Beruflich Dokumente

Kultur Dokumente

BDS Vam+top+® 0 4.500 15.10

Hochgeladen von

Quality controllerOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BDS Vam+top+® 0 4.500 15.10

Hochgeladen von

Quality controllerCopyright:

Verfügbare Formate

Issued on : 24 Oct.

2020

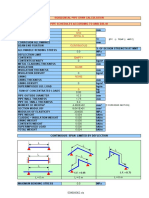

BLANKING DIMENSIONS

Connection Diameter Nominal Weigth Wall Thickness API Drift

VAM TOP ® 4.500 in. 15.10 lb/ft 0.337 in. 3.7010 in.

PIN BOX

PED 4.5000 + 0.0160 / + 0.0450 in. BED 5.0420 0.0000 / + 0.0290 in.

114.300 + 0.400 / + 1.140 mm 128.060 0.000 / + 0.750 mm

MPEL 3.8120 in. MBEL 3.7200 in.

96.830 mm 94.500 mm

PID 3.8150 -0.0090 / + 0.0090 in. BID 3.7980 -0.0090 / + 0.0100 in.

96.900 -0.250 / + 0.250 mm 96.480 -0.250 / + 0.250 mm

MPIL 3.6150 in. MBIL 3.6150 in.

91.830 mm 91.830 mm

a, a' ** 30 -5 / 0 deg b, b' 30 -5 / 0 deg

** For accessories drawings created or revised before September 2011, transitionangle ≤ 45° is acceptable

Blanking Dimensions are the final dimensions.

Extra material (cutting stock) is strongly recommended on the blanked piece in order to cut the full connection (thread, seal,

shoulder, W, D1, D2) in the SAME machining sequence.

When extra material (cutting stock) is not included, particular care shall be taken during the rechuck centering : concentricity

between chuck axis and piece shall be measured circularyand longitudinally (on MBEL or MBIL, MPEL or MPIL) by means of

the dial indicator.

Extra material (cutting stock) recommended value : 0,50 mm (0,020 inch) compared to radius

ConcentricityMax value : 0,10 mm (0,0039 inch).

Despite our best effort, VAM® Services cannot garanty that the blanking dimension are 100 %

correct. It is the role of the company in charge of machining the VAM® thread to ensure that the

blanking dimensions provided on the website are fully compliant with the VAM® thread. VAM®

Services shall not be held responsible if the Blanking Dimensions are not fully compliant.

Das könnte Ihnen auch gefallen

- British Commercial Computer Digest: Pergamon Computer Data SeriesVon EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNoch keine Bewertungen

- Blanking Dimensions: Connection Diameter Nominal Weigth Wall Thickness API DriftDokument1 SeiteBlanking Dimensions: Connection Diameter Nominal Weigth Wall Thickness API DriftKapilNoch keine Bewertungen

- Prime Price List (28 - 04 - 2021)Dokument4 SeitenPrime Price List (28 - 04 - 2021)ascdfgNoch keine Bewertungen

- Unitherm Cat 2210 Pre Insulated TubingDokument2 SeitenUnitherm Cat 2210 Pre Insulated TubingSebas FaustoNoch keine Bewertungen

- EC Classification ENGLISH 9 2018 V2Dokument1 SeiteEC Classification ENGLISH 9 2018 V2HowTo HackNoch keine Bewertungen

- EC Classification ENGLISH 3 2013 V3 FINAL PDFDokument1 SeiteEC Classification ENGLISH 3 2013 V3 FINAL PDFAngel HilasacaNoch keine Bewertungen

- CU400 CU500: Machine SpecificationDokument4 SeitenCU400 CU500: Machine SpecificationГеорги НеновNoch keine Bewertungen

- Gabay Center Pavillion StructuralDokument42 SeitenGabay Center Pavillion StructuralJoshua John JulioNoch keine Bewertungen

- Cu 325Dokument4 SeitenCu 325Pedja BekicNoch keine Bewertungen

- C10T10 14Dokument4 SeitenC10T10 14floreswgNoch keine Bewertungen

- BLANKING VAM TOP ® HC 7in. 26lb-ft API DriftDokument1 SeiteBLANKING VAM TOP ® HC 7in. 26lb-ft API DriftbmwoooooNoch keine Bewertungen

- Price List: Thhn/Thwn-2Dokument5 SeitenPrice List: Thhn/Thwn-2MEL ANGELESNoch keine Bewertungen

