Beruflich Dokumente

Kultur Dokumente

CAM Lab Mtech

Hochgeladen von

rkOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CAM Lab Mtech

Hochgeladen von

rkCopyright:

Verfügbare Formate

M.

TECH – CAD/CAM

CAM LABORATORY

CAM LAB – (12BCM17)

INDEX

EXPT

DATE TOPIC PAGE NO

NO.

INTRODUCTION 02-09

CNC LATHE

1. FACING CYCLE 11-12

2. TURNING CYCLE 13-14

3. THREADING CYCLE 15-16

4. DRILLING CYCLE 17-18

5. GROOVING CYCLE 19-20

CNC MILLING

LINEAR & CIRCULAR INTERPOLATION

6. (SVCET)

22-24

7. MIRRORING 25-26

8. ROTATION 27-28

9. CIRCULAR POCKETING 29-30

10. RECTANGULAR POCKETING 31-32

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 1

M.TECH – CAD/CAM

CAM LABORATORY

INTRODUCTION

WORD DETAILS:

Although the control will, in general, accept part programming words in any

sequence, it is recommended that the following word order for each block is used.

N; G; X or U; Z or W; I; K; F; S; T; M

O: PROGRAM NUMBER

The “O” followed by a 4 digit numeral value is used to assign a program number.

Example:

O1002

N: SEQUEMCE NUMBER

The N word may be omitted. When programmed, the sequence number following

the N address is a four digit numerical value and is used to identify a complete block of

information. Although ascending, descending, or duplicate numbering is allowed, it is

best to program in ascending order in increments of 10. This allows for future editing and

simplified sequence number search.

G: PREPARATORY COMMAND:

The two digit G command is programmed to set up the control to perform an

automatic machine operation. A full list of G codes are given, one G word from each

modal group and one non modal G word can be programmed on the same block.

Example:

Valid N100 G00 G40 G41 G90 G95

*G40 & G41 are from the same group.

A retained G word (Modal) from one group remains active until another G word

from the same group is programmed.

One-shot G words (Non-Modal) must be programmed in every block when

required.

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 2

M.TECH – CAD/CAM

CAM LABORATORY

G-CODES LISTING FOR DENFORD FANUC LATHES:

Note: -NOT ALL G CODES APPLY TO EACH MACHINE.

Group 1 G00 Positioning (Rapid Traverse)

1 G01 Linear Interpolation (Feed)

1 G02 Circular Interpolation CW

1 G03 Circular Interpolation CCW

0 G04 Dwell

0 G10 Offset Value Setting By Program

6 G20 Inch Data Input

6 G21 Metric Data Input

9 G22 Stored Stroke Check On

9 G23 Stored Stroke Check Off

0 G27 Reference Point Return Check

0 G28 Reference Point Return

0 G29 Return from Reference Point

0 G30 Return to 2nd Reference Point

0 G31 Skip Function

1 G32 Thread Cutting

1 G34 Variable Lead Thread Cutting

0 G36 Automatic Tool Compensation X

0 G37 Automatic Tool Compensation Z

7 G40 Tool Nose Radius Compensation cancels

7 G41 Tool Nose Radius Compensation Left

7 G42 Tool Nose Radius Compensation Right

0 G50 Work Co-ord. Change/Max. Spindle Speed setting

0 G65 Macro Call

12 G66 Macro Modal Call

12 G67 Macro Modal Call Cancel

4 G70 Finishing Cycle

4 G71 Stock Removal in Turning

0 G72 Stock Removals in Facing

0 G73 Pattern Repeating

0 G74 Peck Drilling in Z Axis

0 G75 Grooving in X Axis

0 G76 Thread Cutting Cycle

1 G90 Cutting Cycle A

1 G92 Thread Cutting Cycle

1 G94 Cutting Cycle B

2 G96 Constant surface Speed Control

2 G97 Constant Surface Speed Control Cancel

11 G98 Feed per Minute

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 3

M.TECH – CAD/CAM

CAM LABORATORY

11 G99 Feed per Revolution

NOTES FOR G CODE LISTING:

Note 1:-

G Codes of 0 group represent those non modal and are effective to the designated

block.

Note 2:-

G codes of different groups can be commanded to the same block. If more than

one G codes from the same group are commanded, the latter becomes effective.

