Beruflich Dokumente

Kultur Dokumente

Gas Cutting Work: Hazard Identification and Risk Assessment

Hochgeladen von

Achalere Shekhar KashinathOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gas Cutting Work: Hazard Identification and Risk Assessment

Hochgeladen von

Achalere Shekhar KashinathCopyright:

Verfügbare Formate

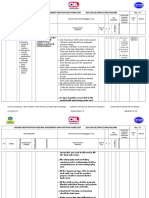

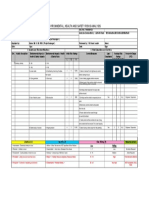

NRP PROJECTS PVT LTD

Hazard Identification and Risk Assessment

GAS CUTTING WORK

Project : Report No :

Client : Location :

Consultant : Date :

HIRA Meeting Attendance Sheet

Sl.No Name Designation Signature Remarks

General Safety Precautions / Instructions.

1. Adhere strictly to work permit System and HSE Manual and HSE Regulations.

2. Follow NRP Emergency Procedure, identify the escape routes and be aware about the nearest and safest Marshaling Point.

3. Conduct a Tool Box Talk at the workplace prior to commencement of work and discuss the Task Risk Assessment content on daily basis.

4. Ensure the use of Job Specific PPE's at all the time & Maintain good housekeeping on daily basis before, during and after the work.

5. Close supervision at all locations and activities to ensure compliance with Method Statement. Only Competent personnel shall be involved in the activity

6. HSE Officer/Assistant shall be available at all times at the workplace area.

7. In case of any emergency Inform to Tel. No.

8. Approved Job procedure and JSA shall be maintained along with the permit.

9. Ensure that first aid box and fire extinguishers are available at Site.

10. Spotlights on HSE with regards to activities performed shall be displayed on site bulletin board and must be followed strictly.

11. Check Tools & equipment's for soundness prior to use and All Electrical/mechanical tools& Equipment must be certified/approved

12. Frequent Joint Site visit shall be conducted by all concerns to ensure Safe working environment and good housekeeping.

13. Appropriate reliever shall be assigned in the absence of key persons.

Risk Rating Risk

S.No Activity Hazards / Causes Effects Risk Rating Existing Controls Additional Control Rating

S P R S P R

1 Gas 1.Back 1. 3 C M 1. Cylinder shall be kept upright 1 C L Emergency vehicle should be L

Cutting Work fire Burn Injury position provided

Tools & 2.Fire/ Explosion 2. Property 2. Combustible materials to be removed from Cylinders should not be placed

Equipments damage the workplace in direct sunlight

3. High pressurized

1.DA Cylinder cylinders 3. Flash back arresters must be provided on Empty cylinders shall not be

both side(cylinder & cutting torch) placed at site

2. Oxygen

cylinder 4. Fire extinguisher shall be provided

3. Regulator 5. Torch condition to be checked

4. Hoses 6. Regulators condition to be good

5. Cutting 7. Cylinder trolley should be provided to keep

torch and shift the cylinders.

8. Hoses condition to be good.Leakage test

shall be conducted.

9. Slandered color hoses to be used(Red-DA,

Black/Blue-O2)

10. Cylinders should be stored in ventilated

area

11. Empty and filled cylinders shall be

segregated

12. Fire blanket to be used

13 Face shield/Goggles shall be worn

14 Leather hand gloves Shall be worn

15. Work should be carried under adequate

supervision

16. First aid box should be provided at site

RISK POTENTIAL MATRIX QUALITATIVE

PROBABILITY

A B C D E

Frequent / Almost

Severity People Assets Environment Reputation Rare Possible Likely Often

certain

Multiple fatalities or

Extensive Massive International

5.Catastrophic permanent total damage. effect. impact. HIGH

disability

Single fatality or

Major National

4. Severe permanent total Major effect.

disability damage. impact.

