Beruflich Dokumente

Kultur Dokumente

Lock T Evo - en - 02-20 PDF

Hochgeladen von

milivoj ilibasicOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lock T Evo - en - 02-20 PDF

Hochgeladen von

milivoj ilibasicCopyright:

Verfügbare Formate

LOCK T EVO TIMBER ETA 19/0831

OUTDOOR CONCEALED HOOK

TIMBER-TO-TIMBER CONNECTOR

ALLUMINIO EVO

Thanks to the special painting it can be used outdoors in service class 3.

Easy and quick to install, it can be fastened with a single type of screw.

OUTDOOR

The joint can be easily disassembled, ideal for the construction of tem-

porary structures exposed to weather.

AGGRESSIVE WOODS

Ideal for applications with woods containing tannin or treated with im-

pregnating agents and other chemical processes.

CHARACTERISTICS

FOCUS outdoor joints that can be disassembled

VIDEO

TIMBER SECTIONS from 53 x 80 mm to 160 x 280 mm Scan the QR Code and watch

STRENGTH Rv,k up to 35 kN the video on our YouTube

channel

FASTENERS HBS PLATE EVO, KKF AISI410

MATERIAL

Aluminium alloy with special paint in graphite

black colour.

FIELDS OF USE

Outdoor timber-to-timber shear joints

• solid timber and glulam

• CLT, LVL

• aggressive woods (containing tannin)

• chemically treated woods

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

SERVICE CLASS 3

The specially painted aluminium alloy together

with the C4 EVO coated screws or martensitic

stainless steel screws allow the joint to be used

in service class 3.

OAK FRAME

Ideal for fastening aggressive woods contain-

ing tannin, such as chestnut and oak. Assembly

with KKF AISI410 outdoor screws.

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

CODES AND DIMENSIONS

LOCK T EVO Ø5

CODE B H s nscrews - Ø nLOCKSTOP - type pcs *

[mm] [mm] [mm] H

H

LOCKTEVO3580 35 80 20 8 - Ø5 2 LOCKSTOP5 50

LOCKTEVO35120 35 120 20 16 - Ø5 4 LOCKSTOP5 25

s s

Screws and LOCK STOP not included in the package. B B

* number of connector pairs

LOCKTEVO3580 LOCKTEVO35120

LOCK STOP Ø5

B B

CODE B H s pcs S S

[mm] [mm] [mm]

H H

LOCKSTOP5 19 27,5 13 100

The use of LOCK STOP is optional and does not affect structural performance.

HBS PLATE EVO

CODE d1 L b TX pcs

[mm] [mm] [mm] d1

HBSPEVO550 5 50 30 TX25 200

L

HBSPEVO570 5 70 40 TX25 100

KKF AISI410

CODE d1 L b TX pcs

[mm] [mm] [mm] d1

KKF550 5 50 30 TX25 200

L

KKF570 5 70 40 TX25 100

MATERIAL AND DURABILITY EXTERNAL LOADS

LOCK T EVO: EN AW-6005A aluminium alloy.

To be used in service classes 1, 2 and 3 (EN 1995-1-1).

Fv

FIELD OF USE

• Timber-to-timber joints between solid timber, glulam,

LVL and CLT structural elements

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

CODES AND DIMENSIONS

LOCK T EVO Ø6

CODE B H s nscrews - Ø nLOCKSTOP - type pcs*

[mm] [mm] [mm]

LOCKTEVO50175 50 175 22 16 - Ø6 4 LOCKSTOP 7 18 H

H

LOCKTEVO75215 75 215 22 36 - Ø6 4 LOCKSTOP 7 12

Screws and LOCK STOP not included in the package.

* number of connector pairs

B s B s

LOCKTEVO50175 LOCKTEVO75215

LOCK STOP Ø6

B

S

CODE B H s pcs

[mm] [mm] [mm]

LOCKSTOP7 26,5 38 15 50 H

The use of LOCK STOP is optional and does not affect structural performance.

HBS PLATE EVO

CODE d1 L b TX pcs

d1

[mm] [mm] [mm]

L

HBSPEVO680 6 80 50 TX30 100

KKF AISI410

CODE d1 L b TX pcs

d1

[mm] [mm] [mm]

L

KKF680 6 80 50 TX30 100

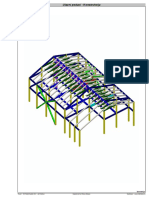

PERGOLAS AND GAZEBOS

Ideal for the construction of wooden structures

placed outdoors and in service class 3. Possibil-

ity to uninstall the joint for seasonal needs.