AXIS DEFINITIONS:-

Z AXIS:-

The Z axis is along a line between the spindle and the tailstock, or the centre line

of rotation of the spindle. Minus (-) movements of the tool are left toward the head stock;

positive (+) movements are right toward the tailstock.

X AXIS:-

The X axis is 90 degrees from the Z axis (perpendicular to the Z axis). Minus (-)

movements of the tool are toward the centre-line of rotation, and positive (+) movements

are away from the centre-line of rotation.

X : X AXIS COMMAND:-

The X word is programmed as a diameter which is used to command a change in

position perpendicular to the spindle centre-line.

U : X AXIS COMMAND:-

The U word is an incremental distance (diameter value) which is used to command

a change in position perpendicular to the spindle centre-line. The movement is the

programmed value.

Z : Z AXIS COMMAND:-

The Z word is an absolute dimension which is used to command a change in

position parallel to the spindle centre-line.

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 4

M.TECH – CAD/CAM

CAM LABORATORY

W: Z AXIS COMMAND:-

The W word is an incremental distance which is used to command a change of

position parallel to the spindle centre-line.

Do not program X & U or Z & W in the same block. If an X axis command calls

for no movement it may be omitted.

X, U or P: DWELL:-

The X word is used with G04 to command a dwell in seconds.

The P word is used with G04 to command a dwell in milliseconds.

I WORD:-

For arc programming (G02 or G03) the I value (with sign) is programmed to define the

incremental distance parallel to the Z axis, between the start of the arc and the arc centre.

K WORD:-

For arc programming (G02 or G03), the K value (with sign) is programmed to define the

incremental distance parallel to the Z axis, between the start of the arc and the arc centre.

The maximum arc for I & K programming is limited to the quadrant. If I or K is zero, it

must be omitted.

F WORD:-

a) In G99 mode the F word is used to command feed/rev.

b) In G98 mode the F word is used to command feed/min.

c) In G32 mode the F word specifies the lead (pitch) of the thread.

P WORD:-

a) Used in automatic cycles to define the first block of a contour.

b) Used with M98 to define a subroutine number.

Q WORD;-

Q words are used in automatic cycles to define the last block of a contour.

R WORD:-

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 5

M.TECH – CAD/CAM

CAM LABORATORY

For circular Interpolation (G02 or G03) the R word defines the arc radius from the centre

of the tool nose radius (G40 active) – or the actual radius required (G41 / G42 active).

S WORD:-

a) In the constant surface speed mode (G96) the four digit S word is used to command

the required surface speed in either feet or metres per minute.

b) In the direct r.p.m. mode (G97), the four digit S word is used to command the spindle

speeds incrementally, in r.p.m., between the ranges available for the machine.

c) Prior to entering constant surface speed mode 9G96) the S word is used to specify a

speed constraint, the maximum speed you wish the spindle to run at. To set this

restraint the S word is programmed in conjunction with the G50 word.

T WORD:-

The T words are used in conjunction with “M06”. These are used to call up the required

tool on an automatic indexing turret machine, and to activate its tool offsets.

M WORD:-

An M word is used to initiate auxiliary functions particular to the machine. One M code

can be programmed within one program block together with other part program information.

M-CODE LIST FOR DENFORD FANUC LATHES:-

All M codes marked with an asterisk will be executed at the end of a block (i.e. after

the axis movement).

NOTE: - NOT ALL M CODES ARE AVAILABLE ON EACH MACHINE.

* M00 PROGRAM STOP

* M01 OPTIONAL STOP

* M02 PROGRAM RESET

M03 SPINDLE FORWARD

M04 SPINDLE REVERSE

* M05 SPINDLE STOP

M06 AUTO TOOL CHANGE

M07 COOLANT “B” ON

M08 COOLANT “A” ON

* M09 COOLANT OFF

M10 CHUCK OPEN

M11 CHUCK CLOSE

M13 SPINDLE FORWARD & COOLANT ON

M14 SPINDLE REVERSE & COOLANT ON

M15 PROGRAM INPUT USING. “MIN P” (SPECIAL

FUNCTION)

M16 SPECIAL TOOL CALL (TOOL CALL IGNORES TURRET)

