Beruflich Dokumente

Kultur Dokumente

Ra Fps-008-Welding

Hochgeladen von

grantOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ra Fps-008-Welding

Hochgeladen von

grantCopyright:

Verfügbare Formate

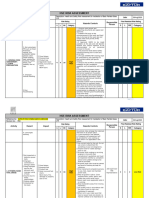

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Purpose

This form aligns the HIRA process called for in accordance with Procedure no. ALLSM-EPR-ENG-STD-0001 and must be filled in as a

Record of a specific Work Procedure.

SMELTER Mortimer Smelter

Production Section

Area

Type of Work Procedure: FPS-008- WELDING Date:

1. Baseline Construction / Installation Procedure (Construction of New Workplace and/or Equipment) Yes No N.A.

Purpose of Work Procedure.

i.e. Smelter No. 2 expansion project

2. Issue Based Construction/Installation Procedure (Construction / Installation pertaining to a change) Yes No N.A.

Purpose of Work Procedure.

i.e. re-routing of HT supply cable

3. Continuous HIRA for Non Routine Maintenance Work (Major Furnace/Smelter Rebuild , Overhaul etc) Yes No N.A.

Purpose of Work Procedure.

i.e. Rebuild of No. 1 Smelter

4. Operating Procedure

(Describe: i.e. Tap Hole Closing Procedure)

5. Maintenance Procedure

(Describe: i.e. Daily Inspection of No.1 Vent Fan)

HIRA Facilitator. Name: Signature:

Responsible Man./Subordinate Man. Name: Signature:

Responsible Engineer. Name: Signature:

Operational Form / Template Page 1 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Responsible SHEQ Man./Safety Officer Name: Signature:

Team Member Occupation Name Signature Team Member Occupation Name Signature

Operational Form / Template Page 2 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Occupation And Risk Rating

Designation of Extreme

Responsible High

Can this Risk Risk Control Measure

Person Medium

Task Hazards Identified Associated Risk Be Eliminated Including Personal

i.e.

Yes / No Protective Equipment

Engineer/Supervis

or/ Low

Foreman

Planning of task Not planning task at Production loss No Supervisor to identify Supervisor Low

hand hazards in specific work

places with employees

and complete Toolbox

talk.

Obtain welding Hand injuries caused Not using required PPE The use of PPE (safety Employees Low

equipment from by the welding machine shoes with spats,

stores. due to pinching. reflective overall, safety

glasses, hard hat, safety

gloves) must be

enforced at all times

even when obtaining

Welder equipment from

store.

Incorrect handling of Not handling material in Employees made aware Employees Low

welding machine. the correct manner at toolbox talk to use the

correct method when

picking up material, with

their legs and not their

back.

Workers must not bend

over material to pick up

Operational Form / Template Page 3 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

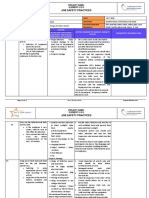

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Occupation And Risk Rating

Can this Risk Risk Control Measure Designation of Extreme

Task Hazards Identified Associated Risk Be Eliminated Including Personal Responsible High

Yes / No Protective Equipment Person Medium

i.e. Low

Engineer/Supervis

they are to crouch down

and then lift. If load is

too heavy for the

individual additional staff

is to be used.

Defective equipment Not visually inspecting Visual pre-use Welder medium

welding equipment inspection done before

Welding equipment

leave stores.

NB-if any of the

following defects are

found during inspection

the Welding equipment

must be returned back

to the store.

1. Damaged plugs.

2. Joints in cable.

3. Damaged earth

clamp.

4. Poor visual

condition.

Defective equipment to

be reported and

deviations to be

recorded on register

Obtain the Hot work is done in an Not obtaining hot work Prior to any work that Employees, Low

necessary Hot Work area where it has not permit prior to work to could lead to flammable Supervisor

Operational Form / Template Page 4 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Occupation And Risk Rating

Can this Risk Risk Control Measure Designation of Extreme

Task Hazards Identified Associated Risk Be Eliminated Including Personal Responsible High

Yes / No Protective Equipment Person Medium

i.e. Low

Engineer/Supervis

Permit if required in been authorised. commence material igniting a hot

certain areas. work permit is to be

obtained after it has

been verified that the

work area is safe for the

planned work.