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

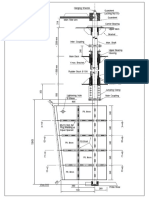

GEOMETRY | LOCK T EVO Ø5

main secondary

element beam

B s B

SINGLE CONNECTOR

MAIN SECONDARY

LOCK T EVO CONNECTOR SCREWS

ELEMENT BEAM

HBS PLATE EVO

column beam

KKF AISI410

type BxHxs nH+nj - ØxL BS,min x HS,min BH,min x HH,min bJ,min x hj,min

[mm] [mm] [mm] [mm] [mm]

with pre-drilling without pre-drilling with pre-drilling without pre-drilling

hole hole hole hole

4+4 - Ø5x50 53 x 50 50 x 95

LOCKTEVO3580 35 x 80 x 20 53 x 80 61 x 80

4+4 - Ø5x70 53 x 70 70 x 95

8+8 - Ø5x50 53 x 50 50 x 135

LOCKTEVO35120 35 x 120 x 20 53 x 120 61 x 120

8+8 - Ø5x70 53 x 70 70 x 135

COUPLED CONNECTORS

MAIN SECONDARY

LOCK T EVO CONNECTOR SCREWS

ELEMENT BEAM

HBS PLATE EVO

column beam

KKF AISI410

type BxHxs nH+nj - ØxL BS,min x HS,min BH,min x HH,min bJ,min x hj,min

[mm] [mm] [mm] [mm] [mm]

with pre-drilling without pre-drilling with pre-drilling without pre-drilling

hole hole hole hole

16+16 - Ø5x50 88 x 50 50 x 135

LOCKTEVO 35120 + 35120 70 x 120 x 20 88 x 120 96 x 120

16+16 - Ø5x70 88 x 70 70 x 135

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

INSTALLATION ON BEAM | LOCK T EVO Ø5

MAIN BEAM SECONDARY BEAM

BF ≥B B

nj

HF ≥H hj hj

HH HH

nH

bj

BH SF = 20 mm

The HF dimension refers to the minimum height of the grooving at constant width. The rounded part must be taken into

account when grooving.

INSTALLATION ON COLUMN | LOCK T EVO Ø5

COLUMN BEAM

B

c

nj

hj hj

nH

bj

BS HS SF = 20 mm

CONNECTOR POSITIONING | LOCK T EVO Ø5

connector cmin

[mm]

LOCKTEVO3580 7,5

LOCKTEVO35120 2,5

For installation on column, respecting the minimum distance of the screw from the unloaded end of the column, requires to lower the

connector by a quantity c, compared to the end of the column. This can be achieved either by raising the column with respect to the to

the top of the beam (as in the image) or by lowering the connector with respect to the top of the beam by a c amount.

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

GEOMETRY | LOCK T EVO Ø6

main secondary

element beam

B s B

SINGLE CONNECTOR

MAIN SECONDARY

LOCK T EVO CONNECTOR SCREWS

ELEMENT BEAM

HBS PLATE EVO

column beam

KKF AISI410

type BxHxs nH+nj - ØxL BS,min x HS,min BH,min x HH,min bJ,min x hj,min

[mm] [mm] [mm] [mm] [mm]

with pre-drilling without pre-drilling with pre-drilling without pre-drilling

hole hole hole hole

LOCKTEVO50175 50 x 175 x 22 8+8 - Ø6x80 68 x 80 80 x 180 68 x 175 80 x 175

LOCKTEVO75215 75 x 215 x 22 18+18 - Ø6x80 93 x 80 80 x 220 93 x 215 105 x 215

COUPLED CONNECTORS

MAIN SECONDARY

LOCK T EVO CONNECTOR SCREWS

ELEMENT BEAM

HBS PLATE EVO

column beam

KKF AISI410

type BxHxs nH+nj - ØxL BS,min x HS,min BH,min x HH,min bJ,min x hj,min

[mm] [mm] [mm] [mm] [mm]

with pre-drilling without pre-drilling with pre-drilling without pre-drilling

hole hole hole hole

LOCKTEVO 50175 + 50175 100 x 175 x 22 16+16 - Ø6x80 118 x 80 80 x 180 118 x 175 130 x 175

