Beruflich Dokumente

Kultur Dokumente

Valves For Cryogenic Service

Hochgeladen von

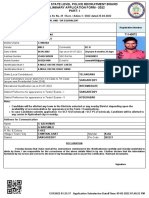

Annamalai Ram JGCOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Valves For Cryogenic Service

Hochgeladen von

Annamalai Ram JGCCopyright:

Verfügbare Formate

Features Details and Reason for the Use (Purpose)

Valves for Material: ASME codes allow materials upto -20ºF(-29ºC). Below this temperature, no property value is available. Present practices are to

design vessels using ASME codes, with material properties at room temperature and conduct Impact Test at the Operating

Cryogenic Service Body and

Pressure Temperature.

Wrought Material for Low temp

(Features & Requirements) More common Material for low temp & cryo temp: ASTM /ASME Material Deg C

Parts: Austenitic SS for Low SA442, Gr. 55, 60 -45º C

Ni Steels for Low Temp SA516, Gr. 55,60,65,70 -45º C

(Prepared by JGC Annamalai) Temp

Grade Dec C Grade Dec C 517 Gr. F -45º C

1 1/4 % Nickel -60º C 304 / 304L -273º C

(1). Normal Temperature Range: 316 / 316L -273º C SA537 Gr. A,B -60º C

2 1/2 % Nickel -60º C

Operating temperature lowest 321 -269º C SA203 Gr. A,B -60º C

3 1/2 % Nickel -101º C 347 -269º C

SA203, G. D,E -101º C

Temperature from -20º F (-29ºC) to 5 % Nickel -130º C 308

309

-273º C

-273º C SA533, Gr. 1,2,3 -73º C

9 % Nickel -196º C

any higher temperature . 310 -273º C SA543Material

Wrought Gr1,2for Low temp

ASTM /ASME Material Deg C

-107º C

SA442, Gr. 55, 60 -45º C

(2). Low Temperature Range or Additional For Low Temp. Range(below -40ºC / -40ºF): Most of Wrought

Castings for Low Temp

ASTM /ASME Material Dec C

SA352, Gr.LCA

the Owners/Users

-32º C

Material for Low temp

517 Gr. F

, use LCB, LCC Steel / Ni Steel / Stainless Steel valve body

SA516, Gr. 55,60,65,70 -45º C

-45º C

ASTM /ASME Material Deg C

SA537 Gr. A,B -60º C

Refregeration Range: - 29º C to -150º Features: material, but they prefer to use extended bonnet, vent

SA352, Gr.LCB

SA352, Gr.LCC

Castings for Low Temp

SA352, Gr.LC1

SA442,hole

-46º C

-46º C

-59º C

Gr. 55, 60 on the -45º C disc, etc. for safety reasons

SA203 Gr. A,B

SA203, G. D,E

-60º C

-101º C

SA516, Gr. 55,60,65,70 -45º C

ASTM /ASME Material Dec C

C (244ºK to 120ºK) Extended Extended Bonnet: ValvesAustenitic

operating inSA352,

cold

SA352, Gr.LC2

Gr.LCA service

SA352, Gr.LC2.1

SA352, Gr.LC3

SS for Low SA352, Gr.LCB

-73º C

-32º C become covered

517

-73º C

-101º C

Gr. F

SA537 Gr. A,B

SA533, Gr. 1,2,3

SA543 Gr1,2

-60º C

-73º C

-45º C with frost and in continuous service at cryo temp, this frost

-107º C

Wrought Material for Low temp

SA352, Gr.LC4

-46º C -115º C ASTM /ASME Material Deg C

(3). Cryogenic Temperature Range: - Bonnet becomes a ball of ice which

Temp

can completely

Grade Dec C

SA352, Gr.LCC encapsulate

SA352, Gr.LC1

-46º C

-59º C

the hand-wheel

SA203 Gr. A,B

SA203, G. D,E

-60º C

-101º C

of ordinary valves, making it difficult to operate. SA442, Gr. 55, 60

SA516, Gr. 55,60,65,70

517 Gr. F

SA537 Gr. A,B

-45º C

-45º C

-45º C

-60º C

304 / 304L -273º C

150º C to -273º C (244ºK to 0ºK)

