Beruflich Dokumente

Kultur Dokumente

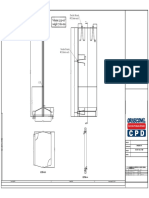

1 Formwork Layout Plan (First Pouring) : A Elevation B Elevation

Hochgeladen von

Mohamed AdelOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 Formwork Layout Plan (First Pouring) : A Elevation B Elevation

Hochgeladen von

Mohamed AdelCopyright:

Verfügbare Formate

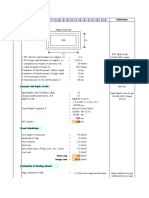

GENERAL NOTES:

D DESIGN BASIS

This lay-out has been prepared based on the information supplied to us by or

on the behalf of the customer. However, it is the client's responsibility to check

and verify that we have correctly interpreted. The requirements, information

and all loading in accordance with UNISTEEL Equiptment Data Sheets,

FORMWORK A Guide to Good Practice 2nd Edition, Ciria Report 108 Concrete

Pressure on Formwork.

UNISTEEL COPYRIGHT

2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m This drawing is an exclusive property of UNITED STEEL INDUSTRIES

WP-5 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-3 WP-6 COMPANY LIMITED. Any unauthorized use of this drawing is Not Valid Unless

Signed and Stamp by our Technical Department. UNISTEEL reserve the right

to amend drawing details and materials subject to stock availability.

MATERIAL PROPERTIES & SPECS.

WP-16

The mechanical properties of the of the raw materials used in fabrication of our

scaffold materials ( Falsework ).

WP-7

I. Steel Members :

WP-1 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-3 WP-4 Source : SABIC ( JIS G3132) Steel Grade SPHT3

WP-11

2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m

SCAFFOLD TUBES :

EN 10219 ; 320N/mm²(46 ksi) (32kg/mm²) (Fy) Min. Yield Stress @3.2mm. wall thickness

H H BS 1139 ; 235N/mm²(34 ksi) (24kg/mm²) (Fy) Min. Yield Stress @4.0mm. wall thickness

WP-9

2.0m

2.0m

II. Aluminum Beam Member : Source : SUPPLIER

Yield Stress, Fy ; 285.00Mpa

Modulus Elasticity ; 69000Mpa

III. Timber Member :

2.0m

2.0m

WP-13

No timber is supplied by UNISTEEL, the timber design is the responsibility of the contractor.

WP-14

To enable us to prepare the design on this drawing, we have assumed the following :

Source : American Forest and Paper Association (Douglas Fir or Southern Pine)

WP-2

Nominal Size ; 4"X4"

WP-2

WP-2

Nominal Size ; 3"X3"

Bending Stress, Fs ; 8.90Mpa

IV. Plywood : Source : Concrete Society Page 39

Species : 18mm. Plywood-European Standard-Birch Through

2.0m

2.0m

Permissable stresses stated in BS 5268 Part 2, assumed to be in sanded condition

2.0m

2.0m

Bending Stiffness Parallel ; 3.23 kNm²

G G Moment of Resistance Parallel ; 0.834 kNm

DESIGN LOADS APPLIED

WP-2

WP-2

WP *|

WP*

Loads on forms and falsework have been analyzed in accordance with Guide

for Formwork and/or Codes of Practice for Falsework. As a result, the structure

detailed on this drawing has been designed to support the following imposed

loads only :

Loads are assumed uniformly distributed

2.0m

2.0m

E E

B

FALSEWORK: FORMWORK:

Concrete Density : Max. Concrete Pressure :

Weight of Formwork : Concrete Temperature :

A

WP-2

WP-2

Liveload : 2.5 kN/m² Rate of Pour :

TIMBER FORMWORK

All timber formwork and bearers are to be provided by the contractor or client.

Timber should have been calculated using the design parameter detailed on

this drawing sheet.

2.0m

2.0m

ERECTION

The Customer is responsible for ensuring that all structure are adequately tied

WP*|*

WP**

F F and/or braced to carry the load and ensure stability as indicated on the

drawing. No ties or braces be removed without the authority of UNISTEEL.

WP-14

This drawing has been prepared using the safe working loads of UNISTEEL

WP-13

equiptment no modification to components, assembly, loading or any other

aspects must be without authority from Technical Dept. of UNISTEEL. No

2.0m

2.0m

responsibilty accepted by UNISTEEL for the design or permormance of

materials not supplied by UNISTEEL.

FOUNDATIONS

WP-10

F

Unless otherwise noted, no soleplates or other means of spreading the

2.0m

2.0m

imposed loads are supplied by UNISTEEL. The customer must ensure that the

WP-12

foundations provided are adequate, where UNISTEEL is supported,

suspended, anchored or tied to a structure or ground is adequate to safety

WP-8

2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m 2.0m support the additional imposed loads.

WP-1 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-3 WP-4

WP-15

TEMPORARY WORKING PLATFORMS

Unless specially stated, It is assumed that any other working platforms ( for

erection or dismantling purposes ) will be designed, supplied and fitted by the

customer. It is the client's responsibility to ensure that working platforms or

means of access necessary for safe access are provided whether shown on

this drawing or not.

TYING AND BRACING / LATERAL STABILITY

WP-6 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-2 2.0m WP-3 2.0m WP-5 The lateral bracing and horizontal butting restraint force required to be

transmitted through the braces is specified in BS 5975 " FALSEWORK ". The

code specifies a minimum lateral stability criteria equivalent to the grater of

either 2.5% of the vertical load in the standard (Post) acting horizontally at the

point of application the load, or horizontal forces from wind, erection

tolerances, non-vertically, concrete pressures and other forces acting as

described in the code.

US DATEDthat

Tensuring ! all structure are adequately tied

The Customer is responsible

and/or braced toN G

carry

TAfor

Sthe ND

KED Aand ensure stability as indicated on the

load

Wor I braces HE C

F

C

drawing.R NoAties WHENbe removed without the authority of UNISTEEL.

C D L ALID

YV

N FUL ( Re-Shoring )

Back RPropping

UCTIO Y

T

CONS propping R

Back N A Back propping

may be required.

I eckin

g is the responsibility of the

1 FORMWORK LAYOUT PLAN(FIRST POURING) customer.

STA

TUS P R EL

IM

isc u s

for d o part

s

pricin

d ch

g an ment un

e

ion, any agre structio

of its co

in

n

n

til

ing is forms n hecked

draw It c

This e client. arked as

ION

by th nd m

ed a

issu s. CT

statu T RU and

ings of the

TUS NS load n

STA CO che c k ed for rpretatio

inte

been with our

E

a s

ing h rdance

draw o

This ity in acc ments.

il e

stab s requir

t'

WP-7 WP-2 WP* WP** WP-8 clien

Scaffolding & Formwork

webmail : www.unisteel.com.sa

WP-15 WP-13 WP-2 WP-2 WP-14 WP-16

CONSULTANT/CLIENT COMMENTS:

( A ) - APPROVED

( B ) - APPROVED WITH COMMENTS

( C ) - APPROVED WITH COMMENTS,

RESUBMITTAL IS REQUIRED

(D)-REJECTED

E

/ /

A ELEVATION B ELEVATION SIGNATURE: DATE:

MAIN OFFICE - FACTORY : RIYADH K.S.A.

TEL. NO.: +966 1 410-5544 FAX. : +966 1 475-5231

P.O. BOX 40555, RIYADH 11511

KINGDOM OF SAUDI ARABIA

Jeddah Branch:

WP-6 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-3 WP-5 Scaffolding & Formwork Tel. No. : +966 2 621-2525 Fax. No. :+966 2 621-2255

webmail : www.unisteel.com.sa

Universal Access No. Dammam Branch:

Tel. No. : +966 3 814 -2075 Fax. No. :+966 3 814 -2079

9200 00 864

A member of Al-Fozan Group of Companies

DENNIS DSM ENGR. MOHAMED ADEL EZZAT

SEP.30.2020 NOV.09.2020

THIS DRAWING IS NOT BE USED FOR CERT. BY :

CONSTRUCTION UNLESS CERTIFIED BY

C ELEVATION ENGINEERING DEPARTMENT.

DATE :

CLIENT:

WP-6 WP-3 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-2 WP-5

SSEM

Qassim Braidah, Kingdom of Saudi Arabia

PROJECT TITLE :

MASHTAL PUMP STATION

DRAWING TITLE :

FORMWORK LAYOUT & ELEVATION

DRAWING NUMBER

D ELEVATION

SCALE A1 DWG 1 UNI20-R-300-WL-001-R0

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Material Submittal HANDRAILDokument6 SeitenMaterial Submittal HANDRAILManu Mohan0% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Suggested Vendor List - OffshoreDokument69 SeitenSuggested Vendor List - Offshoresumit kumarNoch keine Bewertungen

- TWf2020.01 - Management of Scaffolding - 8 September 2020 - FINALDokument26 SeitenTWf2020.01 - Management of Scaffolding - 8 September 2020 - FINALMohamed AdelNoch keine Bewertungen

- LECTURE NOTE 01 - RCC DesignDokument14 SeitenLECTURE NOTE 01 - RCC DesignMohamed AbdNoch keine Bewertungen

- LOD Spec 2016 Part I 2016-10-19 PDFDokument207 SeitenLOD Spec 2016 Part I 2016-10-19 PDFzakariazulkifli92Noch keine Bewertungen

- Dry Van ManualDokument234 SeitenDry Van ManualMichael Yoanito Oliviano100% (1)

- DESIGN OF SLAB - ContdDokument4 SeitenDESIGN OF SLAB - ContdmeenuNoch keine Bewertungen

- Formworks Group 1 - 2Dokument100 SeitenFormworks Group 1 - 2Patrick TulayNoch keine Bewertungen

- Cement Metering ValveDokument11 SeitenCement Metering ValveWise SoNoch keine Bewertungen

- Tax Invoice: Mohamed Adel Al Barsha, Ibis Mall of Emirates Dubai, Al Barsha AEDokument2 SeitenTax Invoice: Mohamed Adel Al Barsha, Ibis Mall of Emirates Dubai, Al Barsha AEMohamed AdelNoch keine Bewertungen

- API 5L GR.B SteelDokument2 SeitenAPI 5L GR.B SteelYosua Rielys PNoch keine Bewertungen

- Noi Bai International Airport Terminal 2 ConstructionDokument2 SeitenNoi Bai International Airport Terminal 2 ConstructionManh TuNoch keine Bewertungen

- MSC TW Cme Flyer 18 19Dokument2 SeitenMSC TW Cme Flyer 18 19Mohamed AdelNoch keine Bewertungen

- TW19.101 - Information Sheet No 7 - Static Load Pile Tests - 29.10.19Dokument5 SeitenTW19.101 - Information Sheet No 7 - Static Load Pile Tests - 29.10.19Mohamed AdelNoch keine Bewertungen

- TW22.085 - Summary - Loddon Viaduct Collapse 1972 From Bragg EtcDokument15 SeitenTW22.085 - Summary - Loddon Viaduct Collapse 1972 From Bragg EtcMohamed AdelNoch keine Bewertungen

- Scaff Accessories-Arabic EnglishDokument8 SeitenScaff Accessories-Arabic EnglishMohamed AdelNoch keine Bewertungen

- ANISH Health Passport 18-12-2021 1.1Dokument1 SeiteANISH Health Passport 18-12-2021 1.1Mohamed AdelNoch keine Bewertungen

- tw13.032 Differences Between Temporary Works and Permanent Works August13 FinalDokument3 Seitentw13.032 Differences Between Temporary Works and Permanent Works August13 FinalMohamed AdelNoch keine Bewertungen

- tw18.073 Information Sheet No 4 Final Scaffolding Faqs 26.10.18Dokument10 Seitentw18.073 Information Sheet No 4 Final Scaffolding Faqs 26.10.18Mohamed AdelNoch keine Bewertungen

- مسا نوبزلا United Steel مقر ةبيرض ةميقلا ةفاضملا ليمعلل مقر لاصتلااDokument1 Seiteمسا نوبزلا United Steel مقر ةبيرض ةميقلا ةفاضملا ليمعلل مقر لاصتلااMohamed AdelNoch keine Bewertungen

- Ref Cli GB 2019 Core-LocDokument7 SeitenRef Cli GB 2019 Core-LocMohamed AdelNoch keine Bewertungen

- Ch31 Shell StructuresDokument7 SeitenCh31 Shell Structureslittle-wing75% (4)

- Fy15 sh-27683-sh5 Level 2 Evaluation Fall Prevention Exam EnglishDokument2 SeitenFy15 sh-27683-sh5 Level 2 Evaluation Fall Prevention Exam EnglishMohamed AdelNoch keine Bewertungen

- Typical PanelDokument1 SeiteTypical PanelMohamed AdelNoch keine Bewertungen

- Not Infected (Negative) : ResultDokument1 SeiteNot Infected (Negative) : ResultMohamed AdelNoch keine Bewertungen

- Mohamed Adel C.VDokument2 SeitenMohamed Adel C.VMohamed AdelNoch keine Bewertungen

- USA 074 Two Start Thread (Double Thread)Dokument1 SeiteUSA 074 Two Start Thread (Double Thread)Mohamed AdelNoch keine Bewertungen

- BEAM SUPPORT CalculationDokument8 SeitenBEAM SUPPORT CalculationMohamed AdelNoch keine Bewertungen

- Molecular Pathology Department: Patient Name Emiratesid Lab NoDokument1 SeiteMolecular Pathology Department: Patient Name Emiratesid Lab NoMohamed AdelNoch keine Bewertungen

- T-Wall Concrete DimDokument1 SeiteT-Wall Concrete DimMohamed AdelNoch keine Bewertungen

- Covid 19 by PCR: Test Name Result Unit Reference RangeDokument2 SeitenCovid 19 by PCR: Test Name Result Unit Reference RangeMohamed AdelNoch keine Bewertungen

- UPDATECALCNOV09Dokument20 SeitenUPDATECALCNOV09Mohamed AdelNoch keine Bewertungen

- 2 Wall Formwork Plan - (Abutment Wall)Dokument1 Seite2 Wall Formwork Plan - (Abutment Wall)Mohamed AdelNoch keine Bewertungen

- Scaffolding LayoutDokument1 SeiteScaffolding LayoutMohamed AdelNoch keine Bewertungen

- T-Wall RFTDokument1 SeiteT-Wall RFTMohamed AdelNoch keine Bewertungen

- Typical PanelDokument1 SeiteTypical PanelMohamed AdelNoch keine Bewertungen

- T-WALL With Strands LiftingDokument1 SeiteT-WALL With Strands LiftingMohamed AdelNoch keine Bewertungen

- Circular Column D 1.2mDokument1 SeiteCircular Column D 1.2mMohamed AdelNoch keine Bewertungen

- Cuplock Scaffold PcsDokument1 SeiteCuplock Scaffold PcsMohamed AdelNoch keine Bewertungen

- Krone 4 Category 6Dokument18 SeitenKrone 4 Category 6jose carlosNoch keine Bewertungen

- Wastewater Engineering - Treatment and Resource Recovery-Metcalf and Eddy 5th Ed (2014) Sección 8-11Dokument8 SeitenWastewater Engineering - Treatment and Resource Recovery-Metcalf and Eddy 5th Ed (2014) Sección 8-11Ricardo Javier PlasenciaNoch keine Bewertungen

- No No - YesDokument3 SeitenNo No - YesYedda M IlaganNoch keine Bewertungen

- Bridge Prelim DesignDokument146 SeitenBridge Prelim DesignSimonNoch keine Bewertungen

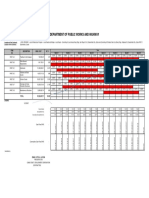

- Department of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractDokument1 SeiteDepartment of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractAdrian Louie Laganzo AquinoNoch keine Bewertungen

- Project 1 Foundation 2019Dokument43 SeitenProject 1 Foundation 2019SaraNoch keine Bewertungen

- N5 Strength of Material and StructuresNovember 2022 Question PaperDokument9 SeitenN5 Strength of Material and StructuresNovember 2022 Question PaperlechutnmNoch keine Bewertungen

- 69 Princes Gate Mews 20180525Dokument16 Seiten69 Princes Gate Mews 20180525Artem EpifanovNoch keine Bewertungen

- Assignment 3 PDFDokument14 SeitenAssignment 3 PDFVishnu RajgopalNoch keine Bewertungen

- Saudi Arabian Oil Company: SECTION 15060 Chilled Water PipingDokument10 SeitenSaudi Arabian Oil Company: SECTION 15060 Chilled Water Pipingthahar ali syedNoch keine Bewertungen

- Ensure Even Preload with Proper Tightening Tools and SequenceDokument2 SeitenEnsure Even Preload with Proper Tightening Tools and SequenceMachineryengNoch keine Bewertungen

- 01 084r34 PDFDokument60 Seiten01 084r34 PDFviniciuspariz100% (1)

- Civil Engineering FundamentalsDokument12 SeitenCivil Engineering FundamentalsAthith D100% (1)

- Fdot Field Manual Final ReportDokument166 SeitenFdot Field Manual Final ReportRainer TafurNoch keine Bewertungen

- Concrete Dams on Rock Foundations AnalysisDokument5 SeitenConcrete Dams on Rock Foundations AnalysisÖzgür DoğanNoch keine Bewertungen

- Profile Sjanizar & Partners PDFDokument19 SeitenProfile Sjanizar & Partners PDFrahmatrasit7742Noch keine Bewertungen

- 04 AdamsParts 71-98Dokument30 Seiten04 AdamsParts 71-98apuhapuh_153349Noch keine Bewertungen

- Data Sheet For Line StopDokument7 SeitenData Sheet For Line StopMathi Vinoth PillaiNoch keine Bewertungen

- WTP& Collection WellDokument431 SeitenWTP& Collection Wellsubramanyam kumarNoch keine Bewertungen

- 7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913Dokument1 Seite7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913魏利强Noch keine Bewertungen