LOCKTEVO 75215 + 75215 150 x 215 x 22 36+36 - Ø6x80 168 x 80 80 x 220 168 x 215 180 x 215

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

INSTALLATION ON BEAM | LOCK T EVO Ø6

MAIN BEAM SECONDARY BEAM

BF ≥B B

nj

HF ≥H

hj hj

HH HH

nH

bj

BH SF = 22 mm

The HF dimension refers to the minimum height of the grooving at constant width. The rounded part must be taken into

account when grooving.

INSTALLATION ON COLUMN | LOCK T EVO Ø6

COLUMN BEAM

B

c

nj

hj

hj hj

nH

bj

BS HS SF = 22 mm

CONNECTOR POSITIONING | LOCK T EVO Ø6

connector cmin

[mm]

LOCKTEVO50175 5

LOCKTEVO75215 15

For installation on column, respecting the minimum distance of the screw from the unloaded end of the column, requires to lower the

connector by a quantity c, compared to the end of the column. This can be achieved either by raising the column with respect to the to

the top of the beam (as in the image) or by lowering the connector with respect to the top of the beam by a c amount.

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

INSTALLATION

EXPOSED INSTALLATION WITH LOCK STOP

1 3

2 4 5 6

Place the connector on the main Place the connector on the sec- Hook the secondary beam fitting It is possible to insert anti-slip

element and fasten the first ondary beam and fasten the first it from the top to the bottom. screws without structural func-

screws. When using LOCK STOP screws. When using LOCK STOP tion, by drilling one hole Ø5 in-

(optional) position LOCK STOP (optional) position LOCK STOP clined at 45° in the upper part of

and fasten the remaining screws. and fasten the remaining screws. the connector. A Ø5 screw must

be inserted in the hole.

CONCEALED INSTALLATION

1

2 3 4 5

Carry out the grooving on the Place the connector on the Hook the secondary beam fitting It is possible to insert anti-slip

main element. Place the con- secondary beam and fasten all it from the top to the bottom. screws without structural func-

nector on the main element and screws. tion, by drilling one or more

fasten all screws. holes Ø5 inclined at 45° in the

upper part of the connector. A

Ø5 screw must be inserted in

the holes.

SEMI-CONCEALED INSTALLATION

2

1 3 4 5

Place the connector on the main Perform full grooving on the Hook the secondary beam fitting It is possible to insert anti-slip

element and fasten all screws. secondary beam. Position the it from the top to the bottom. screws without structural func-

connector and fasten all screws. tion, by drilling one or more

holes Ø5 inclined at 45° in the

upper part of the connector. A

Ø5 screw must be inserted in

the holes.

NOTE: for the geometry of the holes for the optional inclined screws see the "OPTIONAL INCLINED SCREWS" page 70.

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

STATIC VALUES

LOCK T EVO Ø5

LOCK T EVO CONNECTOR TIMBER ALUMINIUM

HBS PLATE EVO

screws

KKF AISI410

type BxHxs nH+nj - ØxL Rv,timber,k Rv,alu,k

[mm] [mm] [kN] [kN]

C24(1) C50 (2)

4+4 - Ø5x50 3,97 5,66

LOCKTEVO3580 35 x 80 x 20 20,0

4+4 - Ø5x70 4,81 6,23

8+8 - Ø5x50 7,94 11,31

LOCKTEVO35120 35 x 120 x 20 20,0

8+8 - Ø5x70 9,62 12,46

16+16 - Ø5x50 15,88 22,62

LOCKTEVO 35120 + 35120 70 x 120 x 20 40,0

16+16 - Ø5x70 19,23 24,92

LOCK T EVO Ø6

LOCK T EVO CONNECTOR TIMBER ALUMINIUM

HBS PLATE EVO

screws

KKF AISI410

type BxHxs nH+nj - ØxL Rv,timber,k Rv,alu,k

[mm] [mm] [kN] [kN]

C24(1) C50 (2)

