Beruflich Dokumente

Kultur Dokumente

Cooling Coil 03

Hochgeladen von

Sam Wang Chern Peng100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

477 Ansichten18 SeitenTrane - Cooling Coil 03

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTrane - Cooling Coil 03

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

477 Ansichten18 SeitenCooling Coil 03

Hochgeladen von

Sam Wang Chern PengTrane - Cooling Coil 03

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 18

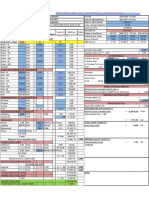

TYPE W

COOLING COIL DIMENSIONAL DATA

18",24",30" & 33" FINNED WIDTH

12" FINNED WIDTH

V2NPT IUiT) RETUi'!!-{

f----- FINHEO L£I'tG;TH + 6~.

~.

F I ,"~EO L.EN~TH ... I~. F[tlNE:O LEUG1H + -4 ~4

2,3,4,6,8,10 & 12 ROW COILS

TABLE 58-1 - Type W Coil Dimensions (Headers 33" and Less)

FINNEO H P

WIOTH c 0 2ROW 3 ROW 4 ROW 6 ROW 8 ROW 10 ROW 12 ROW K 3ROW EVEN ROWS

12 13'1, 2

18 191'2 8'1.

24 251'2 11'1, 6112 8 9'1, 12'1, 151'2 181'" 21'1, 3'10 2 PIs

30 31'1, 14'1,

33 34'1, 15%

NOTE: All dimensions approximate. Submittals on request, 2,3,4,6,8,10 & 12 ROW COILS

2, 3, 4, 6, & 8 ROW COILS

TABLE 58·2 _ Type W Coil Dimensions (36", 42" and 48" Headers)

FINNED H

WIDTH C' C·· O' 0" 2 ROW 3 ROW 4 ROW 5 ROW

36 37112 38'1. 15'\'. 16'/0

42 43112 44% 18:v. 19'1. 6'1, 8 9112 11

48 49'k 501', 21:v. 22'1. 2

K

6 ROW

8 ROW

3 ROW

2,4,6 & 8 ROW

1'1.

12'1,

15Yz

"'C" dimensions lor 2, 3, 4 and 6-row coils w·llh finned lenglhs Ihrough 120".

""C" dimensions for 2, 3, 4 and 6 row coils wilh finned lengths greater than 120" and lor all a-row coils. NOTE: All dimensions approximate. Subrninals on request,

58

~,

TYPE D

F INNED LENGtH. l:tll 1----- FUmED LENGTH ... 6~1

3,4,6,8,10 & 12 ROW COILS 18",24",30" & 33" FINNED WIDTHS

18",24",30" & 33" FINNED WIDTHS

;2:1fz Nf>Y IINTl SUPPLY

12" FINNED WIDTHS

4,6,8,10 & 12 ROW COILS 12" FINNED WIDTH

1

3 ROW - RETURN

lll~ HPT Ol'olfl AEmRl1

3 ROW - SUPPLY 3 ROW - RETURN

TABLE 59-1 _ Type D Coil Dimensions 3 ROW - SUPPLY

FINNED H

iWIOTH C 0 3 ROW 4 ROW 6 ROW BROW 10 ROW 12 ROW K

12 13112 ~

18 19'12 8%

24 251', 11% 8 9!12 12'1, 15'1, 18112 2"" 3'1.

30 3lY, 141'.

33 34Yz 15%

NOTE: All I TYPE DD

d mensions approxtmate. Submittals on request.

6 & 10 ROW SUPPLY

4,8& 12 ROW SUPPLY

TABLE 59-2 - Type DD CDil Dimensions

4,8& 12 ROW COILS

6 & 10 ROW COILS

6 & 10 ROW RETURN

4, B & 12 ROW 6 & 10 ROW

ii/FINNED

. WIDTH C E 4 ROw 6 ROW

18 19'1, 9:v.

24 25'k 12'!i!

30 31112 15'¥, 9112 12'k

33 34'k 171', NOTE: All dimensions approximate, Submittals on requesl.

H

5'1.

W

2

BROW

10 ROW

12 ROW

K

15'k

21'k

18'k

2%

59

COOLING COIL DIMENSIONAL DATA (cont.)

TYPE WD

6,8, 10, 12 ROW

18",24",30",33" FINNED WIDTH

: ..... :::.' . .": ..... .': ', 12 ROW

FINNED.

,WIDTH H H

18 19'1i' 2"

24 25'1,' 12'1.' 2" 5'1." 13/6.'1 12'1,' 15'/2~' 18'1,' 21'/211

30 31'1>" 15'1. 21/1.·~ 5'1.'

33 34'1,' 17'/,' 2'1,' 5'1.' TYPE K

18",24",30" & 33" FINNED WIDTH

12" FINNED WIDTH

2, 3, 4, 6, 8, 10 & 12-ROW COILS

2,,4,6,8,10 & 12-ROW COILS

18",24",30" & 33" FINNED WIDTHS

12" FINNED WIDTH

2 "2 HPT UNl) 'SUPPLY

AI" FLOri

lV, ~PT I HolT1 RETURN

~ ~I

c

_j

:If.NPT (lIHI ORRtl"

3 ROW - SUPPLY

3 ROW - RETURN

3 ROW-SIDE VIEW

3 ROW - SUPPLY

3 ROW - RETURN

30

31'1,

14'1,

33

34'1,

NOTE: All dimensions approximate. suornmais on request,

TYPE P2

2 ROW SUPPLY

TYPE P4

4 ROW SUPPLY

6 ROW SUPPLY

4 & 6 ROW COILS

FOR 2 ROW SEE SUBMIITAL DRAWINGS

ltiNPllINTI VErn

18" & 30" 2·ROW COILS FOR 12" AND 24" FINNED WIDTHS SEE SUBMIITAL

DRAWINGS

1---,"". ~--l 12" THRU 30" 6 ROW COILS FOR 4 AND 8 ROW COILS SEE SUBMIITAL DRAWINGS

12" THRU 30" 4 ROW COILS

FOR 2,6,8 ROW COILS SEE SUBMITTAL DRAWINGS

TYPE P8

:y ... NPT; unl VENT

l!,o-4 }I~HIHLI SUPPI,.:r

18",24" & 30" 8 ROW

24"

4 ROW

TABLE 61-1 - Types P2 P4 and P8 Coil Dimensions

18" & 30" 4 ROW FOR 8 ROW COILS SEE SUBMITTAL DRAWINGS

,

I,ii~ .':.:',' c .':. '.' ,,::: .... ···D :.

TYPES P2 & P4 ..' ' .. TYPE P8 : .. . TYPE 4 .:'

12 13'1,

18 19'1, 19V, 7'1,

24 25'1, 25'1, 10V,

30 31'1.0 31V, 13'12

N OTE. All dmensions approximate. Submittals an request

61

TYPE F - Refrigerant Coils

COOLING COIL DIMENSIONAL DATA (COIlt.)

2,3,4 & 6 ROW COILS (1 CIRCUIT)

2, 3, 4, 6 & 8 ROW COILS (2 CIRCUITS)

ONE DISTRIBUTOR

1--1-0.0. llOUlD D15lRIBUHl~

HORIZONTAL SPLIT

"'MOoD,LICiUID OlSTRIBUrQfI

TABLE 62-3 - Type f

TABLE 62-2 - Type f

4,6 & 8 ROW COILS (2-12 CIRCUITS)

3, 4, 6 & 8 ROW COILS (4-22 CIRCUITS) FOR OPPOSITE END, 3 ROW COILS SEE SUBMITTAL DRAWINGS

ROWS 2 3 4 6 6

B 6'k" S" g'k" 12'k" lS\','

N 2\', 2\', S\', S\', SY> NOTE: All dimensions approximate. Submittals On request.

N CONNECTION

NO: OF G E, FF 1 SET CONNECTIONS 2 SETS CONNECT!ONS L ROWS LOCATION

F!NNED REFRIG, ROWS ALL ALL ROWS ALL ROWS ALL 2,4, ROWS

WIDTH CIRCUiTS 2 3 4 6 S ROWS F G H R F G H R ROWS 6,S 3 2,4,6, a 3

1 2\', 4 S'k 5\', NA - - 1'12 - - NA NA NA NA - 13/. 1'/. SAME END SAME END

2 2V:> 4 2V:> 2'k 2\" 6 6111,6 1'k ,/. 1'/, - 1'12 '/, 'f, 9'/. 11'0/16* 1:v.. SAME END SAME END

12 4 21', 4 2V:> 21'2 21', 6 6'!,. 1'10 "t« 1'/. :v.. 1'12 '/. 1'/. 9'/, 11'/'6 1¥. SAME END SAME END

S 2V:> 2'k 2'12 2'k 2\" 6 5'/. 1'/. 11/8 21/s :v.. 1'10 n« 1'/. S'/. 11i/16 - SAME END OPP,END

1 2112 4 NA NA NA - - 1'12 - - NA NA NA NA - 1'/. l'f. SAME END SAME END

2 21'2 4 2'k NA NA 9 8~J16 1112 'f. 1'/, - 11'. 'I. '/. 9'/. 111/16- 1:v.. SAME END SAME END

16 3 21'2 4 2V:> 21', 21'2 - 9~la 1'10 'I. 1'10 NA NA NA NA 9'/. 111/1(. 1:v.. SAME END SAME END

6 21'2 4 21', 21'2 2\', 9 7l~ 1'1. 1'/. 2'1. 2 l'f. 'I. 1'10 9'1. 111116 I'll SAME END SAME END

12 21'2 21', 21'2 2'12 21'l! 9 61', 11/11 PI. 2'1. 3Y4 1'1. 1'/. 2'1. 8'1. 1\1/t5 - SAME END OPP, END

2 21'2 4 2102 NA NA 12 143/,. 1102 'I. 1'1, - 11'2 '/. 'Ia 9'1. 1lil1o- 1Y4 SAME END SAME END

4 2'k 4 21', 2V:> 21', 12 871,.-. 1'10 'I. 1'1. 6tt/1G 1V2 'I. JlI. 9'/, 111/11) 1:v.. SAME END SAME END

24 8 2\'2 4 2'k 2V:> 21', 12 10'1. 1'/, 1119 2'1. 7'!o1 1'1. '/, 1'10 97Jg 111/n• 1¥, SAME END SAME END

16 21'2 2'12 21'2 2'12 21'2 12 NA NA NA NA 5'/, 1'1. 1'1. 2'/. S'I, 11i-116 ~ SAME END OPP.END

2 21'2 NA NA NA NA 15 20"1,. lV, 'I, 1'1. - 11'2 'I. 'Ia 9'1, 111/Hj· ~ SAME END SAME END

4 21'2 4 NA NA NA 15 • 77/'6 1'10 'I • 1% 6'1. lV, '/. 1'1. 9'/. 111/,S - SAME END OPP. END

30 5 21', 4 2V:> 21'2 NA ~ 141', FIll. 'I. 2'1, NA NA NA NA 9'/. 111/Hi 1"" SAME END SAME END

10 2'k 4 2'12 2V:> 2'k 15 13'1. Fl. 1'/. 2'1. 7'/, 1'1, 'I. 2'1. 97/s 11~Jni 1¥, SAME END SAME END

20 201', 2\', 21'2 2'12 2'12 15 NA NA NA NA 6'1. 1'1. 1'1. 2'/. B'I. 1u/l!; ~ SAME END OPP. END

3 2\'2 4 NA NA NA ~ 19'1. 1'1. 'I, 1"1, NA NA NA NA 9'1. 1"/1£, 1:v.. SAME END SAME END

7 2112 4 2'k 2V:> NA 19'12 14'f. 1'1. 1'/. 2'1. 8'/,. 1'10 'I. 1'/. 9'/. 111/,6 - SAME END OPP. END

33 11 21', 4 2'k 2\'2 2'12 18 13'1,. Fl. 1'1. 2'1. 7'/. 1'/. .. 2'/. 9'1. 11 ~J,G 1"" SAME END SAME END

22 2'/2 21'2 2'12 2V:> 21', 16V:> NA NA NA NA 6,1/'6 1'/. PI. 21/!l- B'I. 11'/Hi - SAME END or=, END NOTE: All dimensions approximate. Submitlals on request. NA ~ Not available as standard

• - 1'1," lor two circuit apl'it coil wilh two sets of connactlons .. - Six. circuit connection 1'/0", five circuit 7/6"

62

TYPE F - Refrigerant Coils (cont.)