Ensure fire extinguisher

is available

Set-up welding Trained persons doing Not using trained person Only trained and Welder Low

equipment where hot work. to do hot work experienced persons

welding must take are to do hot work.

place and inspect

area. (Surface)

Fire hazard is created Not removing or covering Area inspected and all Welder, Low

by the welding splatter combustible materials combustible materials Supervisor

and heat. removed if possible or

must be covered to

prevent the possibility of

a fire or damage to

equipment and water.

In areas where the fire

hazard is very high e.g.

welding near rubber-

lined tanks etc. a

firewatcher is to be in

place with additional fire

equipment.

Operational Form / Template Page 5 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

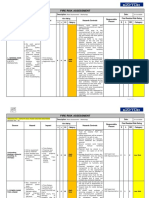

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Occupation And Risk Rating

Can this Risk Risk Control Measure Designation of Extreme

Task Hazards Identified Associated Risk Be Eliminated Including Personal Responsible High

Yes / No Protective Equipment Person Medium

i.e. Low

Engineer/Supervis

If necessary have a fire

hose running into

rubber-lined tanks in the

area.

Tripping hazard caused Not eliminating tripping The welding cables from Welder Low

by welding cables lying hazards by laying cables the welding machine to

all over the work area. away from walkways or the work area must be

overhead laid in an orderly

manner and away from

walkways by running

them overhead and over

walkways and stairways.

Coiled cables will Not uncoiling length of Uncoil complete length Welder Low

cause a magnetic field cable before connecting of cable before

and build up heat. power connecting or switching

on power supply.

Plugging welding Not ensuring appropriate Ensure that the power Welder Low

machine into the voltage of power supply supply is of the

incorrect power supply appropriate voltage and

correct plug.

Welding earth place Not placing earth clamps All earth clamps must Welder Medium

more than 1m away less than 1m away from not be placed more than

from striking point. striking point 1m away from striking

point.

Arc eyes or temporary Not placing welding Welding screens are to Supervisor, medium

blindness to passer- screens where welding be erected, placed or Welder

Operational Form / Template Page 6 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Occupation And Risk Rating

Can this Risk Risk Control Measure Designation of Extreme

Task Hazards Identified Associated Risk Be Eliminated Including Personal Responsible High

Yes / No Protective Equipment Person Medium

i.e. Low

Engineer/Supervis

by’s and welding could affect others hung to prevent the

sparks can lead to welding arc to affect

burns to passer–by’s others and to contain

and damage to welding sparks.

equipment.

No fire extinguisher at No fire extinguisher at Fire extinguishers will be Welder Medium

the point were hot work welding work area close to point where

is taking place. welding takes place in

the event of a fire

starting at the work

station.

Wet welding Placing welding machine Place welding machine Welder Medium

equipment. in moist or wet area in safe dry place or

protect against moist or

splashing of water. No

welding in the rain or

when standing in water

Arcing causes damage Not placing welding Earth cable to be Welder Medium

to instrumentation and screens connected as close as

generating heat. possible to welding

operations and area

around welding activity

must be barricaded and

welding screens placed.

Falling equipment from Not securing equipment All equipment is to be Supervisor, medium

elevated areas. in elevated areas secured in elevated Welder

Set-up welding areas by means of

equipment where slings/chain to secure

Operational Form / Template Page 7 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

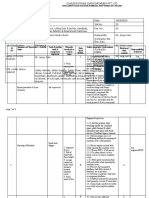

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Occupation And Risk Rating

Can this Risk Risk Control Measure Designation of Extreme

Task Hazards Identified Associated Risk Be Eliminated Including Personal Responsible High

Yes / No Protective Equipment Person Medium

i.e. Low

Engineer/Supervis

welding must take structure.

pace and inspect

area. (Elevated If welding machine is too

big it is advisable to

have long distance

cables used and the

machine left on the

ground level.

Employees falling from Employees not attaching Artisan and assistants Artisan, medium

elevated areas. safety harness above must attach the safety Assistant

themselves ,they can harness to a suitable

slip& fall point above themselves.

