Beruflich Dokumente

Kultur Dokumente

Engine OM 501 LA: Large Adt'S MK Iii

Hochgeladen von

BassieOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Engine OM 501 LA: Large Adt'S MK Iii

Hochgeladen von

BassieCopyright:

Verfügbare Formate

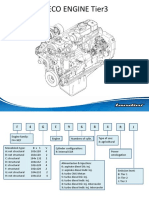

LARGE ADT’s MK III

ENGINE

OM 501 LA

Issue: 3

(April 2004)

Technical Training Documentation

BELL EQUIPMENT COMPANY

Richards Bay

Chapter 5 ENGINE LARGE D-SERIES MK III

THEORY OF OPERATION

1 2 3 4 5 6 7 8 9 10

10

14 11

13 12

16 15

1. Final Fuel Filter.

2. Oil Filter.

3. Engine Exhaust Valve Rocker Arm.

4. Engine Intake Valve Rocker Arm.

5. Engine Exhaust Valve Brake.

6. Fuel Delivery Nozzle.

7. Electronic Unit Pump.

8. Intake Manifold.

9. Turbo Charger

10. Camshaft

11. Starter Motor.

12. Crankshaft.

13. Alternator.

14. Fuel Pump.

15. Flywheel.

16. Oil Pump.

The engine is liquid cooled, 90° V-6 cylinder. The cast iron block is one piece and each cylinder

has a separate cylinder head. It has overhead valves, 4 per cylinder, two intake valves and two

exhaust valves. Roller cam followers ride on the camshaft which move the push rods that open

and close the valves. The Unit pumps also ride on the camshaft which send pressurized fuel

through a solenoid to the fuel pipe to the fuel delivery nozzles, which are located directly over

the top of the piston. The unit pumps are electronically controlled by the MR (Motor Regulator)

or PLD controller, a crankshaft position sensor, camshaft position sensor and unit pump

solenoids.

Bell Training Center Revision 0.3 451

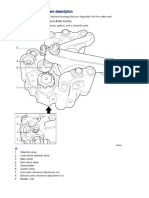

Chapter 5 ENGINE LARGE D-SERIES MK III

FUEL SYSTEM

7.1 8.1 9.1 10.1 11.1 12.1

7 8 9 10 11 12

6

13

4.2

4

5 4.1

5.1

ENGINE

2 1.1

14

1

TR000475

1. Fuel Tank 1.1. Fuel Cap with intergrated check valves

2. Racor Filter (Primary) 3. Fuel Pump

4. Fuel Filter (Secondary) 4.1. Filter Drain Valve (Open when loosened)

4.2. Orifice 5. Cold Start Solenoid

5.1. Cold Start Glow Plug 6. Fuel Temperature Sensor

7 Unit Pump cylinder 1 7.1. Injector cylinder 1

8 Unit Pump cylinder 2 8.1. Injector cylinder 2

9 Unit Pump cylinder 3 9.1. Injector cylinder 3

10 Unit Pump cylinder 4 10.1. Injector cylinder 4

11 Unit Pump cylinder 5 11.1. Injector cylinder 5

12 Unit Pump cylinder 6 12.1. Injector cylinder 6

13. Fuel pressure relief valve 4.5 Bar (65 psi) 14 Heat exchanger

Bell Training Center Revision 0.3 452

Chapter 5 ENGINE LARGE D-SERIES MK III

ELECTRONIC UNIT PUMP - FUEL INJECTION

TR000481

The Unit Pump system is designed to precisely control:

• The start of injection,

• An accurate delivery of a calculated amount of fuel.

• A sharp end of injection.

The fuel system consists of four sub-systems;

• Low Pressure Supply System,

• High Pressure System - Unit Injectors,

• Fuel Delivery Nozzles,

• Control System.

The Unit Pump system has these notable features:

• Precision control of timing and fuel delivery,

• Field proven reliability,

• Electronic control of each cylinder,

• One unit injector per cylinder,

• High injection pressures,

• Low emissions,

• Compact design,

• Eliminates injection pump,

• No injection timing adjustment required

Bell Training Center Revision 0.3 453

Chapter 5 ENGINE LARGE D-SERIES MK III

FUEL DELIVERY

Suction Stage

1 2

4 3

5

12

11 6

7

10

8

13 RETURN FUEL

9 14 LOW PRESSURE

40D3001CFM

1. Fuel Delivery Nozzle.

2. Connector Pipe.

3. Unit Pump.

4. Valve.

5. Solenoid.

6. Supply Gallery in Crankcase.

7. High Pressure Chamber.

8. Pump Plunger.

9. Engine Camshaft.

10. Pressure Relief Chamber.

11. Return Flow Gallery in Crankcase.

12. Bleed-Off Chamber.

13. Return Fuel.

14. Low Pressure.

The Unit Pump (3) ride on individual lobes on the engine camshaft (9). There is one Unit Pump

per cylinder. The Unit Pumps are mounted in the block of the engine under the intake manifold.