FINNED

"WIDTH C D E F H J M CRTS N CRTS

12 13Y2 5'1. 1'/. 1'/. 8

B

18 191'2 6Y2 1% 1% 12

12

24 25Y2 SY4 12 12 Pis 16

16

30 3lV, 6'1. 15 15 1'10 20

20

33 34'1, 61i/16 16'1, 161', 1'1. 22

22

NOTE: All dimensions a roxlrnat 12" & 18" 4,6 & 8 Rows

24",30" & 33" 4,6& 8 Rows

TABLE 63-1 - Type F

pp

12", 18", 24", 30" & 33" 4,6 & 8 Rows

TABLE 63-2 - Type F

e. Submittals on recuest,

VERTICAL SPLITS - (Half-Half Circuited)

FINNED

I> WIDTH C CC D E F G

H J K L M CATS N CRTS

12 13'1, 3:l/1-l; 67/16 1% 3% 1'1.

'I. n« 1'1. 1'1.

18 19'1, 31~/'6 4 4

7Y4 1'1,. 31S/ui 1'/.

1'1. 11/. 21/0 2'1.

24 25'/, 3"11. 10'1. 6 6

1'Sh6 315/16 1'1.

11/13- 1'/. 2'1. 2'/a 8

30 31'1, 311116 13'1, • 8

1"91,6 315/I-Ei 17/a 1'1. 1'10

33 34'12 311/1t. 2'1, 2'/. 10 10

13'1" 1'9/'6 3i5/1f~ 1'1. 1'10 1'10

NOTE: All dimensions approximate. Submittals on request, 2'1. 2'/. 11 11 63

COOLING COIL DIMENSIONAL DATA (cont.)

TYPE F - Refrigerant Coils (cnnt.)

VERTICAL SPLITS (FULL-HALF CIRCUITED)

12" AND 18" 4 ROWS

24", 30", 33" 4 ROWS

12 12 6

1'1. 11/8 1'1. 2'1.

18 19V, 311116 6V, 7%

12 12 10'1. 1'/, 16 8

24 25Y, S¥4

15 15 13'1.. 13/. 20 10

3D 3lY, 61/8

16V. 16V, 13'1,. 1'1. 22 11

33 34V, 6~'/1-6

NOTE: All dimensions approximate. Submillals on request. VERTICAL SPLITS (HALF-FULL CIRCUITED)

12" AND 18" 6,8 ROWS

24",30", 33" 4 ROWS

TABLE 64-2 Type F .: .............. <

MCRTS NCRTS

12· 13'10 2"1,. 5'1. 6'1,. 1% 3% 1'/, 1 I, 10 1 I, 4 8

19/16 3~&/1S F/s 1'1, 1 'I. 2'1. 6 12

18 19V, 3~hG 6Y, 7¥.

12 12 10'/. PIa 8 16

24 25Y, 5'1\1

15 15 13'/. 1'/. 10 20

30 31'12 6'1,

16Y, 16V, 13'11. 1'1. 11 22

33 34V. 6'\116 NOTE: All dtrnensons approximate. Subrnhtals on request.

64

TYPE F - Refrigerant Coils (cont.)

TABLE 65-1 - Vertical Split Availability

NUMBER.

OF • CIRCUITS

DOWNSTREAM ·pOWNSTREAM

. ···i\l~t~~IKJiii/ ··lv~&~kITY ..

i iii UPSTREAM·. ...•... .. . •.•.••••.•. · •• ·.DOWNSTRE.<\~ •.•..••..

···AV:ltl~kI0 ····/Avlitl1kn\)

YES YES NS NS

12"

8 4 2 1

YES YES NS NS

YES YES YES YES

YES YES

YES YES

YES YES

YES YES

YES YES

YES YES

YES YES

YES YES

NS NS

YES YES

YES YES

YES YES

YES YES

YES YES

YES YES

YES YES

YES YES

NS NS

YES YES

YES YES

YES YES

YES YES 18"

12 6 3 2

YES YES NS NS NS

YES YES YES YES NS

16 8

24"

YES YES NS NS

2

YES YES YES YES

20 10 5 4 2

YES YES NS NS NS

22 11 7 3

YES YES YES YES NS

YES YES YES YES

NS - NOT STANDARD

TABLE 65-2 - Non-Vertical Split Availabity for Type F Coils

I;j~~ TOTAL \6{AL COIL. 1:/ li·_iii liA •• · •• ·.•· ••• •••· ..... I

CIR: ·iRJ~ ..... ! ....•....

. coil . COIL PER I~J~i I ..• · Rowi. IRbw

"CIRij·· DISTR; DISTR; r ' •• ROW

2 4 YES YES YES YES YES

B 1 B YES YES YES YES YES

2 2 YES YES YES YES YES

4 1 4 YES YES YES YES YES

12" 2 1 YES YES YES YES YES

2 1 2 YES YES YES YES YES

1 1 1 YES YES YES YES NS

2 6 YES YES YES YES YES

12 1 12 YES YES YES YES YES

2 3 YES YES YES YES YES

6 1 6 YES YES YES YES YES

18" 3 1 3 YES YES YES YES YES

2 1 YES YES YES NS NS

2 1 2 YES YES YES NS NS

1 1 1 YES YES NS NS NS

16 2 8 YES YES YES YES YES

2 4 YES YES YES YES YES

8 1 8 YES YES YES YES YES

24" 2 2 YES YES YES YES YES

4 1 4 YES YES YES YES YES

2 1 YES YES YES NS NS

2 1 2 YES YES YES NS NS

20 2 10 YES YES YES YES YES

2 5 YES YES YES YES YES

10 1 10 YES YES YES YES YES

5 1 5 YES YES YES YES NS

30" 4 2 2 YES YES YES NS NS

1 4 YES YES YES NS NS

2 1 YES NS NS NS NS

2 1 2 YES NS NS NS NS

22 2 11 YES YES YES YES YES

2 YES YES YES YES YES

11 1 11 YES YES YES YES YES

---

33" 2 YES YES YES YES NS

7 1 7 YES YES YES YES NS

3 1 3 YES YES NS NS NS NS - Not Standard.

'Circuits on lhese coils are splil five and six on the ll-circuil coil and three and four on lhe seven-circuit coil. The smaller number of circuits is located on the top half of the COIl.

TABLE 65-3 - Type F Coil Deplh

COIL DEPTH

9Y,

••.... : .•..•...•...•• : : .• :: •••. ··: .•••.• 4 .. ROW:·

NOTE: All dimensions approximate, Submittals on request.

TYPE F - Non-Split 2-12 Circuits

2 ROW 12", 18",24",30" AND 33" FINNED WIDTHS

TABLE 65-4 - Type F

•. FINNED Idi ·/i~i· i F< ··:H·.·i ... '," A: W •• NUMBER.·

:·WIOTH . I·:·.l_ •• .M. CIRCUtTS.

1 t/~ 611/16 'I. 97111 215/" 13/0 12t~/lf; 2

12 13'/~ 1 ~/8 67ha 3J/16 Pis 4

PIG 51/0 1'/0 871a 21lfui- 2'fG 111~hi 8

11{:; 8J/t~ 'I. 2'/i/1G 1;;/a 2

18 19'/z 1 !lIs- 9~'fI; 9718 3l/lls PIs 121~h() 3

VIe. 7~/. 1110 3n/u; 2'/s 6

1'fll 6'/:: , ~/!l 87/s 2H/ul 111~/1I1' 12

Ph 14JI1G 'I. 2~s/~H Pill 2

24 25'h lSI, Sf/Ill. 97/0 3~/16 l"iD 121~f11i- 4

Pia 10'/1l 1'1& 31i/tr~ 2t/l! 8

ltJ:z 20)/u~ 'I. 2l~h5 PIa 2

30 31'h 15111 177/u, 97/H 3:l-/1Ji. 151, 121~flll 4

FIll 14'1/2 'I. 311/u; 2~/B 5

Fie 13'1. PIll- 10

1$/1 1 g~fe 'I. 32f1ll. P/D 3

33 341h PIa 141/-11 111.8 97/1l. 31'/11". 2'/H 12'5/'5 7

F/a 1321113- PIs 11 65

GENERAL PIPING INFORMATION - COOLING COilS

PIPING DETAILS OF WATER COILS

INSTALL COIL

PITCH COIL DOWN

AIR VENT

VENT PLUGS 'SEE"A"

DRAIN PLUGS

TYPE DO AND WO COILS

TYPE WAND P COILS

VENT PLUGS 'SEE "A"

PITCH COIL DOWN

GENERAL PIPING INFORMATION - COOLING COILS

T -"W" "P" "0" and "K" coils are self-venting if water ve-

ype , , I

locity exceeds 1 .5 fps. If less than 1.5 fps, vent by one of the fa -

lowing methods: .

a Install air vent in top pipe plug tappinq of return header.

b. When return line rises and is above top of coil, vent from top of return header horizontally to ret~rn piping.

Type-"OO" coils are self-venting if water velocity exceeds 2.5 fps.

TYPE D AND K COILS PIPING DETAILS OF REFRIGERANT COILS

SOLENOID LIQUID VALVE

EXPANSION VALVE CAPILLARY TUSES

Method of Attaching Thermal Bulb to Suction Line

NOTE' THE EXPANSION VALVE SHOULD BE

. INSTA.LL.ED OJRECTl,.Y ON THE DJs'rRIBUTOR.