The fastening point

must be firm and stable

to support your weight in

the event of a fall.

All workers must be

trained in working at

heights.

Incorrect slinging Not using correct slinging In the event that Rigger, medium

methodology method equipment cannot safely Rigger Ass

be carried to elevated

area, only qualified

Riggers or trained semi-

Operational Form / Template Page 8 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Occupation And Risk Rating

Can this Risk Risk Control Measure Designation of Extreme

Task Hazards Identified Associated Risk Be Eliminated Including Personal Responsible High

Yes / No Protective Equipment Person Medium

i.e. Low

Engineer/Supervis

skilled riggers are to

sling loads.

Set-up welding Unprotected areas can Not barricading the drop Barricade off below the Welder medium

equipment where cause hot slag to fall zone elevated work area with

welding must take onto other persons. yellow and black tape

pace and inspect and barricading and the

area. (Elevated) necessary warning

(Conti.) signage. (See drop zone

procedures)

Fire blankets are to be

used to limit the amount

of slag that can fall from

elevated area.

Commence welding Employees not wearing Injuries Applicable PPE (safety Welder medium

operation. PPE shoes with spats,

reflective overall, double

eye protection, hard hat,

safety gloves, leather

spats, apron) to be

used. (Welding Helmet,

Safety glasses, leather

gloves, leather apron,

safety boots, welding

spats, leather gauntlets

etc.) The working area

must be protected by

Operational Form / Template Page 9 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Occupation And Risk Rating

Can this Risk Risk Control Measure Designation of Extreme

Task Hazards Identified Associated Risk Be Eliminated Including Personal Responsible High

Yes / No Protective Equipment Person Medium

i.e. Low

Engineer/Supervis

means of screens.

Standing in water or Welding while having wet Welder to ensure that Welder medium

wearing wet clothes. clothes on or standing in he is not standing in

water water or that he is

wearing any wet or most

clothes during welding

operations.

Welding fumes can Not avoiding welding Ensure good Welder medium

lead to unhealthy fumes could result in ventilation / direction of

working conditions to injuries and or health the wind to avoid

employees. risks. welding fumes. Dust

masks to be worn where

necessary.

Where applicable,

mechanical ventilation

must be used to extract

fumes.

Completion of task. Smouldering sparks or Not visually inspecting Do inspection after Welder Low

slag can set the area area after welding welding operations has

alight. operations is complete been completed.

Bad housekeeping. Not doing housekeeping It is the responsibility of Welder Low

ongoing everyone on site to

ensure that good

Operational Form / Template Page 10 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

Anglo Platinum

Group Smelters

Ref No ALLSM-EPR-ENG-STD-0001-FRM-002 Date of Implementation 03 January 2008

Version No 3 Last Revision Date 22 January 2009

Occupation And Risk Rating

Can this Risk Risk Control Measure Designation of Extreme

Task Hazards Identified Associated Risk Be Eliminated Including Personal Responsible High

Yes / No Protective Equipment Person Medium

i.e. Low

Engineer/Supervis

housekeeping is

maintained on a

ongoing basis.

Operational Form / Template Page 11 of 11

This document is maintained on an electronic database.

The printed version should be compared as it may be outdated. Date Printed: 24 October 2020

Das könnte Ihnen auch gefallen

- Mobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSVon EverandMobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSBewertung: 1 von 5 Sternen1/5 (1)

- Risk Assessment - Installation of Back Painted GlassDokument7 SeitenRisk Assessment - Installation of Back Painted GlassMuhammad NadeemNoch keine Bewertungen

- Job Safety Practices FirefightingDokument16 SeitenJob Safety Practices Firefightingmohammed tofiqNoch keine Bewertungen

- JSA-Scaffolding Erection & Dismantling Works RV-00Dokument2 SeitenJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNoch keine Bewertungen

- Risk Assessment - T&C For Medium Voltage SwitchgearDokument8 SeitenRisk Assessment - T&C For Medium Voltage SwitchgearMuhammad IrfanNoch keine Bewertungen

- Risk Assessment - T&C For Medium Voltage SwitchgearDokument8 SeitenRisk Assessment - T&C For Medium Voltage SwitchgearMuhammad Irfan0% (1)