There are passages in the block that route fuel to and from the Unit Pumps. The fuel delivery

nozzles (1) are located in the cylinder head and are positioned directly above the pistons. A

connector pipe (2) is used to direct fuel from theUnit Pump to the injector nozzles. Internal pas-

sages in the cylinder heads allow excess fuel from the nozzles to be bled off. A solenoid (5)

controls the fuel metering valve (4). During the suction stage, the pump plunger (8) moves

down. As a result of the constant fuel excess pressure of approximately 600kPa (6 bar) (87

psi) in the fuel low pressure circuit, the high pressure chamber (7) of the unit pump is fitted with

fuel through the supply gallery (6)

Bell Training Center Revision 0.3 454

Chapter 5 ENGINE LARGE D-SERIES MK III

Pre-Delivery Stage

1 2

4 3

5

12

11 6

7

10

8

13 RETURN FUEL

14 LOW PRESSURE

9

40D3002CFM

1. Fuel Delivery Nozzle.

2. Connector Pipe.

3. Unit Pump.

4. Valve.

5. Solenoid.

6. Supply Gallery in Crankcase.

7. High Pressure Chamber.

8. Pump Plunger.

9. Engine Camshaft.

10. Pressure Relief Chamber.

11. Return Flow Gallery in Crankcase.

12. Bleed-Off Chamber.

13. Return Fuel.

14. Low Pressure.

During the pre-delivery stage, the pump plunger (8) moves up. As the valve (4) is not yet

closed, the fuel is first forced into the pressure relief chamber (10), then into the return gal-

lery(11).

Bell Training Center Revision 0.3 455

Chapter 5 ENGINE LARGE D-SERIES MK III

Delivery Stage

1 2

4 3

5

12

11 6

7

10

8

13 RETURN FUEL

14 LOW PRESSURE

15 HIGH PRESSURE

9 40D3003CFM

1. Fuel Delivery Nozzle.

2. Connector Pipe.

3. Unit Pump.

4. Valve.

5. Solenoid.

6. Supply Gallery in Crankcase.

7. High Pressure Chamber.

8. Pump Plunger.

9. Engine Camshaft.

10. Pressure Relief Chamber.

11. Return Flow Gallery in Crankcase.

12. Bleed-Off Chamber.

13. Return Fuel.

14. Low Pressure.

15. High Pressure.

As soon as the valve (4) is closed while the pump plunger (8) is moving towards its top dead

centre, the unit pump is in the delivery stroke. Fuel injection into the combustion chamber takes

place in the delivery stage. During this stage the fuel pressure in the high pressure chamber

(7) rises to a pressure approximately 160 000 kPa (1600 bar) (23 206 psi).

Bell Training Center Revision 0.3 456

Chapter 5 ENGINE LARGE D-SERIES MK III

Residual Stage

1 2

4 3

5

12

11 6

7

10

8

13 RETURN FUEL

14 LOW PRESSURE

9

40D3004CFM

1. Fuel Delivery Nozzle.

2. Connector Pipe.

3. Unit Pump.

4. Valve.

5. Solenoid.

6. Supply Gallery in Crankcase.

7. High Pressure Chamber.

8. Pump Plunger.

9. Engine Camshaft.

10. Pressure Relief Chamber.

11. Return Flow Gallery in Crankcase.

12. Bleed-Off Chamber.

13. Return Fuel.

14. Low Pressure.

After the valve (4) has opened (end of delivery), The fuel pressure in the high pressure cham-

ber (7) is collapsing. The remaining fuel delivery by

the pump plunger (8) up to the apex of the camshaft (9), is again forced into the pressure relief

chamber (10) and the return flow gallery (11).

The pressure relief chamber serves as an expansion chamber for the pressure peaks of the

unit pump in the residual stage. This prevents the pressure ratio of the adjacent unit pumps

being affected through the return flow gallery.