SA203 Gr. A,B -60º C

Extended bonnet valves are designed

316 / 316L

321

-273º C

-273º C

to Gr.LC2.1

prevent

SA352, Gr.LC2

SA352, -73º CthisSA543

-73º C

iceGr1,2

SA533,

ball formation

Gr. 1,2,3 -73º C

-107º C

from reaching the packing when properly installed. SA203, G. D,E

SA533, Gr. 1,2,3

SA543 Gr1,2

-101º C

-73º C

-107º C

-273º C SA352, Gr.LC3 -101º C Wrought Material for Low temp

Extended bonnet valves are308designed

347

to Gr.LC4

-273º C SA352, provide -115ºan

C adequate bonnet length to maintain a steady state temperature at the ASTM /ASME Material Deg C

SA442, Gr. 55, 60 -45º C

309 -273º C SA516, Gr. 55,60,65,70 -45º C

packing, whether installed 310

in cryo -273º C Wrought Material for Low temp

ASTM /ASME Material Deg C

517 Gr. F

SA537 Gr. A,B

SA203 Gr. A,B

-45º C

-60º C

-60º C

SA442, Gr. 55, 60 -45º C

gas or cryo liquid service. Castings for Low Temp

ASTM /ASME Material Dec C

SA352, Gr.LCA -32º C

SA516, Gr. 55,60,65,70

517 Gr. F

SA537 Gr. A,B

-45º C

-45º C

-60º C

SA203, G. D,E

SA533, Gr. 1,2,3

SA543 Gr1,2

-101º C

-73º C

-107º C

SA352, Gr.LCB -46º C

Stem orientation. Liquid should SA352, Gr.LCC

SA352, Gr.LC1

SA352, Gr.LC2

-46º C

-59º C

-73º C

SA203 Gr. A,B

SA203, G. D,E

SA533, Gr. 1,2,3

-60º C

-101º C

-73º C

SA352, Gr.LC2.1 -73º C SA543 Gr1,2 -107º C

not be allowed to contact the SA352, Gr.LC3

SA352, Gr.LC4

-101º C

-115º C

Wrought Material for Low temp

ASTM /ASME Material

SA442, Gr. 55, 60

517 Gr. F

Deg C

-45º C

SA516, Gr. 55,60,65,70 -45º C

-45º C

SA537 Gr. A,B -60º C

packing. For this reason, valves SA203 Gr. A,B

SA203, G. D,E

SA533, Gr. 1,2,3

SA543 Gr1,2

-60º C

-101º C

-73º C

-107º C

be installed with stem in vertical ,

stem up position or max. 45º

from vertical.

Vent Hole Venting: Extended bonnet valves, disc vent are selected for continuous service applications below -50ºF (-45ºC). Gate valves

on Disc. have the potential to trap cryo liquid in the bonnet cavity between two seating faces of the wedge. To prevent excessive

pressure build-up due to vaporization of liquid, when the valve is closed and the ambient temp. increases, consideration must

be given to venting the bonnet chamber pressure. Most common way is to provide a 4 to 6 mm Hole on the face of one side of

the disc, say, on the HP side of the valve. Reason for Providing vent on HP side : When the valve is closed, HP & LP are present.

In addition to stem thrust, the differential pressure(rP) will act & press the disc towards the LP side of seat ring .

"HP" mark Marking: A vertical "Arrow" or “HP” tag is placed on the vented end/flange, say, at the valve inlet side flange/up stream side.

Drip Plate All cryo & low temp valves are insulated. The drip plate acts as support to insulation clad plate at the hole for bonnet

penetration. The valve is normally provided with a circular ring plate/drip plate & it is seal welded to the bonnet extension

and this act as umbrella and allow the water/snow/ice to flow to the cladding sheet.