Major injury or health Localized Considerable

3. Critical

effects

Local damage.

effect. impact. MEDIUM

Minor injury or health Minor

2. Marginal effects damage. Minor effect. Minor impact.

LOW

Slight injury or health

1. Negligible Slight damage. Slight effect. Slight impact.

effects

Das könnte Ihnen auch gefallen

- HDD (Horizontal Directional Drilling) WORK: Project: Report No: Client: Location: Consultant: DateDokument7 SeitenHDD (Horizontal Directional Drilling) WORK: Project: Report No: Client: Location: Consultant: DateAchalere Shekhar Kashinath80% (10)

- Risk AssessDokument5 SeitenRisk AssessAnonymous iI88Lt0% (1)

- Hydro Test (Rev 01)Dokument4 SeitenHydro Test (Rev 01)Binay100% (5)

- 03-HIRA For Welding Work .Dokument2 Seiten03-HIRA For Welding Work .archit kamat89% (9)

- Hydro Test Risk Assessment CS TankDokument3 SeitenHydro Test Risk Assessment CS TankAvinash Rai100% (3)

- Risk Assess JSA Bolt Tightening 012Dokument7 SeitenRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- Job Hazard Analysis of Site SURVEYINGDokument1 SeiteJob Hazard Analysis of Site SURVEYINGYogesh Gowda100% (1)

- Job Safety Analysis Sheet: Electrical IsolationDokument1 SeiteJob Safety Analysis Sheet: Electrical IsolationLal Dhwoj100% (2)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDokument2 SeitenJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- Scrap Material Cutting, Handling & Loading Jha - 2Dokument3 SeitenScrap Material Cutting, Handling & Loading Jha - 2Dwitikrushna Rout100% (5)

- HIRA For Laying of PipelineDokument33 SeitenHIRA For Laying of PipelineVineet Agrawal100% (4)

- JSA For WrappingDokument6 SeitenJSA For WrappingMohammed Minhaj100% (2)

- Jsa For DG Operation PDFDokument5 SeitenJsa For DG Operation PDFajmalvk100% (4)

- WMS-02 - Material Unloading & Shifting by Farana & MannuallyDokument5 SeitenWMS-02 - Material Unloading & Shifting by Farana & MannuallySufiyan Khedekar100% (2)

- All HiraDokument40 SeitenAll Hirarameese muhammed100% (1)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDokument5 SeitenJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNoch keine Bewertungen

- JSA-Vertical Load On Test Pile - REV 0Dokument8 SeitenJSA-Vertical Load On Test Pile - REV 0Sanjay Kumar GhadaiNoch keine Bewertungen

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Dokument3 SeitenHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- Job Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Dokument7 SeitenJob Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Sanjay Kumar GhadaiNoch keine Bewertungen

- JSA SK Erection DismantlingDokument1 SeiteJSA SK Erection DismantlingSamuel Hugos100% (4)

- HIRA & EAI For Installation of LT Supply StationDokument12 SeitenHIRA & EAI For Installation of LT Supply StationDEBASISH KHADANGA100% (1)

- Hazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted CraneDokument1 SeiteHazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted Cranesaravanan .b90% (10)

- JSA of Pipe Unloading.Dokument2 SeitenJSA of Pipe Unloading.vijay kumar singh100% (1)

- 40 JHA On Welding and Gas Cutting PDFDokument4 Seiten40 JHA On Welding and Gas Cutting PDFSunil apexNoch keine Bewertungen

- Master Hazard Identification & Risk Assesment (Hira) : Document No: Rev. 0 DateDokument2 SeitenMaster Hazard Identification & Risk Assesment (Hira) : Document No: Rev. 0 DateHARSHADNoch keine Bewertungen

- JHA PlumberDokument3 SeitenJHA PlumberEko Susanto100% (1)

- Dismantling of WallDokument1 SeiteDismantling of WallChandruNoch keine Bewertungen

- Hazard Identification and Risk Assessment For Pipe LoweringDokument4 SeitenHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Hazard Identification and Risk Assessment For Pipe LoweringDokument4 SeitenHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Hazard Identification and Risk Assessment For Pipe LoweringDokument4 SeitenHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Confined Space Entry For Painting Inside PontoonDokument4 SeitenConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathNoch keine Bewertungen

- Kirks Fire Investigation Brady Fire 7th Edition Ebook PDFDokument61 SeitenKirks Fire Investigation Brady Fire 7th Edition Ebook PDFbruce.glinski869100% (47)

- GB 8624-2006 Burn CharacDokument45 SeitenGB 8624-2006 Burn Charactiruyam@gmail.comNoch keine Bewertungen

- Scrap Material Handling & Loading Jha - 1Dokument2 SeitenScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- 6.chain Pulley BlockDokument2 Seiten6.chain Pulley BlockFrancis Vinoj75% (4)