- JSA Format NEW Equipment ErectionDokument5 SeitenJSA Format NEW Equipment Erectionsakthi venkatNoch keine Bewertungen

- Safe Work Method Statement FormatDokument3 SeitenSafe Work Method Statement FormatTamoor Sarwar100% (1)

- Job Safety Analysis Work SheetDokument5 SeitenJob Safety Analysis Work SheetMuhammad UsmanNoch keine Bewertungen

- Risk AssessmentDokument7 SeitenRisk AssessmentRenjith RaviNoch keine Bewertungen

- HIRARC Install LightingDokument2 SeitenHIRARC Install LightingMohd Faizal SaharNoch keine Bewertungen

- PDF 6jsa of Batching Plant Installation - CompressDokument4 SeitenPDF 6jsa of Batching Plant Installation - CompressRiandoNoch keine Bewertungen

- Paint Work Using Mobile Crane PSO FSD.Dokument5 SeitenPaint Work Using Mobile Crane PSO FSD.fiazhussaindbxNoch keine Bewertungen

- Risk Assessment For Earth Works (Excavation Back Filling) Require...Dokument13 SeitenRisk Assessment For Earth Works (Excavation Back Filling) Require...khalid khan100% (1)

- Rme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20Dokument1 SeiteRme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20nanthan06Noch keine Bewertungen

- Installation of Copper Pipes and Fittings.: Barq Group Risk AssessmentDokument8 SeitenInstallation of Copper Pipes and Fittings.: Barq Group Risk AssessmentYousaf Richu67% (3)

- Opertaing Window LimitsDokument6 SeitenOpertaing Window LimitshejaNoch keine Bewertungen

- Area Hard Barrication JsaDokument7 SeitenArea Hard Barrication JsaJanakiramanNoch keine Bewertungen

- SWMS - Replacement of Light BulbsDokument5 SeitenSWMS - Replacement of Light BulbsHanindita Widhi PangestiNoch keine Bewertungen

- Risk Assessment - Cutting and Chipping of Concrete StructureDokument7 SeitenRisk Assessment - Cutting and Chipping of Concrete StructureHasham KhanNoch keine Bewertungen

- Civil Jobs - Shuttering and ConcretingDokument1 SeiteCivil Jobs - Shuttering and ConcretingSharad IvneNoch keine Bewertungen

- HIRA Cage Ladder & Life Line Installation01Dokument3 SeitenHIRA Cage Ladder & Life Line Installation01R. Ayyanuperumal Ayyanuperumal100% (1)

- 3954-009-JSA-NDT Rev 0Dokument3 Seiten3954-009-JSA-NDT Rev 0Viron BaxhiaNoch keine Bewertungen

- FormDokument2 SeitenFormjoel walkerNoch keine Bewertungen

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Dokument6 SeitenSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarNoch keine Bewertungen

- Risk Assessment - T&C For Water TanksDokument7 SeitenRisk Assessment - T&C For Water TanksMuhammad NadeemNoch keine Bewertungen

- Jsa For HydrotestDokument10 SeitenJsa For HydrotestAnonymous CcGYhZb080% (5)

- Fire Risk Assessment-2Dokument8 SeitenFire Risk Assessment-2Asad RazaNoch keine Bewertungen

- JSA Format Erection of Column 901-C-01Dokument9 SeitenJSA Format Erection of Column 901-C-01sakthi venkatNoch keine Bewertungen

- JSA For Errection of Batching PlantDokument4 SeitenJSA For Errection of Batching Plantasamrat582Noch keine Bewertungen

- HSE Risk Assessment (Contractor)Dokument9 SeitenHSE Risk Assessment (Contractor)Saim AliNoch keine Bewertungen

- JSA 03 Gate Entrance Traffic ProposalDokument10 SeitenJSA 03 Gate Entrance Traffic Proposalrahul tkNoch keine Bewertungen

- Job Safety Analysis FormatDokument2 SeitenJob Safety Analysis FormatSpeed Tech தமிழ்Noch keine Bewertungen

- 003 SWMS - ExcavationDokument11 Seiten003 SWMS - Excavationsasi kumar50% (2)