LOCKTEVO50175 50 x 175 x 22 8+8 - Ø6x80 13,92 18,24 40,0

LOCKTEVO75215 75 x 215 x 22 18+18 - Ø6x80 31,31 41,04 60,0

LOCKTEVO 50175 + 50175 100 x 175 x 22 16+16 - Ø6x80 27,83 36,48 80,0

LOCKTEVO 75215 + 75215 150 x 215 x 22 36+36 - Ø6x80 62,62 82,07 120,0

CONNECTION STIFFNESS: GENERAL PRINCIPLES:

• The sliding module can be calculated according to ETA-19/0831, with the • The design values are obtained from the characteristic values as follows:

following expression: • The coefficient γ M2 is the partial coefficient for aluminium sections subject

to tension, to be taken according to the current regulations used for the

n ρm d

1,5 0,8

kN

calculation. If there are no other provisions, it is suggested to use the value

Kv,ser = provided by EN 1999-1-1, equal to γ M2=1.25.

30 mm • The coefficient γ M the relevant safety coefficient, on the timber connection

side, to be taken according to the current regulations used for the calcu-

where: lation.

d is the diameter of the screw thread in the secondary beam, in mm; • The design strength is obtained from the characteristic values as follows:

ρ m is the average density of the secondary beam, in kg/m3;

n is the number of screws in the secondary beam. Rv,timber,d = Rv,timber,k kmod

Rv,d = min γM

Rv,alu,k

NOTES: Rv,alu,d =

γM2

(1)

Values calculated according to ETA-19/0831, ETA-11/0030 and EN 1995-1-1

for screws without pre-drilling hole. The strength value can be accepted as • Dimensioning and verification of the timber elements must be carried out

valid, for higher safety standards, even in the presence of pre-drill. ρ k=350 separately. In particular, for loads perpendicular to the beam axis, it is rec-

kg/m3 has been taken in consideration in the calculation. ommended to perform a splitting check in both wooden elements.

(2)

Values calculated according to ETA-19/0831, ETA-11/0030 and EN 1995-1-1 • If coupled connectors are used, special care must be taken in alignment

for screws with pre-drilling hole. ρ k=430 kg/m3 has been taken in consider- during installation to avoid different stresses in the two connectors.

ation in the calculation.

• Screws with the same length must be used in all holes, separately for each

side of the connector. It is possible to use screws of different length in the

two connectors, main element side and secondary beam side.

• The connector must always be fully fastened using all the holes.

• The pre-drill is not required for screws on main or secondary beam, with

characteristic density ρ k≤420 kg/m3 . The pre-drill is mandatory on main or

secondary beam with characteristic density ρ k> 420 kg/m3 .

• For screws on column, pre-drilling is always mandatory.

CONCEALED BEAM JOINTS | LOCK T EVO | 02-20

Das könnte Ihnen auch gefallen

- Mazak QT 200 250 Nexus Operating Manual PDFDokument466 SeitenMazak QT 200 250 Nexus Operating Manual PDFosteanu100% (2)

- PM High Strength Magnetic Alloys PDFDokument13 SeitenPM High Strength Magnetic Alloys PDFSAMIT JAINNoch keine Bewertungen

- KS Series Master Format CSI SpecificationDokument14 SeitenKS Series Master Format CSI SpecificationMohammad Maher AlSafariniNoch keine Bewertungen

- Heat of Mixing/solution PDFDokument9 SeitenHeat of Mixing/solution PDFnhalieza1067Noch keine Bewertungen

- Lock T - en - 02-20 PDFDokument14 SeitenLock T - en - 02-20 PDFmilivoj ilibasicNoch keine Bewertungen

- "T" Shaped Post Base: InvisibleDokument6 Seiten"T" Shaped Post Base: Invisiblemilivoj ilibasicNoch keine Bewertungen

- TITAN S-En-Technical-Data-SheetDokument13 SeitenTITAN S-En-Technical-Data-SheetSlayde TanaNoch keine Bewertungen

- Uk Grid Datasheet Chicago Metallic Clip in D 02 2021Dokument6 SeitenUk Grid Datasheet Chicago Metallic Clip in D 02 2021Mohamed AzabNoch keine Bewertungen

- L-Bolt Anchor Bolts: Simpson Strong-Tie Wood Construction Connectors - Canadian Limit States DesignDokument1 SeiteL-Bolt Anchor Bolts: Simpson Strong-Tie Wood Construction Connectors - Canadian Limit States DesignHakan EzcanNoch keine Bewertungen