- Hydraulic Breakers and Silent Demolition ToolsDokument24 SeitenHydraulic Breakers and Silent Demolition ToolssinanNoch keine Bewertungen

- Steam Condenser Protection Bursting Discs TitleDokument1 SeiteSteam Condenser Protection Bursting Discs TitleMasood AlamNoch keine Bewertungen

- Dorman HandbookDokument4 SeitenDorman HandbooksharathkammarNoch keine Bewertungen

- Price List 22042013 National CablesDokument8 SeitenPrice List 22042013 National CablesSukhirthan SenthilkumarNoch keine Bewertungen

- Firtop Filters: 900Lb Rating RTJ Witch Hat Temporary StrainerDokument1 SeiteFirtop Filters: 900Lb Rating RTJ Witch Hat Temporary StrainerNagLakshmananNoch keine Bewertungen

- BD 9.875 62.80 0.625 VAM TOP Casing Regular Regular 680Dokument1 SeiteBD 9.875 62.80 0.625 VAM TOP Casing Regular Regular 680Mufaddal RNoch keine Bewertungen

- Datasheet: ULO Pipeline SupportDokument1 SeiteDatasheet: ULO Pipeline SupportSanjeevi ParthasarathiNoch keine Bewertungen

- Cu400mrd Cu500mrd Cu580mrdDokument4 SeitenCu400mrd Cu500mrd Cu580mrdAndres Isaac Salvatierra LauraNoch keine Bewertungen

- Ba Threads SpecDokument1 SeiteBa Threads Specprasadjoshi781429Noch keine Bewertungen

- Sr. No. Particular Tie BeamDokument12 SeitenSr. No. Particular Tie BeamHarsh BhavsarNoch keine Bewertungen

- Engineering: Timing Belt DrivesDokument34 SeitenEngineering: Timing Belt DrivesbennyfergusonNoch keine Bewertungen

- CU400M CU500M CU580M: Machine SpecificationDokument4 SeitenCU400M CU500M CU580M: Machine SpecificationEl nabahin FerasNoch keine Bewertungen

- AKPLAST PLASTIC TUBE INVOICEDokument1 SeiteAKPLAST PLASTIC TUBE INVOICEkapil salveNoch keine Bewertungen

- V Guard Wires Cables Price List Dec 2023Dokument6 SeitenV Guard Wires Cables Price List Dec 2023BhagyaNoch keine Bewertungen

- Nullifire B270 - High Strength Compound: 1. Product DescriptionDokument4 SeitenNullifire B270 - High Strength Compound: 1. Product Descriptionnewnse2008Noch keine Bewertungen

- Product Data Sheet - : Anixter Catalog PageDokument2 SeitenProduct Data Sheet - : Anixter Catalog PageEdwin Bonie Huacan LopezNoch keine Bewertungen

- MM1500i Internal Flange Facing MachineDokument3 SeitenMM1500i Internal Flange Facing MachineDI DINoch keine Bewertungen

- ENGINEERING SPECSDokument28 SeitenENGINEERING SPECSJoan LamedaNoch keine Bewertungen

- New T 8 Low Arm Modular SystemDokument1 SeiteNew T 8 Low Arm Modular Systembantal empukNoch keine Bewertungen

- Tolerancias: Ejemplos de Problema DirectoDokument1 SeiteTolerancias: Ejemplos de Problema DirectoJose Felipe Arce MateosNoch keine Bewertungen

- Astm Standard Dimensions: Schedule 80 CPVC FittingsDokument56 SeitenAstm Standard Dimensions: Schedule 80 CPVC Fittingsvhench0127Noch keine Bewertungen

- Polycab Cable Price List DTD 1st May 2017Dokument21 SeitenPolycab Cable Price List DTD 1st May 2017dheerajdorlikarNoch keine Bewertungen

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Dokument5 SeitenDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Raja Sekaran SajjaNoch keine Bewertungen

- CH: 86+300 - Minor Bridge: 0.825 0.825 2.450 0.100 0.100 13.850 Abutment To DamohDokument6 SeitenCH: 86+300 - Minor Bridge: 0.825 0.825 2.450 0.100 0.100 13.850 Abutment To DamohkadampNoch keine Bewertungen

- Retaining Wall-1Dokument6 SeitenRetaining Wall-1Rajendra BadjatyaNoch keine Bewertungen