More: For Additional info : (1). ISO-21011, Cryo Valves, (3). En-1626-Valves for Cryo Service,

(2). MSS-SP-134A, Valves for Cryo Service, (4). BS-6364-Valves for Cryogenic Service

Das könnte Ihnen auch gefallen

- Event Management (MAX FIT)Dokument12 SeitenEvent Management (MAX FIT)vkrish6Noch keine Bewertungen

- Links To GoodnessDokument194 SeitenLinks To GoodnessKevin Itwaru0% (3)

- Sample Procedure Qualification Record (PQR) : (Smaw, Gmaw, Gtaw, Fcaw, Ofw, Paw)Dokument2 SeitenSample Procedure Qualification Record (PQR) : (Smaw, Gmaw, Gtaw, Fcaw, Ofw, Paw)Thanakit Srisaeng0% (1)

- Arc Basics - FA 2009 ISO 14175 Revised StandardDokument10 SeitenArc Basics - FA 2009 ISO 14175 Revised StandardCatalinNoch keine Bewertungen

- CIGWELDDokument244 SeitenCIGWELDrodastrid5653100% (1)

- Poster DIN EN 1090-1 ENG Final PDFDokument1 SeitePoster DIN EN 1090-1 ENG Final PDFlth770310Noch keine Bewertungen

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Dokument16 SeitenNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNoch keine Bewertungen

- Quick Guide To Welding Procedure Qualification (WPS & PQR)Dokument5 SeitenQuick Guide To Welding Procedure Qualification (WPS & PQR)Annamalai Ram JGCNoch keine Bewertungen

- Bright Annealing Process of Stainless S Teel TubeDokument2 SeitenBright Annealing Process of Stainless S Teel TubeViraj ShiroleNoch keine Bewertungen

- KGP-Flamme Cutting Proce For BEI PDFDokument4 SeitenKGP-Flamme Cutting Proce For BEI PDFoomoomNoch keine Bewertungen

- Comparison of Welding Inspector Qualification or Certification SchemesDokument7 SeitenComparison of Welding Inspector Qualification or Certification Schemeswahyu santosoNoch keine Bewertungen

- Course Module 4Dokument6 SeitenCourse Module 4Makise AghataNoch keine Bewertungen

- Iso 14343-2017Dokument24 SeitenIso 14343-2017getatodicaNoch keine Bewertungen

- SAW Flux StorageDokument2 SeitenSAW Flux StorageTrung Tinh HoNoch keine Bewertungen

- BS 1724 (Bronze Welding by Gas)Dokument24 SeitenBS 1724 (Bronze Welding by Gas)nandi_scrNoch keine Bewertungen

- Preheat RequirementsDokument3 SeitenPreheat RequirementsVJG369Noch keine Bewertungen

- Bright Annealing Copper and Its AlloysDokument4 SeitenBright Annealing Copper and Its Alloysmp87_ingNoch keine Bewertungen

- ISO - TR - 15608 - Welding Guide Line PDFDokument10 SeitenISO - TR - 15608 - Welding Guide Line PDFDacher DanielNoch keine Bewertungen

- Wps For Aluminium WeldingDokument8 SeitenWps For Aluminium WeldingMohammed MusaNoch keine Bewertungen

- Qualification Testing of Welders - Fusion Welding: Part 1: SteelsDokument10 SeitenQualification Testing of Welders - Fusion Welding: Part 1: SteelsKadri HelmiNoch keine Bewertungen

- Supercito (E 42 5 B 32 h5)Dokument1 SeiteSupercito (E 42 5 B 32 h5)brunizzaNoch keine Bewertungen

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Dokument2 SeitenSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzNoch keine Bewertungen