- J Trunking WebDokument10 SeitenJ Trunking Webgad3rstNoch keine Bewertungen

- About WELDA Anchor PlateDokument1 SeiteAbout WELDA Anchor PlateFircijevi KurajberiNoch keine Bewertungen

- Flue-Systems GBDokument16 SeitenFlue-Systems GBOwenNoch keine Bewertungen

- Alumidi: Concealed Bracket With and Without HolesDokument12 SeitenAlumidi: Concealed Bracket With and Without HolesAlex ZecevicNoch keine Bewertungen

- Screw in Plug Type Connectors HX HLDokument8 SeitenScrew in Plug Type Connectors HX HLra5tr@Noch keine Bewertungen

- Codes and Dimensions: Small Head ScrewDokument2 SeitenCodes and Dimensions: Small Head ScrewiuliandurdureanuNoch keine Bewertungen

- Type Sct25 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestDokument6 SeitenType Sct25 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestHAFIZNoch keine Bewertungen

- Alumaxi: Concealed Bracket With and Without HolesDokument10 SeitenAlumaxi: Concealed Bracket With and Without HolesAlex ZecevicNoch keine Bewertungen

- Self-Drilling Dowel: Steel and AluminumDokument6 SeitenSelf-Drilling Dowel: Steel and AluminumLucas SeñaNoch keine Bewertungen

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDokument1 Seite200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNoch keine Bewertungen

- StrainerDokument2 SeitenStrainermayNoch keine Bewertungen

- Kolom K2Dokument1 SeiteKolom K2Al-Fatih Kids ChannelNoch keine Bewertungen

- KOP en Technical Data SheetDokument6 SeitenKOP en Technical Data SheetmcbluedNoch keine Bewertungen

- HBS SOFTWOOD-en-technical-data-sheetDokument4 SeitenHBS SOFTWOOD-en-technical-data-sheetKenan AvdusinovicNoch keine Bewertungen

- SHIMANO 105 Front Derailleur: (2x11-Speed) Black / SilverDokument1 SeiteSHIMANO 105 Front Derailleur: (2x11-Speed) Black / SilverBrandon GomezNoch keine Bewertungen

- Kolom K1Dokument1 SeiteKolom K1Al-Fatih Kids ChannelNoch keine Bewertungen

- Details 5 of 3 StoreysDokument13 SeitenDetails 5 of 3 StoreysEdison MamintaNoch keine Bewertungen

- SBD en Technical Data SheetDokument8 SeitenSBD en Technical Data SheetJonathanFallasNoch keine Bewertungen

- Anchor Channel Typical Product Catalogue 2019.4.9 PDFDokument43 SeitenAnchor Channel Typical Product Catalogue 2019.4.9 PDFSultana KhanumNoch keine Bewertungen

- Timken Ball Bearing Catalog 10734Dokument126 SeitenTimken Ball Bearing Catalog 10734محمد داخلNoch keine Bewertungen

- Bandes Sika PVCDokument4 SeitenBandes Sika PVCyazid BankaiNoch keine Bewertungen

- Timken Ball Bearings CatalogDokument126 SeitenTimken Ball Bearings Catalogmohananc67Noch keine Bewertungen

- TW10 Flanged Thermowell: Part of Your BusinessDokument2 SeitenTW10 Flanged Thermowell: Part of Your BusinessogyriskyNoch keine Bewertungen

- Asia Range Electrical FastenersDokument28 SeitenAsia Range Electrical FastenersFarah Diba Pos-PosNoch keine Bewertungen

- Large Diameter: Couplings OD355.6 - 816Dokument4 SeitenLarge Diameter: Couplings OD355.6 - 816Joh SongthamNoch keine Bewertungen

- Flexible Rubber Joint: Design Connection Face To Face Marking Tests Corrosion ProtectionDokument4 SeitenFlexible Rubber Joint: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNoch keine Bewertungen

- SIka Water Bar - 05Dokument3 SeitenSIka Water Bar - 05jb.dqaNoch keine Bewertungen

- DesignManual Vol31 Steel StudDokument32 SeitenDesignManual Vol31 Steel StudAnas AsshiddiqiNoch keine Bewertungen