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDokument6 SeitenPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNoch keine Bewertungen

- JSA Earthpit Construction GeneralDokument4 SeitenJSA Earthpit Construction Generalmukka88Noch keine Bewertungen

- JSA Format NEW Equipment ErectionDokument5 SeitenJSA Format NEW Equipment Erectionsakthi venkatNoch keine Bewertungen

- HIRA, TCS-ACP Sheet FixingDokument2 SeitenHIRA, TCS-ACP Sheet FixingGowtham Kishore75% (4)

- JSA For Installation of Fire PumpsDokument2 SeitenJSA For Installation of Fire Pumpsperquino oasan100% (3)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Reinforcement WorkDokument2 SeitenJob Safety Analysis (Jsa) : Title of Activity / Work: Reinforcement Workba ratnaparkhe67% (3)

- Mivan Risk AssessmentDokument3 SeitenMivan Risk AssessmentBineeshNoch keine Bewertungen

- Jsa For Operating A BobcatDokument2 SeitenJsa For Operating A Bobcatsoubhagya100% (2)

- 12-JSA Pipe Erection Work - Existing Pipe RackDokument4 Seiten12-JSA Pipe Erection Work - Existing Pipe RackSwaminathan ThayumanavanNoch keine Bewertungen

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDokument5 SeitenJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (3)

- Jsa For Radiography WorkDokument2 SeitenJsa For Radiography WorkVipul ShankarNoch keine Bewertungen

- Dye Penetrant Test (DPT) JsaDokument3 SeitenDye Penetrant Test (DPT) JsaDautsons Infratech75% (4)

- Job Safety Analysis: Page 1 of 4Dokument4 SeitenJob Safety Analysis: Page 1 of 4RakeshkasarlaNoch keine Bewertungen

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDokument9 SeitenJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Grinding ActivityDokument1 SeiteGrinding ActivityKrishna Patil100% (2)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDokument5 SeitenThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNoch keine Bewertungen

- JSA For DuctDokument13 SeitenJSA For DuctRakeshkasarlaNoch keine Bewertungen

- JSA Hydrant Pipe LineDokument7 SeitenJSA Hydrant Pipe Lineakshay pradeepNoch keine Bewertungen

- JSA - Hydro-Testing of Pipe & EquipmentDokument1 SeiteJSA - Hydro-Testing of Pipe & EquipmentRajuNoch keine Bewertungen

- Jsa For Applying Bituminous Roof Treatment On BuildingsDokument3 SeitenJsa For Applying Bituminous Roof Treatment On BuildingsMohammed Minhaj100% (1)

- HIRA - Height WorkDokument3 SeitenHIRA - Height WorkHiralal Pattanayak100% (2)

- Jsa Slip FormDokument5 SeitenJsa Slip Formputrasejahtra50% (2)

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDokument12 SeitenUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- DLF PCC HiraDokument6 SeitenDLF PCC HiraskfahimuddinNoch keine Bewertungen

- JSA For Bobcat OperationDokument2 SeitenJSA For Bobcat Operationwahyu nugrohoNoch keine Bewertungen

- HIRA - Carpentry Work-018Dokument8 SeitenHIRA - Carpentry Work-018Satya Naidu100% (1)

- JSA For HILTIDokument3 SeitenJSA For HILTIMohammed Minhaj100% (1)

- Hazard Identification and Risk Assessment For Grit Blasting & CoatingDokument4 SeitenHazard Identification and Risk Assessment For Grit Blasting & CoatingAchalere Shekhar KashinathNoch keine Bewertungen

- HIRA of Gas Cutting Work.Dokument1 SeiteHIRA of Gas Cutting Work.Gyanendra SrivastavaNoch keine Bewertungen

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokument2 SeitenJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNoch keine Bewertungen

- RA HSE 12 001 Process Rev03Dokument3 SeitenRA HSE 12 001 Process Rev03zarni77Noch keine Bewertungen

- Hazard Identification and Risk Assessment For Grit Blasting & CoatingDokument4 SeitenHazard Identification and Risk Assessment For Grit Blasting & CoatingAchalere Shekhar KashinathNoch keine Bewertungen

- (Lea) Industrial Security ManagementDokument32 Seiten(Lea) Industrial Security ManagementShania MadridondoNoch keine Bewertungen