Bell Training Center Revision 0.3 457

Chapter 5 ENGINE LARGE D-SERIES MK III

CHARGE AIR SYSTEM

An entirely new concept has been developed for the charge air ducting of the 500 Series En-

gine. A compact charge air housing, in single unit format for the V6-engine with combined or

separate cold and hot air pipes is screwed centrally to the crankcase by means of clamps with

vertical bolts. This arrangement makes the housing easy to remove and install. The charge air

housing is elastically isolated from the individual cylinder heads by means of elastomer seals,

thereby reducing noise and compensating the tolerances and differing thermal expansion

rates.The V6-engines has one turbocharger.The turbine and compressor are designed for

rapid and dynamic torque build up even at low engine speeds, with ample torque response be-

tween 1000 and 1500 rpm

TR000478

Bell Training Center Revision 0.3 458

Chapter 5 ENGINE LARGE D-SERIES MK III

ELECTRONIC CONTROL

PLD

TR000479

The MR (Motor Regulator) or also known as the PLD is mounted on the right HAND side of the

engine and is the heart of the Electronic control.The PLD has a small Heat Exchanger mounted

on the side of it to cool the unit. Diesel Oil from the tank in vented through this cooler.

The PLD permanently receives all relevant engine data from the numerous sensors on the en-

gine which include crankshaft sensor, camshaft sensor,charge air pressure sensor ,

atmospheric sensor,fuel temperature sensor etc.The information recieved from these sensors

is used to manage the ideal time of fuel injection and quantity, in respect to engine operating

and external factors.

Effective protection of engine from overloading can also be achieved.

Warning signals or critical states (oil pressure, coolant temperature, engine speed etc.) can

also be achieved by activating certain parameters.

The PLD has two Connectors:

55 PIN CONNECTOR

This connector connects all the sensors and solenoids on the engine to the electronic control

unit (PLD).

16 PIN CONNECTOR

The 16 Pin connector connects the ADM or ECU in the cab to the PLD via a Mercedes Benz

Data cable (CAN BUS)

Battery positive,Ignition positive,Ground,Starter input and Outputs are also connected to this

connector.