- DIN 2080 enDokument45 SeitenDIN 2080 enalphatoolsNoch keine Bewertungen

- Boddingtons CatalogueDokument83 SeitenBoddingtons CatalogueAnonymous 1dCz409sNoch keine Bewertungen

- Rudder Sample DrawingDokument6 SeitenRudder Sample DrawinggksahaNoch keine Bewertungen

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Dokument1 SeiteASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Anonymous 0x2pwMCWgjNoch keine Bewertungen

- Buchanan 200 Series-19-20Dokument2 SeitenBuchanan 200 Series-19-20JuanPerezRooneyNoch keine Bewertungen

- Ridge Vent Connector: Soil and Vent ComponentsDokument1 SeiteRidge Vent Connector: Soil and Vent ComponentsBoraNoch keine Bewertungen

- Inova Ball Joints JBDokument2 SeitenInova Ball Joints JBSympatyagaNoch keine Bewertungen

- Firepro Ductrock Slab Installation GuideDokument6 SeitenFirepro Ductrock Slab Installation GuideKelvin JinNoch keine Bewertungen

- C 015 Arch Shade B مظلة سيارات قوسDokument4 SeitenC 015 Arch Shade B مظلة سيارات قوسGameTasticNoch keine Bewertungen

- PVC HorDokument2 SeitenPVC HorJackyNoch keine Bewertungen

- Full Threaded Screw With Cylindrical Head: TensionDokument24 SeitenFull Threaded Screw With Cylindrical Head: TensionSichen DongNoch keine Bewertungen

- ZP00707 GB 2Dokument40 SeitenZP00707 GB 2grandtrading.egNoch keine Bewertungen

- Type Sct50 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestDokument6 SeitenType Sct50 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestHAFIZNoch keine Bewertungen

- T05™ Series: Replacement Seals To Suit Flygt and Grindex PumpsDokument24 SeitenT05™ Series: Replacement Seals To Suit Flygt and Grindex PumpsAlex VarNoch keine Bewertungen

- LT21665Dokument2 SeitenLT21665Manuel RoblesNoch keine Bewertungen

- 5-3 AC 121 - Fixed GrilleDokument1 Seite5-3 AC 121 - Fixed GrilleGopi nathNoch keine Bewertungen

- Heat Exchanger 521.49Dokument1 SeiteHeat Exchanger 521.49dejanpecicNoch keine Bewertungen

- Temp-Pro: Thermowell CatalogDokument26 SeitenTemp-Pro: Thermowell CatalogSaeed VuNoch keine Bewertungen

- Ylon Insert: Revised 406Dokument6 SeitenYlon Insert: Revised 406williaqNoch keine Bewertungen

- Timken Ball Bearing Catalog 10734Dokument126 SeitenTimken Ball Bearing Catalog 10734NeoNoch keine Bewertungen

- Cable Chains in Bright Zinc Plated Steel: Inner Height (D) 32 MMDokument2 SeitenCable Chains in Bright Zinc Plated Steel: Inner Height (D) 32 MMboba78Noch keine Bewertungen

- En 112231 R Tfix 8S - Universal - Facade - FixinDokument3 SeitenEn 112231 R Tfix 8S - Universal - Facade - FixindomoozoologNoch keine Bewertungen

- Lovair - L-990 (991 992) Sensor Tap - Parts ListDokument1 SeiteLovair - L-990 (991 992) Sensor Tap - Parts ListNguyên Trịnh CaoNoch keine Bewertungen

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleVon EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleBewertung: 5 von 5 Sternen5/5 (1)

- Tower - 3D Model Builder 8.4 - x64 Edition Radimpex - WWW - Radimpex.rs Registered To Milivoj IlibasicDokument18 SeitenTower - 3D Model Builder 8.4 - x64 Edition Radimpex - WWW - Radimpex.rs Registered To Milivoj Ilibasicmilivoj ilibasicNoch keine Bewertungen

- Hexagonal Head Bolt: Codes and DimensionsDokument5 SeitenHexagonal Head Bolt: Codes and Dimensionsmilivoj ilibasicNoch keine Bewertungen

- Epo-Fix Plus: High-Performance Epoxy Chemical AnchorDokument3 SeitenEpo-Fix Plus: High-Performance Epoxy Chemical Anchormilivoj ilibasicNoch keine Bewertungen