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 6

M.TECH – CAD/CAM

CAM LABORATORY

M19 SPINDLE ORIENTATE

M20 SPINDLE INDEX A

M21 SPINDLE INDEX 2A

M22 SPINDLE INDEX 3A

M23 SPINDLE INDEX 4A

M25 QUILL EXTEND

M26 QUILL RETRACT

M29 SELECT “DNC” MODE

M30 PROGRAM RESET & REWIND

M31 INCREMENT PARTS COUNTER

M37 DOOR OPEN TO STOP

M38 DOOR OPEN

M39 DOOR CLOSE

M40 PARTS CATCHER EXTEND

M41 PARTS CATCHER RETRACT

M43 SWARF CONVEYOR FORWARD

M44 SWARF CONVEYOR REVERSE

* M45 SWARF CONVEYOR STOP

M48 LOCK % FEED AND % SPEED AT 100%

M49 CANCEL M48 (DEFAILT)

M50 WAIT FOR AXIS IN POSITION SIGNAL (CANCELS

CONTINUOUS PATH)

M51 CANCEL M50 (DEFAILT)

M52 PULL-OUT IN THREADING = 90 DEGREES (DEFAILT)

M53 CANCEL M52

M54 DISABLE SPINDLE FLUCTUATION TESTING DEFAILT)

M56 SELECT INTERNAL CHUCKING (FROM PLC EDITION

“F”)

M57 SELECT EXTERNAL CHUCKING (FROM PLC EDITION

“F”)

M62 AUX. 1 ON

M63 AUX. 2 ON

M64 AUX. 1 OFF

M65 AUX. 2 OFF

M98 SUB PROGRAM CALL

M99 SUB PROGRAM END

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 7

M.TECH – CAD/CAM

CAM LABORATORY

PROGRAM AND SUBROUTINE IDENTIFICATION:-

The first block of a program/subroutine must contain a program number “O”.

The program would be as follows:-

Nested to Four Levels

M98

SUB PROGRAM CALL

P9999 5678

No

No. OF REPEATS

SUBPROGRAMS (SUNROUTINES):

By using the program jump functions, it is possible to simplify a machining program with

repeated machining or function sequences.

The machining sequences, which are repeated and can be used several times, are stored as

subroutines and called up using the program jump functions.

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 8

M.TECH – CAD/CAM

CAM LABORATORY

M98 – Jump command to another program.

M99 – Return command

Main Program Sub-Program Sub-Program

O0005 0241 0340

M98 P0241 M98 P20340 M 30 M99

M98 P20340 repeats program 0340 twice.

M99 can be used to return to the start of the program.

: 0010

N10 M00

N980 M99P10

M99 generally indicates the end of a subroutine and allows the jump back to the main

program. If it is used with “P” address, this indicates the “Jump To” block number.

The program will read the M99 P10 (GOTO N10) i.e. automatic return to line ten.

Line N10 must read M00 to stop the cycle for component loading. All information prior

to N10-i.e. standard tool geometry- would not be read after the first cycle. Therefore M30 would

not be programmed in this case.

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 9

M.TECH – CAD/CAM

CAM LABORATORY

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 10

M.TECH – CAD/CAM

CAM LABORATORY

EXPT NO:01

DT:

FACING CYCLE

[BILLET X25 Z70]

G21 G98;

G28 U0W0;

M06 T1;(FACING TOOL)

M03 S1200;

G00 X26 Z0;

G94 X0 Z-0.5 F50;

Z-1.0

Z-1.5

Z-2.0

Z-2.5

Z-3.0

Z-3.5

Z-4.0

Z-4.5

Z-5.0

Z-5.5

Z-6.0

Z-6.5

Z-7.0

Z-7.5

Z-8.0

Z-8.5

Z-9.0

Z-9.5

Z-10.0

G28 U0W0;

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 11

M.TECH – CAD/CAM

CAM LABORATORY

M05;

M30;

All dimensions are in mm.

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 12

M.TECH – CAD/CAM

CAM LABORATORY

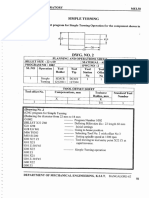

EXPT NO:02

DT:

TURNING CYCLE

[BILLET X28 Z70]

G21 G98;

G28 U0W0;

M06 TI;(FACING TOOL)

M03 S1000;

G00 X25 Z1;

G90 X24 Z-45 F50;

X23

X22

X21

X20

X19 Z-40

X18

X17

X16

X15

X14 Z-20

X13

X12

X11

X10

G28 U0W0;

M05;

M30;

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 13

M.TECH – CAD/CAM

CAM LABORATORY

All dimensions are in mm.

