Beruflich Dokumente

Kultur Dokumente

Tesi HE Pneumatic Retraction Unit - Power Technology

Hochgeladen von

Rajesh SirsathOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tesi HE Pneumatic Retraction Unit - Power Technology

Hochgeladen von

Rajesh SirsathCopyright:

Verfügbare Formate

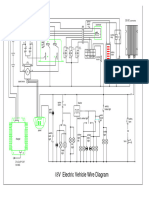

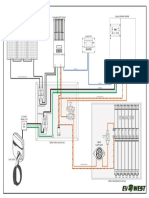

FROM THE

COMPANIES

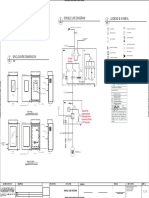

High-energy pneumatic

Energize Igniter

Command / from DCS

Interface Relay

retraction ignition unit L

X1

L

Protection Fuses

Protection Fuse

N N

5x20 - 6.3A T

X1 Power supply Spark tip

0 Terminal point

230 VAC

T

The introduction of High Energy he introduction of High Energy expenditures. Conventional igniters

Retractable Igniters comes manufacturers, including Tesi, have 25μF

X2

Retractable Igniters comes from from the need to reduce manu- accepted this challenge by developing

HEA Status

Igniter running

1

X2

2200 V HE Spark rod

connection box

the need to reduce manufac- facturing and operating costs a High-Energy (HE) system that, unlike (feedback to

DCS)

0

X2

in thermal power plants. In thermal power High Voltage (HV) igniters, presents 2

turing and operating costs in plants, which are mostly coal-ired, the electrical requirements so to deliver en- GND

thermal power plants most frequent way to start coal combus- ergy up to 24 Joules, needed to light the

tion in boilers is to ignite HFO (Heavy Fuel HFO directly, without use of gas. The

Oil). Main HFO burners, in turn, are lighted coniguration of this new high-energy High energy

by gas pilot burners, mainly natural gas. technology ensures that the type of fuel Transformer TR

terminal points

Pilot torches have no real function for the employed (liquid or gaseous) does not overtemperature 240-2100 Vac

process; their lame is only used to light affect ignition. High-Energy igniters have thermostat - 120 °C

the main burner and to support combus- been designed in order to resist to high

tion. Usually the pilot is turned on irst; temperatures, since for a reliable igni-

then, after having detected the lame, fuel tion, the positioning of the ignition tip Spark gap

1400 V

is introduced to ignite the main burner. close to the fuel mixture is key. Inside

This process presents a number of rel- the power plant boiler, main HFO burn-

evant operating costs: ers are not ixed but can rotate +/- 15° tion (both manufacturing and operating) reaches the threshold switching voltage retracted position of the spark-tip.

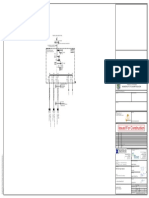

■ pilot torches costs (usually there are 24 in order to create a unique central ire- deriving from the replacement of pilot of the spark-gap device, the gap will ion- The unit is powered by compressed air

in a middle size power plant); ball to heat up the whole furnace before torches and gaseous fuel previously ize. The discharge current will low from and must be connected to an instru-

■ pilot torches related equipment coal is injected. High-energy igniters, needed to light HFO. the capacitor through the spark gap to ment air circuit in which the air is pre-

■ BMS (Burner Management System) therefore, has to be able to tilt accord- the spark tip through a high-energy cable treated to remove water, oil and solid

costs; ingly to the main burners angle, having a THE HIGH ENERGY CIRCUITRY and the spark rod. The spark is generated particles. Air pressure has to be in the 4

■ cost of natural gas burned in pilot lexibility of 30°. This lexibility to follow The High Energy electric Spark dis- through special semiconductor material, to 7 bar range. It can be equipped with

torches. the angle of HFO burners allow to spark charge Igniter works on the principle of not in the air, and therefore is not affected a two-speed regulator, so that speed in

and light directly heavy fuel oil lames. storing an electric charge in a capaci- by any environmental condition. When both directions can be inely adjusted if