- Hexagonal Head Bolt: Codes and DimensionsDokument1 SeiteHexagonal Head Bolt: Codes and Dimensionsmilivoj ilibasicNoch keine Bewertungen

- DJURASEVIC Povrsine PDFDokument8 SeitenDJURASEVIC Povrsine PDFmilivoj ilibasicNoch keine Bewertungen

- Argument Essay 1Dokument5 SeitenArgument Essay 1api-549207860Noch keine Bewertungen

- A434 03Dokument1 SeiteA434 03asepoNoch keine Bewertungen

- Automated Car Jack PDFDokument3 SeitenAutomated Car Jack PDFakashlogic100% (1)

- Aluminium and CorrosionDokument12 SeitenAluminium and CorrosionMehman NasibovNoch keine Bewertungen

- Impact TestDokument7 SeitenImpact TestChukkaNoch keine Bewertungen

- Astm D 2014 - 97 (2010)Dokument5 SeitenAstm D 2014 - 97 (2010)alexander guerraNoch keine Bewertungen

- Foundations of College Chemistry 13th Edition Hein Arena Test BankDokument6 SeitenFoundations of College Chemistry 13th Edition Hein Arena Test BankCharles Davis100% (33)

- Waste Heat Recovery at Compressor Stations: The Path Towards Novel and High-Impact Technologies and Their ImplementationDokument33 SeitenWaste Heat Recovery at Compressor Stations: The Path Towards Novel and High-Impact Technologies and Their ImplementationraaaghaffarNoch keine Bewertungen

- Sb70491atosh9 PDFDokument1 SeiteSb70491atosh9 PDFCarlosNoch keine Bewertungen

- 5000M MotionSetup 70000420C Nov09 PDFDokument32 Seiten5000M MotionSetup 70000420C Nov09 PDFspeedtunningNoch keine Bewertungen

- Fibre Reinforced Concrete PDFDokument6 SeitenFibre Reinforced Concrete PDFAref AbadelNoch keine Bewertungen

- Conectores 15000 Psi MS-02-335Dokument10 SeitenConectores 15000 Psi MS-02-335Pierre MejiaNoch keine Bewertungen

- Samsung Compressor: Il-Free Centrifugal Air Compressor M/SM100/SME SeriesDokument11 SeitenSamsung Compressor: Il-Free Centrifugal Air Compressor M/SM100/SME SeriesSharad KokateNoch keine Bewertungen

- Rev.02 Panther T8 Parts CatalogDokument184 SeitenRev.02 Panther T8 Parts CatalogJovita UvijindiaNoch keine Bewertungen

- Electric Conductivity (EC) MeterDokument3 SeitenElectric Conductivity (EC) MeterThanh NguyênNoch keine Bewertungen

- Operations Manual Tracks PDFDokument59 SeitenOperations Manual Tracks PDFELMERNoch keine Bewertungen

- Aqualine SinglesoftenerDokument2 SeitenAqualine Singlesoftenernermeen ahmedNoch keine Bewertungen

- CP Repair Tools and EquipmentDokument68 SeitenCP Repair Tools and EquipmentJay R BallonNoch keine Bewertungen

- 01 July 2023 Price List Fan For PDFDokument10 Seiten01 July 2023 Price List Fan For PDFadnanchem16Noch keine Bewertungen

- Fundamentals of Metal Casting (Richard A. Flinn)Dokument336 SeitenFundamentals of Metal Casting (Richard A. Flinn)Formula Firestorm100% (1)

- Fisher GX Control Valve and Actuator SystemDokument36 SeitenFisher GX Control Valve and Actuator Systemsugeng wahyudiNoch keine Bewertungen

- ASTM For InsulationDokument4 SeitenASTM For InsulationTheOne YasirNoch keine Bewertungen

- She 29Dokument124 SeitenShe 29fitashah2634Noch keine Bewertungen

- Southwire Mining Product CatalogDokument32 SeitenSouthwire Mining Product Catalogvcontrerasj72Noch keine Bewertungen

- ROLLING MILL REPORT RevampDokument31 SeitenROLLING MILL REPORT RevamprohitNoch keine Bewertungen

- MdriveDokument104 SeitenMdriveAlejandroSosaVieraNoch keine Bewertungen