- Jha Piping Insulation Installation and Dismantle Work p28Dokument12 SeitenJha Piping Insulation Installation and Dismantle Work p28AmirHakimRusli100% (1)

- GGH Basket RemovelDokument9 SeitenGGH Basket Removeltamoor sarwarNoch keine Bewertungen

- JSP For AsphaltDokument8 SeitenJSP For Asphaltmohammed tofiqNoch keine Bewertungen

- RA For Hvac Duct InstallationDokument10 SeitenRA For Hvac Duct InstallationAnandu Ashokan88% (8)

- JSA CABLE TaggingDokument5 SeitenJSA CABLE TaggingthennarasuNoch keine Bewertungen

- Risk Assessement For AAES ProductsDokument4 SeitenRisk Assessement For AAES ProductsAzhar Shaikh100% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDokument9 SeitenRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Assessment SheetDokument4 SeitenRisk Assessment Sheetfuturecolor7Noch keine Bewertungen

- Abish Sukumaran .Dokument18 SeitenAbish Sukumaran .Nayanthara VarmaNoch keine Bewertungen

- JSA ELETRICAL MaintenanceDokument17 SeitenJSA ELETRICAL MaintenanceWeru MorrisNoch keine Bewertungen

- Ig2 Forms Electronic Submission v5.1Dokument20 SeitenIg2 Forms Electronic Submission v5.1Muhammad Ahmad100% (2)

- Jha Unitec Repair of CR 4 Acs 012123Dokument7 SeitenJha Unitec Repair of CR 4 Acs 012123JulzNoch keine Bewertungen

- ISC-JSA Grouting Works For Shared FenceDokument4 SeitenISC-JSA Grouting Works For Shared FenceSameer AlmahboubNoch keine Bewertungen

- JSA - Non-Destructive Testing (NDT) - Liquid Penetrant TestDokument5 SeitenJSA - Non-Destructive Testing (NDT) - Liquid Penetrant TestRajuNoch keine Bewertungen

- Ra - Central StoreDokument4 SeitenRa - Central StorealbinkhanNoch keine Bewertungen

- 3-RA Cement PlasteringDokument5 Seiten3-RA Cement Plasteringhsem Al EimaraNoch keine Bewertungen

- Backfilling ENDokument5 SeitenBackfilling ENTilalNoch keine Bewertungen

- Flushingchemical Cleaning of Chilled Water PipesDokument9 SeitenFlushingchemical Cleaning of Chilled Water PipesAnandu AshokanNoch keine Bewertungen

- Safe Work Method StatementDokument12 SeitenSafe Work Method StatementJanakiramanNoch keine Bewertungen

- JHA For IAQ Monitoring CCB & AMB Seraya - 002 (2020)Dokument2 SeitenJHA For IAQ Monitoring CCB & AMB Seraya - 002 (2020)Deanz KmcNoch keine Bewertungen

- Job Safety Analysis PSA-MailDokument50 SeitenJob Safety Analysis PSA-MailechaNoch keine Bewertungen

- Expansion Joints in Columns JSA HSE ProfessionalsDokument1 SeiteExpansion Joints in Columns JSA HSE ProfessionalsSamadov 13Noch keine Bewertungen

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Dokument6 SeitenThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Nitesh kumar yadavNoch keine Bewertungen

- New Hirarc Permit h1 PCWDokument4 SeitenNew Hirarc Permit h1 PCWSyed Faris Bin Syed ZainuddinNoch keine Bewertungen

- 1 - JSA Erectoin and Dismantling of ScaffoldingDokument5 Seiten1 - JSA Erectoin and Dismantling of ScaffoldingAijaz AhmedNoch keine Bewertungen

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Dokument2 SeitenJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNoch keine Bewertungen

- BSA - Safe Working at Height On SteelworkDokument95 SeitenBSA - Safe Working at Height On SteelworkgrantNoch keine Bewertungen

- ISO Training List - ConstructionDokument2 SeitenISO Training List - ConstructiongrantNoch keine Bewertungen

- Accident Investigation 3Dokument33 SeitenAccident Investigation 3grantNoch keine Bewertungen

- ElectricalsafetyDokument27 SeitenElectricalsafetyNitin K RaviNoch keine Bewertungen