- Storing and Redrying Electrodes-Lincoln ElectricDokument3 SeitenStoring and Redrying Electrodes-Lincoln ElectricjasminneeNoch keine Bewertungen

- S/A 106 Spec Sheet A106 Pipe Specifications: ScopeDokument7 SeitenS/A 106 Spec Sheet A106 Pipe Specifications: ScopeyanurarzaqaNoch keine Bewertungen

- GTAW Welding of CP Titanium and Ti6Al4VDokument1 SeiteGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarNoch keine Bewertungen

- PART 92 Cu-Ni Welding - Part 1 Cu-Ni Material PropertiesDokument16 SeitenPART 92 Cu-Ni Welding - Part 1 Cu-Ni Material Propertiesravindra_jivaniNoch keine Bewertungen

- ITP For Drum Screen InspectionDokument1 SeiteITP For Drum Screen InspectionkapsarcNoch keine Bewertungen

- Poster Qualifizierungsweg en Final LowDokument1 SeitePoster Qualifizierungsweg en Final Lowlth770310Noch keine Bewertungen

- Flame StraighteningDokument3 SeitenFlame StraighteningAvishek Gupta100% (1)

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitDokument3 SeitenInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadNoch keine Bewertungen

- Steel Properties Material Grade Comparison ChartDokument1 SeiteSteel Properties Material Grade Comparison Chartgk80823Noch keine Bewertungen

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Dokument2 SeitenWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiNoch keine Bewertungen

- VR 14-01 Supplier TC en 1090 Ce Marking Issue 1-15Dokument7 SeitenVR 14-01 Supplier TC en 1090 Ce Marking Issue 1-15Bryan GonzalesNoch keine Bewertungen

- Din en Iso 15614 - 5 - 2004Dokument28 SeitenDin en Iso 15614 - 5 - 2004Alfalloy Testing and Inspection Services Pvt. Ltd.Noch keine Bewertungen

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDokument1 SeiteField Welding Inspection Checklist: Wisconsin Department of TransportationDele TedNoch keine Bewertungen

- Wps Sp14 Reva PDFDokument9 SeitenWps Sp14 Reva PDFravi00098Noch keine Bewertungen

- BS en 1090 - A Legal Requirement For The Structural Steel Industry (CE Marking)Dokument3 SeitenBS en 1090 - A Legal Requirement For The Structural Steel Industry (CE Marking)alanlongfieldNoch keine Bewertungen

- Fb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDokument13 SeitenFb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDan DumbravescuNoch keine Bewertungen

- WPQ WeldCanada PDFDokument1 SeiteWPQ WeldCanada PDFAhmad DanielNoch keine Bewertungen

- SB410 (JIS) - Worldwide Equivalent Grades 11Dokument1 SeiteSB410 (JIS) - Worldwide Equivalent Grades 11valli raju100% (1)

- Sfa 5.3 PDFDokument14 SeitenSfa 5.3 PDFWidya widyaNoch keine Bewertungen

- OneCIS - ASME CA Connect BrochureDokument20 SeitenOneCIS - ASME CA Connect BrochureBayu Jatmiko0% (1)

- ASMEDokument38 SeitenASMEshazanNoch keine Bewertungen

- Portfolio Storage&Drying Control ProcedureDokument4 SeitenPortfolio Storage&Drying Control Procedurelaz_kNoch keine Bewertungen

- En 15085-2020-What Has ChangedDokument2 SeitenEn 15085-2020-What Has ChangedBoran YelkenciogluNoch keine Bewertungen

- Common Datasheets Ampco Gas Metal-Arc WeldingDokument2 SeitenCommon Datasheets Ampco Gas Metal-Arc WeldingMaulana Mufti MuhammadNoch keine Bewertungen

- 121 T BW FPDokument4 Seiten121 T BW FPA. ΒρατσισταNoch keine Bewertungen

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationDokument12 SeitenDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaNoch keine Bewertungen