Bell Training Center Revision 0.3 459

Chapter 5 ENGINE LARGE D-SERIES MK III

ELECTRICAL SCHEMATIC

B16

2 BK/ YL 0.5 N3-1

1 BR/ YL 0.5

PLD

N3-20

B15

2 BR/ VL 0.5 N3-19

ENGINE

1 BK/ VL 0.5 N3-2

CONTROL

2 WH/ YL 0.5

UNIT

N3-3

B65

1 RD/ YL 0.5 N3-34

2 BR/ WH 0.5 N3-15

B11

1 GY/ BR 0.5 N3-39

N3-4

N3-5

B90 3 GN 0.5 N3-7

1 BL 0.5 N3-22

4 VL 0.5 N3-29

TEMP

2 BR/ BK 0.5 N3-48

B12 1 GN/ BL 0.5 N3-32

2 GR/ YL 0.5 N3-10 X106

BR/ GY 0.5 MR-1

3 N3-6

MR-3

N3-8

MR-4

2 YL 0.5 N3-49

B14 MR-2

1 WH 0.5 N3-33

MR-9

2 BL/ WH 0.5 N3-30

START MR-11

1 RD/ BK 0.5

S10

MR-15

RD/ WH 0.5 N3-35

2

STOP N3-11

V6 S11

1

N3-12

MR-6

GY/ BK 1.5

MR-8

N3-54

Y9 4 1 Y6 MR-12

GY/ WH 1.5 N3-53

WH/ RD 1.5 MR-13

N3-47

Y10 Y7 N3-16

5 2

GY/ BL1.5 N3-44

RD/ BL 1.5 N3-9

Y11 6 3 Y8 WH/ BL 1.5

GY/ YL 1.5 N3-45

N3-14

N3-17

N3-18

N3-21

LEGEND

N3-24

UNIT DESCRIPTION

N3-26

B11 OIL TEMPERATURE SENSOR

N3-27

B12 OIL PRESSURE SENSOR

N3-28

B14

CAM SHAFT SENSOR N3-31

B15

B16 CRANK SHAFT SENSOR N3-36

B65 COOLANT TEMPERATURE SENSOR

B90 CHARGE AIR PRESSURE AND TEMPERATURE SENSOR N3-40

S10 START BUTTON N3-41

S11 STOP BUTTON N3-42

Y6 UNIT PUMP SOLENOID CYLINDER 1 N3-43

Y7 UNIT PUMP SOLENOID CYLINDER 2 N3-46

Y8 UNIT PUMP SOLENOID CYLINDER 3 N3-50

Y9 UNIT PUMP SOLENOID CYLINDER 4 N3-51

Y10 UNIT PUMP SOLENOID CYLINDER 5

N3-52

Y11 UNIT PUMP SOLENOID CYLINDER 6

N3-55

TR000476

Bell Training Center Revision 0.3 460

Chapter 5 ENGINE LARGE D-SERIES MK III

REMOVE PAGE AND

INSERT PLD SCHEMATIC

TR001094

Bell Training Center Revision 0.3 461

Chapter 5 ENGINE LARGE D-SERIES MK III

COLD START OPERATION

2

3

1. Glow Plug.

2. Solenoid.

3. Cold Start Jet.

The cold start system operates only when the engine coolant temperature is below 15° C

(59° F). When the key switch is tuned to the “ON” the position, the glow plug (1) begins to heat

up and the indicator light on the dash will light up. Light will stay on and the glow plug will con-

tinue to heat up for approximately twenty seconds.

When the key switch is turned to the START position, the solenoid (2) is energized, allowing

fuel to flow to the cold start jet (3). The fuel from the jet is sprayed on the glow plug causing

the fuel to atomize. The atomized air/fuel mixture is directed to the cylinders by the incoming

air through the intake manifold.

Bell Training Center Revision 0.3 463

Chapter 5 ENGINE LARGE D-SERIES MK III

ENGINE MALFUNCTIONS

Table 1:

Symptom Problem Solution

Starter motor turns engine too Batteries under charged Recharge or replace batteries.

slowly

Poor engine ground connection. Repair, clean or secure

connections.

Loose or dirty battery terminals. Clean and tighten battery

terminals.

Worn starter motor. Perform starter load test.

Hydraulic Cut Off Solenoid Check if brakes are chargring

Valve. while cranking.Check for

hydraulic pressure on ML1 while

cranking, If a pressure is visible

replace solenoid.

Hard starting when cold Defective cold start aid. See previous page.

Incorrect valve clearance. Adjust valve clearance .

Compression too low. Test compression.

Engine turns but does not start Insufficient fuel in fuel tank. Fill tank and bleed system.

Compression too low. Test compression.

Low fuel pump pressure. Test fuel pump pressure.

Engine stops soon after starting Insufficient fuel in fuel tank. Fill tank and bleed system.

Air in fuel system. Bleed system, check and repair

air entry.

Blocked fuel filters. Replace fuel filters.

Low fuel pump pressure. Test fuel pump pressure

Check fault codes.

Engine misfires Incorrect valve clearance. Adjust valve clearance.

Compression too low. Test compression.

Low fuel pump pressure. Test fuel pump pressure

Low engine oil pressure Incorrect grade of oil. Change oil.

Low pump output. Test oil pump pressure.

Pressure relief valve stuck. Install new pressure relief valve

Engine bearings worn. Remove, inspect and repair.

Abnormal oil consumption Crankcase breather or line Inspect and repair.

blocked.

Valve stem seals worn Replace valve stem seals.

Valve guides worn. Replace valve guides.

Piston rings worn; cylinders Test compression

scored.

Bell Training Center Revision 0.3 464

Chapter 5 ENGINE LARGE D-SERIES MK III

Table 1:

Symptom Problem Solution

Excessive vibration at any Worn or broken engine Inspect, repair or replace.

speed. mountings.

Drive shaft out off balance. Balance or replace.

Black smoke from exhaust. Inlet system restricted. Service and repair inlet system.

Incorrect grade of fuel. Reset valve clearance.

Worn fuel delivery nozzles. Replace fuel delivery nozzles

White smoke from exhaust. Engine running too cold. Check that thermostats are not

stuck open.

Worn fuel delivery nozzles. Replace fuel delivery nozzles

Pistons, rings or liners scored. Test compression.

Check cylinder head gasket.

Coolant entering cylinder bores. Replace cylinder head gasket.

Cold start solenoid defective. Test solenoid.

Bell Training Center Revision 0.3 465

Chapter 5 ENGINE LARGE D-SERIES MK III

ENGINE ADJUSTMENTS

DISPLAY MENU TACHOMETER

bell 4206d

0N

712 n/min

2314

27.7 volts

GD1029CFM

The tachometer on the Menu Display Unit is accurate for test work.