SUCTION LINE TO COMPRESSOR

NOTE: REFER TO THE TRANE REFRIGE;RA'tION MANUAL FOR COMPLETE sUCTEON AND LIQUID LINE pipiNG A.RRANGEMENTS. THIS MANUAL ALSO EXPLAINS EX PAN· SlON VA.LVE INSTALl.ATION AND SUPERHEAT SETTlNG.

TYPE F COILS

66

MECHANiCAL SPECIfiCATIONS All COOLING cons

GENERAL

Coil capacities, pressure drops and selection procedures certified in accordance with ARI Standard 410.

Tubes- Round seamless sis-inch 00 copper (red brass - optional) tubes expanded into full fin collars for permanent fin-tube bond and expanded into cast iron headers (headers 33-inches or less) for permanent leak tight joint.

Fins - Configurated, plate-type aluminum or copper fins with full fin collars for maximum fin-tube contact and accurate spacing, mechanically bonded to tubes for permanent fin-tube bond.

Casings - Galvanized steel, 16-gauge casings on coils with headers 33-inches or less. Galvanized steel, 16-gauge channels with 14-gauge center and end supports on coils with 36,42 and 48-inch headers up through 6-rows and 120 inches. Galvanized steel, 14-gauge channels and center and end supports on coils with 36,42 and 48-inch headers and greater than 6-rows or 120 inches in length. One or more galvanized steel center tube supports on lengths over 42 inches.

Air Bypass and Water Carryover Arrestor - Foam sealing strip located between casino bottom channel and fins.

Tests and Working Pressures (all coils except type f) - Coils are proof tested at 300 psig and leak tested at 200 psig air pressure under water. The coils are suitable for working pressures and temperatures up to 200 psig and 220 F as standard.

Type F coils are proof tested at 450 psig and leak tested at 300 psig air pressure under water, cleaned, dehydrated and sealed with dry nitrogen charge. Suitable for working pressures up to 300 psig.

HEADERS

Type W Coils - Gray cast iron (finely dispersed graphite, peralitic) for 12 through 33-inch header heights. Round seamless copper tubes with an internal threaded adapter for direct pipe connection for 36, 42 and 48-inch header heights.

Type K Coils - Gray cast iron inlet, outlet and intermediate-removable headers. Inlet and outlet headers are internally threaded for direct piping connections. Removable headers bolted to flat steel plates and gasketed with red rubber. Tubes rolled into steel plates and headers to form permanent, pressure-tight, mechanical joint.

Type D, DO, WD, P2, P4 and P8 - Gray cast iron inlet, outlet and intermediate headers. Inlet and outlet headers have internal pipe threads for direct piping connections.

Type F Coils - Venturi Type refrigerant distributor of low pressure drop design. arranged for down feed with male sweat connections and a maximum of 12 circuits per distributor. Two distributors are provided when more than 12 circuits are required or the system requires a split evaporator. Round, seamless copper tube suction header and round seamless distributor tubes.

67

HOT WATER COIL SELECTION

EXAMPLE D Problem:

Determine the coil rows and fin spacing required to meet the following system heating requirements. Determine air and water pressure drops.

Given:

9,600 scfm to be heated from 20 F to 65 F with water entering at 160 F and leaving at 140 F. Coil face velocity not to exceed 750 fpm.

Selection: Prima-Flo

1. Heating load (0)

0= 1.085 x scfm x ATR

= 1.085 x 9,600 x (65-20) = 469,000 Btuh

2. Water requirement (gpm)

o 469,000

gpm = 500 x WTD "" 500 x (160-140) = 46.9 gpm

3. Face velocity (fpm)

. . 9600 scfm

Minimum allowable face area = '750 fpm

12.8 ft2

From Table 29-1, select a 24" x 78" (13 ft2), type W coil for hot water service.

. 9600 scfm

Actual face velocity (fpm) "" '13 ft2

4. Tube water velocity (fps)

Converting gpm to fps (Table 73-1);

f - gpm x 1.66 46.9 x 1.66

ps - Finned Width 24"

5. Coil coefficient (CC)

a. ATR 65 - 20

1'fD"" 160 - 20 0.321

b. WTD = 160 - 140 = 0 444

ATR 65 -20 .

738 fpm

3.24 fps

c. Using the ratios in "a" and "b" and assuming a multirow coil, a coil coefficient of 0,415 is read from Chart 72-1.

6. Inside heat transfer factor (F;) Average water temperature ::=

EWT + LWT 160 + 140

2 2

From Chart 73-2 at 150 F and 3.24 fps, F; = 0.115

150 F

NOTE: If turbulators are used, read "F," at twice the water velocity (150 F and 6,48 fps).

7. Outside heat transfer factor (Fo)

Assume a 2-Row coil; N = 2. determine the total heat transfer factor (Ft).

F = 92.17 x N

t CC x fpm

92.17 x 2

0,415 x 738::= 0.602

Fa = F, - F; zi: 0.602 - 0.115 = 0.487

8. Fin spacing (fins/tt)

At Fo = 0.487 and face velocity of 738 fpm, the fin spacing required is read as 85 fins/ft. (Prima-Flo fins).

9. Air friction (in. H20)

Dry air friction of 0.26 in. of H20 is read from Chart 82-3 at 738 fpm and 85 fins/ft (at standard air density).

10. Water pressure drop (ft. H20)

Interpolating from the Table 84-1 and 84-2 at 3.24 fps for a 24" x 78", 2-Row, type W coil:

a. Header loss = 0.92 ft H20

b. Tube loss, according to type of coil, is interpolated at 78" as 1.04. Pressure drop correction factor at 150 F is 1.05. Corrected tube loss = 1.04 x 1.05 = 1.09 (Chart 84-1 and Table 84-3).

c. Total wpd = 0.92 + 1.09 = 2.01

NOTE: Siqma-Flo" selection obtained by referencing siqrna-tlo charts.

To select WA, WC, T, ST or n coils, use the above procedure with the correct gpm - fps conversion from Table 73-1.

EXAMPLE D1 - TYPE rr Problem:

Determine the coil rows and fin spacing required to meet the following system heating requirements. Determine air and water pressure drops.

Given:

1,500 sctrn to be heated from 10 F to 55 F with water entering at 180 F and leaving at 160 F. Coil face velocity not to exceed 750 fpm.

Selection: Prima-Flo®

1. Heating load (0)

0= 1.085 x scfm x ATR

= 1.085 x 1,500 x (55-10) = 73,238 Btuh

2. Water requirement (gpm)

o 73,238

gpm = 500 x WTD "" 500 x (180-160) = 7.32 gpm

3. Face velocity (fpm)

. . 1500 scfm

Minimum allowable face area = 750 fpm

2.0 ft2

From Table 29-1, select a 12" x 24" (13 f(2), type n coil for hot water service.

. 1500 scfm

Actual face velocity (fpm) = 2.0 750 fpm

4. Tube water velocity (fps) Converting gpm to fps (Table 73-1)

fps = 0.5525 x gpm = 0.5525 x 7.32 = 4.04 fps

68

5. Coil coefficient (Ce)

a. ATR 55 - 10

ITD= 180 - 10= 0.265

b. WTD 180 - 160

ATR = 55 -10

0,444

c. Using the ratios in a and b and assuming a single row coil, a coil coefficient of 0.320 is read from Chart 71-1.

6. Inside heat transfer factor (F;) Average water temperature =

EWT + LWT 180 + 160

2 2

170 F

From Chart 73-2 at 170 F and 4.04 fps, Fj "" 0.096

NOTE: If turbulators are used, read "F;" at twice the water velocity (170 F and 8.0 Ips).

7. Outside heat transfer factor (Fo)

Assume a i-Row coil; N = 1. Determine the total heat transfer factor (Ft).

92.17 x N CC x fpm

92.17 x 1

0.320 x 750 = 0.384

Fo "" Ft - F; = 0.384 - 0.096 = 0.288

8. Fin spacing (fins/ft)

At Fo = 0.288 and face velocity of 750 fpm, the fin spacing required is read from Chart 74-1 as 135 fins/ft. (Prima-Flo fins).

9. Air friction (in. H20)

Dry air friction of 0.20 in. of H20 is read from Chart 82-1 at 750 fpm and 135 fins/ft (at standard density).

10. Water pressure drop (ft. H20)

a. Headerloss: From the Table 84-1, interpolating at 4.04 fps for type n coil:

Header loss = 2.35 ft H20

b. Tube Loss: Interpolating from Table 84-2 for a type n coil, finned length = 24, without turbulators, water velocity = 4.04 fps.

Tube water pressure drop = 1.85 ft

- Per note #3 (Table 84-2), Multiplier = 0.5.

- Per note #4 (Table 84-2), Finned Width Water Pres-

sure Drop Correction Factor for a type n coil (Table 84-3) for aFinned Width of 12 inch, Multiplier = 1.33 - Per note #5 (Table 84-2), Temperature Correction Factor for Water Pressure Drop (Chart 84-1) is 1.01.

Final tube water pressure drop =

1.85 ft x 0.5 x 1.33 x 1.01 = 1.243 ft

c. Total wpd = 2.350 + 1.243 = 3.593 ft

~JOTE: Sigma-Flo @ selection obtained by referencing Sigma-Flo charts.

FIXED COIL CAPACITY DETERMINATION EXAMPLE E

Problem:

Determine the heating capacity of a given coil. It is sometimes desireable to have chilled water coils provide heating as well as cooling. In these instances the coil rows and fin spacing have already been dictated by the cooling requirements and it is necessary to determine the coil's hot water heating capacity.

Given:

24" x 60", 4-row, 130 fins/ft, Sigma-Flo ® fins, type W coil to heat 6,000 scfm at 30 F air with 35 gpm of 180 F water.

Solution:

1. Tube water velocity (fps)

Using Table 73-1, the tube velocity at 35 gpm and 24" width = 2,42 Ips.

2. Face velocity (fpm)

Face velocity = f scfm ace area

6,000 scfm x (144 in/tt) = 600 f

(24" x 60") pm

3. Outside heat transfer factor (F 0)

At 600 fpm and 130 fins/ft (Sigma-Flo), F 0 = 0.290 (Chart 75- 2).

4. Inside heat transfer factor (F;)

Assume an average water temperature at 140 F*. From Chart 73-2, at 2,42 fps and 140 F, F; = 0.135.

Total heat transfer factor ( Ft) = Fo + Fi

Ft = 0.290 + 0.135 = 0.425

5. Leaving air temperature (LAT)

a. Coil coefficient (CC) = 92.17 x N 92.17 x 4

Ft x fpm 0.425 x 600

CC = 1.45

N = number of rows

b. WTD scfm 6000

ATR =460 x gpm= 460 x 35

0.372

c. Using the values in "a" and "b" and referring to Chart

72-1, ATRIlTD = 0.705.

d. ITO = EWT - EAT = 180 - 30 = 150 F.

e. ATR = (ATRIITD) x lTD = 0.705 x 150 = 106 F

f. LA T = EAT + ATR = 30 + 106 = 136 F.

6. Coil heating capacity (0)

o = 1.085 x scfm x ATR = 1.085 x 6000 x 106 = 690,000 Btuh

NOTE: Prima-Flo selection obtained by reterenctnu Prima-flo charts.