- 602 Ssab Toolox Machining Rec 6 PDFDokument20 Seiten602 Ssab Toolox Machining Rec 6 PDFRodolfoMarín100% (1)

- Design CalDokument19 SeitenDesign CalneelNoch keine Bewertungen

- Data Sheet: Steam Condenser Protection Type HOV-SCDokument2 SeitenData Sheet: Steam Condenser Protection Type HOV-SCRonak PatelNoch keine Bewertungen

- Ajiya 2018 CATALOGUE-B2 Rev10-1Dokument4 SeitenAjiya 2018 CATALOGUE-B2 Rev10-1manova enterpriseNoch keine Bewertungen

- 125KVA Generator InstallationDokument3 Seiten125KVA Generator InstallationErickson GeraldNoch keine Bewertungen

- Piston Seals: Technical DetailsDokument4 SeitenPiston Seals: Technical DetailsRPINILLA (EICO S.A.)Noch keine Bewertungen

- DS Ipex Pipe SCH40 & SCH80Dokument3 SeitenDS Ipex Pipe SCH40 & SCH80KPHMXNoch keine Bewertungen

- Data Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerDokument1 SeiteData Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerSteve NewmanNoch keine Bewertungen

- Product Category 1 Price List 2015 - 2Dokument13 SeitenProduct Category 1 Price List 2015 - 2MRC WeldingNoch keine Bewertungen

- Plastic Injection Molding Tolerance GuideDokument2 SeitenPlastic Injection Molding Tolerance GuideRavindra ErabattiNoch keine Bewertungen

- KEI LDC List Price - 1st Feb 2023Dokument1 SeiteKEI LDC List Price - 1st Feb 2023Ganesh KatadeNoch keine Bewertungen

- Documents - Pub Pipe Span With Point LoadsDokument75 SeitenDocuments - Pub Pipe Span With Point LoadsThanhNoch keine Bewertungen

- 02-Ducting SmacnaDokument4 Seiten02-Ducting SmacnaSonghengNoch keine Bewertungen

- 2008 Honda CR-V: Engine AssemblyDokument7 Seiten2008 Honda CR-V: Engine Assemblyfrancisco Alba100% (1)

- Data Sheet 31 - Fig Tp703 Flat Plate StrainerDokument1 SeiteData Sheet 31 - Fig Tp703 Flat Plate StrainerSteve NewmanNoch keine Bewertungen

- Data Sheet 31 - Fig TP703 Flat Plate StrainerDokument1 SeiteData Sheet 31 - Fig TP703 Flat Plate StrainerSteve NewmanNoch keine Bewertungen

- Data Sheet 30a - Fig TB705 Basket (Top Hat) StrainerDokument1 SeiteData Sheet 30a - Fig TB705 Basket (Top Hat) StrainerSteve NewmanNoch keine Bewertungen

- MW Microwhirl Misting NozzleDokument1 SeiteMW Microwhirl Misting NozzleblondtumbalaNoch keine Bewertungen

- 04 Measurement Sheet Invoce Creek 8.02.2021Dokument8 Seiten04 Measurement Sheet Invoce Creek 8.02.2021Jaren SobremisanaNoch keine Bewertungen

- KEI W F List Price 12th Dec 2020Dokument2 SeitenKEI W F List Price 12th Dec 2020Prateek Agarwal100% (1)

- British Commercial Computer Digest: Pergamon Computer Data SeriesVon EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNoch keine Bewertungen

- Breakout - NCR Writing and ClosureDokument30 SeitenBreakout - NCR Writing and ClosureMichael HicksNoch keine Bewertungen

- List of Connectors PDFDokument3 SeitenList of Connectors PDFYojan Sebastian MastropieroNoch keine Bewertungen

- Control Plan TemplateDokument1 SeiteControl Plan TemplaterajarajanNoch keine Bewertungen

- API 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingDokument10 SeitenAPI 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingQuality controller0% (1)

- Writing Vocabulary To Describe ChartsDokument4 SeitenWriting Vocabulary To Describe ChartsQuality controllerNoch keine Bewertungen

- Api 6a 21 Ed Summary of ChangesDokument2 SeitenApi 6a 21 Ed Summary of ChangesQuality controller100% (3)

- API Tubing and Casing Dimensions GuideDokument45 SeitenAPI Tubing and Casing Dimensions GuideRyan LlanetaNoch keine Bewertungen

