Beruflich Dokumente

Kultur Dokumente

HEMPADUR MULTI-STRENGTH 35530 Black

Hochgeladen von

Ruby Faith EspinosaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HEMPADUR MULTI-STRENGTH 35530 Black

Hochgeladen von

Ruby Faith EspinosaCopyright:

Verfügbare Formate

Product Data

HEMPADUR MULTI-STRENGTH 35530

35530 : BASE 35539 : CURING AGENT 95530

Description: HEMPADUR MULTI-STRENGTH 35530 is a solvent-free, two-component, high-build, polyamine cured

epoxy paint, which cures to a coating with good resistance to fresh water, sea water, crude oil, and to

abrasion.

Applicable in thick coats by standard heavy duty airless spray equipment.

Harmless to grain cargo.

Recommended use: As a heavy duty coating on steel exposed to abrasion where solvent-free materials are required. Full

colour retention will be of secondary importance.

If solvent containing paints are accepted, HEMPADUR MULTI-STRENGTH 45751 substitutes.

As a lining in potable water tanks and pipelines. Please see Certificates/Approvals.

For application in warm climates. Please see APPLICATION CONDITIONS overleaf.

Service temperature: Maximum, dry exposure only: 140°C/284°F.

In water (no temperature gradient): 35°C/95°F

Certificates/Approvals: Approved by WRAS for potable water up to 23°C/73°F.

Certified by NSF International to NSF/ANSI standard 61- Drinking Water System Components - Health

Effects. Please consult http://info.nsf.org/Certified/PwsComponents/, Certified Products & Systems for

detailed information.

Complies with EU Directive 2004/42/EC: subcategory j.

Availability: Part of Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Shade nos/Colours: 19990 / Black

Finish: Semi-gloss

Volume solids, %: 100

Theoretical spreading rate: 3.3 m2/l [132.3 sq.ft./US gallon] - 300 micron/12 mils

Flash point: 100 °C [212 °F]

Specific gravity: 1.3 kg/litre [11.2 lbs/US gallon]

Surface-dry: 6 hour(s) 20°C/68°F

Through-dry: 15 hour(s) 20°C/68°F

Fully cured: 7 day(s) 20°C/68°F

VOC content: 9 g/l [0.1 lbs/US gallon]

.

The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

APPLICATION DETAILS:

Version, mixed product: 35530

Mixing ratio: BASE 35539 : CURING AGENT 95530

3 : 1 by volume

Stir CURING AGENT before adding it to the BASE.

Application method: Airless spray / Brush

Thinner (max.vol.): Do not dilute. (Consult the separate APPLICATION INSTRUCTIONS)

Pot life: 1 approx. hour(s) 20°C/68°F (Consult the separate APPLICATION INSTRUCTIONS)

Nozzle orifice: 0.019 - 0.031 "

Nozzle pressure: >250 bar [>3625 psi]

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: HEMPEL'S TOOL CLEANER 99610

Indicated film thickness, dry: 300 micron [12 mils] see REMARKS overleaf

Indicated film thickness, wet: 300 micron [12 mils]

Overcoat interval, min: see REMARKS overleaf

Overcoat interval, max: see REMARKS overleaf

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Safety Data Sheets and follow all local or national safety regulations.

Date of issue: July 2016 Page: 1/2

Product Data

HEMPADUR MULTI-STRENGTH 35530

SURFACE PREPARATION: New steel: Remove oil and grease etc. thoroughly with suitable detergent. Remove salts and other

contaminants by high pressure fresh water cleaning. Abrasive blasting to near white metal Sa 2½ (ISO

8501-1:2007) with a surface profile corresponding to Rugotest No. 3, BN10a, Keane-Tator Comparator

3.0 G/S, or ISO Comparator Rough Medium (G). Apply immediately after cleaning. All damage of

shopprimer and contamination from storage and fabrication should be thoroughly cleaned prior to

overcoating.

Repair and maintenance: Remove oil and grease etc. thoroughly with suitable detergent. Remove

salts and other contaminants by high pressure fresh water cleaning. Old steel surfaces having been

exposed to salt water, excessive amounts of salt residues in pittings may call for abrasive blasting, high

pressure fresh water hosing, drying, and finally, dry abrasive blasting again.

Concrete: Remove slip agent and other possible contaminants by emulsion washing followed by high

pressure hosing with fresh water. Remove scum layer and loose matter to a hard, rough and uniform

surface, preferably by abrasive blasting, possibly by other mechanical treatment or acid etching. Seal

surface with suitable sealer, as per relevant painting specification.

APPLICATION CONDITIONS: Apply only on a dry and clean surface with a temperature above the dew point to avoid condensation.

Use only where application and curing can proceed at temperatures above: 10°C/50°F. The

temperature of paint itself should be 15°C/59°F or above. In-can temperature of the paint should

preferably be below 25°C/77°F. Curing requires a relative humidity of: maximum 85%. For application

in warm climates, HEMPADUR MULTI-STRENGTH 45751 may preferably replace HEMPADUR MULTI-

STRENGTH 35530 as a heavy duty coating. For potable water tanks and pipes please check local

product assortment.

PRECEDING COAT: None, or as per specification. Recommended systems are: HEMPADUR SEALER 05990 or

HEMPADUR 15590 (According to separate APPLICATION INSTRUCTIONS)

SUBSEQUENT COAT: None, or as per specification. Recommended systems are: HEMPADUR or HEMPATHANE

REMARKS:

Certificates/Approvals: NSF certification applies to the product as well as production site – at present this NSF certificate is

valid only for paint material produced at following Hempel factories in: Hempel (USA) Inc., Conroe.

The WRAS approval is valid once the final coating has cured for at least the following number of days:

7 days (20°C/68°F).

Weathering/service temperatures: The natural tendency of epoxy coatings to chalk in outdoor exposure and to become more sensitive to

mechanical damage and chemical exposure at elevated temperatures is also reflected in this product.

Application(s): Disinfection by for instance chlorination can be very aggressive towards the coating and separate

instructions are available.

Film thicknesses/thinning: May be specified in another film thickness than indicated depending on purpose and area of use. This

will alter spreading rate and may influence drying time and overcoating interval. Normal range dry is:

200-300 micron/8-12 mils

Overcoating: Overcoating intervals related to later conditions of exposure: If the maximum overcoating interval is

exceeded, roughening of the surface is necessary to ensure intercoat adhesion.

Before overcoating after exposure in contaminated environment, clean the surface thoroughly with high

pressure fresh water hosing and allow drying.

A specification supersedes any guideline overcoat intervals indicated in the table.

Environment Atmospheric, medium

Surface temperature: 10°C (50°F) 20°C (68°F) 30°C (86°F)

Min Max Min Max Min Max

HEMPADUR 40 h 12½ d 16 h 5d 8h 2½ d

Environment Immersion

HEMPADUR 40 h 12½ d 16 h 5d 8h 2½ d

NR = Not Recommended, Ext. = Extended, m = minute(s), h = hour(s), d = day(s)

Overcoating note: Stir the individual BASE and CURING AGENT thoroughly before mixing and again after mixing until a

uniformly coloured mixture is obtained. If colour stability is requested for exposure to sunshine, it is

recommended to topcoat with eg HEMPATHANE TOPCOAT 55210.

Potable water tanks: See APPLICATION INSTRUCTIONS, as to time before taking into use and post

treatment of coated surfaces to be in contact with potable water.

Note: HEMPADUR MULTI-STRENGTH 35530 For professional use only.

ISSUED BY: HEMPEL A/S 3553010500

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet

represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions

of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed

in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said

GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Date of issue: July 2016 Page: 2/2

Das könnte Ihnen auch gefallen

- Key Nursing SkillsDokument359 SeitenKey Nursing Skillsmordanga100% (6)

- Pre Commissioning Check List of GeneratorDokument26 SeitenPre Commissioning Check List of GeneratorSUROHMAN ROHMANNoch keine Bewertungen

- ASTM Standards For WoodDokument7 SeitenASTM Standards For WoodarslanengNoch keine Bewertungen

- Geotextiles and Geomembranes HandbookVon EverandGeotextiles and Geomembranes HandbookT.S. IngoldBewertung: 5 von 5 Sternen5/5 (1)

- Gas Sweetening and Processing Field ManualVon EverandGas Sweetening and Processing Field ManualBewertung: 4 von 5 Sternen4/5 (7)

- Detailers Dictionary Volume 2: The Industry StandardVon EverandDetailers Dictionary Volume 2: The Industry StandardNoch keine Bewertungen

- Tips To Diagnose & Address Common Horse AilmentsDokument6 SeitenTips To Diagnose & Address Common Horse AilmentsMark GebhardNoch keine Bewertungen

- Hempadur 15570Dokument2 SeitenHempadur 15570Edwin HarrisNoch keine Bewertungen

- Energy Savings at DCL PDFDokument83 SeitenEnergy Savings at DCL PDFnsprasad88100% (1)

- Product Data: Hempel'S 15asgDokument2 SeitenProduct Data: Hempel'S 15asgwahyu0% (1)

- PDS en-GB 45751Dokument2 SeitenPDS en-GB 45751Anuar SalehNoch keine Bewertungen

- 200 State Council Members 2010Dokument21 Seiten200 State Council Members 2010madhu kanna100% (1)

- Proposed Temporary FacilitiesDokument2 SeitenProposed Temporary FacilitiesRuby Faith EspinosaNoch keine Bewertungen

- Hempadur 85531 PDFDokument2 SeitenHempadur 85531 PDFvitharvan0% (1)

- Nomenclature Practice ProblemsDokument4 SeitenNomenclature Practice ProblemsMax DavidsonNoch keine Bewertungen

- Product Data: Hempadur Multi-Strength 35530Dokument2 SeitenProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarNoch keine Bewertungen

- PDS Hempadur 35560 en-GBDokument2 SeitenPDS Hempadur 35560 en-GBErwin MalmsteinNoch keine Bewertungen

- Pds Hempadur 85671 En-GbDokument2 SeitenPds Hempadur 85671 En-GbPrabath Nilan GunasekaraNoch keine Bewertungen

- Hempadur 85671Dokument2 SeitenHempadur 85671EkoAndriAntoNoch keine Bewertungen

- Pds Hempadur 85671Dokument2 SeitenPds Hempadur 85671Namta GeorgeNoch keine Bewertungen

- PDS HEMPADUR 85671 en-GB PDFDokument2 SeitenPDS HEMPADUR 85671 en-GB PDFMohamed Farhan B PositiveNoch keine Bewertungen

- PDS Hempadur 85671 en-GBDokument2 SeitenPDS Hempadur 85671 en-GBfaisalfaiNoch keine Bewertungen

- Product Data: HEMPADUR 85671Dokument2 SeitenProduct Data: HEMPADUR 85671EngTamerNoch keine Bewertungen

- PDS Hempadur Multi-Strength 45753 en-GBDokument2 SeitenPDS Hempadur Multi-Strength 45753 en-GBJosip LasanNoch keine Bewertungen

- Hempadur Multi-Strength GF 35870 PDFDokument3 SeitenHempadur Multi-Strength GF 35870 PDFAnuar SalehNoch keine Bewertungen

- PDS Hempadur Hi-Build 45200 en-GBDokument2 SeitenPDS Hempadur Hi-Build 45200 en-GBvitharvanNoch keine Bewertungen

- PDS Hempadur 85671 en-GBDokument3 SeitenPDS Hempadur 85671 en-GBvitharvanNoch keine Bewertungen

- MS GF 35870 en-GBDokument2 SeitenMS GF 35870 en-GBLinnie McleodNoch keine Bewertungen

- Hempadur Quattro InglesDokument3 SeitenHempadur Quattro InglesElizabeth Maria Bazán MoralesNoch keine Bewertungen

- Pds Hempadur 35900 En-GbDokument2 SeitenPds Hempadur 35900 En-Gbluisbarrios104Noch keine Bewertungen

- Hempadur Primer 15300Dokument3 SeitenHempadur Primer 15300vitharvanNoch keine Bewertungen

- Pds Hempadur Glass Flake 35851 En-GbDokument2 SeitenPds Hempadur Glass Flake 35851 En-GbIlham NugrohoNoch keine Bewertungen

- PDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBDokument2 SeitenPDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBEli KhawNoch keine Bewertungen

- Product Data: HEMPADUR 45143Dokument2 SeitenProduct Data: HEMPADUR 45143JoaoNoch keine Bewertungen

- PDS HEMPATHANE FAST DRY 55750 en-GBDokument2 SeitenPDS HEMPATHANE FAST DRY 55750 en-GBEli KhawNoch keine Bewertungen

- 151SGDokument2 Seiten151SGdcsamaraweeraNoch keine Bewertungen

- PDS Hempatex Hi-Build 46330 en-GBDokument2 SeitenPDS Hempatex Hi-Build 46330 en-GBSARAVANANoch keine Bewertungen

- PDS Hempadur Multi-Strength 35842 en-GBDokument2 SeitenPDS Hempadur Multi-Strength 35842 en-GBIfrahimNoch keine Bewertungen

- PDS Hempathane HS 55610 en-GBDokument3 SeitenPDS Hempathane HS 55610 en-GBalouisNoch keine Bewertungen

- 15553Dokument2 Seiten15553danish100% (1)

- Hempaline Prepare 130Dokument2 SeitenHempaline Prepare 130CRISTIAN SILVIU IANUCNoch keine Bewertungen

- PDS Hempathane HS 55610 en-GBDokument3 SeitenPDS Hempathane HS 55610 en-GBAnonymous HPlNDhM6ejNoch keine Bewertungen

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDokument2 SeitenHempel'S Vinyl Ester GF 35910: Description: Recommended UseSurendra KumarNoch keine Bewertungen

- Hempaprime Multi 500 Summer 45950Dokument3 SeitenHempaprime Multi 500 Summer 45950omar alkarabliehNoch keine Bewertungen

- Paint Specification HamadourDokument2 SeitenPaint Specification HamadourAbdul Majid LodhiNoch keine Bewertungen

- PDS HEMPADUR EASY 47700 en GBDokument3 SeitenPDS HEMPADUR EASY 47700 en GBharshana divankaNoch keine Bewertungen

- Hempadur 15553Dokument2 SeitenHempadur 15553EngTamerNoch keine Bewertungen

- HempadurDokument2 SeitenHempadurLuciano SalituriNoch keine Bewertungen

- Product DataDokument2 SeitenProduct DataegomoNoch keine Bewertungen

- Pds Hempadur Spray-Guard 35493 En-GbDokument2 SeitenPds Hempadur Spray-Guard 35493 En-GbKhyle Laurenz DuroNoch keine Bewertungen

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDokument2 SeitenHempel'S Vinyl Ester GF 35910: Description: Recommended UseEngTamerNoch keine Bewertungen

- PDS en-GB 16490Dokument2 SeitenPDS en-GB 16490Anuar SalehNoch keine Bewertungen

- PDS Hempadur Fast Dry 15560 en-GBDokument2 SeitenPDS Hempadur Fast Dry 15560 en-GBErwin MalmsteinNoch keine Bewertungen

- Hempathane Hs 55610 55610 En-GbDokument2 SeitenHempathane Hs 55610 55610 En-GbfaizalNoch keine Bewertungen

- Pds Hempatex Hi-Build 46410 En-GbDokument2 SeitenPds Hempatex Hi-Build 46410 En-GbMohamed ChelfatNoch keine Bewertungen

- Hempalin Enamel 52140Dokument2 SeitenHempalin Enamel 52140EngTamerNoch keine Bewertungen

- Hempel - S Zinc Primer 16490Dokument2 SeitenHempel - S Zinc Primer 16490Haryanto RNoch keine Bewertungen

- Pds Hempadur Mastic 45880 En-GbDokument3 SeitenPds Hempadur Mastic 45880 En-GbQA QCNoch keine Bewertungen

- APCS-26T HempelDokument5 SeitenAPCS-26T HempelarjunmohananNoch keine Bewertungen

- Hempadur Fast Dry 17410 En-GbDokument2 SeitenHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaNoch keine Bewertungen

- Hempadur Mastic 45881-12170Dokument3 SeitenHempadur Mastic 45881-12170Bang OchimNoch keine Bewertungen

- Pds Hempadur 85671 En-GbDokument3 SeitenPds Hempadur 85671 En-GbMario KoričanNoch keine Bewertungen

- In 1st-PDS Hempadur 15570 en-GB PDFDokument3 SeitenIn 1st-PDS Hempadur 15570 en-GB PDFdcsamaraweeraNoch keine Bewertungen

- Hempadur Mastic 45880 Product Data SheetDokument3 SeitenHempadur Mastic 45880 Product Data SheetDeepak YadavNoch keine Bewertungen

- Product DataDokument2 SeitenProduct DatapoerwntiNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionVon EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNoch keine Bewertungen

- Meo Office Profile - FinalDokument8 SeitenMeo Office Profile - FinalRuby Faith EspinosaNoch keine Bewertungen

- MilestonesDokument2 SeitenMilestonesRuby Faith EspinosaNoch keine Bewertungen

- Enhancement On Coffee Processing Facility (Roasting Machine)Dokument16 SeitenEnhancement On Coffee Processing Facility (Roasting Machine)Ruby Faith EspinosaNoch keine Bewertungen

- Drawings - Cover & FrameDokument4 SeitenDrawings - Cover & FrameRuby Faith EspinosaNoch keine Bewertungen

- Di Cover - Comparison TableDokument4 SeitenDi Cover - Comparison TableRuby Faith EspinosaNoch keine Bewertungen

- Litter Bin - Compliance StatementDokument9 SeitenLitter Bin - Compliance StatementRuby Faith EspinosaNoch keine Bewertungen

- Upvc Pipes - ComplianceDokument6 SeitenUpvc Pipes - ComplianceRuby Faith EspinosaNoch keine Bewertungen

- BMP (Class 14 - Class-17) WeldingDokument24 SeitenBMP (Class 14 - Class-17) WeldingAsesh PramanikNoch keine Bewertungen

- Respirator LangmanDokument10 SeitenRespirator LangmanSavu MalinaNoch keine Bewertungen

- Showalter Female MaladyDokument13 SeitenShowalter Female MaladyKevin Sebastian Patarroyo GalindoNoch keine Bewertungen

- Epigenetics & HomoeopathyDokument17 SeitenEpigenetics & HomoeopathyBishal100% (1)

- @9negros Occidental Vs BezoreDokument3 Seiten@9negros Occidental Vs BezoreSimeon SuanNoch keine Bewertungen

- Brief Psychological Interventions For Borderline Personality Disorder. A Systematic Review and Meta-Analysis of Randomised Controlled TrialsDokument9 SeitenBrief Psychological Interventions For Borderline Personality Disorder. A Systematic Review and Meta-Analysis of Randomised Controlled TrialsFELIPE ROJAS TRAVERSONoch keine Bewertungen

- Amsoil Synthetic CVT Fluid (CVT)Dokument2 SeitenAmsoil Synthetic CVT Fluid (CVT)amsoildealerNoch keine Bewertungen

- Two Drugs Are No More Effective Than One To Treat Common Kidney DiseaseDokument3 SeitenTwo Drugs Are No More Effective Than One To Treat Common Kidney DiseaseGlogogeanu Cristina AndreeaNoch keine Bewertungen

- Research Paper CalamansiDokument7 SeitenResearch Paper Calamansih040pass100% (1)

- 14.08.22 - OSR - STAR CO-SC - Jee - Adv - 2021 - P1 - GTA-11 (P1) - QPDokument19 Seiten14.08.22 - OSR - STAR CO-SC - Jee - Adv - 2021 - P1 - GTA-11 (P1) - QPPratyek ThumulaNoch keine Bewertungen

- PsychodramaDokument5 SeitenPsychodramaAkhila R KrishnaNoch keine Bewertungen

- TDS-PE-102-UB5502H (Provisional) 2019Dokument2 SeitenTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNoch keine Bewertungen

- Anthropometric Article2Dokument11 SeitenAnthropometric Article2Lakshita SainiNoch keine Bewertungen

- Define and State The Purpose of Therapeutic DietDokument10 SeitenDefine and State The Purpose of Therapeutic DietKen GarciaNoch keine Bewertungen

- TRAFFIC RULES PDF Project ReportDokument18 SeitenTRAFFIC RULES PDF Project ReportShweta SharmaNoch keine Bewertungen

- Deviance, Crime, and Social ControlDokument17 SeitenDeviance, Crime, and Social ControlSaad MaqboolNoch keine Bewertungen

- Homoeopathic Treatment of Complicated Sebaceous Cyst - A Case StudyDokument5 SeitenHomoeopathic Treatment of Complicated Sebaceous Cyst - A Case StudyDr deepakNoch keine Bewertungen

- Gene SileningDokument30 SeitenGene SileningSajjad AhmadNoch keine Bewertungen

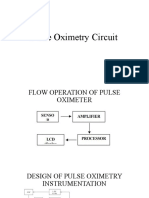

- Pulse Oximetry CircuitDokument19 SeitenPulse Oximetry Circuitنواف الجهنيNoch keine Bewertungen

- Principles in Biochemistry (SBK3013)Dokument3 SeitenPrinciples in Biochemistry (SBK3013)Leena MuniandyNoch keine Bewertungen

- Basic PreservationDokument14 SeitenBasic Preservationrovinj1Noch keine Bewertungen

- MCQ Questions For Class 10 Science Periodic Classification of Elements With AnswersDokument30 SeitenMCQ Questions For Class 10 Science Periodic Classification of Elements With AnswersAymen WaelNoch keine Bewertungen

- Specification and Maintenance Manual: Sequence Flashing Lights (SFL)Dokument13 SeitenSpecification and Maintenance Manual: Sequence Flashing Lights (SFL)Javier Eduardo Alzate BogotaNoch keine Bewertungen