• This water temperature will yield a slightly conservalive "F('lactor. but eliminates the need for a trial and error selection.

69

STEAM COIL SELECTION

EXAMPLE F - Type A and AA Coils

Type A coil selection using Charts 80-1 and 81-1. Problem:

Select the proper fin spacing and number of rows required to heat 15,000 scfm from 40 F to 226 F with 90 psig steam pressure. Maximum face velocity shall be 750 tprn. Steam distribution coil is not required.

Determine:

1. Coil size, rows or coil bank and fin spacing.

2. Air pressure drop.

Selection:

1. Coil size

Minimum face area = 157~~0 = 20 ft2

From Table 29-1, select a 30" x 96"

2. Effectiveness (ATR/ITD)

At 90 psig, saturated steam temperature is read to be 331 F from Chart 70-1.

ATR 226 - 40

1'fD= 331 - 40 = 0.639

TABLE 70-1 - Properties of Steam*

GAUGE PRESS (LBS) TEMP. F LAT. HEAT VAPOR

2 219 965

5 227 960

10 239 952

15 250 945

20 259 939

25 267 933

30 274 928

40 287 919

50 298 911

60 307 904

70 316 897

80 324 891

90 331 885

100 338 880

125 353 868

150 366 857

175 377 847

200 388 838 NOTE. Use with Charts 77·1. 78·1. 79·1.80·1. and 81-1.

3. Rows and fin spacing

a. Referencing Charts 78-1 and 79-1, an effectiveness of 0.639 corresponds to a capacity that exceeds the capabilities of a single one-row steam coil.

b.

Determine the effectiveness per coil required if two identical t-row steam coils are selected.

E~~R) EA=

1 - Vr-:1--____"(_-"'~T=;::-<:"')-T-O-T =

_ Vi - 0.639

1

(ATR\ ITO) EA = 0.399

c. Referencing Chart 78-1 , with an effectiveness of 0.399, the capacity required per coil can still not be met by two Prima-Flo coils. From Chart 79-1, select two SigmaFlo ® coils with 159 fins/fL

4. Air pressure drop (APD - in. H20)

Chart 82-2 for a t-row, Sigma-Flo coil with 159 finslft at 750 fpm face velocity gives an APD of 0.33. Since two coils are required, total APD = 2 x 0.33 = 0.66 in. of H20.

NOTE: Select a Type "A" coil since steam distributing is not required. Condensate loading check is not required for Type "A" coils.

EXAMPLE G - Type T, ST, Nand NS CoilS

Type NS coil selection using Charts 77-1, 78-1, and 79-1. Problem:

Select coil(s) to heat 2,000 scfm from 60 Fto 1 05 F using five psig steam. A type NS coil is to be used. Maximum face velocity is 800 fpm.

Determine:

1. Coil size, rows or coil bank and fin spacing.

2. Actual versus maximum pounds of condensate/hour.

3. Airside pressure drop.

Selection: (Sigma-Flo)

t. Coil size

Minimum face area = 28~~0 = 2.5 ft2

From Table 29-1, select a 12" x 30" coil with a face area of 2.5 fF.

2. Heating load (Q)

Q = 1.085 x scfm x ATR

= 1.085 x 2000 x (105-60) = 97,650 Btuh

3. Pounds of condensate per square foot of coil face area (PCH == Ibs. condensate/hr; LHV = latent heat of vaporization) = 960. (Table 70-1)

PCH Q

Face area = "7L'7H7."V"""""':x==f-ac-e-ar-e-a = 40.7 lbs. condensaterhr-tt."

From Chart 83-3, at 5 psig steam and 30-inches in length,

the maximum condensate loading is 117 Ibs. condensate/

hr. ft2. Therefore, this condensate loading is acceptable.

4. Adjusted leaving air temperature (LA T)

From Chart 83-5, the capacity correction factor, FLc = 0.999

Q x FLC .

1.085 x SCFM + EAT = Adjusted LAT

9~:~~~ ~ ~09~~ + 60 = 105.0

5. Effectiveness (ATR/ITD)

AT 5 psig, saturated steam temperature is read to be 227 F from Table 70-1.

ATR 105 - 60

ITO = 227 - 60 0.270

6. Rows and fin spacing

From Chart 77-1, at a face velocity of 800 fpm and an effectiveness of 0.270, a Sigma-Flo coil with 85 fins/ft may be selected.

7. Air pressure drop (APD - in. H20)

For a t-row, Sigma-Flo coil with 85 fins/ft at a face velocity of 800 fpm, the APD == 0.28 in. of H20 (Chart 82-2).

70

CHART 71-1 - One-Row Water Sensible Heating Coil Coefficients (eel

0.80

III 0.75

III

W

Z

W

> 0.70

i=

o

W

II..

II..

W 0.65

II

c..

:Eo.: 0.60

~:E

mW

-ll-

=>m

m-l

>-=> 0.55

ccm

C>-

ccCC

_C

<tcc 0.50

(!l-

z«

-(!l

CCz

w_

I-CC

Zw 0.45

WI-

IIlZ

=>w

ZIIl

-=>

:Ez 0040

o.:~

:E .

wc..

1-::

mW 0.35

-ll-

=>cc

mW

>-~

r§:: 0.30

cc(!l

-z

«-

(!lCC

Z~ 0.25

-z

:.tw

W

-l

\I 0.20

CCIC

~t:

0.15

0.10 o.

0

:E

c..

: :: (!l

II.. x

0.25 o 0

III <0

..,.

0.:

::

W

I-

m

....I

0.: =>

:E m

0.75 W >-

l- cc

cc C

W a:

. , i :;;{

.00 o

. , e z

z a:

~ W

.25 I-

W z

...J W

III III

=> =>

.. .50 z Z

! :E ::!E

0.: 0.:

1.75 ::!E ::!E

." W

.. I- W

I-

a: m

W -l

i =>

m

" >-

e a:

~ C

CC a:

W :;;{

I-

Z (!l

W Z

~

W

-l

II

CICC

I- I-

:: « COIL COEFFICIENT (CC)

NOTE:

1 ATD '" AIR TEMPERATURE DROP 2 ATR '" AIR TEMPERATURE RISE

3 WTD '" WATER TEMPERATURE DROP 4 WTR '" WATER TEMPERATURE RISE

5 ITO = INITIAL TEMPERATURE DIFFERENCE

71

CHART 72-1 - Multirow Water Sensible Cooling and Heating Coil Coefficients (CC)

o

o

0.2

Jl!j ~

.95 I 0.5

ill I

i I

, i

O •

. 90 ,

i I I

I I

I

I i

.85 ,

i 1.

, I

, lJlJll

JlllU.IU I

.80 JUJU

! JUt I I

i I ,

I I I

I'

.75 i I 1.

I

I I !

II

, I

0 .• "

I

I

0.65 I I 1.

, ,

I I

I , I I

, i I I

.uuuu

0.60 uum

lWl I

, I lWl

I 1

Jill mm I I

, ruu , I

,.~~ i Wll I

I I !L I

~ I

2

o.so I I

I I

! ,I i

I ,

,

1!Zll1

0.45

ill. ,

I I

!

i i

,

.u !

I I I

I Ii'

I

0.35 , "

I I i

I I I I

I I I

I I

I I I I ! I

'v , , ,

, , I

, , I I ,

I

U ,

0.2v !

v.;. , lllilii I , I

~ I -

v..-'! I , I I

,

0201 ~ ! !

1 I~ ,

, I I' I

j , ,-j

I I 1

I . 1 i !

" 1 I I ~ , I

, I I

0.1" i I i ,

I I I I I

I I

, i ~w

I I 3.0 4.0

0.10 0.6 0.8 1.0 .5 2.0 o

o

o

o

0- :: we.: 1-:: r:ow ....II;;Jr:o r:o....l >-;;J o:r:o 0>- 0:0: ;:{o

(!)!:!: z<[ -(!) ffiz

1-zO:

w~ {/)z ;;JW z{/) ~;;J e..:~ :::: we..:

I-::E r:ow ...JI;;Jo: r:ow

>-!;t ~:;:

O:(!) -z <[-

(!)O:

ZW -I-

~z

WW ....I

0:10

1-1-

<[-

0.3 0.4

COIL COEFFICIENT rcci

NOTE:

1 ATD = AIR TEMPERATURE DROP 2 ATR = AIR TEMPERATURE RISE

3 WTD = WATER TEMPERATURE DROP 4 WTR = WATER TEMPERATURE RISE

5 lTD = INITIAL TEMPERATURE DIFFERENCE

72

5

o

75

00

::E ::ED.. u..(!) ux {/)o

<0 '<t

II

e..: ::E W Ir:o ...J .;;J D..r:o

::E>Wo:

50 I- c 0:0: w_

!;t<[

:;:~ ~ii:

_W

~!Z

.75 W W

....Itt) {/);;J

~~

-:: :: .

.00 e..::E

~w

1-1-

o:~

w;;J

!;tr:o :;:>(!)o: zO 2.50 _ 0:

ffi<i

I-(!) Zz

w-

~

W ....I

25

3.00

4.00

6.00

CORRECTION FOR NONSTANDARD AIR

When specified cfrn is not based on standard conditions (70 F and 29.92" Hg), the cfm must be corrected to standard conditions before using the capacity/friction charts and tables.

Using Chart 73-1, Air Density Ratios:

Actual CFM Standard CFM = Air Density Ratio

The air friction determined from the Friction Chart using standard efm must be corrected as follows:

Friction (Standard) x Air Density Ratio = Friction (Actual)

CHART 73-1 - Air Density Ratios

o

\i

0: ,_

t:::

II) z w o 0:

<

TEMPERATURE (FJ

CHART 73-2 - Heating Coil Inside Heat Transfer Factor - (FI) o 0 . N

TABLE 73-1 - FPS, GPM Conversion Facto

W 1.66 x gpm ST

FPS = Finned Width (In.)

1 & 2 Row 3.32 x gpm

Po 'I:nA lUI:. ruu ER WA&WC FPS = Finned Widlh (In.)

TE~'lP. (OF)

14~b,

Hie

180~~

" }0

~I ~

,I e-

......... , I

~I

I~~

~

~~

-"'~r:::"

I~

p:::: 0) tC!

d ,...

LC CD t'!

d ,...

a:

0

I- '<I'

0 0

Lt

a:

LU CI)

U. LU

CI) OJ

Z :J

<I: I-

a:

I- C\I

~ 3d

LU :J

J: u,

LU

c

CI)

Z

,... C\I

0 0 rs

&T

FPS = 1.105 x gpm

IT

FPS = 0.5525 x gpm

,..,

o

.5

1.0

2.0

4.0

6.0

8.0

WATER VELOCITY (FPS)

73

CHART 74-' - One-Row Healing - Prima-Flo - (Fo)

0.5

0.8

0.9 1.0

0.7

OUTSIDE HEAT TRANSFER FACTOR (Fol

CHART 74-2 - One-Row Heating - Sigma-Flo ® (Fa)

E w

z

~

tI) e Z

~

tI)

z i:i:

OUTSIDE HEAT TRANSFER FACTOR

(Fol

74

CHART 75-1 - Multi-row Heating and Cooling - Prima-Flo - (Fo)

90

E 110

.._

tn

Z

~ 120

rn

C!l

z

G 130

~

rn

Z 140

i:i:

150

160

170 0.7

0.8

0.9 1.0

OUTSIDE HEAT TRANSFER FACTOR (Fol CHART 75-2 - Multi-row Healing and Cooling - Sigma-Flo ® (Fo)

P 110

u..