- BPVC Ix QW-482Dokument2 SeitenBPVC Ix QW-482ganesh82Noch keine Bewertungen

- WPS PQR 12 PDFDokument9 SeitenWPS PQR 12 PDFVinay YadavNoch keine Bewertungen

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDokument3 SeitenTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNoch keine Bewertungen

- Wps GT 9b Cvn90 Rev 1 PDFDokument6 SeitenWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNoch keine Bewertungen

- Ds Universal Wps Migmag enDokument6 SeitenDs Universal Wps Migmag enMarija IvanovskaNoch keine Bewertungen

- Welding Recommendation TS890Dokument2 SeitenWelding Recommendation TS890max_powerNoch keine Bewertungen

- WPSGMAW90 102011ExamplePDFDokument1 SeiteWPSGMAW90 102011ExamplePDFBhavani PrasadNoch keine Bewertungen

- Data Sheet Material 2.4819Dokument3 SeitenData Sheet Material 2.4819BoberNoch keine Bewertungen

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDokument7 SeitenJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCTrường Tùng LýNoch keine Bewertungen

- Office: Printout Sample - ASME WPSDokument2 SeitenOffice: Printout Sample - ASME WPSDanem HalasNoch keine Bewertungen

- Valve Material Pressure/Temperature Ratings Asme B16.34Dokument4 SeitenValve Material Pressure/Temperature Ratings Asme B16.34se781Noch keine Bewertungen

- Valve Body Bolt Temp Rating For ValvesDokument4 SeitenValve Body Bolt Temp Rating For ValvesVinothkumarNoch keine Bewertungen

- Tds - Master Quench ADokument2 SeitenTds - Master Quench ANashrul HakimNoch keine Bewertungen

- Heat Transfer Oil - Total Seriola K 3120 SpecDokument3 SeitenHeat Transfer Oil - Total Seriola K 3120 SpecQuang VũNoch keine Bewertungen

- High Temperature High Tension Alloy Bolt MaterialDokument11 SeitenHigh Temperature High Tension Alloy Bolt MaterialdanamuanNoch keine Bewertungen

- Cryogenics - A Quick GuideDokument7 SeitenCryogenics - A Quick GuideAnnamalai Ram JGCNoch keine Bewertungen

- The Importance of Welding Electrode FluxDokument105 SeitenThe Importance of Welding Electrode FluxAnnamalai Ram JGCNoch keine Bewertungen

- Welding Distortion and Its ControlDokument53 SeitenWelding Distortion and Its ControlAnnamalai Ram JGC100% (1)

- ASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesDokument9 SeitenASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesAnnamalai Ram JGC100% (2)

- Breech-Lock Arrangement-High Pressure Shell & Tube Heat ExchangersDokument1 SeiteBreech-Lock Arrangement-High Pressure Shell & Tube Heat ExchangersAnnamalai Ram JGC100% (1)

- Austenitic Stainless Steels, Problems-Failures-DifficultiesDokument69 SeitenAustenitic Stainless Steels, Problems-Failures-DifficultiesAnnamalai Ram JGC100% (2)

- Cryogenics - in BriefDokument4 SeitenCryogenics - in BriefAnnamalai Ram JGCNoch keine Bewertungen

- Daily Price Monitoring: Retail Prices of Selected Agri-Fishery Commodities in Selected Markets in Metro ManilaDokument3 SeitenDaily Price Monitoring: Retail Prices of Selected Agri-Fishery Commodities in Selected Markets in Metro ManilaRio CorralNoch keine Bewertungen

- ACC 101 - 3rd QuizDokument3 SeitenACC 101 - 3rd QuizAdyangNoch keine Bewertungen

- Rule 63Dokument43 SeitenRule 63Lady Paul SyNoch keine Bewertungen

- A Study of A Skirtless Hovercraft DesignDokument71 SeitenA Study of A Skirtless Hovercraft DesignSunil Kumar P GNoch keine Bewertungen