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 14

M.TECH – CAD/CAM

CAM LABORATORY

EXPT NO:03

DT:

THREADING CYCLE

[BILLET X25 Z70]

G21 G98;

G28 U0W0;

M06 TI (CALLING THREADING TOOL);

M03 S600;

G00 X26 Z0;

G76 P021560 Q50 R0.1;

G76 X23.774 Z-25 P613 Q100 F1;

G28 U0W0;

M05;

M30;

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 15

M.TECH – CAD/CAM

CAM LABORATORY

All dimensions are in mm.

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 16

M.TECH – CAD/CAM

CAM LABORATORY

EXPT NO:04

DT:

DRILLING CYCLE

[BILLET X25 Z70]

G21 G98;

G28 U0W0;

M06 T2;

M03 S1000;

G00 X0Z1;

G74 R1;

G74 X0 Z-5 Q500 F30;

G28 U0 W0;

M06 T4;

G00 X0 Z1;

G74 R1;

G74 X0 Z-20 Q500 F30;

G28 U0 W0;

M06 T6;

G00 X0 Z1;

G74 R1;

G74 X0Z-25 Q500 F30;

G28 U0W0;

M05;

M30;

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 17

M.TECH – CAD/CAM

CAM LABORATORY

All dimensions are in mm.

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 18

M.TECH – CAD/CAM

CAM LABORATORY

EXPT NO: 05

DT:

GROOVING CYCLE

[BILLET X25 Z70]

G21 G98;

G28 U0W0;

M06 T1;(CALLING FACING CYCLE)

M03 S1000;

G00 X26Z0;

G94 X0 Z-0.5 F50;

Z-1.0

Z-1.5

G28 U0W0;

G00 X26Z0;

G90 X26Z0;

G90 X25 Z-36.5 F30;

X24

X23

G28 U0W0;

M06 T3; (CALLING GROOVING TOOL)

G00 X24 Z-13.5;

G75 R1;

G75 X70 Z-31.5 P200 Q1000 F30;

G28 U0W0;

M05;

M30;

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 19

M.TECH – CAD/CAM

CAM LABORATORY

All dimensions are in mm.

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 20

M.TECH – CAD/CAM

CAM LABORATORY

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 21

M.TECH – CAD/CAM

CAM LABORATORY

EXPT NO:06

DT:

LINEAR & CIRCULAR INTERPOLATION

(SVCET)

G21 G94

G91 G28 Z0

G28 X0 Y0

M06 T06

M03 S1300

G90 G00 X0 Y0 Z5

[S]

G00 X2 Y30

G01 Z-1 F60

G01 X10 Y30

G03 X15 Y35 R5

G01 X15 Y 37.5

G03 X10 Y42.5 R5

G01 X07Y42.5

G02 X2 Y47.5 R5

G01 X2 Y50

G02 X7 Y55 R5

G01 X15 Y55

G00 Z2

[V]

G00 X20 Y55

G01 Z-1 F60

G01 X27.5 Y30

G01 X33 Y55

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 22

M.TECH – CAD/CAM

CAM LABORATORY

G00 Z2

[C]

G00 X51 Y55

G01 Z-1 F60

G01 X43 Y55

G03 X38 Y50 R5

G01 X38 Y35

G03 X43 Y30 R5

G01 X51 Y30

G00 Z2

[E]

G00 X69 Y55

G01 Z-1F60

G01 X56 Y55

G01 X56 Y42.5

G01 X69 Y42.5

G01 X56 Y42.5

G01 X56 Y30

G01 X69 Y30

G00 Z2

[T]

G00 X81.5 Y30

G01 Z-1 F60

G01 X81.5 Y55

G01 X74 Y55

G01 X87 Y55

G00 Z2

G91 G28 Z0

G28 X0Y0

M05

M30

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 23

M.TECH – CAD/CAM

CAM LABORATORY

LINEAR & CIRCULAR INTERPOLATION

(SVCET)

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 24

M.TECH – CAD/CAM

CAM LABORATORY

EXPT NO:07

DT:

MIRRORING

G21 G94

G91 G28 Z0

G28 X0 Y0

M06 T06

M03 S1500

G90 G00 X0 Y0 Z5

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 25

M.TECH – CAD/CAM

CAM LABORATORY

M98 P4646

M70

M98 P4646

M80

M70

M71

M98 P4646

M80

M81

M71

M98 P4646

M81

G91 G28 Z0

G28 X0 Y0

M05

M30

O4646

G00 X10 Y10

G01 Z-1.5 F80

G01 X30 Y10

G03 X10 Y30 R20

G01 X10 Y10

G00 Z5

M99

MIRRORING

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 26

M.TECH – CAD/CAM

CAM LABORATORY

EXPT NO:08

DT:

ROTATION

G21 G94

G91 G28 Z0

G28 X0 Y0

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 27

M.TECH – CAD/CAM

CAM LABORATORY

M06 T06

M03 S1300

G90 G00 X0Y0 Z5

M98 P1234

G68 X0Y0R90

M98 P1234

G68 X0Y0R180

M98 P1234

G68 X0Y0R270

G69

G91 G28 Z0

G28 X0Y0

M05

M30

O1234

G00 X0Y0

G01 Z-1 F60

G01 X20 Y-10

G01 X40 Y0

G01 X20 Y10

G01 X0 Y0

G00 Z5

M99

ROTATION

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 28

M.TECH – CAD/CAM

CAM LABORATORY

EXPT NO:09

DT:

CIRCULAR POCKETING

G21 G94

G91 G28 Z0

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 29

M.TECH – CAD/CAM

CAM LABORATORY

G28 X0Y0

M06 T05

M03S1200

G90 G00X0 Y0 Z5

G170 R0P0 Q1 X0 Y0 Z-10 I0.5 J0.1 K20

G171 P50 S1500 R60 F60 B1800 J100

G170 R0 P1 Q1 X0 Y0 Z-10 I0 J0 K20

G171 P50 S1500 R60 F60 B1800 J100

G00 Z5

M05

G91 G28 Z0

G28 X0 Y0

M30

CIRCULAR POCKETING

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 30

M.TECH – CAD/CAM

CAM LABORATORY

EXPT NO:10

DT:

RECTANGULAR POCKETING

G21 G94

G91 G28 Z0

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 31

M.TECH – CAD/CAM

CAM LABORATORY

G28 X0 Y0

M06 T04

M03 S1200

G90 G00 X0 Y0 Z5

G172 I30 J30 K0 P0 Q1 R0 X-15 Y-15 Z-10

G173 I0.1 K0.1 P50 S1500 R60 F50 B1800 J100

G172 I30 J30 K0 P1 Q1 R0 X-15 Y-15 Z-10

G173 I0 K0 P50 S1500 R60 F50 B1800 J100

G00 Z5

M05

G91 G28 Z0

G28 X0 Y0

M30

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 32

M.TECH – CAD/CAM

CAM LABORATORY

RECTANCULAR POCKETING

SRI VENKATESWARA COLLEGE OF ENGINEERING AND TECHNOLOGY 33

Das könnte Ihnen auch gefallen

- Cim Lab Viva TipsDokument5 SeitenCim Lab Viva Tipsshivaling battarkiNoch keine Bewertungen

- VMC ProgrammingDokument22 SeitenVMC ProgrammingDynamic bhagwanNoch keine Bewertungen

- CNC Programming WRKB Lathe Sample LockedDokument51 SeitenCNC Programming WRKB Lathe Sample Lockedkree_bigdaddy100% (1)

- Experiment 6 - CNC Programing-MillingDokument9 SeitenExperiment 6 - CNC Programing-MillingG. Dancer GhNoch keine Bewertungen

- G Code Table PDFDokument38 SeitenG Code Table PDFmanish_chaturvedi_6100% (2)

- Unit - 8: CNC ProgrammingDokument21 SeitenUnit - 8: CNC ProgrammingVarshaNoch keine Bewertungen

- CNC ProgDokument38 SeitenCNC ProgPoornima JoshiNoch keine Bewertungen

- Turning: Chapter ObjectivesDokument78 SeitenTurning: Chapter ObjectivesDany EscobarNoch keine Bewertungen

- 00 EAGLE FANUC OiDokument60 Seiten00 EAGLE FANUC OiFranciscoDanielRamirezFloresNoch keine Bewertungen

- G CodesDokument8 SeitenG Codesdinesh2705Noch keine Bewertungen

- List of G Codes: SR - NO. Code Function 1. 2. 3. 4Dokument28 SeitenList of G Codes: SR - NO. Code Function 1. 2. 3. 4pmagrawal100% (1)

- A2100 Iso PDFDokument202 SeitenA2100 Iso PDFAmit JholaparaNoch keine Bewertungen