W

z

~ 120

tI)

(!)

Z 130

13

~

rn

z 140

i:i:

150

160

170 OUTSIDE HEAT TRANSFER FACTOR

(Fol

75

.5

C

~

II:

I=' t-

u.. ~ .4

--

(/j (/)

Z (/)

~ w

Z

(/j w

o >

z i=

(3 o

~ w .3

II..

(/j II..

Z W

u:.

.2 CHART 76-1 - Alternate Tube Heating - Prima-Flo - (Fo)

0.5 0.6

OUTSIDE HEAT TRANSFER FACTOR (FoJ

1.2

CHART 76·2 - Alternate Tube Heating - Sigma-Flo ® - (Fo)

z

~

til (!) Z

~

a. tn

Z iL

OUTSIDE HEAT TRANSFER FACTOR (FoJ

76

CHART 77·1 - Modulated Steam Coils, Types Nand NS

FACE VELOCITY (FPM)

77

CHART 78-1 - Full Tube Steam Coils - Prima-Flo - TYJles A, T and ST

CHART 79-1 - Full Tube Steam Coils - Sigma-Flo ® - TYJles A, T and ST

_65 .65

.6 .6

.55 .55

.5 .5

5" .45 5" .45

I--

I-- <::.

<::. II:

II: I--

I-- s .4

s .4

U) U)

C/)

U) UJ

W Z

z .35 w .35

w >

> 1=

1= 0

0 .3 UJ .3

UJ u,

u, u,

u, UJ

UJ

.25 .25

.2 .2

.15 .15

.1 .1 E

......

U)

z

FACE VELOCITY (FPM)

78

70

80

90

100

t='

u,

...... 110

U)

z

~

C/) 120

(j

z

13

c;t 130

e,

C/)

Z

u::

140

150

160

170 FACE VELOCITY (FPM)

79

CHART 80-1 - Alternate Tube Steam Coils - Prima-Flo - Type AA

CHART 81-1 - Alternate Tube Steam Coils - Sigma-Flo ® - Type AA

.65

.6 .6

I

.55

.5 .5

0

C I--

I-- .45 ::::::

:::::. II:

I--

tt :5-

~ .4 en .4

en

en w

!/) z

w w

z .35 > .35

w i=

>

i= o

w

e u..

w .3 u.. .3

u.. w

u..

w

.25 .25

.2 .2

.15 .15

.1 .1 70

80

90

100

t 110

<,

en

z

~

en 120

C!l

z

(3 130

~

!/)

z

u:: 140

150

160

170

...

...

FACE VELOCITY (FPM) FACE VELOCITY [FPM)

81

80

CHART 82-1 - Dry-Air Friction, One-Row Heating - Prima-Flo

1.00,-r---r---r---r---'---'1-.--,---~--~--~---r--~--' ,

~

Z o

g

~

a:

=< ~

I 0.10

..

~ O .• ·-t---+~"'"

!--_!---.-...!1. ' , i

,---r---i-~I

I I I i

, I I

CHART 82-3 -- Dry-Air Friction, Mullirow Healing and Cooling - Prima-Flo

a.o ..• '.0 '.0 1.0.0

1 .• ... M a.o

3 .•

1.' 2.' 3,' ... ..0

1 .• 2.0 3 .o ..• 5 .•

... ..•

3 .o

2 .e

1 .• 2.' 3 .o

1.S z.o •. S

1.' 1.' ,.0

\ .o

0.00 1.2 1.'

0,75 1.0

o. 60 ... 1 .o

.,SO .oa

....

•..

o, " .00

0.:1.0 ... . ..

O.2~ ...

0.:30 D'l·" .., .... f..--r-r-r--r--!-----!-----+--:;/r-t--+---+---+- .} 01. . ••

]

".-L---L..:.::...L...._L...._L....--L....--L_.L..,_L,.:-::._.L'SO::---'.1 so =--'.,1"'.,..-.L o. - 0 6- ROWS 8 ROWS 10 ROWS

l

160 \10 tROWS .(1\0\1115 ~.rL-~-~-~9-0-~lOO-~"-.-~1.-0-~'~30--,L •• __ ,~~-~---L-~ 1 ROW

FIN SPACINGS {FUiSfFTI

CHART 82-2 - Dry-Air Friction, One-Row Healing - Sigma-Flo ®

"

Q

q

:I:

...

0

~ 0.20

z

0

>=

lJ e. 1

ii:

...

a:

=<

..J

'"

~

W

l:

...

0

!!

e, ------1

, __ L_L: ----!~~~~--~. --~~--L

. ---"--1

0 •• >+--+-

FIN SPACINGS (FIN5/FT}

FIN SPACINGS (F:lNSffTJ

e.o e. 0 10.0

4 .a ... B.O

3 .s 4 .a 6,0

3 .• '.0 '.0

2.' ' .e

3 .o

ao

I.. . .. 3.0

1.S 2 .• • .s

1.' 1.' a.e

1.S

1.0

•• 2AOWS 4ROWS

O.C _ .01

6 sows 10 ROWS

FIN SPA.CINGS (FINS/FT]

82

- .01

CHART 83-1 - Dry Air Friction - Sigma-Flo ® Type Nand NS

~

'" z

s

'" <!J

Z (3

it

[I)

z u:

ISOTHERMAL AIR FRICTION (IN. OF H,O)

CHART 83-2 - One-Row Type T and ST Steam Coil Condensate Cut-~!!,Curve (for 2-Row, Divide Max. Length by 2)

CHART 83-4 - Type T and ST Steam Coil Length Correction

,

... ~.!

.E!; ....

1:1 __ ~_~ __ . . .,,_ ... _ .

'" 51)

"

·-·T-·--·~~~~~ -T- .... - ...... ,

100 200 300 500

"

CHART 83-3 - Type Nand NS Steam Coil Condensate Cut-Off Curve

---,--~~~ . -:-----T··----r---o ~-----

l00PSlG a 60 14.0 220

S PSrG 0 10 20 30 • n S o 6' 70 80 90 '00 ,

"0 1>0 13.

10 PSrC- 0 10 ~O ao .0 50 ,

60 70 80 .0 '00 110 120 130

15 PSIG 0 , o z 0 .0 .0 , r~

so 6. 70 80 go- 100 ,.0 140

25 PS~G 0 .0 4. so 8. , ,

'00 12. ,.0

lBS, CONDENSATE/HA __ FP FACE AREA 83

TABLE 84-1 - Header Water Pressure Drop (Ft. H20) for Connectors Headers, and Tube Entrance and Exit

,

COIL FINNED WATER VELOCITY (FPS}

TYPE WIDTH 0.5 1 2 3 4 5 6 7 8

12".24" 0.04 0.16 0.66 1.48 2.63 4.11 5.92 B.06 10.53

WC 18" 0.05 0.22 0.87 1.97 3.50 5.47 7.88 10.73 14.01

30",33" 0.03 0.13 0.53 1.20 2.14 3.34 4.Bl 6.54 8.55

W-l·Row All 0.05 0.13 0.52 UO 2.10 3.33 4.79 6.47 8.52

6",9",12" 0.04 0.15 0.62 1.31 2.43 3.81 5.51 7.41 9.74

WA-l·Row

18" Thru 33" 0.03 0.13 0.49 1.07 1.92 3.00 4.37 5.SS 7.72

12", lS", 24" 0.02 0.10 0.36 0.80 1.28 2.19 3.15 4.23 552

W-2·Row 30",33" 0.03 0.13 0.53 1.17 2.07 3.22 4.65 6.41 8.25

36", 42", 4S" - 0.20 0.81 1.82 3.22 5.04 7.25 9.88 12.89

12".18" 0.01 0.04 0.16 0.35 0.63 0.98 1.41 1.92 2.50

WA-2·Row 24" 0.01 0.05 0.22 0.49 0.87 1.36 1.96 2.66 3.48

30",33" 0.02 0.09 0.34 0.78 1.38 2.16 3.11 4.23 5.52

rr All 0.04 0.14 0.57 1.29 2.30 3.60 5.18 7.05 9.21

All Row TABLE 84-2 - Tube Water Pressure Drop (Ft.)

WC VELOCITY WITH TURBULATORS VELOCITY WITHOUT TURBULATORS

2-ROWW (FPS} (FPS}

FINNED

LENGTH 0.5 1.0 2.0 3.0 4.0 0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 S.O

12 .016 .056 0.192 0.40 0.68 0.006 0,016 0.06 0.12 0.20 0.30 0.42 0.54 0.66

24 0.03 0.11 0.39 O.SO 1.36 0.012 0.032 0.12 0.24 0.40 0.60 0.84 1.06 1.36

36 0.05 0.17 0.58 1.20 2.04 0.018 0.046 0.18 0.36 0.60 0.90 1.26 1.62 2.04

48 0.07 0.23 0.77 1.60 2.72 0.024 0.064 0.24 0.48 0.80 1.20 1.66 2.16 2.72

60 0.06 0.28 0.95 2.00 3.40 0.030 0.080 0.30 0.60 1.00 1.50 2.10 2.70 3.40

72 0.10 0.34 1.15 2.40 4.08 0.036 0.096 0.36 0.72 1.20 1.80 2.52 3.24 4.08

84 0.11 0.39 1.35 2.80 4.76 0.42 0.112 0.42 0.84 1.40 2.10 2.94 3.78 4.76

96 0.13 0.45 1.54 3.20 5.44 0.04B 0.126 O.4B 0.96 1.60 2.40 3.36 4.32 5.44

108 0.15 0.51 1.74 3.60 6.12 0.054 0.144 0.54 1.08 1.80 2.70 3.78 4.86 6.12

120 0.16 0.56 1.92 4.00 6.80 0.060 0.160 0.60 1.20 2.00 3.00 4.20 5.40 6.80

132 0.18 0.62 2.11 4.40 7.48 0.066 0.176 0.66 1.32 2.20 3.30 4.62 5.94 7.48

144 0.20 0.68 2.30 4.80 8.16 0.72 0.192 0.72 1.44 2.40 3.60 5.04 6.48 8.16

rOTE: For 1 row W, WA coils (all lin spacings), multiply above values by 0.5.