- 99 Top IELTS CollocationsDokument1 Seite99 Top IELTS Collocationsamirlove20667% (6)

- Report Writing SamplesDokument7 SeitenReport Writing SamplesQuality controllerNoch keine Bewertungen

- API Spec 7-1 Drill Stem ManufacturingDokument1 SeiteAPI Spec 7-1 Drill Stem ManufacturingQuality controller0% (1)

- GRR Study MSA TemplateDokument21 SeitenGRR Study MSA TemplateaadmaadmNoch keine Bewertungen

- 651 - Burst Pressure Versus Casing Wear Calculation DDDokument4 Seiten651 - Burst Pressure Versus Casing Wear Calculation DDQuality controllerNoch keine Bewertungen

- Electromagnetic SpectrumDokument3 SeitenElectromagnetic SpectrumQuality controllerNoch keine Bewertungen

- API 5B Updates (16th Edition)Dokument9 SeitenAPI 5B Updates (16th Edition)Albert Tu100% (1)

- ANSI ASME B1.5 Acme StandardDokument123 SeitenANSI ASME B1.5 Acme StandardRagesh VVNoch keine Bewertungen

- Accceptance CriteriaDokument4 SeitenAccceptance CriteriaQuality controllerNoch keine Bewertungen

- WPS & PQRDokument84 SeitenWPS & PQRjoseph.maquez24100% (4)

- Electromagnetic SpectrumDokument3 SeitenElectromagnetic SpectrumQuality controllerNoch keine Bewertungen

- ASME B1.8-1988 Stub Acme Screw Threads (B1.8 - 1988)Dokument42 SeitenASME B1.8-1988 Stub Acme Screw Threads (B1.8 - 1988)Quality controllerNoch keine Bewertungen

- Ansi B89.1.10M-2001Dokument26 SeitenAnsi B89.1.10M-2001arabcal100% (1)

- Vtes Vtes Vtes Vtes Vtes Vtes Vtes Vtes: Api Spec Q1 ReviewDokument8 SeitenVtes Vtes Vtes Vtes Vtes Vtes Vtes Vtes: Api Spec Q1 ReviewQuality controller100% (1)

- Asme B89 1 13 2001Dokument27 SeitenAsme B89 1 13 2001Quality controllerNoch keine Bewertungen

- API Spec 6A 21st Edition ChangesDokument43 SeitenAPI Spec 6A 21st Edition ChangesQuality controller83% (6)

- API Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure Gerdes 2010Dokument8 SeitenAPI Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure Gerdes 2010Quality controllerNoch keine Bewertungen

- API Spec 5CT IntroductionDokument37 SeitenAPI Spec 5CT IntroductionChandrasekhar Sonar100% (2)

- API Spec 7-1 Drill Stem ManufacturingDokument1 SeiteAPI Spec 7-1 Drill Stem ManufacturingQuality controllerNoch keine Bewertungen

- ARAMCO Engineering - Standard - Selection of Flanges, Stud Bolts, and GasketsDokument17 SeitenARAMCO Engineering - Standard - Selection of Flanges, Stud Bolts, and GasketsQuality controllerNoch keine Bewertungen

- API Flange Bolt & Ring Chart for Oil & Gas Piping SystemsDokument1 SeiteAPI Flange Bolt & Ring Chart for Oil & Gas Piping SystemsPrasetiyo SholehNoch keine Bewertungen

- Flange Gasket, Bolt, Wrench and Torque Reference ChartDokument13 SeitenFlange Gasket, Bolt, Wrench and Torque Reference Chartrlk2806100% (1)

- API Spec 7-1 Drill Stem ManufacturingDokument1 SeiteAPI Spec 7-1 Drill Stem ManufacturingQuality controller0% (1)

- Hydradrive 106U0300E2 OsaluetteloDokument60 SeitenHydradrive 106U0300E2 OsaluetteloMakeNoch keine Bewertungen

- SDDokument9 SeitenSDrudy pumacahuaNoch keine Bewertungen

- Standard Pilot Assisted Load ControlDokument28 SeitenStandard Pilot Assisted Load ControlOscar GuaricalloNoch keine Bewertungen

- Gear Pumps PartsDokument41 SeitenGear Pumps PartsKudanthai Senthilkumar100% (1)