- 5 - G-CodeDokument55 Seiten5 - G-CodefamilyumaNoch keine Bewertungen

- Ipt CodesDokument6 SeitenIpt CodesAbdul QyyoomNoch keine Bewertungen

- Fanuc Ot CNC Program Manual Gcodetraining 588Dokument104 SeitenFanuc Ot CNC Program Manual Gcodetraining 588hiepkhachbk2010824350% (2)

- Manual FanucDokument104 SeitenManual FanucTauasi TauasisNoch keine Bewertungen

- G M Codes For Turning and MillingDokument10 SeitenG M Codes For Turning and MillingParanthaman RamanNoch keine Bewertungen

- G-Code - Wikipedia, The Free EncyclopediaDokument6 SeitenG-Code - Wikipedia, The Free EncyclopediajoydeepNoch keine Bewertungen

- G CodeDokument83 SeitenG CodeEmanuelNoch keine Bewertungen

- Code Description Milling (M) Turning (T) Corollary InfoDokument11 SeitenCode Description Milling (M) Turning (T) Corollary InfoDilshad MalikNoch keine Bewertungen

- VMC Manual Programming Handbook - Chinmaya BeheraDokument19 SeitenVMC Manual Programming Handbook - Chinmaya BeherapradeepNoch keine Bewertungen

- GTCNC 150it IiDokument4 SeitenGTCNC 150it Iilukman hakimNoch keine Bewertungen

- Syllabus Me0423 - Computer Aided Manufacturing Laboratory: PurposeDokument10 SeitenSyllabus Me0423 - Computer Aided Manufacturing Laboratory: PurposefamilyumaNoch keine Bewertungen

- 5 - G-CodeDokument55 Seiten5 - G-CodeTan TeongShengNoch keine Bewertungen

- CNC Turning Programming Exellent ExplainationDokument29 SeitenCNC Turning Programming Exellent ExplainationschrienerNoch keine Bewertungen

- CNC Programming Tutorials Examples G M Codes G M Programming Tutorial ExampleDokument340 SeitenCNC Programming Tutorials Examples G M Codes G M Programming Tutorial ExampleYassin Belkacem100% (2)

- Description For M Codes3Dokument19 SeitenDescription For M Codes3balabooksNoch keine Bewertungen

- Cad Cam End Sem VDDokument90 SeitenCad Cam End Sem VDDerik NelsonNoch keine Bewertungen

- G-Code For CNC MachineDokument13 SeitenG-Code For CNC MachinezokiplusNoch keine Bewertungen

- New Microsoft Word DocumentDokument19 SeitenNew Microsoft Word DocumentŤhåýğųŢjNoch keine Bewertungen

- G Codes and M CodesDokument10 SeitenG Codes and M CodesHarsh YadavNoch keine Bewertungen

- G-Code For CNC MachineDokument13 SeitenG-Code For CNC MachinezokiplusNoch keine Bewertungen

- G-Code InstructionsDokument55 SeitenG-Code InstructionsSantiago LopezNoch keine Bewertungen

- Turning Centers Machine Code GlossaryDokument3 SeitenTurning Centers Machine Code GlossaryLaura BNoch keine Bewertungen

- F L8 TA 202 NC Part ProgrammingDokument26 SeitenF L8 TA 202 NC Part ProgrammingShiva Krishna BhagavatulaNoch keine Bewertungen

- CNC-Lab Mechanical ManualDokument21 SeitenCNC-Lab Mechanical ManualHaresh RaisinghaniNoch keine Bewertungen

- G Code Programming G - Code Programming (PDFDrive) PDFDokument56 SeitenG Code Programming G - Code Programming (PDFDrive) PDFhasan alsarrafNoch keine Bewertungen

- Jm201 - CNC MillingDokument24 SeitenJm201 - CNC MillingMuhd Zulhusni Ag Jaludin100% (1)

- 2.5 Programming Functions: (Mm/min or Inch/min) (Mm/rev or Inch/rev)Dokument59 Seiten2.5 Programming Functions: (Mm/min or Inch/min) (Mm/rev or Inch/rev)Srinivas YadavNoch keine Bewertungen

- CNC Programming 1Dokument26 SeitenCNC Programming 1mohamed alsalhyNoch keine Bewertungen

- Robots and Computer Controlled MachinesDokument2 SeitenRobots and Computer Controlled MachinesManish SinghNoch keine Bewertungen