Main boilers manufacturers, realizing the HE igniters, furthermore, are able to tor and discharging it through a special the energy is delivered as spark to the necessary.

high expenses involved in this process, satisfy an additional requirement: being spark tip to produce electrical sparks of igniter tip, the storage capacitors will be

have set themselves the challenge to in direct contact with lames, they are suficient energy to ignite oil particles. completely discharged as sparks at the CONCLUSIONS

minimize manufacturing and operating provided with a retraction device devel- When the High Energy system is ener- igniter tip, and immediately the charg- HE ignition systems, compared to tradi-

costs arising from using pilot torches. oped to protect the tip from lames once gized by the control room, 230 Volts AC, ing of the capacitors will start again. The tional ignition methods, present a series

It was therefore necessary to design a sparking is inished. In conclusion, the 50 Hz, the high energy control circuit charge-discharge cycle will be repeated of operational beneits:

new tool with electrical and mechanical new ignition tool presents several ad- automatically regulates the power (volt- at the rate of 4 times per second (+/- ■ possibility to ignite directly low lam-

characteristics capable of replacing pilots vantages, mainly related to the stream- age and current) to be supplied to the 10%) to produce sparks at the same rate. mable fuels;

thus allowing a decrease in power plant lining of the process and costs reduc- primary side of the transformer. The energy of each spark is proportional ■ replacement of traditional air/gas pilot

The power is always the minimum value to the square of capacitor voltage peak torches;

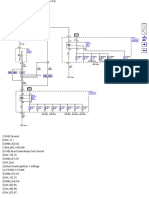

required to reach the preset perfor- and half value of capacitance (E=½CV²). ■ retraction systems protecting tips from

mances in terms of output energy and dirt and lames;

rate, so that device overheating is THE RETRACTOR UNIT ■ lexible rod to follow the main burners

limited. An overheating protection circuit The retractor assembly is a pneumatically angle.

is still provided to avoid any damage in operated system designed to advance

the case of highly intensive use of the the spark tip into the burner zone and re- All these elements turn in a consider-

device. Electrical power supplied to tract the spark tip after successful ignition able reduction in manufacturing and

the primary winding of the transformer or after the lapse of a preset time. operational costs of power plants man-

induces a high voltage on the secondary The retractor assembly is equipped agement. In brief, HE Ignition systems

winding of the power transformer; this is with a solenoid valve for controlling the can provide the most reliable and cost-

rectiied and the capacitor is charged. pneumatic cylinder and end point limit effective fuel ignition whether gas, light

Andrea Vercellone, Tesi Spa When the voltage of the capacitor switches for detecting the advanced or oil, diesel or heavy oil is used.

54 I Power Technology 11-12 2014 n. 86 Power Technology 11-12 2014 n. 86 I 55

Das könnte Ihnen auch gefallen

- +12 VDC +24 VDC: Vehicle Wiring Diagram 12V & 24V Systems 10/30/08Dokument2 Seiten+12 VDC +24 VDC: Vehicle Wiring Diagram 12V & 24V Systems 10/30/08Lucyan IonescuNoch keine Bewertungen

- Wiring Harness Single Line DiagramDokument1 SeiteWiring Harness Single Line Diagramrohan yajurvediNoch keine Bewertungen

- Super X WiringDokument1 SeiteSuper X WiringlNoch keine Bewertungen

- M1200 PinoutDokument2 SeitenM1200 PinoutRaviVelugulaNoch keine Bewertungen

- Gate Beban Murni Beban Induktif 100mH.5A Beban Tahanan Manusia 0... UrefDokument1 SeiteGate Beban Murni Beban Induktif 100mH.5A Beban Tahanan Manusia 0... UrefSeptian SyahNoch keine Bewertungen