- Tip Edge Technique: P. John PG StudentDokument112 SeitenTip Edge Technique: P. John PG Studentjohn suryavardhanNoch keine Bewertungen

- Unique Drum Assembly - Sheet 1 of 2: B - 22 SD-100D TFDokument2 SeitenUnique Drum Assembly - Sheet 1 of 2: B - 22 SD-100D TFRICHARD BURBANONoch keine Bewertungen

- 3.HYDRANT For TejgaonDokument6 Seiten3.HYDRANT For Tejgaonmujahid_islam85Noch keine Bewertungen

- Close Top Cover Error Phaser 7400Dokument2 SeitenClose Top Cover Error Phaser 7400trumukyNoch keine Bewertungen

- Hochdruckpumpe KD716 Stopfbuchsumruestung e PDFDokument1 SeiteHochdruckpumpe KD716 Stopfbuchsumruestung e PDFธนวัตร อยู่สุขNoch keine Bewertungen

- Caterpillar Cat 329DL EXCAVATOR (Prefix WLT) Service Repair Manual (WLT00001 and Up) PDFDokument22 SeitenCaterpillar Cat 329DL EXCAVATOR (Prefix WLT) Service Repair Manual (WLT00001 and Up) PDFfkdmmaNoch keine Bewertungen

- Indeks Parca NumaraDokument20 SeitenIndeks Parca NumaraWilson JhNoch keine Bewertungen

- Bridon Wire Rope CatalogueDokument66 SeitenBridon Wire Rope Cataloguetunggularif0% (1)

- Blohm + Voss Pipe Handling Equipment ManualDokument72 SeitenBlohm + Voss Pipe Handling Equipment ManualDaniel TostaNoch keine Bewertungen

- 59 Why Nuts and Bolts Come Loose V1Dokument2 Seiten59 Why Nuts and Bolts Come Loose V1jillianixNoch keine Bewertungen

- Mechanical Technician: QualificationDokument4 SeitenMechanical Technician: Qualificationjohn MNoch keine Bewertungen

- Safe Working Practices: Wood Turning LathesDokument7 SeitenSafe Working Practices: Wood Turning LathesCamilo CubidesNoch keine Bewertungen

- Lehry MRPDokument67 SeitenLehry MRPvinayak abhaleNoch keine Bewertungen

- LEAK PRESSURE TEST TITLEDokument68 SeitenLEAK PRESSURE TEST TITLEJayaraman KamarajNoch keine Bewertungen

- Technical Information Series F: Flow Control ValvesDokument4 SeitenTechnical Information Series F: Flow Control ValvesAde Indra Wijaya100% (1)

- BP Sling SpecificationDokument9 SeitenBP Sling SpecificationSinoj AntonyNoch keine Bewertungen

- Metal Forming 2998Dokument22 SeitenMetal Forming 2998RRR180Noch keine Bewertungen

- PC75UU-1 Hydraulic Pump Parts ListDokument2 SeitenPC75UU-1 Hydraulic Pump Parts Listeshopmanual baruNoch keine Bewertungen

- Offshore Skid ModulesDokument3 SeitenOffshore Skid ModulesKumar PNoch keine Bewertungen

- Mac 2009Dokument60 SeitenMac 2009Ridwan Pramudya100% (1)

- Series Full-Port Brass Ball Valve: DescriptionDokument1 SeiteSeries Full-Port Brass Ball Valve: DescriptionGreg FarzettaNoch keine Bewertungen

- Rapid spin washer-extractors spare partsDokument25 SeitenRapid spin washer-extractors spare partsNữa Đi EmNoch keine Bewertungen

- Bolt Torque Values - FLUOROLON (Sheet Ring Gaskets / Raised Face Flanges)Dokument5 SeitenBolt Torque Values - FLUOROLON (Sheet Ring Gaskets / Raised Face Flanges)rizky efrinaldoNoch keine Bewertungen

- PLXRMM1606A - R410A Non-Inverter Wall Mounted FTN-A Series Myanmar PDFDokument8 SeitenPLXRMM1606A - R410A Non-Inverter Wall Mounted FTN-A Series Myanmar PDFWai Lwin Ko100% (1)

- Wire Guard PDFDokument4 SeitenWire Guard PDFKavyatanuja NomulaNoch keine Bewertungen

- HPT Tech ManualDokument12 SeitenHPT Tech Manual1mmahoney100% (1)