- Fire Extinguisher TrainingDokument30 SeitenFire Extinguisher TrainingenvsandyNoch keine Bewertungen

- Handtool Safe UsageDokument42 SeitenHandtool Safe UsagegrantNoch keine Bewertungen

- 1 Osha 2Dokument19 Seiten1 Osha 2grantNoch keine Bewertungen

- 1 PM Proj 06 - Major Design Change Report - Revised JHLDokument4 Seiten1 PM Proj 06 - Major Design Change Report - Revised JHLgrantNoch keine Bewertungen

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDokument1 SeitePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNoch keine Bewertungen

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDokument1 SeitePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNoch keine Bewertungen

- PM Site 15b - Site Materials Control - REVISED JHLDokument2 SeitenPM Site 15b - Site Materials Control - REVISED JHLgrantNoch keine Bewertungen

- PM Site 07a - Revised JHLDokument1 SeitePM Site 07a - Revised JHLgrantNoch keine Bewertungen

- PM Proj 01 Wi-Method Statement - Revised JHLDokument11 SeitenPM Proj 01 Wi-Method Statement - Revised JHLgrantNoch keine Bewertungen

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDokument1 SeitePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNoch keine Bewertungen

- Amc She Env Pro 0011 Used Oil HandlingDokument7 SeitenAmc She Env Pro 0011 Used Oil HandlinggrantNoch keine Bewertungen

- 6 PM PROJ 06 - Change of Scope FormDokument2 Seiten6 PM PROJ 06 - Change of Scope FormgrantNoch keine Bewertungen

- PM Site 02b - Revised JHL #Dokument1 SeitePM Site 02b - Revised JHL #grantNoch keine Bewertungen

- 2 PM PROJ 06 - Major Design Change Register - REVISED JHLDokument2 Seiten2 PM PROJ 06 - Major Design Change Register - REVISED JHLgrantNoch keine Bewertungen

- Working On HeightsDokument5 SeitenWorking On HeightsgrantNoch keine Bewertungen

- PM PROJ 01-Project Execution Procedure - REVISED JHL XXDokument1 SeitePM PROJ 01-Project Execution Procedure - REVISED JHL XXgrantNoch keine Bewertungen

- Amc She Env Pro 0013 Hydrocarbon and Chemical Spills Clean UpDokument8 SeitenAmc She Env Pro 0013 Hydrocarbon and Chemical Spills Clean UpgrantNoch keine Bewertungen

- Working at Heights Rescue PlanDokument2 SeitenWorking at Heights Rescue PlangrantNoch keine Bewertungen

- Amc She Env Pro 0007 Hazardous Materials ManagementDokument29 SeitenAmc She Env Pro 0007 Hazardous Materials ManagementgrantNoch keine Bewertungen

- Working at Heights Rescue PlanDokument2 SeitenWorking at Heights Rescue PlangrantNoch keine Bewertungen

- Working at HeightsDokument1 SeiteWorking at HeightsgrantNoch keine Bewertungen

- X Pgndp0464 03 Eci SPC 019 Ups Specification RevaDokument9 SeitenX Pgndp0464 03 Eci SPC 019 Ups Specification RevagrantNoch keine Bewertungen

- Working On HeightsDokument5 SeitenWorking On HeightsgrantNoch keine Bewertungen

- Working On HeightsDokument5 SeitenWorking On HeightsgrantNoch keine Bewertungen

- Working at Heights Rescue PlanDokument2 SeitenWorking at Heights Rescue PlangrantNoch keine Bewertungen

- X PGNDP0464 03 ECI SPC 020 Control Valve Specification RevADokument7 SeitenX PGNDP0464 03 ECI SPC 020 Control Valve Specification RevAgrantNoch keine Bewertungen

- P Safety Ekc367 - 1pdfDokument10 SeitenP Safety Ekc367 - 1pdfAdawiyah Az-zahraNoch keine Bewertungen

- Group 4Dokument59 SeitenGroup 4Esmel Jane Cañedo PeñaflorNoch keine Bewertungen

- Risk Assessment MatrixDokument2 SeitenRisk Assessment MatrixShahul VmNoch keine Bewertungen