- Markx Wiring DiagramDokument1 SeiteMarkx Wiring DiagramjohnNoch keine Bewertungen

- Lux M11 Led 2cilindrosDokument2 SeitenLux M11 Led 2cilindrosalmasasrlinformesNoch keine Bewertungen

- 48v Wiring DiagramDokument1 Seite48v Wiring DiagramKammoeNoch keine Bewertungen

- VN1648 RHD 02 XX DR e 1001Dokument1 SeiteVN1648 RHD 02 XX DR e 1001Franc Loui Mata PerolNoch keine Bewertungen

- E6 Servo Full Manual PDFDokument2 SeitenE6 Servo Full Manual PDFRomain JRNoch keine Bewertungen

- ArranqueDokument1 SeiteArranqueJorge LecchiNoch keine Bewertungen

- 20kv Single LineDokument11 Seiten20kv Single LineAmir hosain AsadiNoch keine Bewertungen

- Bring Your World To Light: Led LightsDokument15 SeitenBring Your World To Light: Led Lightsakhtar nawazNoch keine Bewertungen

- LT9 LED - 6 X 240W LED Lamps: Total 180,000 Lumens - Mast Height: 9000Mm - Yanmar 3 Cylinder EngineDokument2 SeitenLT9 LED - 6 X 240W LED Lamps: Total 180,000 Lumens - Mast Height: 9000Mm - Yanmar 3 Cylinder EnginerioajisaputrariyantoNoch keine Bewertungen

- Stoeger Airguns Product Catalog 2022Dokument10 SeitenStoeger Airguns Product Catalog 2022Jack JackNoch keine Bewertungen

- JCB LT9 MHDokument2 SeitenJCB LT9 MHNikkikumar MaisuriyaNoch keine Bewertungen

- Electrical Plan 1Dokument1 SeiteElectrical Plan 1Kherstine Muyano TantayNoch keine Bewertungen

- Captain Model EU 273 Stage V SmallDokument2 SeitenCaptain Model EU 273 Stage V SmallDeep DaveNoch keine Bewertungen

- b4 28 Ignition MotronicDokument25 Seitenb4 28 Ignition MotronicSamuelNoch keine Bewertungen

- Sohal Ak25 P Mig TorchDokument1 SeiteSohal Ak25 P Mig Torchamithaldar57270Noch keine Bewertungen

- 6SE709x xxx84Dokument1 Seite6SE709x xxx84qwasawsewNoch keine Bewertungen

- From April 2007-03-01Dokument1 SeiteFrom April 2007-03-01martin ortizNoch keine Bewertungen

- GA 26-30 FS Service Diagram EN Pune 9097554751-01Dokument2 SeitenGA 26-30 FS Service Diagram EN Pune 9097554751-01Mantenimiento Argen Peanuts SANoch keine Bewertungen

- Fusion Magic Fuel Usage and Contributions (Version 1)Dokument2 SeitenFusion Magic Fuel Usage and Contributions (Version 1)myinves00Noch keine Bewertungen

- Mechanical, Electrical & Plumbing (Mep) DrawingsDokument9 SeitenMechanical, Electrical & Plumbing (Mep) DrawingsNana Barima100% (1)

- Colour Wiring Diagram Enfield 12v AcdcDokument1 SeiteColour Wiring Diagram Enfield 12v AcdcKarthik Nayak RN50% (4)

- Protection Circuit Schematic - 2002-07-003Dokument1 SeiteProtection Circuit Schematic - 2002-07-003TetroVorinNoch keine Bewertungen

- Ignition Main RelaysDokument2 SeitenIgnition Main RelaysMartin Alonso Garcia GarciaNoch keine Bewertungen

- Pool Heater Schematic PDFDokument1 SeitePool Heater Schematic PDFRJ ParkerNoch keine Bewertungen

