 SeitenSafety Issues On Dryerareej athirahNoch keine Bewertungen

- Sil PDFDokument12 SeitenSil PDFChandrasekhar ElliahNoch keine Bewertungen

- HSE - Design Codes - PlantDokument32 SeitenHSE - Design Codes - PlantPaul EkeNoch keine Bewertungen

- Prevention of Occupational Health Hazards in Belt Conveyor at Mtps-IDokument9 SeitenPrevention of Occupational Health Hazards in Belt Conveyor at Mtps-IuknandiNoch keine Bewertungen

- Predesign With Safety in MindDokument11 SeitenPredesign With Safety in Mindrudy_423522658Noch keine Bewertungen

- Energies: Structural Design Simulation of Bayonet Heat Exchanger For Sulfuric Acid DecompositionDokument18 SeitenEnergies: Structural Design Simulation of Bayonet Heat Exchanger For Sulfuric Acid DecompositionboeiniNoch keine Bewertungen

- Servswitch Wizard Dvi DL: Network ServicesDokument31 SeitenServswitch Wizard Dvi DL: Network ServicesboeiniNoch keine Bewertungen

- Servswitch Wizard Dvi DL: Network ServicesDokument31 SeitenServswitch Wizard Dvi DL: Network ServicesboeiniNoch keine Bewertungen

- 314 - Multi EffectDokument2 Seiten314 - Multi EffectboeiniNoch keine Bewertungen

- Pages From Hybrid Cooling10Dokument3 SeitenPages From Hybrid Cooling10boeiniNoch keine Bewertungen

- Pages From Hybrid Cooling-5Dokument2 SeitenPages From Hybrid Cooling-5boeiniNoch keine Bewertungen

- Pages From Hybrid Cooling-3Dokument2 SeitenPages From Hybrid Cooling-3boeiniNoch keine Bewertungen

- Pages From Mod9-5Dokument2 SeitenPages From Mod9-5boeiniNoch keine Bewertungen

- Pages From Hybrid Cooling-4Dokument2 SeitenPages From Hybrid Cooling-4boeiniNoch keine Bewertungen

- Pages From Hybrid Cooling-2Dokument2 SeitenPages From Hybrid Cooling-2boeiniNoch keine Bewertungen

- Pages From Hybrid Cooling1Dokument2 SeitenPages From Hybrid Cooling1boeiniNoch keine Bewertungen

- Pages From Mod9-4Dokument2 SeitenPages From Mod9-4boeiniNoch keine Bewertungen

- Analysis of Hazards: Nptel - Chemical Engineering - Chemical Engineering Design - IIDokument2 SeitenAnalysis of Hazards: Nptel - Chemical Engineering - Chemical Engineering Design - IIboeiniNoch keine Bewertungen

- Module # 9: Process Hazards and Safety Measures in Equipment Design: Process Hazards, SafetyDokument2 SeitenModule # 9: Process Hazards and Safety Measures in Equipment Design: Process Hazards, SafetyboeiniNoch keine Bewertungen

- Pages From Vacuum - Condensers-5Dokument1 SeitePages From Vacuum - Condensers-5boeiniNoch keine Bewertungen

- Pages From Vacuum - Condensers-9Dokument1 SeitePages From Vacuum - Condensers-9boeiniNoch keine Bewertungen

- 2E VACUUM CONDENSERS (Shell & Tube Type) : Applications SpecificationsDokument1 Seite2E VACUUM CONDENSERS (Shell & Tube Type) : Applications SpecificationsboeiniNoch keine Bewertungen

- Pages From Vacuum - Condensers-8Dokument1 SeitePages From Vacuum - Condensers-8boeiniNoch keine Bewertungen

- Pages From Vacuum - Condensers-3Dokument2 SeitenPages From Vacuum - Condensers-3boeiniNoch keine Bewertungen

- Pages From Vacuum - Condensers-6Dokument1 SeitePages From Vacuum - Condensers-6boeiniNoch keine Bewertungen

- Pages From Vacuum - Condensers2Dokument2 SeitenPages From Vacuum - Condensers2boeiniNoch keine Bewertungen

- Pages From Vacuum - Condensers-4Dokument2 SeitenPages From Vacuum - Condensers-4boeiniNoch keine Bewertungen

- Generator Set Diesel Cummins DQKAN 60Hz 2500kwe OpenDokument3 SeitenGenerator Set Diesel Cummins DQKAN 60Hz 2500kwe OpenMarcio RoterNoch keine Bewertungen

- MT Unit 6 Fluid Moving Machines Pumps Prof R R JoshiDokument25 SeitenMT Unit 6 Fluid Moving Machines Pumps Prof R R Joshiaditya panchalNoch keine Bewertungen

- Thermo Assignment #6Dokument10 SeitenThermo Assignment #6mohamedNoch keine Bewertungen

- HRSG SimulationDokument7 SeitenHRSG Simulationkaruna346Noch keine Bewertungen

- Am100kxmdfhtc VRFDokument2 SeitenAm100kxmdfhtc VRFSANDRANoch keine Bewertungen

- ASMEDokument3 SeitenASMEsevero970% (3)