- ABB Safety MannualDokument102 SeitenABB Safety MannualSainu Kalathingal100% (1)

- Poster HaccpDokument1 SeitePoster HaccpgiacentNoch keine Bewertungen

- Continuity: Prevention & MitigationDokument3 SeitenContinuity: Prevention & MitigationKit Augustine TantoyNoch keine Bewertungen

- Bloodborne Pathogens NCSBN LinkDokument13 SeitenBloodborne Pathogens NCSBN LinkKevin C. AguilarNoch keine Bewertungen

- 16 12 16 MSDS Compair FF 2000 Screw Uk En-1Dokument18 Seiten16 12 16 MSDS Compair FF 2000 Screw Uk En-1stijn VanhauwaertNoch keine Bewertungen

- Cis51 - Construction Fire SafetyDokument2 SeitenCis51 - Construction Fire SafetyDarko ZovkoNoch keine Bewertungen

- Southern Electronics (Bangalore) PVT LTD: (SEPL)Dokument9 SeitenSouthern Electronics (Bangalore) PVT LTD: (SEPL)SANJAYSINH PARMARNoch keine Bewertungen

- Health, Safety and Security Procedures: Learner GuideDokument46 SeitenHealth, Safety and Security Procedures: Learner GuideMacario Roy Jr AmoresNoch keine Bewertungen

- Disaster Readiness and Risk ReductionDokument14 SeitenDisaster Readiness and Risk ReductionJayson DesearNoch keine Bewertungen

- Confined Space Entry ProcedureDokument6 SeitenConfined Space Entry ProcedureNabeel NawazNoch keine Bewertungen

- Chap1 Introduction To Occupational Safety HealthDokument17 SeitenChap1 Introduction To Occupational Safety HealthNur FazilahNoch keine Bewertungen

- Checklist Safety and Health Induction For New Laboratory UsersDokument3 SeitenChecklist Safety and Health Induction For New Laboratory UsersAbdullahNoch keine Bewertungen

- Copal Ogl 2: Safety Data SheetDokument33 SeitenCopal Ogl 2: Safety Data SheetshareavNoch keine Bewertungen

- Fire Warden and Fire Drill ProcedureDokument9 SeitenFire Warden and Fire Drill ProcedurePaul HammerNoch keine Bewertungen

- S101 PDFDokument2 SeitenS101 PDFNibhaNoch keine Bewertungen

- COVID-19 Preparedness and Response Plan Template - Updated 6.8.20 - 202006081252049904Dokument8 SeitenCOVID-19 Preparedness and Response Plan Template - Updated 6.8.20 - 202006081252049904Sujit ShahNoch keine Bewertungen

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDokument6 SeitenJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Safety AuditSDokument5 SeitenSafety AuditSsanjeev kumarNoch keine Bewertungen

- AMEF REDUCTOR FALK 21620 - Wilbert PeraltaDokument1 SeiteAMEF REDUCTOR FALK 21620 - Wilbert PeraltaTom WilberNoch keine Bewertungen

- Sample HSE PlanDokument20 SeitenSample HSE Plankoo langot100% (2)

- Iec 61511 PDFDokument4 SeitenIec 61511 PDFScribdSnake1230% (1)

- Safety Data Sheet: Acematt TS 100Dokument6 SeitenSafety Data Sheet: Acematt TS 100Mahmoud FlefilNoch keine Bewertungen

- SDS Shotcrete 513 2017 PDFDokument10 SeitenSDS Shotcrete 513 2017 PDFBrian SachoNoch keine Bewertungen

- Disaster Risk Reduction and ManagementDokument18 SeitenDisaster Risk Reduction and ManagementMichelle AposagaNoch keine Bewertungen

- 01 3500 Special ProceduresDokument2 Seiten01 3500 Special ProceduresJoice Chiø VelascoNoch keine Bewertungen

- Dr. Lavanya - Infection Control Risk Assessment (ICRA)Dokument37 SeitenDr. Lavanya - Infection Control Risk Assessment (ICRA)Lucas TobingNoch keine Bewertungen

- OSHA Letter of Interpretation PSM HarmonDokument8 SeitenOSHA Letter of Interpretation PSM HarmonvcilibertiNoch keine Bewertungen