SLOW AND FAST IDLE ADJUSTMENT

There is no slow or fast idle adjustment. If slow or fast idle is not within specification, check for

an engine mechanical problem or an electrical failure.

Slow Idle Speed RPM’s - - - - - - - - - - - - - - - - 600 ± 20

Fast Idle Speed RPM’s- - - - - - - - - - - - - - - - 2240 ± 20

Bell Training Center Revision 0.3 466

Chapter 5 ENGINE LARGE D-SERIES MK III

VALVE CLEARANCE ADJUSTMENT

To prevent accidental starting of the engine while performing valve adjustments, always turn battery

disconnect switch to “OFF”

NOTE:Check and adjust valve clearance only when engine is COLD.

Remove rocker arm cover.

Install cranking device DC280088.

There is 37 slots (1) machined in the flywheel. One slot has a dimple in it. This is the TDC tim-

ing mark. Turn engine in the direction of rotation until TDC timing mark (2) on flywheel lines up

in centre of the window in timing case.

Note: All valves can be adjusted in two crankshaft positions.

Rocker arms and push rods for number one cylinder should be loose. If not, rotate engine 360°.

Engine must be at TDC on the compression stroke for number one cylinder.

Note: When adjusting valve clearance, the bolt on the valve bridge should on no account be loosened.

Bell Training Center Revision 0.3 467

Chapter 5 ENGINE LARGE D-SERIES MK III

Measure the valve clearance between the rocker arm and the valve bridge with a feeler gauge.

4

1

5

2

6

3

With number one cylinder on TDC, Check the valve clearance on cylinder one - intake and ex-

haust, cylinder two - exhaust, cylinder three - intake, cylinder four - exhaust and cylinder six -

intake. Crank engine until cylinder five is on TDC (cylinder one valve overlap):

Check valve clearance on cylinder two - intake, cylinder three - exhaust, cylinder four - intake,

cylinder five - intake and exhaust and cylinder six - exhaust.

Intake Valve Clearance - - - - - - - - -0.40 mm (0.016in.)

Exhaust Valve Clearance - - - - - - - -0.60 mm (0.024in.)

Locknut tightening torque - - - - - - - - - - 50Nm (37 lb-ft)

To adjust clearance: Loosen locknut (1) and turn adjusting screw (2) in or out depending on

gap to big or small. Tighten locknut to specification while holding adjusting screw in position.

Adjust valves in same order used for checking. Check clearance again after tightening locknut.

Bell Training Center Revision 0.3 468

Chapter 5 ENGINE LARGE D-SERIES MK III

EXHAUST BRAKE ADJUSTMENT

With engine off, check the clearance between the control arm (1) and the stop (2). In the brake

valve “OFF” position, the control arm should be resting on the stop.

Disconnect the air line (3) from the cylinder. Connect a regulated air supply line to the cylinder.

Regulate air pressure so pressure is approximately 740 - 810 kPa (7.4 - 8.1 bar) (107 - 117

psi).

2 3

1

4

Check control arm (1) to stop (2) clearance. The control arm must not rest on the stop. There

must be slight clearance between the control arm and stop to ensure that exhaust brake is fully

closed.

If adjustment is needed, loosen locknut (3), remove clip (4) and disconnect cylinder from

control arm. Turn rod end (5) for adjustment.

Bell Training Center Revision 0.3 469

Chapter 5 ENGINE LARGE D-SERIES MK III

ENGINE TESTS

CYLINDER COMPRESSION TEST

Note: Compression pressures are affected by the cranking speed of the engine. Before beginning the

test, ensure that the batteries are fully charged and the starter motor is in a good working condition.

Remove fuel delivery nozzle from cylinder being tested.

Install compression tester adapter (1) into cylinder head.

Install holddown clamp (2) using an M10 x 1.5 x 70 mm long cap screw (3).

Install compression tester to adapter.

Engine must not be started with fuel line from the unit pump disconnected. Remove the F16 ECU Power

Relay fuse to prevent engine from starting.Remove the F16 ECU/EUI Power Relay Fuse.

Crank engine approximately ten seconds. Record readings and compare to specification.

Engine Compression Pressure - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - 2800kPa (28 bar) (406 psi)

Permissible Difference Between Cylinders - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - -400kPa (4 bar) (58psi).