- Covid ReportDokument89 SeitenCovid ReportBrynne ConnollyNoch keine Bewertungen

- Gamesa Wind Turbine Element UpgradesDokument1 SeiteGamesa Wind Turbine Element Upgradesstanislav uzunchevNoch keine Bewertungen

- Siemens Power Engineering Guide 7E 223Dokument1 SeiteSiemens Power Engineering Guide 7E 223mydearteacherNoch keine Bewertungen

- 20779A ENU CompanionDokument86 Seiten20779A ENU Companionmiamikk204Noch keine Bewertungen

- Leadership and Decision Making PDFDokument34 SeitenLeadership and Decision Making PDFNhi PhamNoch keine Bewertungen

- Pharmacology NCLEX QuestionsDokument128 SeitenPharmacology NCLEX QuestionsChristine Williams100% (2)

- SS 531 2006 Code of Practice For Lighting of Work Places Part 1 PDFDokument13 SeitenSS 531 2006 Code of Practice For Lighting of Work Places Part 1 PDFEdmund YoongNoch keine Bewertungen

- BCCA Semester New Syllabus Direction 2016-17 PDFDokument76 SeitenBCCA Semester New Syllabus Direction 2016-17 PDFChetana Gorakh100% (1)

- Ch-3 BUFFETDokument9 SeitenCh-3 BUFFETJanith prakash567Noch keine Bewertungen

- Software Test ISO StandardsDokument2 SeitenSoftware Test ISO StandardsTony DavisNoch keine Bewertungen

- Module 8 - Simple Interest and Compound InterestDokument11 SeitenModule 8 - Simple Interest and Compound InterestDawn Juliana AranNoch keine Bewertungen

- Samsung UDC and UEC Series Video Wall DisplaysDokument12 SeitenSamsung UDC and UEC Series Video Wall DisplaysWebAntics.com Online Shopping StoreNoch keine Bewertungen

- Public Instructions For Death CorrectionsDokument4 SeitenPublic Instructions For Death CorrectionsMukuru TechnologiesNoch keine Bewertungen

- CreatorsXO JuneDokument9 SeitenCreatorsXO JuneGaurav KarnaniNoch keine Bewertungen

- 02-15 QCS 2014Dokument17 Seiten02-15 QCS 2014Raja Ahmed HassanNoch keine Bewertungen

- Ruggedbackbone Rx1500 Rx1501Dokument13 SeitenRuggedbackbone Rx1500 Rx1501esilva2021Noch keine Bewertungen

- Latest Eassy Writing Topics For PracticeDokument18 SeitenLatest Eassy Writing Topics For PracticeAnjani Kumar RaiNoch keine Bewertungen

- Marc-André Ter Stegen PES 2021 StatsDokument1 SeiteMarc-André Ter Stegen PES 2021 StatsSom VasnaNoch keine Bewertungen

- E-Booklet Tacompact Board 2021Dokument6 SeitenE-Booklet Tacompact Board 2021embenNoch keine Bewertungen

- HACCP Coconuts 2019Dokument83 SeitenHACCP Coconuts 2019Phạm Hồng Ngân100% (4)

- INTERFACING LCD WITH 8051 MIROCONTROLLER With CodeDokument14 SeitenINTERFACING LCD WITH 8051 MIROCONTROLLER With CodeRajagiri CollegeNoch keine Bewertungen

- Option - 1 Option - 2 Option - 3 Option - 4 Correct Answer MarksDokument4 SeitenOption - 1 Option - 2 Option - 3 Option - 4 Correct Answer MarksKISHORE BADANANoch keine Bewertungen

- Roasted and Ground Coffee Manufacturing Industry Feasibility StudyDokument22 SeitenRoasted and Ground Coffee Manufacturing Industry Feasibility StudyGhirmaye AbebeNoch keine Bewertungen

- UntitledDokument1 SeiteUntitledsai gamingNoch keine Bewertungen