- CADCAM CNC Unit-3.1Dokument54 SeitenCADCAM CNC Unit-3.1kiranchennoju2004Noch keine Bewertungen

- FANUCMDokument24 SeitenFANUCMpramodgowdruNoch keine Bewertungen

- EN - Complete Sinumerik Operate Milling - v26Dokument690 SeitenEN - Complete Sinumerik Operate Milling - v26Hieu Nguyen100% (1)

- Mill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram ExampleDokument73 SeitenMill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram Exampleسليمان مصريNoch keine Bewertungen

- MSC Lecture 6Dokument28 SeitenMSC Lecture 6Chán Chênh VênhNoch keine Bewertungen

- CNC CodeDokument9 SeitenCNC CodeMochammad Karim Al AminNoch keine Bewertungen

- Programming Fanuc OtDokument13 SeitenProgramming Fanuc OtsaminziNoch keine Bewertungen

- MANUAL BrusilicaDokument56 SeitenMANUAL BrusilicaAjdinNoch keine Bewertungen

- CNC Programming Part 2Dokument64 SeitenCNC Programming Part 2Manjunatha GrNoch keine Bewertungen

- Me 473 - Unit 4 - 1Dokument70 SeitenMe 473 - Unit 4 - 1Ama Serwaa YeboahNoch keine Bewertungen

- FanucDokument10 SeitenFanucgigofive66Noch keine Bewertungen

- Manual - CNC SoftwareDokument36 SeitenManual - CNC SoftwareYshNoch keine Bewertungen

- Group 24 (Solar Mobile ChargingDokument22 SeitenGroup 24 (Solar Mobile ChargingBanothu RameshNoch keine Bewertungen

- My CNCDokument5 SeitenMy CNCzoranteicNoch keine Bewertungen

- Anais Do Workshop De Micro-ondasVon EverandAnais Do Workshop De Micro-ondasNoch keine Bewertungen

- Projects With Microcontrollers And PICCVon EverandProjects With Microcontrollers And PICCBewertung: 5 von 5 Sternen5/5 (1)

- Applications of Ultrasonic Machining:: Chemical Machining (CHM) Electro-Chemical Machining (ECM)Dokument2 SeitenApplications of Ultrasonic Machining:: Chemical Machining (CHM) Electro-Chemical Machining (ECM)rkNoch keine Bewertungen

- Dom LabDokument29 SeitenDom LabrkNoch keine Bewertungen

- Notes Me 112 Concepts in Engineering Design Unit 3Dokument23 SeitenNotes Me 112 Concepts in Engineering Design Unit 3rkNoch keine Bewertungen

- List of Experiments: Mandava Institute of Engineering and TechnologyDokument2 SeitenList of Experiments: Mandava Institute of Engineering and TechnologyrkNoch keine Bewertungen

- 104.random Vibration Analysis of A Rotary CompressorDokument1 Seite104.random Vibration Analysis of A Rotary CompressorrkNoch keine Bewertungen

- Design and Study State Thermal Analysis of Super Heater CoilsDokument1 SeiteDesign and Study State Thermal Analysis of Super Heater CoilsrkNoch keine Bewertungen

- Manufacturing of Piston: Mechanical EngineeringDokument7 SeitenManufacturing of Piston: Mechanical EngineeringrkNoch keine Bewertungen

- Mechanical r10 Second MidDokument1 SeiteMechanical r10 Second MidrkNoch keine Bewertungen

- PLC Lab ManualDokument28 SeitenPLC Lab ManualrkNoch keine Bewertungen

- Lab Manual: Fourth Year Semester-VIIDokument53 SeitenLab Manual: Fourth Year Semester-VIIrk0% (1)

- NoteDokument130 SeitenNoterkNoch keine Bewertungen

- DMM Ii Mid Ii DecDokument4 SeitenDMM Ii Mid Ii DecrkNoch keine Bewertungen

- Mi 123Dokument2 SeitenMi 123rkNoch keine Bewertungen

- Institute of Aeronautical EngineeringDokument11 SeitenInstitute of Aeronautical EngineeringrkNoch keine Bewertungen

- Composite Materials: Composite Materials Are Commonly Classified at Following Two Distinct LevelsDokument3 SeitenComposite Materials: Composite Materials Are Commonly Classified at Following Two Distinct LevelsrkNoch keine Bewertungen

- WWW - Manaresults.co - In: Set No. 1Dokument3 SeitenWWW - Manaresults.co - In: Set No. 1rkNoch keine Bewertungen