- OMM GR1605说明书 英文20190122Dokument85 SeitenOMM GR1605说明书 英文20190122Bahrudin Lingai100% (1)

- MSDS Jasmine Perfume OilDokument5 SeitenMSDS Jasmine Perfume OilSavina IvanovaNoch keine Bewertungen

- SprinklersDokument2 SeitenSprinklersMohamed El MorsyNoch keine Bewertungen

- Protective TextilesDokument6 SeitenProtective TextilesKhubab ShakerNoch keine Bewertungen

- Week 11Dokument82 SeitenWeek 11Ska dooshNoch keine Bewertungen

- Pranat Combustion and FlameDokument21 SeitenPranat Combustion and FlameSanket KheriaNoch keine Bewertungen

- M SF 142 PDFDokument43 SeitenM SF 142 PDFRezaNoch keine Bewertungen

- 181 213 PDFDokument340 Seiten181 213 PDFRune gNoch keine Bewertungen

- Skeptics Guide To The ParanormalDokument270 SeitenSkeptics Guide To The ParanormalBahadur Comrade100% (8)

- Research The Occupants Safe Egress of Underground Pedestrian Street Based On The Analysis of Fire Smoke MovementDokument7 SeitenResearch The Occupants Safe Egress of Underground Pedestrian Street Based On The Analysis of Fire Smoke MovementJaponec PicturesNoch keine Bewertungen

- Medical Store ManagementDokument54 SeitenMedical Store ManagementhargovindpandeyNoch keine Bewertungen

- Survive This!! Nightworld Items and WeaponsDokument32 SeitenSurvive This!! Nightworld Items and Weaponspegore9448Noch keine Bewertungen

- SPE Paper 69679Dokument0 SeitenSPE Paper 69679Nicholas GarrettNoch keine Bewertungen

- Sds 401 enDokument7 SeitenSds 401 enkamals55Noch keine Bewertungen

- Dirr G12 W11-W19Dokument44 SeitenDirr G12 W11-W19Maverick Flare50% (2)

- Industrial Spray-Applied Fireproofing: Isolatek Type M-II/P Cafco Fendolite M-II/PDokument2 SeitenIndustrial Spray-Applied Fireproofing: Isolatek Type M-II/P Cafco Fendolite M-II/PCIAKNoch keine Bewertungen

- Assignment 3Dokument9 SeitenAssignment 3PUBG SlayerNoch keine Bewertungen

- Material Safety Data Sheet: 1 Identification of SubstanceDokument5 SeitenMaterial Safety Data Sheet: 1 Identification of SubstanceCOKDEHNoch keine Bewertungen

- Catalog - Fire Rated Paint - Cementitious PaintDokument4 SeitenCatalog - Fire Rated Paint - Cementitious PaintCost RootsNoch keine Bewertungen

- Lesson Plan: Trade: Welder Module/Unit: 1Dokument2 SeitenLesson Plan: Trade: Welder Module/Unit: 1Amar jit mohantyNoch keine Bewertungen

- Skum Silv-Ex G F201132 - FDS14121 0214 LR PDFDokument2 SeitenSkum Silv-Ex G F201132 - FDS14121 0214 LR PDFAhmed El Sayed SalamaNoch keine Bewertungen

- Excel Chapter 1 Lab 1Dokument5 SeitenExcel Chapter 1 Lab 1Alberto PreciadoNoch keine Bewertungen

- CTM502 - 31MAY07 - PWT4.5and6.8TierIII - GBDokument938 SeitenCTM502 - 31MAY07 - PWT4.5and6.8TierIII - GBGermán100% (2)

- Service Manual: M154/M155/M174/M175/ A0A7/M287/M0BBDokument184 SeitenService Manual: M154/M155/M174/M175/ A0A7/M287/M0BBAndrey KhodanitskiNoch keine Bewertungen

- MSDS015 001 FormalinDokument14 SeitenMSDS015 001 FormalinKeslingSanitasiNoch keine Bewertungen

- The Smarter Way of Fire Fighting: - Water Mist SystemsDokument16 SeitenThe Smarter Way of Fire Fighting: - Water Mist SystemsAhmed El Sayed SalamaNoch keine Bewertungen

- PPR Pipe InfoDokument5 SeitenPPR Pipe InfoAlex DulayNoch keine Bewertungen