- Bombas KMSDokument4 SeitenBombas KMSAntonio Carlos Kerber PinhoNoch keine Bewertungen

- Mixing Eductors Mixing EductorsDokument1 SeiteMixing Eductors Mixing Eductorsdetreomycyna100% (1)

- Turgo Spear Nozzle DesignDokument15 SeitenTurgo Spear Nozzle DesignCliff smythNoch keine Bewertungen

- Snox Pet Coke BoilersDokument14 SeitenSnox Pet Coke BoilersФранческо ЛеньямеNoch keine Bewertungen

- In Case of FireDokument2 SeitenIn Case of FireLiliannaNoch keine Bewertungen

- 300 TPD Recovery BoilerDokument17 Seiten300 TPD Recovery Boilerhemendra499Noch keine Bewertungen

- Phase II Boiler QuestionsDokument12 SeitenPhase II Boiler QuestionsNithin VargheseNoch keine Bewertungen

- Hydrogen Truck by ICEDokument9 SeitenHydrogen Truck by ICEDaniel Carmona AriasNoch keine Bewertungen

- TurboDokument2 SeitenTurboFalgon IslamNoch keine Bewertungen

- Energy in Steady Flow-Part 4Dokument35 SeitenEnergy in Steady Flow-Part 4shazaib aliNoch keine Bewertungen

- 10 11648 J Ogce 20210906 13Dokument13 Seiten10 11648 J Ogce 20210906 13altamirano21Noch keine Bewertungen

- Engine Driven RefrigerationDokument2 SeitenEngine Driven RefrigerationValentin LupascuNoch keine Bewertungen

- Group 2 Main Control Valve: 1. StructureDokument23 SeitenGroup 2 Main Control Valve: 1. StructureАлексейNoch keine Bewertungen

- Triplex Plunger Pump Preventive Maintenance GuidelinesDokument1 SeiteTriplex Plunger Pump Preventive Maintenance GuidelinesthunderNoch keine Bewertungen

- Liebert CW: System Design Manual - 26-181kW, 50 & 60HzDokument28 SeitenLiebert CW: System Design Manual - 26-181kW, 50 & 60HzPablo gilNoch keine Bewertungen

- MIE1132H 2024 Annotated BibliographyDokument9 SeitenMIE1132H 2024 Annotated Bibliographymatthew.wp.gillespieNoch keine Bewertungen

- Lecture 3 - 5 - High Pressure BoilersDokument32 SeitenLecture 3 - 5 - High Pressure BoilersFEALABREPORTSNoch keine Bewertungen

- LTI Boiler Application 3pagesDokument3 SeitenLTI Boiler Application 3pagesVijay - Spantech EngineersNoch keine Bewertungen

- Application Note Siddique Ice Factory IslamabadDokument2 SeitenApplication Note Siddique Ice Factory Islamabadshahid sidiqueNoch keine Bewertungen

- Course Solar Energy EdX OVERVIEWDokument6 SeitenCourse Solar Energy EdX OVERVIEWtim philipNoch keine Bewertungen

- Nuclear Power PlantDokument7 SeitenNuclear Power PlantzzaanNoch keine Bewertungen

- Leonics Inverter - SGP210 SeriesDokument0 SeitenLeonics Inverter - SGP210 SerieskapishsharmaNoch keine Bewertungen

- When You Flick A SwitchDokument2 SeitenWhen You Flick A SwitchMaulana 'Olan' RifqiNoch keine Bewertungen

- Uygulama 1-2 & Ornek SorularDokument16 SeitenUygulama 1-2 & Ornek SorularRSS RSSNoch keine Bewertungen

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemVon EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNoch keine Bewertungen

- Laws of UX: Using Psychology to Design Better Products & ServicesVon EverandLaws of UX: Using Psychology to Design Better Products & ServicesBewertung: 5 von 5 Sternen5/5 (9)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tVon EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tBewertung: 4.5 von 5 Sternen4.5/5 (27)

- 507 Mechanical Movements: Mechanisms and DevicesVon Everand507 Mechanical Movements: Mechanisms and DevicesBewertung: 4 von 5 Sternen4/5 (28)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneVon EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EVon EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EBewertung: 3 von 5 Sternen3/5 (6)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsVon EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNoch keine Bewertungen

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsVon EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsBewertung: 4 von 5 Sternen4/5 (11)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessVon EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNoch keine Bewertungen

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesVon EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNoch keine Bewertungen

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceVon EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceBewertung: 4 von 5 Sternen4/5 (19)

- A Complete Guide to Safety Officer Interview Questions and AnswersVon EverandA Complete Guide to Safety Officer Interview Questions and AnswersBewertung: 4 von 5 Sternen4/5 (1)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionVon EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNoch keine Bewertungen

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableVon EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNoch keine Bewertungen

- Workbook to Accompany Maintenance & Reliability Best PracticesVon EverandWorkbook to Accompany Maintenance & Reliability Best PracticesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen