Beruflich Dokumente

Kultur Dokumente

Wiring: Digital Controller Instruction Manual

Hochgeladen von

Edy WijayaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wiring: Digital Controller Instruction Manual

Hochgeladen von

Edy WijayaCopyright:

Verfügbare Formate

Warning Symbols Specifications

Power supply voltage 100 to 240 VAC, 50/60 Hz or

Precautions for Safe Use

E5EC Do not touch the terminals while power is being supplied.

CAUTION

Be sure to observe the following precautions to prevent operation failure, malfunction, or adverse affects on the

performance and functions of the product. Not doing so may occasionally result in unexpected events. Use the

Operating voltage range

Power consumption

24 VAC, 50/60 Hz / 24VDC

85 to 110% of the rated voltage

Option 000:

Approx. 4.1 VA (100 to 240 VAC)

Doing so may occasionally result in minor injury due to electric shock.

Digital Controller Do not allow pieces of metal, wire clippings, or fine metallic shavings or filings from installation to

product within specifications.

(1) The product is designed for indoor use only. Do not use the product outdoors. Do not use or store the product

Approx. 3.0 VA (24 VAC)/approx. 1.7 W (24 VDC)

All other specifications:

enter the product. Doing so may occasionally result in electric shock, fire, or malfunction. in any of the following locations. Approx. 5.1 VA (100 to 240 VAC)

• Places directly subject to heat radiated from heating equipment. Approx. 3.9 VA (24 VAC)/approx. 2.3 W (24 VDC)

Do not use the product where subject to flammable or explosive gas. Otherwise, minor injury from Indication accuracy Thermocouple:

• Places subject to splashing liquid or oil atmosphere.

explosion may occasionally occur. (Ambient temperature: 23°C) (±0.3 % of indication value or ±1°C,

EN INSTRUCTION MANUAL Never disassemble, modify, or repair the product or touch any of the internal parts. Minor electric

shock, fire, or malfunction may occasionally occur.

• Places subject to direct sunlight.

• Places subject to dust or corrosive gas (in particular, sulfide gas and ammonia gas).

• Places subject to intense temperature change.

whichever is greater) ±1 digit max.

Platinum resistance thermometer:

(±0.2 % of indication value or ±0.8°C,

CAUTION - Risk of Fire and Electric Shock • Places subject to icing and condensation. whichever is greater) ±1 digit max.

Thank you for purchasing the OMRON E5EC Digital Controller. • Places subject to vibration and large shocks. Analog input: ±0.2 % FS ±1 digit max.

a) This product is UL recognized as Open Type Process Control Equipment. It must be mounted in an enclosure

This manual describes the functions, performance, and that does not allow fire to escape externally.

(2) Use/store within the rated temperature and humidity ranges. Event input Output current: approx. 7 mA per contact.

Provide forced-cooling if required. Contact input ON:1 kΩ max., OFF: 100 kΩ min.

application methods needed for optimum use of the product. b) More than one disconnect switch may be required to de-energize the equipment before servicing. (3) To allow heat to escape, do not block the area around the product. No-contact input ON: residual voltage 1.5 V max.,

OFF: leakage current 0.1 mA max.

Please observe the following items when using the product. c) Signal inputs are SELV, limited energy. Do not block the ventilation holes on the product. Remote SP input 4 to 20 mA DC or 0 to 20 mA DC

(4) Be sure to wire properly with correct polarity of terminals. 0 to 5 V DC or 0 to 10 V DC

• This product is designed for use by qualified personnel with a d) Caution: To reduce the risk of fire or electric shock, do not interconnect the outputs of different Class 2 circuits.

(5) Use the specified size of crimped terminals (M3, width 5.8 mm or less) for wiring. To connect bare wires to the Control output 1 Relay output: SPST-NO,

knowledge of electrical systems. If the output relays are used past their life expectancy, contact fusing or burning may occasionally occur. Always terminal block, use copper braided or solid wires with a gage of AWG24 to AWG18 (equal to a cross- 250 VAC, 5 A (resistive load)

consider the application conditions and use the output relays within their rated load and electrical life expectancy. sectional area of 0.205 to 0.8231 mm2). (The stripping length is 6 to 8 mm.). Up to two wires of same size and Electrical life of relay: 100,000 operations

• Before using the product, thoroughly read and understand this The life expectancy of output relays varies considerably with the output load and switching conditions. type, or two crimped terminals can be inserted into a single terminal. Voltage output (for driving SSR):

manual to ensure correct use. (6) Do not wire the terminals which are not used. 12 VDC ±20%, 40 mA for one control output,

Loose screws may occasionally result in fire. Tighten the terminal screws to the specified torque of 0.43 to 0.58 N·m. 21 mA if there are two control outputs

(7) Allow as much space as possible between the controller and devices that generate a powerful high-frequency

• Keep this manual in a safe location so that it is available for Set the parameters of the product so that they are suitable for the system being controlled. If they are not suitable, or surge.

Current output: 4 to 20 mA DC, 0 to 20 mA DC

unexpected operation may occasionally result in property damage or accidents. Load: 500Ω max.

reference whenever required. Separate the high-voltage or large-current power lines from other lines, and avoid parallel or common wiring Control output 2 Relay output: SPST-NO,

A malfunction in the Temperature Controller may occasionally make control operations impossible or prevent with the power lines when you are wiring to the terminals. 250 VAC, 5 A (resistive load)

alarm outputs, resulting in property damage. To maintain safety in the event of malfunction of the Digital Controller, (8) Use this product within the rated load and power supply. Electrical life of relay: 100,000 operations

Voltage output (for driving SSR): 12 VDC, 21 mA

OMRON Corporation take appropriate safety measures, such as installing a monitoring device on a separate line.

Do not allow dirt or foreign objects to enter the jacks on the Digital Controller or cable connector pins. Otherwise,

(9) Make sure that the rated voltage is attained within two seconds of turning ON the power using a switch or

relay contact. If the voltage is applied gradually, the power may not be reset or output malfunctions may occur. Current output: 4 to 20 mA DC or 0 to 20 mA DC

with load of 500 Ω max.

(10) Make sure that the Digital Controller has 30 minutes or more to warm up after turning ON the power before

©All Rights Reserved fire may occasionally occur.

starting actual control operations to ensure the correct temperature display.

Control method

Auxiliary outputs

ON/OFF or 2-PID control

Relay outputs: 250 VAC, two outputs: 3 A

(11) When executing self-tuning, turn the load and the unit ON simultaneously, or turn the load ON before you turn

Refer to the E5CC/E5EC Digital Controllers User’s Manual (Cat. No. H174) the controller ON.

(resistive load), four outputs: 2 A (resistive load)

Electrical life of relay: 100,000 operations

Ambient temperature –10 to 55°C

for detailed application procedures. Suitability for Use (12) A switch or circuit breaker should be provided close to this unit.

The switch or circuit breaker should be within easy reach of the operator, and must be marked as a (Avoid freezing or condensation)

OMRON shall not be responsible for conformity with any standards, codes, or regulations that disconnecting means for this unit. Ambient humidity RH25 to 85%

Safety Precautions apply to the combination of the products in the customer's application or use of the product. (13) Do not use paint thinner or similar chemical to clean with. Use standard grade alcohol. Storage temperature –25 to 65°C

(Avoid freezing or condensation)

(14) Design system (control panel, etc) considering the 2 second of delay that the controller’s output to be set after Altitude Max. 2,000 m

Key to Warning Symbols Take all necessary steps to determine the suitability of the product for the systems, machines, power ON. Recommended fuse T2A, 250 VAC, time-lag,

and equipment with which it will be used. (15) The output may turn OFF when shifting to certain levels. Take this into consideration when performing control. low-breaking capacity

Know and observe all prohibitions of use applicable to this product. (16) The number of non-volatile memory write operations is limited. Therefore, use RAM write mode when Weight Approx. 210 g (Digital Controller only)

Indicates a potentially hazardous situation which, if frequently overwriting data during communications or other operations. Degree of protection Front panel: IP66

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE (17) When disassembling the Temperature Controller for disposal, use suitable tools. Rear case: IP20, Terminal section: IP00

not avoided, is likely to result in minor or moderate Installation environment Installation category II, pollution

injury or property damage. Read this manual OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN (18) Do not connect USB-Serial Conversion Cables to both the front-panel Setup Tool port and the serial connector.

degree 2 (as per IEC61010-1)

CAUTION carefully before using the product. DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY The Digital Controller may be damaged or may malfunction. Memory protection Non-volatile memory

(19) Do not exceed the communications distance that is given in the specifications and use the specified (Number of write operations: 1,000,000)

RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT communications cable. Refer to the E5CC/E5EC Digital Controllers User’s Manual (Cat. No. H174) for the Transfer output 4 to 20 mA DC with load of 500 Ω max.

1654642-3 OR SYSTEM.See also Product catalog for Warranty and Limitation of Liability. communications distance and cable specifications. 1 to 5 VDC with load of 1 kΩ min.

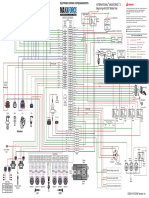

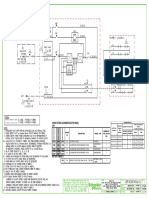

Wiring Dimensions Installation Connections (The applicability of the electric terminals varies with the type of machine.) Do not connect anything to the terminals that are shaded gray.

Dimensions (mm) (64) In the pack: Individual mounting (mm) Side-by-side mounting (mm) • 100 to 240 VAC

• 24 VAC/VDC (no polarity) E5EC *5 Options

4 60

48 1.5 44 • Main unit 004 005 008 009 010

• Watertight packing (48 x number of units–2.5) + 0

1 Control output 1 2. Control outputs 5. Options Communications Four event inputs Communications, two event Communications, two event Four event inputs

Relay output and two event inputs inputs, and one CT inputs, and two CTs and one CT

• Two mounting brackets 250 VAC, 5A Control output 2 Auxiliary output 1, 2, 3

B(+) B(+) B(+)

• Instruction manual Waterproofing is impossible (resistive load) Relay output Relay output 13 13 13 13 13

Voltage output 250 VAC, 3 A RS-485 RS-485 RS-485

• Terminal cover with side-by-side (for driving SSR) (resistive load)

250 VAC, two outputs: 3 A

(resistive load) 14 14 14 14 14

A(−) EV3 A(−) A(−) EV3

(Provided only for models

92 + 00.8

installation. When 12 VDC, 40 mA Voltage output 250 VAC, four outputs: 2 A 15 15 15 15 15

(resistive load) EV4 EV4

with "-500" suffix.) waterproofing is required, fit 21 mA if there are two (for driving SSR)

110

91

96

12 VDC, 21 mA

16 16 16 16 16

control outputs

Solderless terminal size: M3 watertight packing on the Current output Current output 17 17 17 17 17

EV1 EV1 EV1 EV1 EV1

Terminal cover: backside of front panel. 0 to 20 mA DC 0 to 20 mA DC

4 to 20 mA DC 18 18 18 18 18

4 to 20 mA DC EV2 EV2 EV2 EV2 EV2

120 min

Load: 500 Ω max. Load: 500 Ω max. 19 19 19 19 19

(Model: E53-COV24)

USB-Serial Conversion Cable 45 + 00.6 *1 Input Power Supply 20 20

CT1

20

CT1

COM 20

CT1

20

The E5EC is set for a K thermocouple (input type of CT2

(Sold Separately) • Insert the main unit through the mounting hole in the panel (1-8 mm 5) by default. If a different sensor is used, an input

100 to 240 VAC

24 VAC/DC 21 21 21 21 21

(E58-CIFQ2) thickness). Insert the mounting brackets (supplied) into the fixing

error (s.err) will occur. Check the setting of the Input 1 1 012

Type parameter. 011 Communications, four event inputs,

92 + 00.8

* Do not remove the terminal block. Doing so may result in failure or malfunction. slots located on the top and bottom of the rear case. 2 2 Six event inputs, one CT, one CT, transfer output, and remote SP

• Tighten the two mounting screws on the top and bottom of the transfer output, and remote SP B(+)

* A Setup Tool port is provided on the bottom of the product. Use this port to connect a personal *2 Control Outputs (no polarity) 13 13

computer to the product when using the Setup Tool. The E58-CIFQ2 USB-Serial Conversion adapter to keep them balanced, and finally tighten them to a torque RX QX CX QQ RS-485

14 14

Cable is required to connect to the port shown in the above figure. The E58-CIFQ2-E USB-Serial of between 0.29 and 0.39 N·m. One relay One voltage output One linear Two voltage outputs EV3 A(−)

15 15

Conversion Cable is required to connect to the port on the front panel. (Do not use the product • When more than one machine is installed, make sure that the output (for driving SSR) current output (for driving SSRs) EV4

with the USB-Serial Conversion Cable left permanently connected.) ambient temperature does not exceed the specified limit. 28 16 28 16

3 3 + 3 + 3 + 1 25 13

Refer to the instruction manual provided with the USB-Serial Conversion Cable for details on − − − 29 17 29 17

4 4 4 4 2 26 14 EV5 EV1 EV5 EV1

connection methods. EV6

30 18 30 18

5 5 5 5 3 27 15 EV2 EV6 EV2

+ + 31 19 + 31 19

− 4 28 16

Names of Parts on Front Panel 6 6 6 6

5 29 17

Transfer V +

output I32

CT1

20

Transfer V +

output 32

I CT1

20

− 33 21 − 33 21

QR RR CC 6 30 18

• °C / °F : temperature unit Operation indicators + 34 + 34

• No.1 display • STOP: control stop indicator Voltage output (for driving Two relay Two linear 7 31 19 Remote V + Remote V +

The temperature unit is displayed when the • SUB1: Auxiliary output 1 indicator Lit when event input or “Run/Stop” is stopped during SSRs) and relay output outputs current outputs 8 32 20 SP mA 35 SP mA 35

displayed value is a temperature. Process value or set data type − 36 − 36

• SUB2: Auxiliary output 2 indicator operation. 3 3 3 9 33 21

Either C or F is displayed according to the set • No.2 display + + 014

• SUB3: Auxiliary output 3 indicator During control stop, functions other than control output − − 10 34 22

value of the temperature unit. Set point, set data read-out value or changed are valid. 4 4 4 013 Communications, four event inputs,

11 35 23 Six event inputs, transfer output, transfer output, and remote SP

• Shift key (PF key) input value • OUT1: Control output 1 indicator 5 5 5 +

The default PF Setting parameter is for shifting For a current output, lit except for a

• CMW: communications writing enable/ disable indicator and remote SP B(+)

Lit when communications writing is “enabled” and is 6 6 6 − 12 36 24 13 13

the digit. This is a function key. When it is 0% output. RS-485

pressed, the function set for the PF Setting • No. 3 display out when it is “disabled”. 14 14

• OUT2: Control output 2 indicator EV3 A(−)

parameter will operate. MV, Soak Time Remain, and Multi-SP. 15 15

• : Protection indicator EV4

• Up and Down keys • RSP: Remote SP indicator *3 Auxiliary Outputs 28 16 28 16

• Front-panel Setup Tool port Lit when Setting Change Protect is ON (disables the *4 Sensor Temperature/Analog Input

Each press of U key increments or advances Lit when the assigned function is ON. Auxiliary outputs 1 and 2 Auxiliary outputs 1 to 4 29 17 29 17

This port is used to connect the Controller to a Up and Down Keys). TC Pt I V EV5 EV1 EV5 EV1

computer to use the Setup Tool. the values displayed on the No.2 display. 30 18 30 18

• TUNE: • MANU: Manual output indicator 7 7 22 22 + 22 22 EV6 EV2 EV6 EV2

Auxiliary output 4

Each press of D key decrements or returns the Flashing during self-tuning. 8 8 − mA − + 31 19 + 31 19

Lit when the Auto/Manual Mode is set to Manual Auxiliary output 3 23 23 23 23 Transfer V + Transfer V +

• Level key values displayed on the No.2 display. Lit during auto-tuning. 9 9 − V 32 20 I32 20

Mode. Auxiliary output 2 + 24 24 24 24 output I output

Use this key to change levels: 10 10 + − 33 21 − 33 21

• Mode key Auxiliary output 2

Press this key to change the contents of the display. 11 11 +

34 + 34

Press this button for 1 s or longer for reverse scroll. Auxiliary output 1 Auxiliary output 1 Remote V + 35 Remote V + 35

12 12 SP mA SP mA

• Press the O key and the M key − 36 − 36

* When complying with EMC standards, the line connecting the sensor must be 30 m or less.

together for at least 3 seconds to switch to protect level. If the cable length exceeds 30 m, compliance with EMC standards will not be possible.

Operation Menu Operation stopped. Check the wiring before turning ON the power supply.

Only the value set to the “ins: Temperature Input Shift” parameter is applied to the entire temperature input range. When the

Input Type Initial Setting Level (Control/alarm are both stopped.) Adjustment Level

process value is 200 °C, the process value is treated as 201.2 °C after input shift if the input shift value is set to 1.2 °C.

The process value is treated as 198.8 °C after input shift if the input shift value is set to –1.2 °C.

Input type Input Setting Setting range *5 POWER ON

Platinum 0 -200 to 850 (°C) /-300 to 1500 (°F)

in-t alt3 Alarm 3 Type:

*3 *8 l.adj Adjustment Level

Displayed only once when *6 sp-3 SP 3

*6 c-db Dead Band

resistance Pt100 1 -199.9 to 500.0 (°C) /-199.9 to 900.0 (°F) Input Type *3 *6 Specified

thermometer 2 0.0 to 100.0 (°C) /0.0 to 210.0 (°F) 5 2 models only *4 Operation Level entering Adjustment Level. 0 0.0

3 -199.9 to 500.0 (°C) /-199.9 to 900.0 (°F) M M M M

JPt100 M AT Execute/Cancel Manual Reset Value

4 0.0 to 100.0 (°C) /0.0 to 210.0 (°F)

in-h

Scaling Upper Limit

alh3 Alarm 3 *6 at 100%AT Execute at-2 *6 sp-4 SP 4

*6 of-r Clears the offset

K 5 -200 to 1300 (°C) /-300 to 2300 (°F) (only when setting *6 PV/SP

50.0

Thermocouple *6

100 analog input) 0.2 Hysteresis

25 s.err is displayed when *6 al1l (The No.3 display off 40%AT Execute at-1 0 during P or PD control.

6 -20.0 to 500.0 (°C) /0.0 to 900.0 (°F) Alarm Value

connected sensor is Lower Limit 1 *4 has been omitted.) M M M

J 7 -100 to 850 (°C) /-100 to 1500 (°F) M M 0 different from input type. 0

8 -20.0 to 400.0 (°C) /0.0 to 750.0 (°F) in-l Scaling Lower Limit

alt4 Alarm 3 Type: M M cmwt Communications Writing *6 sp-5 SP 5

*6 hys Hysteresis

Temperature inputs

(only when setting *6 Specified *3 *6 (Heating)

*6 Hold O down *6 Auto/Manual Switch

off 0 1.0

T 9 -200 to 400 (°C) /-300 to 700 (°F) 0 analog input) 2 models only *4 a-m PID control only. *6 al-2 Alarm Value 2 *4

10 -199.9 to 400.0 (°C) /-199.9 to 700.0 (°F) M for at least Auto/Manual Switch M M M

11

M Addition. 0

E -200 to 600 (°C) /-300 to 1100 (°F) Press O sp-6 chys

L 12 -100 to 850 (°C) /-100 to 1500 (°F) dp

Decimal Point

alh4 Alarm 3 3 seconds M M *6 spmd SP Mode *6

SP 6

*6

Hysteresis

*6 (only when setting *6 (Cooling)

U 13 -200 to 400 (°C) /-300 to 700 (°F) 0 analog input) 0.2 Hysteresis (No.1 display flashes,

m-sp Multi-SP Set Point *6 al2h (less than lsp 0 1.0

then the control stops.) *6 Alarm Value U

M M

14 -199.9 to 400.0 (°C) /-199.9 to 700.0 (°F) M M 0

Selection

0 pper Limit 2 *4 1 second) M

Temperature °C= c Heater Current 1

sp-7 soak

N 15 -200 to 1300 (°C) /-300 to 2300 (°F)

d-u o1st Control Output 1 M M *6 ct1 *6

SP 7

*6 Soak Time

R 16 0 to 1700 (°C) /0 to 3000 (°F) *6

Unit

°F= f *6 Hold O down 0.0

Value Monitor

0 1

S 17 0 to 1700 (°C) /0 to 3000 (°F) c (C stands for Celsius, F 4-20 Signal

for at least *6 rsp Remote SP Monitor *6 al2l Alarm Value

(Unit: A) *7

for Fahrenheit) M Lower Limit 2 *4 M M M

B 18 100 to 1800 (°C) /0 to 3200 (°F) M

1 second 0.0 0

W 19 0 to 2300 (°C) /0 to 2300 (°F) sl-h o2st Control Output 2 M M *6 hb1 Heater Burnout

Detection 1 *6 ins Process Value

*6 wt-b Wait Band

SP Upper Limit *6 Input Shift

PL II 20 0 to 1300 (°C) /300 to 3200 (°F) 4-20 Signal

sp-m al-3 0.0 (Unit: A) *7 0.0 off

10 -70°C 21 /0 to 190 (°F)

1300 *6 Set Point During *6 Alarm Value 3 *4

Infrared 0 to 90 (°C) M SP Ramp M M M

22 /0 to 240 (°F) M 0 0

Thermosensor 60 -120°C 0 to 120 (°C) Heater Current 2

ct2 Value Monitor inrt mv-s

ES1B 115 -165°C 23 0 to 165 (°C) /0 to 320 (°F) sl-l SP Lower Limit *6 trst Transfer Output M M *6 *6 Process Value

Slope Coefficient

*6 MV at Stop

Heater Current 1 1.000 0.0

140 -260°C 24 0 to 260 (°C) /0 to 500 (°F) -200 4-20 Signal

ct1 *6 al3h 0.0 (Unit: A) *7

*6 Value Monitor Alarm Value

4 to 20mA 25 M Upper Limit 3 *4 M M M

0.0 0

input type

Current input 0 to 20mA Use the following ranges for scaling: -1999 M (Unit: A) *7

Heater Burnout

rss mv-e

Analog

26 PID ON/OFF tr-t M M hb2 Remote SP

1 to 5V 27 to 9999, -199.9 to 999.9, -19.99 to 99.99, cntl In ON/OFF control = onof *6

Transfer Output *6 Detection 2 *6

Input Shift

*6 MV at PV Error

-1.999 to 9.999 off Type

ct2 Heater Current 2

al3l 0.0 (Unit: A) *7 0.0 0.0

Voltage input 0 to 5V 28 onof In 2-PID control = pid *6 Value Monitor *6 Alarm Value

M Lower Limit 3 *4 M M M

0 to 10V 29 M Standard or Heating/Cooling

0.0 (Unit: A) *7 0

s-hc Standard control = stnd *6 tr-h Transfer Output M M *6 lcr1 Leakage Current 1

Value Monitor *6 rsrt Remote SP *6 sprt SP Ramp Set Value

*The default is“5”. Slope Coefficient

Heating and cooling control = h-c 100.0 Upper Limit

lcr1

Leakage Current 1

al-4 Alarm Value 4 *4 0.0 (Unit: A) *7 1.000 off

*s.err will be displayed when a platinum resistance thermometer is mistakenly connected stnd (Select standard control or heating *6 Value Monitor *6

M M

M M

while input type is not set for it. To clear the s.err display, correct the wiring and cycle the M and cooling control as required) 0.0 (Unit: A) *7 0

power supply.

st ST (Self-tuning) tr-l Transfer Output M M *6 hs1 HS Alarm 1

*6 p Proportional *6 sprl SP Ramp Set Value

*6 on *6 (Unit: A) *7 (SP Ramp Fall Value)

ST ON =

0.0 Lower Limit

lcr2 Leakage Current 2

al4h 50.0 8.0 Band same

Alarms on ST OFF = off *6 Value Monitor *6 Alarm Value

M M

M Upper Limit 4 *4 M

M 0.0 (Unit: A) *7 0 Leakage Current 2

Alarm output function ptrn ev-1 Event Input M M *6 lcr2 Value Monitor *6 i Integral Time *6 ol-h MV Upper Limit

Program Pattern *6 (Unit: secs)

Setting Alarm type msp0 Assignment 1

prst al4l 0.0 (Unit: A) *7 233 100.0

Positive alarm value (X) Negative alarm value (X) off *6 Program Start *6 Alarm Value

M

M Lower Limit 4 *4 M M

M rset 0

0 No alarm function Output off

cp Control Period (Heating) ev-2 Event Input M M *6 hs2 HS Alarm 2

*6 d Derivative Time *6 ol-l MV Lower Limit

*6 *6 (Unit: A) *7 (Unit: secs)

Vary with

(Unit: Seconds)

stop Assignment 2

sktr o 50.0 40 0.0

*1 1 Deviation upper/lower limit L H

"L", "H" values

20 *Voltage output (for driving SSR): 2 *6 Soak Time Remain *6 MV Monitor

M M

ON

M (Heating) M

OFF M 0 0.0

SP

X X Control Period (Cooling) ev-3 M M sp-0 SP 0 c-p orl MV Change

2 Deviation upper limit ON

OFF

ON

OFF *6 c-cp (Unit: Seconds) *6

Event Input

Assignment 3 RUN/STOP

*6

0

*6

8.0

Proportional

Band (Cooling)

*6

0.0 Rate Limit

SP SP

20 *Voltage output (for driving SSR): 2 none *6 r-s run *6

When control start = c-o MV Monitor

M M

X X

M (Cooling) M

3 Deviation lower limit ON ON M run When control stop = stop 0.0 Integral Time

OFF

SP

OFF

SP

orev Direct/Reverse Operation ev-4 Event Input M M *6 sp-1 SP 1

*6 c-i (Cooling) *6 sqrp Extraction of Square

L H In Reverse operation (Heating) = or-r

*6 Root Low-cut Point

Vary with none Assignment 4 0 233 (unit: s) 0.0

*1 4 Deviation upper/lower range

ON

OFF "L", "H" values or-r In Direct operation (Cooling) = or-d *6 al-1 Alarm Value 1 *4 M

SP

M M M

M 0

*1 5 Deviation upper/lower limit ON

L H Vary with

ev-5 M sp-2 SP 2 c-d Derivative Time

standby sequence ON OFF "L", "H" values *6 alt1 Alarm 1 Type: *3 *6

Event Input *6

0

*6 (Cooling) Adjustment level is for entering

SP

Specified models only *4 none Assignment 5

al1h Alarm Value 40 (unit: s) set values and shift values for

Deviation upper limit X X 2 *6 M control.

6 ON ON

M Upper Limit 1 *4 M

standby sequence ON OFF

SP

OFF

SP M 0

Deviation lower limit ON

X

ON

X

alh1 *6 ev-6 Event Input M

7 standby sequence ON OFF

SP

OFF

SP

*6

0.2

Alarm 1 Hysteresis

none Assignment 6

Operation level should normally be used during operations.

Error Display (troubleshooting)

ON

X

ON

X M M When an error has occurred, the No.1 display shows the error code. Take

8 Absolute value upper limit Extraction of

OFF

0

OFF

0

*6 alt2 Alarm 2 Type:

*3 *6 sqr Square Root Enable

(Only when analog necessary measure according to the error code, referring the table below.

X X Specified models only *4 off Hold O and M keys Hold O and M keys

9 Absolute value lower limit ON

OFF

ON 2 input is set)

OFF Status at error

0 0 M M down for at least 1 second down for at least 3 seconds

X Move to Advanced No.1 display Meaning Action

Absolute value upper limit X

amov Control

10 standby sequence ON

ON

OFF

ON

OFF *6 alh2 Alarm 2 Hysteresis *6 Function Setting output Alarm

0 0

0.2 0 Level Check the setting of the Input Type parameter, Operates

11 Absolute value lower limit ON

X

ON

X

M M Protect Level s.err (S. Err) Input error

*2

check the input wiring, and check for broken or

shorts in the temperature sensor.

OFF as above the

upper limit.

standby sequence ON OFF 0 OFF 0

Initial setting level enables users to specify their preferred operating conditions After the correction of A/D converter error, turn the

12 LBA (only for alarm 1) (input type, alarm type, control method, etc.) Move to Protect Level power OFF then back ON again. If the display

pmov Displayed only when a chgp Changed

Parameters Only e333 (E333) A/D converter error

remains the same, the controller must be repaired. OFF OFF

password is set. Restricts If the display is restored to normal, then a

13

0 moving to Protect Level. off *2 probable cause can be external noise affecting the

PV Change Rate Alarm *3: Refer to the adjoining tables for details of input types and alarm types. M Operation / Adjustment Protect M control system. Check for external noise.

*4: Applicable only to models with alarm functions. Parameter Mask

Restricts displaying and

14 SP absolute value upper limit ON

X

ON

X

*5: Operation is stopped when moved to the initial setting level. oapt modifying menu items in pmsk Enable

Displayed only

Turn the power OFF then back ON again. If the

display remains the same, the controller must be

OFF OFF Operation, Adjustment, and

0 0

(control/alarm are both stopped.) 0 Manual Control Levels. on when a parameter e111 (E111) Memory error repaired. If the display is restored to normal, then OFF OFF

X mask is set. a probable cause can be external noise affecting

15 SP absolute value lower limit ON ON

X

*6: The grayed-out setting items may not be displayed according to the models M Initial Setting / M

OFF the control system. Check for external noise.

0

OFF

0 and setting. icpt Communication Protect

Restricts movement to the prlp Move to

X X *7: Applicable only to models with heater burnout functions. Protect Level If the input value exceeds the display limit (-1999 to 9999), though it is within the control

16 MV absolute value upper limit ON ON 1 Initial Setting, Communications 0

OFF OFF *8: The four numeric digits of the product code are displayed in the No. 2 Setting, and Advanced Function range, [[[[ will be displayed under -1999 and ]]]] above 9999. Under these conditions,

0 0 M Setting Levels. M control output and alarm output will operate normally. Refer to the E5CC/E5EC Digital

X X display. The setting cannot be changed and there is nothing that you need

17 MV absolute value lower limit ON

OFF

ON

OFF to set. wtpt Setting Change Protect

Restricts changes to settings Controllers User’s Manual (Cat. No. H174) for the controllable ranges.

0 0

X X

off by operating the front panel keys.

*2: Error shown only for "Process value / Set point". Not shown for other status.

18 RSP absolute value upper limit ON ON M

OFF OFF

0

0

X X

pfpt PF Key Protect

19 RSP absolute value lower limit ON ON Restricts PF key operation.

OFF OFF off

0 0

M OMRON EUROPE B.V.

*1: Upper and lower limits can be set for parameters 1, 4 and 5 to provide for Wegalaan 67-69, NL-2132 JD Hoofddorp The Netherlands

different types of alarm. These are indicated by the letter "L" and "H". Restricts which settings can be displayed or changed, and restricts

change by key operation. Phone 31-2356-81-300

• The default alarm type is "2"

FAX 31-2356-81-388

OMRON ELECTRONICS LLC

Other functions One Commerce Drive Schaumburg, IL 60173-5302 U.S.A

Conformance to EN/IEC Standards Refer to the E5CC/E5EC Digital Controllers User’s Manual (Cat. No. Phone 1-847-843-7900

H174) for information on the Advanced Function Setting Level,

This is a class A product.

Monitor/Setting Item Level, Manual Control Level, and other functions.

FAX 1-847-843-7787

In residential areas it may cause radio interference, in which case the user OMRON ASIA PACIFIC PTE. LTD.

Refer to the E5CC/E5EC Digital Controllers Communications Manual

may be required to take adequate measures to reduce interference.

(Cat. No. H175) for information on communications. No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Conformance to Safety Standards Phone 65-6835-3011

FAX 65-6835-2711

Reinforced insulation is provided between input power supply, relay

outputs, and between other terminals. OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku, Kyoto 600-8530 JAPAN

Das könnte Ihnen auch gefallen

- Nature Explorers Classroom Awards and RewardsVon EverandNature Explorers Classroom Awards and RewardsNoch keine Bewertungen

- E5cc Instruction Sheet enDokument1 SeiteE5cc Instruction Sheet enMuhammad Fariz Mat DarusNoch keine Bewertungen

- Manual E5ac Pr2asm 804 Open&CloseDokument2 SeitenManual E5ac Pr2asm 804 Open&CloseNguyễn Hào QuangNoch keine Bewertungen

- Instant Assessments for Data Tracking, Grade 1: Language ArtsVon EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNoch keine Bewertungen

- Quickstart: Audio/Video Inputs/Outputs/Reference Power Cabling Control CablingDokument2 SeitenQuickstart: Audio/Video Inputs/Outputs/Reference Power Cabling Control CablingINTERGUEST GuestNoch keine Bewertungen

- Manual de Instruccion 5kvaDokument1 SeiteManual de Instruccion 5kvaJuanca PiaNoch keine Bewertungen

- Al924a GB 019221900 1123 23062014Dokument1 SeiteAl924a GB 019221900 1123 23062014mahaNoch keine Bewertungen

- 2P162816-1 Dcs302ca61Dokument1 Seite2P162816-1 Dcs302ca61Ruan FernandesNoch keine Bewertungen

- E 5 EwlDokument2 SeitenE 5 EwlawatsiemensNoch keine Bewertungen

- Electrical Specifications 注意事項: Power Input WiringDokument2 SeitenElectrical Specifications 注意事項: Power Input WiringAmmar AlkindyNoch keine Bewertungen

- Epmab Epmab/A: PhotocellsDokument2 SeitenEpmab Epmab/A: PhotocellsSupuran RichardoNoch keine Bewertungen

- Plts Chemco Karawang 3.2 MWP: LegendDokument3 SeitenPlts Chemco Karawang 3.2 MWP: LegendmuliamakmurNoch keine Bewertungen

- Specifications 注意事項: Safety WiringDokument2 SeitenSpecifications 注意事項: Safety WiringMalik MayNoch keine Bewertungen

- Enlzt145260ra Inv 1kvaDokument2 SeitenEnlzt145260ra Inv 1kvaumair_aeNoch keine Bewertungen

- IM05D01C03-01E 06E 003.usDokument12 SeitenIM05D01C03-01E 06E 003.usTeteNoch keine Bewertungen

- Getting Ready Safety Precautions: User'S Guide Guía Del UsuarioDokument2 SeitenGetting Ready Safety Precautions: User'S Guide Guía Del UsuarioAnonymous 1iyu38Noch keine Bewertungen

- Philips A17r8mpw-001 Ba17p5f0103 2 PsuDokument5 SeitenPhilips A17r8mpw-001 Ba17p5f0103 2 Psujose luis montillaNoch keine Bewertungen

- 300 WATTS: 12 V Prim 190 To 440 V + Active PFCDokument1 Seite300 WATTS: 12 V Prim 190 To 440 V + Active PFCGuillaume FoubertNoch keine Bewertungen

- 6112 A 543 BFFD 8Dokument2 Seiten6112 A 543 BFFD 8CLIMA NOBRENoch keine Bewertungen

- Operating Instructions Mpa de en FR PT It Es Ja ZH Im0046064Dokument2 SeitenOperating Instructions Mpa de en FR PT It Es Ja ZH Im0046064qway896Noch keine Bewertungen

- Jayson Ruales Final Output p1Dokument1 SeiteJayson Ruales Final Output p1Arnel Pamaos Lopiba MontañezNoch keine Bewertungen

- Omron E5cwlDokument1 SeiteOmron E5cwlgillang1Noch keine Bewertungen

- Overveiw CNC Ver1.5 2021-06-07Dokument1 SeiteOverveiw CNC Ver1.5 2021-06-07Kien Nguyen TrungNoch keine Bewertungen

- Delta Electronics DVP28SV 128337Dokument2 SeitenDelta Electronics DVP28SV 128337Apurva GajwaniNoch keine Bewertungen

- Per 583430 PDFDokument1 SeitePer 583430 PDFavo638Noch keine Bewertungen

- Samsung-led-monitor-SA300 Service ManualDokument41 SeitenSamsung-led-monitor-SA300 Service ManualLuciano GerloNoch keine Bewertungen

- AMPLIFICADORDokument2 SeitenAMPLIFICADORJuanNoch keine Bewertungen

- Plano ElectricoDokument2 SeitenPlano Electricomauricio suarezNoch keine Bewertungen

- GOOLOO GE1200 - User ManualDokument1 SeiteGOOLOO GE1200 - User ManualzoltanpolyakNoch keine Bewertungen

- Eplob Eplob/A Epmob Epmob/A: PhotocellsDokument2 SeitenEplob Eplob/A Epmob Epmob/A: PhotocellsSupuran RichardoNoch keine Bewertungen

- Pioneer DVD Player DV-3022KVDokument2 SeitenPioneer DVD Player DV-3022KVricardo4roNoch keine Bewertungen

- 1007-ZN01-BM-103 - Small Power LayoutDokument1 Seite1007-ZN01-BM-103 - Small Power LayoutMHD MKNoch keine Bewertungen

- CTW320 Msy 00 El Abd 5002 03Dokument1 SeiteCTW320 Msy 00 El Abd 5002 03Jafffar MahasnehNoch keine Bewertungen

- CAP-1901-EM-02 - AC Switchboard-1Dokument1 SeiteCAP-1901-EM-02 - AC Switchboard-1Nindy FebrianiNoch keine Bewertungen

- Batteries: Color Code For Schematic LinesDokument2 SeitenBatteries: Color Code For Schematic LinesIsaac NewtonNoch keine Bewertungen

- AmpworksBass EFG1Dokument5 SeitenAmpworksBass EFG1Jaasiel AcenderStudioNoch keine Bewertungen

- Chaoshan Electrical PlanDokument3 SeitenChaoshan Electrical PlanRonielle MercadoNoch keine Bewertungen

- switchrack 참고도면 PDFDokument19 Seitenswitchrack 참고도면 PDFYoung-seok HwangNoch keine Bewertungen

- SPR3 en Tcd210147ad 20220704 Inst WDokument2 SeitenSPR3 en Tcd210147ad 20220704 Inst WManel CoelloNoch keine Bewertungen

- RC 1082 OmDokument56 SeitenRC 1082 OmCapitanSalamiNoch keine Bewertungen

- Digital HV 5KV Insulation Tester HTC 6250INDokument1 SeiteDigital HV 5KV Insulation Tester HTC 6250INindustrialindiaNoch keine Bewertungen

- NHA31477 25 QSG P5x20Dokument5 SeitenNHA31477 25 QSG P5x20samy.musNoch keine Bewertungen

- ABB - AF - Contactor - 4poleDokument6 SeitenABB - AF - Contactor - 4poleAhmad HamdanNoch keine Bewertungen

- Plakat Transient Immunity TestingDokument1 SeitePlakat Transient Immunity TestingSKN PiorunNoch keine Bewertungen

- NumericalRelaySelectionTable 756179 ENyDokument1 SeiteNumericalRelaySelectionTable 756179 ENyFaruk PatelNoch keine Bewertungen

- Getting Ready Safety Precautions: User'S Guide Guía Del UsuarioDokument2 SeitenGetting Ready Safety Precautions: User'S Guide Guía Del UsuarioMiguel Angel Cara RiosNoch keine Bewertungen

- LW130W Quick Manual TurDokument1 SeiteLW130W Quick Manual TurCarlo AlexandreNoch keine Bewertungen

- Simatic S5: System Manual CPU 100/102/103Dokument512 SeitenSimatic S5: System Manual CPU 100/102/103SanjeewaNoch keine Bewertungen

- Led TV: User ManualDokument2 SeitenLed TV: User Manualpernak pernik unikNoch keine Bewertungen

- SLD PV SolarDokument1 SeiteSLD PV SolarKhaliqus ShabirNoch keine Bewertungen

- Darlington: Silicon PNP Epitaxial Planar TransistorDokument1 SeiteDarlington: Silicon PNP Epitaxial Planar Transistormarcelo giussaniNoch keine Bewertungen

- 380910-Eia-0010-01 (2), Temp PDB-02 & 03Dokument1 Seite380910-Eia-0010-01 (2), Temp PDB-02 & 03Nikhil SutharNoch keine Bewertungen

- 3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPDokument2 Seiten3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPLượng Nguyễn XuânNoch keine Bewertungen

- Tan-Delta and Capacitance Test Set For HT Generator/Motor TestingDokument3 SeitenTan-Delta and Capacitance Test Set For HT Generator/Motor Testingmustafa180567% (3)

- Darlington: Silicon PNP Epitaxial Planar TransistorDokument1 SeiteDarlington: Silicon PNP Epitaxial Planar Transistorroberto carlos martinez narvaezNoch keine Bewertungen

- Product Data Sheet: MVS XF 100/130V AC/DCDokument1 SeiteProduct Data Sheet: MVS XF 100/130V AC/DCRyan TriadhitamaNoch keine Bewertungen

- Diagrama Electrico 785dDokument10 SeitenDiagrama Electrico 785dFrank Agurto LucianoNoch keine Bewertungen

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Dokument1 SeiteDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Elcio BrembattiNoch keine Bewertungen

- Instrument Hookup 8Dokument1 SeiteInstrument Hookup 8Wael ZakariaNoch keine Bewertungen

- Din en 1706Dokument20 SeitenDin en 1706ljtyk100% (4)

- BS Iec 60076-15-2015Dokument34 SeitenBS Iec 60076-15-2015Bilal QasimNoch keine Bewertungen

- Din en 1706Dokument20 SeitenDin en 1706ljtyk100% (4)

- BS en 764-7-2002 - Pressure Equipment Part 7Dokument42 SeitenBS en 764-7-2002 - Pressure Equipment Part 7Edy Wijaya100% (1)

- Electrical Symbols BS en 60617Dokument4 SeitenElectrical Symbols BS en 60617Rob Pettit0% (2)

- BS Iec 60076-15-2015Dokument34 SeitenBS Iec 60076-15-2015Bilal QasimNoch keine Bewertungen

- BS EN 334-2005 Gas Pressure Regulators For Inlet Pressures Up To 100 Bar PDFDokument65 SeitenBS EN 334-2005 Gas Pressure Regulators For Inlet Pressures Up To 100 Bar PDFMahmoud Kasban67% (3)

- Sling Table To Bs en 13414 For Iwrc PDFDokument1 SeiteSling Table To Bs en 13414 For Iwrc PDFPretyboy LovelyboyNoch keine Bewertungen

- New Weights Brochure en 2007Dokument16 SeitenNew Weights Brochure en 2007Edy WijayaNoch keine Bewertungen

- Bs en Iso 14122 Part 2 PDFDokument16 SeitenBs en Iso 14122 Part 2 PDFadasadNoch keine Bewertungen

- +GF+ BS en 10242Dokument45 Seiten+GF+ BS en 10242stignz100% (2)

- Sling Table To Bs en 13414 For Iwrc PDFDokument1 SeiteSling Table To Bs en 13414 For Iwrc PDFPretyboy LovelyboyNoch keine Bewertungen

- BS En-12285-1Dokument159 SeitenBS En-12285-1shaggeruk85% (13)

- BS en 12540-2000 - Corrosion Protection of MetalDokument26 SeitenBS en 12540-2000 - Corrosion Protection of MetalEdy WijayaNoch keine Bewertungen

- +GF+ BS en 10242Dokument45 Seiten+GF+ BS en 10242stignz100% (2)

- BS En-12285-1Dokument159 SeitenBS En-12285-1shaggeruk85% (13)

- New Weights Brochure en 2007Dokument16 SeitenNew Weights Brochure en 2007Edy WijayaNoch keine Bewertungen

- Electrical - Cara Baca Kode Toggle SwitchDokument3 SeitenElectrical - Cara Baca Kode Toggle SwitchEdy WijayaNoch keine Bewertungen

- +GF+ BS en 10242Dokument45 Seiten+GF+ BS en 10242stignz100% (2)

- Perbedaan ISO9001 PDFDokument6 SeitenPerbedaan ISO9001 PDFdevanyactqNoch keine Bewertungen

- Electrical - Cara Baca Kode Toggle SwitchDokument3 SeitenElectrical - Cara Baca Kode Toggle SwitchEdy WijayaNoch keine Bewertungen

- New Weights Brochure en 2007Dokument16 SeitenNew Weights Brochure en 2007Edy WijayaNoch keine Bewertungen

- Perbedaan ISO9001 PDFDokument6 SeitenPerbedaan ISO9001 PDFdevanyactqNoch keine Bewertungen

- New Weights Brochure en 2007Dokument16 SeitenNew Weights Brochure en 2007Edy WijayaNoch keine Bewertungen

- Draft ASX Operating Rules ProceduresDokument101 SeitenDraft ASX Operating Rules ProceduresEdy WijayaNoch keine Bewertungen

- JAS 1608 Rev. 2005 PDFDokument17 SeitenJAS 1608 Rev. 2005 PDFMayra Sánchez CabanillasNoch keine Bewertungen

- Dokumen Wajib ISO 14001 2015Dokument1 SeiteDokumen Wajib ISO 14001 2015Vina AfilianiNoch keine Bewertungen

- R111 2 E04Dokument37 SeitenR111 2 E04Firmansyah Budhi SaputhraNoch keine Bewertungen

- Sni Iso 14001 2015 Sistem Manajemen Lingkungan Persyaratan Dengan Panduan PenggunaanDokument2 SeitenSni Iso 14001 2015 Sistem Manajemen Lingkungan Persyaratan Dengan Panduan PenggunaanEdy WijayaNoch keine Bewertungen

- TCL Inverter Repair Guide LinDokument52 SeitenTCL Inverter Repair Guide LinJosè Ramòn Silva AvilèsNoch keine Bewertungen

- IQ4 Operating Instructions PDFDokument60 SeitenIQ4 Operating Instructions PDFMzeeshan Akram75% (4)

- Fangling Shape Cutting Control System: Operation and Installation ManualDokument147 SeitenFangling Shape Cutting Control System: Operation and Installation ManualJulio Ortega NNoch keine Bewertungen

- SPD3000 UserManual enDokument41 SeitenSPD3000 UserManual enmarquitos550bNoch keine Bewertungen

- Switches and Relays For The Power IndustryDokument82 SeitenSwitches and Relays For The Power IndustryMuhamad PriyatnaNoch keine Bewertungen

- 800T/H 30 MM Push Buttons: Time-Tested Durability, Industry Proven - A Legacy of LeadershipDokument8 Seiten800T/H 30 MM Push Buttons: Time-Tested Durability, Industry Proven - A Legacy of LeadershipluisNoch keine Bewertungen

- Abs HaldexDokument2 SeitenAbs HaldexBom_Jovi_681Noch keine Bewertungen

- AmwDokument19 SeitenAmwprasadgayuNoch keine Bewertungen

- Filtro Hidráulico Pi410 MahleDokument5 SeitenFiltro Hidráulico Pi410 MahleHIDRAFLUIDNoch keine Bewertungen

- WPS30S in D S e PDokument8 SeitenWPS30S in D S e PMesfin MamoNoch keine Bewertungen

- Instruction Manual Sunstar SPS-E1201H PDFDokument49 SeitenInstruction Manual Sunstar SPS-E1201H PDFMaskusyani88% (8)

- Omron Sysmac C200he-Cpu42Dokument259 SeitenOmron Sysmac C200he-Cpu42cuervocrowNoch keine Bewertungen

- 506118-000 MK-IV Rev J PDFDokument32 Seiten506118-000 MK-IV Rev J PDFMarran AlmarraniNoch keine Bewertungen

- Chlorination General SpecsDokument8 SeitenChlorination General Specsraghuwanshi12Noch keine Bewertungen

- Mongoose PT PRO and Meerkat Field Maintenance Checklist - RevDokument6 SeitenMongoose PT PRO and Meerkat Field Maintenance Checklist - RevSamuel RahonNoch keine Bewertungen

- S Kotch Spare PartsDokument8 SeitenS Kotch Spare PartsAnonymous u0wETydFNoch keine Bewertungen

- Toyota RAV4 Wiring DiagramsDokument188 SeitenToyota RAV4 Wiring DiagramsFarouk75% (4)

- DAF CF Electrical System (To Chassis 0E621376) Service ManualDokument792 SeitenDAF CF Electrical System (To Chassis 0E621376) Service ManualAlex100% (3)

- G300 - Wiring DiagramDokument3 SeitenG300 - Wiring DiagramAsad NizamNoch keine Bewertungen

- Product Catalogue 2013 Low Res VersionDokument82 SeitenProduct Catalogue 2013 Low Res VersionNaing Oo KyawNoch keine Bewertungen

- Switch Fuse Unit 32A..1200A OS1GB 1SCC311013C0201 - 19-06 - LowDokument186 SeitenSwitch Fuse Unit 32A..1200A OS1GB 1SCC311013C0201 - 19-06 - LowPrakash KandasamyNoch keine Bewertungen

- Cummins 3100 Series Generator Operation Service ManualDokument20 SeitenCummins 3100 Series Generator Operation Service ManualDennis100% (44)

- Almega Manual 1Dokument63 SeitenAlmega Manual 1Tecwyn WebsterNoch keine Bewertungen

- 16H Plano Eléctrico NA Version 6ZJDokument2 Seiten16H Plano Eléctrico NA Version 6ZJmanryNoch keine Bewertungen

- T1201 Operation ManualDokument4 SeitenT1201 Operation ManualTestor Nestor BNoch keine Bewertungen

- Bus Bar Seminer PresentationDokument28 SeitenBus Bar Seminer PresentationEr Chandan Baishya100% (1)

- PC01040102 0316 en Viking ProductCatalogue Gas VSN200Dokument120 SeitenPC01040102 0316 en Viking ProductCatalogue Gas VSN200ioan cristian cotorobaiNoch keine Bewertungen

- Hand and Power Tools For ConstructionDokument41 SeitenHand and Power Tools For ConstructionTamoy CooreNoch keine Bewertungen

- 980C Wheel Loader: Machine Harness Connector and Component LocationsDokument2 Seiten980C Wheel Loader: Machine Harness Connector and Component LocationsRafa GarciaNoch keine Bewertungen