- Manufacturing Engineering Technology 7Th Full ChapterDokument41 SeitenManufacturing Engineering Technology 7Th Full Chapterpenny.rodriguez567100% (19)

- Cobra Lathe ManualDokument29 SeitenCobra Lathe ManualGerDen100% (1)

- Locknut EarthTagDokument1 SeiteLocknut EarthTagradikahendryNoch keine Bewertungen

- GB Catalog Update 2013-1 Inlay LRDokument296 SeitenGB Catalog Update 2013-1 Inlay LRsaotinhyeu307783Noch keine Bewertungen

- Material EsDokument54 SeitenMaterial EsRichardNoch keine Bewertungen

- Change !!: Change Change Change ChangeDokument20 SeitenChange !!: Change Change Change Changexmen norNoch keine Bewertungen

- Akhil LPSGDokument18 SeitenAkhil LPSGPARSHANTNoch keine Bewertungen

- Torque Value - With MetricDokument2 SeitenTorque Value - With MetricSubash NagaNoch keine Bewertungen

- Alform Laser Produktfolder en 1112Dokument6 SeitenAlform Laser Produktfolder en 1112szystNoch keine Bewertungen

- W 2019 A - Merged - WatermarkDokument18 SeitenW 2019 A - Merged - WatermarkDivya ChandewarNoch keine Bewertungen

- Makita Accessories Catalogue 2022 23Dokument234 SeitenMakita Accessories Catalogue 2022 23Hadi Santoso100% (1)

- Iso 4034-5Dokument10 SeitenIso 4034-5Debkov RomanNoch keine Bewertungen

- Clausing Full Line Catalog 2014Dokument135 SeitenClausing Full Line Catalog 2014Carlos Volnei FerreiraNoch keine Bewertungen

- Non Conventional PDFDokument5 SeitenNon Conventional PDFRavichandran GNoch keine Bewertungen

- 2010 ASME Section VIII Division 1 Uw-14 (D) Pag 125Dokument1 Seite2010 ASME Section VIII Division 1 Uw-14 (D) Pag 125pipochelinNoch keine Bewertungen

- Is 10685-1983 (R.a. 2019)Dokument3 SeitenIs 10685-1983 (R.a. 2019)HARIOM INSTRU-LABSNoch keine Bewertungen

- Sheet Metal Forming ProcessesDokument41 SeitenSheet Metal Forming ProcessesSumairNoch keine Bewertungen

- Casting Material Carbon Steel A27 GR 65 35Dokument8 SeitenCasting Material Carbon Steel A27 GR 65 35Abdul RozaqNoch keine Bewertungen

- Fabrication of MetalDokument22 SeitenFabrication of MetalaurangzaibNoch keine Bewertungen

- Annealing Process: Physical Properties of Annealed MetalsDokument5 SeitenAnnealing Process: Physical Properties of Annealed MetalsAntonius TanNoch keine Bewertungen

- FCD 450-10Dokument2 SeitenFCD 450-10MohammedFaisalGirachNoch keine Bewertungen

- Clad PQRDokument5 SeitenClad PQRRinshadNoch keine Bewertungen

- SMTCL Cak CNC LatheDokument7 SeitenSMTCL Cak CNC Lathes_barriosNoch keine Bewertungen

- Modification Designof Vise Clamp On Phantomatic Machine: Quality FormDokument68 SeitenModification Designof Vise Clamp On Phantomatic Machine: Quality FormKevin Christian PlataNoch keine Bewertungen

- Seminar On Non Conventional MachiningDokument34 SeitenSeminar On Non Conventional MachiningMohit Gulati60% (5)

- Difference Between Forging and CastingDokument2 SeitenDifference Between Forging and CastingMOHAMMAD ALINoch keine Bewertungen

- Hex Head Bolt Din 933: Aa Az MXL Weight Kg/PieceDokument11 SeitenHex Head Bolt Din 933: Aa Az MXL Weight Kg/PieceszystNoch keine Bewertungen

- Suggested Wps Forms ASME - IX 2010Dokument5 SeitenSuggested Wps Forms ASME - IX 2010Ajay ChodankarNoch keine Bewertungen

- Module 6-Lathe Machine (Topics) PDFDokument1 SeiteModule 6-Lathe Machine (Topics) PDFFayyaz NadeemNoch keine Bewertungen