VELOCITY WITH TURBULATORS VELOCITY WITHOUT TURBULATORS

T,ST. rr (FPS) (FPS}

FINNED

LENGTH 0.5 1.0 2.0 3.0 4.0 0.5 1.0 2,0 3.0 4.0 5.0 6.0 7.0 8.0

6 0.07 0.26 0.87 1.83 3.06 0.02 0.07 0.26 0.54 0.91 1.35 1.89 2.50 3.18

12 0.10 0.34 1.16 2.43 4.07 0.03 0.10 0.35 0.72 1.21 1.80 2.50 3.30 4.22

18 0.12 0.42 1.44 3.03 5.07 0.04 0.12 0.44 0.90 1.50 2.24 3.13 4.15 5.26

24 0.15 0.51 1.73 3.62 6.07 0.05 0.15 0.52 1.08 1.Bl 2.69 3.76 4.97 6.30

30 0.17 0.59 2.02 4.25 7.10 0.06 0.17 0.61 1.28 2.11 3.14 4.39 5.81 7.37

36 0.19 0.68 2.31 4.86 8.10 0.06 0.20 0.70 1.44 2.41 3.58 5.01 6.64 8.40

42 0.22 0.76 2.59 5.43 9.10 0.07 0.22 0.79 1.62 2.71 4.03 5.64 7.46 9.45

48 0.24 0.78 2.73 5.69 9.63 0.08 0.26 0.87 1.79 3.02 4.48 6.22 8.17 10.41

60 0.29 0.94 3.29 6.85 11.59 0.10 0.31 1.05 2.16 3,64 5.39 7.49 9,84 12.54

72 0.33 1.10 3.82 7.96 13.47 0.11 0.36 1.22 2.51 4.23 6.27 6.71 11.43 14.57

84 0.38 1.25 4.37 9.09 15.39 0.13 0.41 1.40 2.86 4.83 7.16 9.95 13.07 16.65

96 0.43 1.41 4.91 10.23 17.32 0.15 0.46 1.57 3.22 5.44 8.05 11.20 14.70 18.72 1. 1-Row T, ST and 2-Row IT - use values as shown. 2.2-Row T, ST - Multiply values by 2.

3.1·Row n - Multiply values by 0.5.

4. All Rows T, IT, ST - Multiply values by correction factors In Table 84·3.

5.AII Rows T. ST. Tl', WC, W, and WA - Multiply values by ccrrecucn factors in Chart 84-1.

CHART 84-1 - Temperature Correction Factor for Water Pressure Drop

Table 84-3 - Finned Width Water Pressure Drop Correction Factors for T, ST or TT Coils

FINNED WIDTH MULTIPLIER

6" 0.67

9" 1.00

12" 1.33

15' 1.67

18" 2.00

24" 267

30' 3.33

33" 3.67 ~

'" a:

~ 150

::; SB++i"t

.. ::Ii

l!!

'" w

,_

~ 100 W

~

1.4 1~ 1~ 1~ 1~

T~MPE;RATURE CORRE;CTION FACTOR FOR WAT~R PR~SSURE DROP

0.9

84

TYPE WAND WA -1-Row

HEATING COil DIMENSIONAL DATA

TYPE WAND WA - 2-Row 12" FINNED WIDTH

TABLE 85-1 - Type Wand WA - i-Row Coil Dimensions

FINNED

WIDTH C E F K .. :".

P (NPl} V (NPT) W(NPT)

6 7'k 3 19/Hi PI, 1 :v..

4!-il

9 10V. 4Y. 19/'6 PI, 1 :v..

4Ya

12 13V, 6 lY, 11-2 1% y, 4~~

18 19'1> 93,1, lV, 1')-:, 2'k y, 4V,

24 25Y, 12~~ lV, n~ 2V> 'k 4V,

30 31V. 15% lV. 2 2'k V, S~.

33 34Y, 17\4 lV, 2 2'1> V, 5~'

NOTE: All dimen i sons approxrnata, Submittals on request,

F

Tj,L

TYPE WAND WA - 2-Row

18", 24", 30" & 33" FINNED WIDTH

TABLE 85·2 - Type Wand WA (2·Row) Coil Dimensions (Headers 33" and Less)

FINNED WIDTH C D

12 13V>

18 19V, 8\4

24 25Y, 11%

30 31V, 14Y,

33 34V, 15')-:, NOTE. All dimensions approximate. Submittals on request.

TYPE W - 2·Row

36",42" & 48" FINNED WIDTHS

NOTES - • Less than 120 inches long .

•• Greater than 120 inches long.

TABLE 85-3 - Type W

FINNED 2·ROW

WIDTH C' C' D E H

36 37V. 38Y, 15¥<!

42 43Y, 44Y, 18:v.. m 6Y,

48 59Y, 50V, 21% NOTES.

1. Less than 120 inches long

2. Greater than 120 inches long.

85

TYPE we

12" & 18" FINNED WIDTHS

24",30" & 33" FINNED WIDTHS

TABLE 86·1 - Type WC Coil Dimensions

FINNED

WIDTH C D E K P (NPT) R (NPT) W

12 13V, - 1'1. 2V, 1 1 514

18 19V, - 1'1. 3 1 1 5~~

24 25V, 13V, PI, 3% lV, 1\', 6

30 3lY. 17V, 15116 3% 2Y. lV, 6

33 34V, 18% 1'1,. 3V. 2V, 11'> 6 NOTE: All drnensions approxtrnate. Subrnlttals on request.

TYPE T

1 ROW

2 ROW

TABLE 86·2 - Type T Coil Dimensions

FINNED WIDTH C

6 7V,

9 lOY,

12 nv,

15 16V,

18 19V, NOTE: All dimensions approximate. Submittats on request.

86

TYPE TT

TYPE 8T

HEATING COIL DIMENSIONAL DATA (cont.)

1 ROW

TABLE 87·1 - Type IT Coil Dimensions

C

FINNED WIDTH 1 &2RDW

9 10V,

12 13V2

18 19V,

24 25V,

30 3lY,

33 341'> NOTE: All dimensions approximate. Submittals on request.

TABLE 87-2 - Typs ST Coil Dimensions

FINNED WIDTH C

6 6T/Ji!

9 91/32

12 127/32

15 15'1"

18 18'/" NOTE. All dirnensions approximate Submittals on request.

87

2 ROW

I',

GENERAL PIPING INFORMATION

HEATING COilS

Proper installation, piping and trapping is necessary to insure satisfactory heating coil operation and prevent operational damage under service conditions. The Trane Company manufactures a complete line of traps, valves, vents and strainers for use with Trane Heating Coils. These specialties are described in the Trane Steam Specialties catalog, OS STSP-1.

These installation recommendations and piping diagrams must be followed to assure satisfactory, trouble-free operation.

TYPE A AND AA

GENERAL

1. Support all piping independently of coils.

2. Provide swing joints or flexible fittings in all piping connections adjacent to heating coils, to absorb expansion and contraction strains.

3. Install coils so air passes through fins in proper direction

(stenciled on top of coil channel).

STEAM COILS

IMPORTANT: Condensate must flow freely from coil at al! times to prevent physical coil damage from water hammer, unequal thermal stresses, freeze-up and/or corrosion.

1. Instal! V2-inch-15 degree swing check vacuum breaker in unused condensate return tapping as close as possible to coil (Type N, NS and A). Type T coils require location of vacuum breaker as near as possible to supply connection. Vent vacuum breaker line to atmosphere or connect into return main at discharge side of steam trap. Vacuum relief is particularly important when coil is controlled by modulating steam supply or two-position (on-Off) automatic steam supply valve. See Figures 90-1 through 91-1.

12" MIN.

":~

t

fiGURE 89-1 - Type A o~, N Steam Coils, Horizontal Tubes for Horizontal Airflow

TABLE 8B-1 Type A and AA Coil Dimensions

-

FINNED

WIDTH C E K P(MPTi F L R (NPT) S W

6 7'1. 3 1% 1 1'/" P/'s '10 m 4l-3

9 10\1., 4\1., 1% 1 1'''. 1'/,. " Ha 4118

1'2 13';' 6 1V2 lV, 19/16 1l/1G % 1% 4'/.

18 19'1, 9:.v4 1% 2'1, 111/16 1% 1 n. 4'1,

24 25'1, 12% 1% 2\1., 1\1., 1,. 1Y4 m 5

30 31'1, 15% 2 2\1., 1'12 1Ya lV. m 5'1,

33 34\1., 171'. 2 2'12 1'12 H'. 1Y4 H, 5'1. NOTE: All dimensions approxmate. Submittals on request.

2. Pitch coils (Type A) V4-inch per foot of coil length down toward coil return connection when installed with tubes horizontal. Do not pitch Type T coils.

3. Proper steam trap selection and installation is necessary for satisfactory coli performance and service life.

a. Select trap based on maximum possible condensate rate and recommended load factors.

b. Locate steam trap discharge at least 12 inches below condensate return tapping. This provides sufficient hydrostatic head pressure to overcome trap losses and assure complete condensate removal.

c. Float and thermostatic traps are preferred because of gravity drain and continuous discharge operation.

d. Use float and thermostatic traps with atmospheric pressure gravity condensate return with automatic controls or where possibility of low pressure supply steam exists.

TYPE NS

TYPE N

FIGURE 89-2 - Type A or N Steam Coil, Vertical Tubes for Horizontal Airflow'

GY·8

TABLE BB 2 T pe Nand NS Coil Dimensions

e. Bucket traps should only be used when supply steam is unmodulated and 25 psig or higher.

f. When installed with series airflow, size traps for each coil using capacity of first coil in airflow direction.

g. Always trap each coil separately. to prevent condensate holdup in one or more coils.

h. Always install strainers as close as possible to inlet side of trap.

- Y

FINNED NAND NS N NS NAND NS N NS N NS N NS

WIDTH C E K K P (NPT) R(NPT) S S T T W W

12 13'1. 5Y. 1 ~ '/1 s 2\1., 1'h 1 21'. 113/16 2V. 1Sho. 5')/16 3'1,

18 19'1. BY. 1"11E- 2'12 2 1 2Y4 113/11:; 2'h 1'1" 59/16 3'1.

11Y. 2'1,. 2'1. 2'/2 lV. 2'1. 1% 2'!. 1%. 6'1,. 4'1.

24 25Y,

31Y. 14Y. 2'1,. 3'1, 3 lV. 2'/s 1Y2 2'!. 1'1. 6'1" 4%

30

17!1. 2'1 is 3'1a 3 1'1. 2'1, W, 2~4 lV. 6'1,. 4'10

33 34\02 NOTE: All dimensions approximate. Subm,llals on request,

FIGURE 89-3 - Type T and ST Steam Coil, Horizontal Tubes for Horizontal Airflow

88

89

PIPING

FO

4. Do not modulate Type A, Tor 8T coils. Use two-position (onoff) steam supply control. CAUTION: Open this type valve slowly to prevent possible coil damage. Do not use Type T or 8T coils when entering air is 32 F or less because they are not completely drainable when steam supply is off. Under freezing ambient conditions, steam supplied to Type A coils with on-off control must be 5 psig or higher or intake dampers must be tightly closed to prevent freezing.

5. Use V-port modulating valves to obtain gradual modulating action.

6. Control each coil bank separately when installing coils for series airflow with automatic steam control valves.

7. Do not modulate steam or use on-off supply control on systems with overhead or pressurized returns unless condensate is drained by gravity to receiver (vented to atmosphere) and returned to main by condensate pump.

8. At startup with dampers, slowly turn steam on full for at least 10 minutes before opening fresh air intake.

9. Pitch all supply and return steam piping down a minimum of one inch per 10 feet in direction of flow.

10. Do not drain steam mains or take-offs through coils. Drain mains ahead of coils through steam trap to return line.

11. Do not bush or reduce coil return tapping size. Run return pipe full size of steam trap connection except for short nipple screwed directly into coil condensate connection.

12. Overhead returns require 1 psig pressure at steam trap discharge for each two-foot elevation to assure continuous condensate removal.

HOT WATER COILS

1. Type Wand WA hot water coils are self-venting, if water velocity exceeds 1.5 fps. If below 1.5 fps, vent by one of the following methods:

a. Install airventin top pipe plug tapping of return header.

b. When return line rises and is above top of coil, vent from top of return header horizontally to return piping.

2. Do not modulate waterflow on coils exposed totreezing air.

3. When pitched V4-inch per foot towards the header, one-row type Wand WA coils are completely drainable,

4. To drain type WC coils, install level with drain pipe and gate valve.

CODE OF SYSTEM COMPONEr~TS (PiPING DIAGRAMS)

FT - Float and thermostatic steam trap BT - Bucket steam trap

GV - Gate valve

OV ~ Automatic two-position (on-off) control valve TV - Automatic three-way control valve

VB - Vacuum breaker, 15 degree swing

Check valve CV - Check valve 8T - Strainer

AV - Automatic or manual air vent

N~H

G COilS (ennt.)

FIGURE 90·1 - Type A, N Dr NS Stearn Coil, Vertical Up Airflow'

MV·5

fULL Silt OF STEAM [RAP CONNECTION

FIGURE 90-2 - Type NS steam Coils, Horizontal Tubes for Horizontal Airflow

MY· s

FIGURE 90-3 - Type NS Stearn Coil, Vertical Tubes for Horizontal Airflow·

NOTE:

Numbers an schematic diagrams reference pertinent notes in copy. See CODE for component abbreviations.

90

FULL SllE OF MMH

FIGURE 91-1 - Type A Stearn Coils, High Pressure, Vertical Tubes for Horizontal Airflow'

ORAIN

FIGURE 91-2 - Type T and ST Water Coit

DRAIN

FIGURE 91-3 - Type WC Water Coil (See Note 19)

ARI Certification, the standard coil

is that of horizontal tubes on vertical face with horizontal airflow.

FIGURE 91·4 - Type A Stearn Coils, High Pressure, Horizontal Tubes and Airflow

DRAIH

FIGURE 91-5 - Type Wand WA Dne- Row Water Coil (See Note 3)

DRAIN

FIGURE 91·6 - Type Wand WA Two-Row Water Coil NOH:

Numbe,. on schematic diagrams reference pertinent notes in cnpv. See CODE for component ahbreviaticns.

91

MECHANICAL SPECIFICATIONS All HEATING COILS

GENERAL

Coil capacities, pressure drops and selection procedures certified in accordance with ARI Standard 410.

Tubes - Round sis-inch or t-inch 00 copper (red brass - optional) tubes expanded into full fin collars for permanent fin-tube bond and expanded into cast iron headers (headers 33-inches or less) for permanent ieaktight joint.

Fins - Configurated, plate-type aluminum or copper tins with full fin collars for maximum fin-tube contact and accurate spacing, mechanically bonded to tubes for permanent fin-tube bond.

CASINGS

Galvanized Steel-16-gauge galvanized steel casings, center and end supports are provided on all coils with header heights 33 inches or less. On 36, 42 and 48-inch header height coils up to six rows and 120 inches in length, 16-gauge casings with 14- gauge end and center supports are provided. On 36, 42 and 48- inch header height coils greater than six rows of 120 inches in length, 14-gauge casings, center and end supports are provided. Coated, galvanized steel center tube supports are provided on ordering lengths over 42 inches.

Stainless Steel - 16 gauge #304 Stainless Steel Casings, center and end supports can be provided on all coil types (except N, NS and ST) up to eight rows and 144 inches in length.

Headers - Gray cast iron (finely dispersed graphite, peralitic) for 12 through 33-inch header heights. Round seamless copper tubes with an internal threaded adapter for direct pipe connection for 36, 42 and 48-inch header heights.

Tests - All coils are proof tested at 1.5 times maximum working pressure, then leak tested at maximum working pressure. Minimum test pressures are 300 psig proof test and 200 psig leak test.

Turbulators (optional) - Bronze, spring type turbulators.

COIL TYPES

Type WC Hot Water Coils - One row, SIs-inch 00 tubes, same end connections. Maximum working ratings: 200 psig, 250 F (copper or red brass tubes).

Type W Hot Water Coils - SIs-inch 00 tubes. One-row coil has opposite end connections; two-row coil has same end connections. For 12 through 33-inch header heights, tube-to-header joints are cold rolled for pressure-tight joints. For 36, 42 and 48- inch header heights, tubes are brazed into extruded header holes. Maximum working ratings: One-Row: 200 psig, 325 F (standard copper tubes), 200 psig, 388 F (red brass tubes); Two-Row: 200 psig, 220 F (copper or red brass tubes).

Type WA Hot Water Coils- SIs-inch 00 tubes. One-row coil has opposite-end connections; two-row coil has same end con-

The Trane Company

North American Commercial Group 3600 Pammel Creek Road

La Crosse, WI 54601-7599

An American-Standard Company

nections. For 12 through 33-inch header heights, tube-to-header joints are cold rolled for pressure-tight joints. Maximum Working Ratings: One-Row: 200 psig, 325 F (standard copper tubes), 200 psig, 388 F (red brass tubes); Two-Row: 200 psig, 220 F (copper or red brass tubes).

Type n Hot Water Coils - One or two rows, SIs-inch 00 tubes, same end connections. Headers 3f4-inch, NPT (female) connections. Maximum working ratings: 225 psig, 325 F (standard copper tubes), 275 psig, 400 F (red brass tubes).

Type T and ST Steam or Hot Water Coils- One or two rows, %inch 00 tubes, single tube continuous circuit, same end 3M-inch, NPT (male) connections. Tube joints rolled for pressure-tight joint. Maximum working ratings: Hot water: 225 psig, 325 F (standard copper tubes), 275 psig, 400 F (red brass tubes). Steam: 100 psig, 400 F (standard copper tubes), 200 psig, 400 F (red brass tubes).

Type A Steam Coils- One row, Sis-inch 00 tubes, opposite end connections. Tube joints reinforced with brass bushings. Steam deflectors provided opposite supply connector to prevent impingement of steam into tubes in connection area. Maximum working ratings: 100 psig, 400 F (standard copper tubes), 200 psig, 400 F (red brass tubes).

Type NS Steam Coils-One-row, steam distributing tube with 1- inch 00 condensing tubes; same end connections. Uniform leaving-air distribution. No more than 4 F temperature difference between leaving air from any lengthwise quadrant of coil area (based on nine or more equal area temperature readings in any given quadrant) and average leaving air temperature over entire coil face area. Distributor tubes with die-formed Directional Kinetic Orifices discharge steam in the direction of condensate flow, Tubes located concentrically within condensing tubes by corrosion resistant support clips. Steam deflectors provided opposite supply connection to prevent impingement of steam into tubes in connection area. Maximum working ratings: 100 psig, 400 F (standard copper tubes), 200 psig, 400 F (red brass tubes).

Type N Steam Coils - One-row, steam distributing tube with 1- inch 00 condensing tubes; opposite end connections. Uniform leaving-air distribution. No more than 4 Ftemperature difference between leaving air from any length-wise quadrant of coil area (based on nine or more equal area temperature readings in any given quadrant) and average leaving air temperature over entire coil face area. Distributor tubes with die-formed Directional Kinetic Orifices. Tubes located concentrically within the condensing tubes by corrosion resistant support clips. Steam deflectors provided opposite supply connection to prevent impingement of steam into tubes in connection area. Maximum working ratings: 100 psig, 400 F (standard copper tubes), 200 psig, 400 F (red brass tubes).

Since The Trane Company has a poncy 01 continuous product Improvement It reserves the fight 10 change dcsiqn and specrlicanon Without nonce

COIL-DS-1 June 1985

PL-AH-CO IL -OOO-DS-l·685 Supersedes COIL-DS-l 684-

COIL-CS·1A 485

Das könnte Ihnen auch gefallen

- System Duct Pressure Loss CalculationDokument6 SeitenSystem Duct Pressure Loss CalculationijkendrickNoch keine Bewertungen

- Expansion tank calculationsDokument5 SeitenExpansion tank calculationspsjjoshi0% (1)

- Calculating cooling load for a battery roomDokument2 SeitenCalculating cooling load for a battery roomMohammed IqbalNoch keine Bewertungen

- Pressure drop computation for chilled water pump sizing in RKH Project, Saudi ArabiaDokument17 SeitenPressure drop computation for chilled water pump sizing in RKH Project, Saudi ArabiaabdullahNoch keine Bewertungen

- PL 3900 Battery Room Ventilation SystemDokument2 SeitenPL 3900 Battery Room Ventilation SystemcandratrikusumaNoch keine Bewertungen

- Chilled Water Pump Head Calculation SummaryDokument15 SeitenChilled Water Pump Head Calculation SummaryZain ShariffNoch keine Bewertungen

- Humidification Load Calculation Armstrong PDFDokument3 SeitenHumidification Load Calculation Armstrong PDFsyedNoch keine Bewertungen

- RTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20Dokument1 SeiteRTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20alvinchuanNoch keine Bewertungen

- Fahu 2 (Te)Dokument15 SeitenFahu 2 (Te)Abdo RagabNoch keine Bewertungen

- Condenser & EvaporatorDokument21 SeitenCondenser & EvaporatorfitratulqadriNoch keine Bewertungen

- Chilled Water Pump Head Calcultion: Section Valves & Fitings Pipe Size (Inch) Description of The Pipe RunDokument3 SeitenChilled Water Pump Head Calcultion: Section Valves & Fitings Pipe Size (Inch) Description of The Pipe Runganesh gundNoch keine Bewertungen

- Chilled Water Buffer Tank SelectionDokument2 SeitenChilled Water Buffer Tank SelectionSlobodan BanicNoch keine Bewertungen

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Dokument1 SeitePart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanNoch keine Bewertungen

- Basics of Refrigeration - EvaporatorsDokument32 SeitenBasics of Refrigeration - Evaporatorsfarazgazanfar-1Noch keine Bewertungen

- Machinery Room Ventilation Analysis ToolDokument48 SeitenMachinery Room Ventilation Analysis ToolDon Quijote de la ManchaNoch keine Bewertungen

- Project:: Chilled Water Pump Head CalculationDokument1 SeiteProject:: Chilled Water Pump Head CalculationClarkFedele27Noch keine Bewertungen

- Coil Selection For 38 TR Ahu r0 18.12.2006Dokument2 SeitenCoil Selection For 38 TR Ahu r0 18.12.2006Mohsin ShaikhNoch keine Bewertungen

- Heat Load Estimation MS1525 DesignDokument10 SeitenHeat Load Estimation MS1525 Designhans weemaesNoch keine Bewertungen

- Evaporator DesignDokument1 SeiteEvaporator DesignNaqqash SajidNoch keine Bewertungen

- Fans Static Head Calculation SheetDokument1 SeiteFans Static Head Calculation SheetraifaisalNoch keine Bewertungen

- Cooling Load CalculationDokument32 SeitenCooling Load CalculationHenry San PedroNoch keine Bewertungen

- Ahu 6 Alternate ArrangementDokument4 SeitenAhu 6 Alternate Arrangementnaresh100% (1)

- 2 Way & 3 Way Modulating Valve Selection ProcedureDokument5 Seiten2 Way & 3 Way Modulating Valve Selection ProcedureJuan Altamirano RojasNoch keine Bewertungen

- 7D162B Pressure Drop For Double Pipe Heat Exchanger SiDokument4 Seiten7D162B Pressure Drop For Double Pipe Heat Exchanger SiparagmhamunkarNoch keine Bewertungen

- Heat Load Sheet - Individual RoomDokument2 SeitenHeat Load Sheet - Individual RoomAnonymous 78q4M6g3RNoch keine Bewertungen

- Chiller Size CalculatorDokument4 SeitenChiller Size CalculatormpokeNoch keine Bewertungen

- Calculating Expansion Tank VolumeDokument5 SeitenCalculating Expansion Tank VolumeAhmed AliNoch keine Bewertungen

- K-Flex Calculation Based On Ambient Temperature 30°C, RH 75% & H 11 (Final)Dokument1 SeiteK-Flex Calculation Based On Ambient Temperature 30°C, RH 75% & H 11 (Final)Ah BengNoch keine Bewertungen

- Chilled Water Pump Head CalculationDokument18 SeitenChilled Water Pump Head CalculationPeshoMagdyNoch keine Bewertungen

- Project: FT Catcher Fpso Feed: Hvac - Heater Load CalculationDokument7 SeitenProject: FT Catcher Fpso Feed: Hvac - Heater Load CalculationinstrengNoch keine Bewertungen

- Shop Drawing: Welcome Air-Tech (M) SDN BHDDokument1 SeiteShop Drawing: Welcome Air-Tech (M) SDN BHDKarthi KeyanNoch keine Bewertungen

- Head Calculation Hydronic PipingDokument18 SeitenHead Calculation Hydronic Pipingjomy_pj8106Noch keine Bewertungen

- REFREG CHARGE CALCDokument12 SeitenREFREG CHARGE CALCKhadija MirajNoch keine Bewertungen

- Yazd-System Description For Clean Drain System PDFDokument7 SeitenYazd-System Description For Clean Drain System PDFace-winnieNoch keine Bewertungen

- Design Note For Air Reciever TankDokument6 SeitenDesign Note For Air Reciever TankJoshua Balaram RaoNoch keine Bewertungen

- Average Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Dokument7 SeitenAverage Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Alexandre HugenNoch keine Bewertungen

- Pressure Drop Calculation For Fan (Exf-Bsc-02) Typical Calculation For Fan (Exf-Bsc-02)Dokument10 SeitenPressure Drop Calculation For Fan (Exf-Bsc-02) Typical Calculation For Fan (Exf-Bsc-02)ibnrafeeqNoch keine Bewertungen

- AHU Load Calculations for G-Block Tablet ExpansionDokument22 SeitenAHU Load Calculations for G-Block Tablet ExpansionamitbslpawarNoch keine Bewertungen

- Fgas Refrigerant CalculatorDokument10 SeitenFgas Refrigerant CalculatorKumar sssssNoch keine Bewertungen

- Coil Selection FormatDokument6 SeitenCoil Selection FormatTanveer AzizNoch keine Bewertungen

- Equations: Hvac Equations, Data, and Rules of ThumbDokument21 SeitenEquations: Hvac Equations, Data, and Rules of ThumbzodedNoch keine Bewertungen

- Water Cooled Centrifugal Chiller Technology FeaturesDokument16 SeitenWater Cooled Centrifugal Chiller Technology Featuresthu hangNoch keine Bewertungen

- Daikin AHU Integration KitDokument4 SeitenDaikin AHU Integration Kiterdo mandanaNoch keine Bewertungen

- 07/06/2019 427071582.xls Chiller - Fix CAP+Stepless: Degradation CalculationDokument7 Seiten07/06/2019 427071582.xls Chiller - Fix CAP+Stepless: Degradation CalculationselisenNoch keine Bewertungen

- Shell and Tube Heat Exchanger Design: Fig. 4 Fig. 2Dokument42 SeitenShell and Tube Heat Exchanger Design: Fig. 4 Fig. 2songjihyo16111994Noch keine Bewertungen

- Selection Sheet - 30XA452 Screw ChillerDokument1 SeiteSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478Noch keine Bewertungen

- Heat Load CalculationsDokument35 SeitenHeat Load CalculationsAbiodun Ilori100% (1)

- Stair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Dokument7 SeitenStair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Shabeer HamzaNoch keine Bewertungen

- Water-Cooled Series R (TM) RTHD Product ReportDokument2 SeitenWater-Cooled Series R (TM) RTHD Product ReporttrangocvuNoch keine Bewertungen

- Determine cooling coil and reheater outputs for office AC systemDokument4 SeitenDetermine cooling coil and reheater outputs for office AC systemRashel Hasan100% (1)

- Dr. Fixit Newcoat 105 1 PDFDokument3 SeitenDr. Fixit Newcoat 105 1 PDFmohdrashidNoch keine Bewertungen

- HVAC Thermal Load EstimatingDokument28 SeitenHVAC Thermal Load EstimatingIntisar Ali SajjadNoch keine Bewertungen

- Pump power and sizing calculationDokument1 SeitePump power and sizing calculationVIVEKZI0Noch keine Bewertungen

- Ngineering ATA: Temperature & Altitude Effects On FansDokument3 SeitenNgineering ATA: Temperature & Altitude Effects On FansMohamed TahounNoch keine Bewertungen

- 2K Method Excess Head Loss in Pipe FittingsDokument8 Seiten2K Method Excess Head Loss in Pipe Fittingsjxd3261Noch keine Bewertungen

- HVAC Systems Duct Design-Duct P DropDokument1 SeiteHVAC Systems Duct Design-Duct P DropmhmdjdgmailcomNoch keine Bewertungen

- Despiece ZZR250Dokument69 SeitenDespiece ZZR250JoseSeguelaNoch keine Bewertungen

- WD GF 20170107Dokument1 SeiteWD GF 20170107प्रणव प्रकाशNoch keine Bewertungen

- Williston 4 PlexDokument14 SeitenWilliston 4 Plexsharilyn6156Noch keine Bewertungen

- To Be FilledDokument28 SeitenTo Be FilledAhmed MohammedNoch keine Bewertungen

- Ite Note On Vessel With CalculationDokument21 SeitenIte Note On Vessel With CalculationSam Wang Chern Peng100% (1)

- Eng Legal System - PYEDokument20 SeitenEng Legal System - PYESam Wang Chern PengNoch keine Bewertungen

- O&M CompleteDokument36 SeitenO&M CompleteSam Wang Chern PengNoch keine Bewertungen

- Cooling Coil 02Dokument14 SeitenCooling Coil 02Sam Wang Chern Peng0% (1)

- Trane CoilDokument47 SeitenTrane CoilSam Wang Chern Peng100% (5)

- DDM - Daikin AHUDokument27 SeitenDDM - Daikin AHUSam Wang Chern Peng100% (1)

- Ite Note On Process PlantDokument14 SeitenIte Note On Process PlantSam Wang Chern PengNoch keine Bewertungen

- McQuay Eco System TrainingDokument336 SeitenMcQuay Eco System TrainingSam Wang Chern PengNoch keine Bewertungen

- Trane - Cent Water ChillerDokument16 SeitenTrane - Cent Water ChillerSam Wang Chern Peng100% (2)

- Trane - CentraVac StarterDokument28 SeitenTrane - CentraVac StarterSam Wang Chern PengNoch keine Bewertungen

- Grundfos NKDokument121 SeitenGrundfos NKSam Wang Chern PengNoch keine Bewertungen

- Trane - Centravac ControlDokument16 SeitenTrane - Centravac ControlSam Wang Chern Peng100% (1)

- Trane - VAV ICSDokument21 SeitenTrane - VAV ICSSam Wang Chern PengNoch keine Bewertungen

- Cooling Coil 01Dokument15 SeitenCooling Coil 01Sam Wang Chern Peng100% (3)

- Carrier AHUDokument19 SeitenCarrier AHUSam Wang Chern Peng75% (4)

- Trane - Tracer 100 ICSDokument17 SeitenTrane - Tracer 100 ICSSam Wang Chern PengNoch keine Bewertungen

- MMM395 - Barkhausen NDT Research NotesDokument144 SeitenMMM395 - Barkhausen NDT Research NotesSam Wang Chern PengNoch keine Bewertungen

- MMM380 - MechatronicDokument130 SeitenMMM380 - MechatronicSam Wang Chern PengNoch keine Bewertungen

- Trane - End Dvcs TRND & ActuatorsDokument9 SeitenTrane - End Dvcs TRND & ActuatorsSam Wang Chern PengNoch keine Bewertungen

- Trane - 01 Advantage ComfortDokument13 SeitenTrane - 01 Advantage ComfortSam Wang Chern PengNoch keine Bewertungen

- MMM235 - Winch DesignDokument33 SeitenMMM235 - Winch DesignSam Wang Chern Peng100% (2)

- Bock Semi Hermatic - Full CatalogueDokument180 SeitenBock Semi Hermatic - Full CatalogueSam Wang Chern Peng100% (3)

- Buddhaguna ChantDokument44 SeitenBuddhaguna ChantSam Wang Chern Peng100% (1)

- Trane - Ref System - Eqpt RM DesignDokument26 SeitenTrane - Ref System - Eqpt RM DesignSam Wang Chern Peng100% (1)

- Bock - Vehicle Refrigerant Compressor CatalogueDokument36 SeitenBock - Vehicle Refrigerant Compressor CatalogueSam Wang Chern Peng100% (1)

- BUS3310 - Strategic Management & Technology ChangeDokument130 SeitenBUS3310 - Strategic Management & Technology ChangeSam Wang Chern PengNoch keine Bewertungen

- MMM251 - Control EngineeringDokument154 SeitenMMM251 - Control EngineeringSam Wang Chern PengNoch keine Bewertungen

- MMM351 - Machine DynamicsDokument104 SeitenMMM351 - Machine DynamicsSam Wang Chern PengNoch keine Bewertungen

- EEE3235 - Electrical EngineeringDokument99 SeitenEEE3235 - Electrical EngineeringSam Wang Chern Peng0% (1)