- EV West Off Grid Back Up PDFDokument1 SeiteEV West Off Grid Back Up PDFim247blackNoch keine Bewertungen

- EV West Off Grid Back Up PDFDokument1 SeiteEV West Off Grid Back Up PDFfoxNoch keine Bewertungen

- 182mm Cells Mono PERC With MBB & Half-Cut Technology: Quality GuaranteeDokument2 Seiten182mm Cells Mono PERC With MBB & Half-Cut Technology: Quality Guaranteewali gul wali khanNoch keine Bewertungen

- Wiring Lampu Mercury & FlourecentDokument2 SeitenWiring Lampu Mercury & FlourecentMuhamad PriyatnaNoch keine Bewertungen

- Customer Installation: 1102 K/ InternalDokument11 SeitenCustomer Installation: 1102 K/ InternalgetdatamachinaNoch keine Bewertungen

- IC-Engines LAB: Mechanical Engineering Department, IST, IslamabadDokument4 SeitenIC-Engines LAB: Mechanical Engineering Department, IST, IslamabadShahzaib Anwar OffNoch keine Bewertungen

- HFDSR - 1500kw 6kv Drwg.Dokument4 SeitenHFDSR - 1500kw 6kv Drwg.Sulistyono SulistyonoNoch keine Bewertungen

- T4 Base Wiring From May 1999 OnDokument23 SeitenT4 Base Wiring From May 1999 OnOHW SERNoch keine Bewertungen

- Max Fuse: ...... A: Main Power Supply ........... V ...... HZ 3Dokument18 SeitenMax Fuse: ...... A: Main Power Supply ........... V ...... HZ 3Abdellah Ibrahim100% (1)

- Overall Electrical Wiring DiagramDokument144 SeitenOverall Electrical Wiring DiagramArnuphap SudwaiyonNoch keine Bewertungen

- L1 + N + - Plastika Karton Gajbice: I8 I7 I6 I5 I4 I3 I2 I1 N L1Dokument1 SeiteL1 + N + - Plastika Karton Gajbice: I8 I7 I6 I5 I4 I3 I2 I1 N L1daddyriderNoch keine Bewertungen

- Subm Mittal D Data - MD Outdo DV-V105 Oor Uni 5W/DVN IT N1: F FeaturesDokument2 SeitenSubm Mittal D Data - MD Outdo DV-V105 Oor Uni 5W/DVN IT N1: F FeaturesJunior Pantaleon QuispeNoch keine Bewertungen

- WererrDokument1 SeiteWererrA cheng yangNoch keine Bewertungen

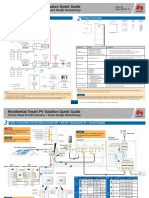

- Residential Smart PV Solution Quick Guide (Three-Phase PV+ESS Scenario + Smart Dongle Networking)Dokument8 SeitenResidential Smart PV Solution Quick Guide (Three-Phase PV+ESS Scenario + Smart Dongle Networking)Amer CajdricNoch keine Bewertungen

- Plano 1306Dokument5 SeitenPlano 1306Daniel ArdilaNoch keine Bewertungen

- 1.5MW Offgrid Solar Solution LayoutDokument1 Seite1.5MW Offgrid Solar Solution Layoutpeter LamurenNoch keine Bewertungen

- Regulacija 24 VDokument2 SeitenRegulacija 24 Vsandra1833Noch keine Bewertungen

- Governor DrawingDokument6 SeitenGovernor DrawingPratikTiwariNoch keine Bewertungen

- WM Porsche 928 Wiring Diagram - 1986Dokument20 SeitenWM Porsche 928 Wiring Diagram - 19869TECHNIK50% (2)

- WW - Scharan Airbeg 1995-02Dokument1 SeiteWW - Scharan Airbeg 1995-02stanioNoch keine Bewertungen

- 3mm LED MountDokument1 Seite3mm LED MountGregorNoch keine Bewertungen

- Powerwall 2 With Gateway 2 System Diagrams (Australia)Dokument2 SeitenPowerwall 2 With Gateway 2 System Diagrams (Australia)Onur Kaya0% (1)

- BrochureDokument2 SeitenBrochureDeepak VermaNoch keine Bewertungen

- JUPITER 9000K H1PreliminaryDokument1 SeiteJUPITER 9000K H1PreliminaryMarian FlorescuNoch keine Bewertungen

- TyB - Spark Extinguishing SystemsDokument8 SeitenTyB - Spark Extinguishing SystemsAlexandre Machado Dos SantosNoch keine Bewertungen

- EARCON Builders: Recommended Size of TransformerDokument1 SeiteEARCON Builders: Recommended Size of TransformerderfliwNoch keine Bewertungen

- Single Line Diagram 3 General Notes & Specification 1 Legend & Symbol 4Dokument1 SeiteSingle Line Diagram 3 General Notes & Specification 1 Legend & Symbol 4Abnar KumplishaNoch keine Bewertungen

- Tube&Tri Proof LightsDokument17 SeitenTube&Tri Proof LightsAdam Andrew OngNoch keine Bewertungen

- Delta PLC Dvp-slim-DIDODokument2 SeitenDelta PLC Dvp-slim-DIDOLuis RobertoNoch keine Bewertungen

- Illumination Layout For Power Gen Set BuildingDokument11 SeitenIllumination Layout For Power Gen Set BuildingDakore PorbeniNoch keine Bewertungen

- Keywords: Stall, Parallel Operation of Axial Flow Fans, Anti-Stall DeviceDokument6 SeitenKeywords: Stall, Parallel Operation of Axial Flow Fans, Anti-Stall DeviceRajesh SirsathNoch keine Bewertungen

- Disocont Tersus (DT-9) Legacy: Stock Feeder Controller UpgradeDokument2 SeitenDisocont Tersus (DT-9) Legacy: Stock Feeder Controller UpgradeRajesh SirsathNoch keine Bewertungen

- RKLISX!202 1-22/84: CIN No. L26941Up1983pLCO27278Dokument10 SeitenRKLISX!202 1-22/84: CIN No. L26941Up1983pLCO27278Rajesh SirsathNoch keine Bewertungen

- OPTIONS - January 2022Dokument1 SeiteOPTIONS - January 2022Rajesh SirsathNoch keine Bewertungen

- 103 CLT (For Conductive Media) : Features: SpecificationsDokument4 Seiten103 CLT (For Conductive Media) : Features: SpecificationsRajesh SirsathNoch keine Bewertungen

- Contracts 2Dokument3 SeitenContracts 2Rajesh SirsathNoch keine Bewertungen

- CIN: U40109MH2005SGC153645: (A Govt. of Maharashtra Undertaking)Dokument1 SeiteCIN: U40109MH2005SGC153645: (A Govt. of Maharashtra Undertaking)Rajesh SirsathNoch keine Bewertungen

- Options - December 2021Dokument1 SeiteOptions - December 2021Rajesh SirsathNoch keine Bewertungen

- Power Sector Eastern Region, Dj-9/1, Salt Lake City, Kolkata - 700 091 (033) 23211960 23211798/ 1691Dokument3 SeitenPower Sector Eastern Region, Dj-9/1, Salt Lake City, Kolkata - 700 091 (033) 23211960 23211798/ 1691Rajesh SirsathNoch keine Bewertungen

- Larsen & Toubro: STOCK CODE: 500510 Stock Code: LTDokument4 SeitenLarsen & Toubro: STOCK CODE: 500510 Stock Code: LTRajesh SirsathNoch keine Bewertungen

- Revisedchecklist 13032015Dokument29 SeitenRevisedchecklist 13032015Rajesh SirsathNoch keine Bewertungen

- Oil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersDokument8 SeitenOil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersRajesh SirsathNoch keine Bewertungen

- NovLight SeemaDokument1 SeiteNovLight SeemaRajesh SirsathNoch keine Bewertungen

- Scrip Code - 500180 Symbol - HDFCBANK: June 20, 2020 BSE Limited The National Stock Exchange of India LimitedDokument1 SeiteScrip Code - 500180 Symbol - HDFCBANK: June 20, 2020 BSE Limited The National Stock Exchange of India LimitedRajesh SirsathNoch keine Bewertungen

- Ip Transducers Series 500FCDokument2 SeitenIp Transducers Series 500FCRajesh SirsathNoch keine Bewertungen

- Salary Scale 1 53 PDFDokument1 SeiteSalary Scale 1 53 PDFRajesh SirsathNoch keine Bewertungen

- Report On Pressure Control OperationDokument3 SeitenReport On Pressure Control OperationRajesh SirsathNoch keine Bewertungen

- Fire Fighting SystemDokument9 SeitenFire Fighting SystemRajesh SirsathNoch keine Bewertungen

- Oil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersDokument8 SeitenOil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersRajesh SirsathNoch keine Bewertungen

- Tps Parli: Pay Fixation Arrears: Apr-2018 To Sep-2018Dokument1 SeiteTps Parli: Pay Fixation Arrears: Apr-2018 To Sep-2018Rajesh SirsathNoch keine Bewertungen

- Electronic Remote Water Level Indicator Type EWLI-3B: EL65 EL60Dokument34 SeitenElectronic Remote Water Level Indicator Type EWLI-3B: EL65 EL60Rajesh SirsathNoch keine Bewertungen

- Paystub 000000Dokument1 SeitePaystub 000000Rajesh SirsathNoch keine Bewertungen

- D18 - 70 Minutes of Meeting 09 06 2017Dokument17 SeitenD18 - 70 Minutes of Meeting 09 06 2017Rajesh SirsathNoch keine Bewertungen

- Kawas (Liq) TPC U-7 (RLNG) Kawas (RLNG) Gandhar (RLNG) : State Mod Stack of Variable Charges (VC) For Oct-2020 (R1)Dokument1 SeiteKawas (Liq) TPC U-7 (RLNG) Kawas (RLNG) Gandhar (RLNG) : State Mod Stack of Variable Charges (VC) For Oct-2020 (R1)Rajesh SirsathNoch keine Bewertungen

- The Kyoto ProtocolDokument2 SeitenThe Kyoto ProtocolCha-am Jamal100% (1)

- Civil Engineering Department DCC50252 Building ServicesDokument5 SeitenCivil Engineering Department DCC50252 Building ServicesNalliz MuthusamyNoch keine Bewertungen

- Physics SP - 1 SolutionsDokument20 SeitenPhysics SP - 1 SolutionsAjitesh AwasthiNoch keine Bewertungen

- Picket Fence Free FallDokument3 SeitenPicket Fence Free FallAndrei IorgaNoch keine Bewertungen

- Green Analytical Chemistry Aplplication and EducationDokument14 SeitenGreen Analytical Chemistry Aplplication and EducationItha Hernita NoviantiNoch keine Bewertungen

- ES Notes 6 Environmental Policies and PracticesDokument8 SeitenES Notes 6 Environmental Policies and Practicessuprithagowda834Noch keine Bewertungen

- Demo 30 Kiran NCERT Geography Class VI To XII CompendiumDokument30 SeitenDemo 30 Kiran NCERT Geography Class VI To XII CompendiumPrince X DebashisNoch keine Bewertungen

- Carrier Handbook of Air Conditioning System Design Part 1Dokument2 SeitenCarrier Handbook of Air Conditioning System Design Part 1Dharani PathyNoch keine Bewertungen

- Loeblein Physics Clicker Questions2013Dokument296 SeitenLoeblein Physics Clicker Questions2013rg280cNoch keine Bewertungen

- Early Universe, Black Hole EvaporationDokument6 SeitenEarly Universe, Black Hole Evaporationrla97623Noch keine Bewertungen

- BSC Environmental Management Semester Ii, Spring Semester 2021Dokument22 SeitenBSC Environmental Management Semester Ii, Spring Semester 2021Temphel LhendupNoch keine Bewertungen

- Lesson Plan 2 Biomass and Wind EnergyDokument9 SeitenLesson Plan 2 Biomass and Wind EnergyPrachi SharmaNoch keine Bewertungen

- Meftah 2019Dokument7 SeitenMeftah 2019Bekraoui KeltoumNoch keine Bewertungen

- Hot Weather Concreting Cold Weather ConcretingDokument46 SeitenHot Weather Concreting Cold Weather ConcretingIRFAN SHARNoch keine Bewertungen

- Andaman Chronicle, August 11, 2021.pmdDokument6 SeitenAndaman Chronicle, August 11, 2021.pmdobaid44Noch keine Bewertungen

- Atomic Spectroscopy - Nicolas H. BingsDokument31 SeitenAtomic Spectroscopy - Nicolas H. BingsAngelIsaiNoch keine Bewertungen

- Small Scale & Mini LNG Liquefaction Systems: Gas Systems: Product InformationDokument2 SeitenSmall Scale & Mini LNG Liquefaction Systems: Gas Systems: Product InformationsatishchemengNoch keine Bewertungen

- Graphic Sedimentary Log PDFDokument2 SeitenGraphic Sedimentary Log PDFemilia597Noch keine Bewertungen

- Mind Map For Science Year 5Dokument43 SeitenMind Map For Science Year 5usemyknow.blogspot.com100% (11)

- Calizas y Dolomitas Rescursos en British ColumbiaDokument156 SeitenCalizas y Dolomitas Rescursos en British ColumbiaEsteban Manrique ZúñigaNoch keine Bewertungen

- Language Arts Worksheet Cause and Effect Weathering 1Dokument2 SeitenLanguage Arts Worksheet Cause and Effect Weathering 1api-357642928100% (3)

- DRRR 12 Lesson 1 - 5 Finale 1Dokument29 SeitenDRRR 12 Lesson 1 - 5 Finale 1Johnlery Farofil ReprotoNoch keine Bewertungen

- Comparing Masses of Reactants and ProductsDokument4 SeitenComparing Masses of Reactants and ProductsDaniel TriumbariNoch keine Bewertungen

- Sustainable Energy 2Nd 2Nd Edition Richard A Dunlap Full Download ChapterDokument51 SeitenSustainable Energy 2Nd 2Nd Edition Richard A Dunlap Full Download Chapterkari.schreck473100% (6)

- Unsw Ume m1 Vent&Mineserv NotesDokument140 SeitenUnsw Ume m1 Vent&Mineserv Noteskrainajacka100% (2)

- Day 1 - Full ScriptDokument4 SeitenDay 1 - Full ScriptThái Hà ĐỗNoch keine Bewertungen

- Amara Raja EPC Projects BU - Walk-In Interviews On 21st & 22nd May '22-1Dokument1 SeiteAmara Raja EPC Projects BU - Walk-In Interviews On 21st & 22nd May '22-1SatishNoch keine Bewertungen

- Concentrated Solar Power Project in Anantapur District of Andhra PradeshDokument37 SeitenConcentrated Solar Power Project in Anantapur District of Andhra PradeshKrishna ChowdaryNoch keine Bewertungen

- Introduction IELTS - Matching HeadingDokument19 SeitenIntroduction IELTS - Matching HeadingFitri RahmawatiNoch keine Bewertungen

- BIENES Science 8 Quarter 2 Exam 2Dokument6 SeitenBIENES Science 8 Quarter 2 Exam 2Irish Campomanes BienesNoch keine Bewertungen