Bell Training Center Revision 0.3 470

Chapter 5 ENGINE LARGE D-SERIES MK III

FUEL PUMP PRESSURE TEST

Specification

Pressure At Slow Idle210 -300 kPa (2.1 - 3 bar) (30 - 44psi).

Pressure At Fast Idle500 - 600kPa (5 - 6 bar) (73 - 87psi).

Essential Tools

Parker No. 34982-16-6: Banjo Union.

Parker No. 0502-12-12: 1 1/16 - 12M x 3/4 - 14NPT F Adapter.

Parker No. 3/4 x 1/2 PTR: 3/4 - 14 NPT M x 1/2 - 14 NPT F Pipe Thread Reducer.

Parker No. 1/2 x 3/8 PTR: 1/2 - 14 NPT M x 3/8 - 18 NPT F Pipe Thread Reducer.

Parker No. 30182-6-6: 3/8 - 18 NPT M x 3/8 Barb Fitting.

Service Equipment And Tools

Hydraulic Tester.

0.5 to 15 GPM Lt. Flow Meter.

5 4 3

1

1

40D3005CFM

Connect banjo union fittings (1) to fuel pump outlet port and fuel filter inlet.

Connect fittings (2 - 5) to flow meter and flow meter to hydraulic tester.

Run engine at slow idle and measure fuel pump pressure. Compare to specification.

Run engine at fast idle and compare to specification.

Bell Training Center Revision 0.3 471

Chapter 5 ENGINE LARGE D-SERIES MK III

OIL PUMP PRESSURE TEST

Specification

Engine Oil Pressure at Slow Idle - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50kPa (0.5 bar) (7.3psi).

Engine Oil Pressure at Fast Idle - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 250 kPa (2.5 bar) (36.3psi).

Essential Tools

Parker No. 8M16F80MX: M 16 x 1.5 M x 3/4 - 16 M 37° Adapter.

3/4 - 16 M 37° x 3/4 - 16 F 37° Sw 90° Elbow.

7/16 - 20 M 37° x 3/4 - 16 F 37° Reducer.

Service equipment and tools

413 kPa (4.1 bar) (60psi) Gauge.

1

2

40D3006CFM

Remove engine oil pressure sensor.

Install adapter (1), elbow (2) and reducer (3) to engine and connect gauges to fittings.

Note:To achieve an accurate oil pressure reading, warm engine to 105° C (220° F).

Run engine at slow idle. Compare reading to specification.

Run engine at fast idle. Compare reading to specification.

Bell Training Center Revision 0.3 472

Das könnte Ihnen auch gefallen

- Mechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionVon EverandMechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionA. SherryBewertung: 4 von 5 Sternen4/5 (5)

- b50d Mki EngineDokument24 Seitenb50d Mki EngineMIANoch keine Bewertungen

- MuhammadSharjeelChawla Powerplants2Dokument5 SeitenMuhammadSharjeelChawla Powerplants2Engineer ChawlaNoch keine Bewertungen

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsVon EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsNoch keine Bewertungen

- Bell B25D & B30D Engine Operation InfoDokument16 SeitenBell B25D & B30D Engine Operation InfoOthnielNoch keine Bewertungen

- Chapter 5 Power Train: 1. Removal and Installation (MC Models) ................................................. 5-1Dokument9 SeitenChapter 5 Power Train: 1. Removal and Installation (MC Models) ................................................. 5-1Christian BedoyaNoch keine Bewertungen

- DIESEL ENGINE ISUZU 4JG2 Service ManualDokument48 SeitenDIESEL ENGINE ISUZU 4JG2 Service ManualArmando Orta90% (10)

- Hydraulic Fan Student Booklet EngDokument16 SeitenHydraulic Fan Student Booklet Engali100% (2)

- Chapter 5 Power Train: 1. Removal and Installation (MC Models) ................................................. 5-1Dokument14 SeitenChapter 5 Power Train: 1. Removal and Installation (MC Models) ................................................. 5-1Christian BedoyaNoch keine Bewertungen

- 80 MH GBDokument112 Seiten80 MH GBNil AcuñaNoch keine Bewertungen

- DV15 (T) (Ti) (Tis)Dokument101 SeitenDV15 (T) (Ti) (Tis)irwan yuniardi100% (2)

- STMG 799 - 33 - Text Reference 01/05Dokument47 SeitenSTMG 799 - 33 - Text Reference 01/05ait mimouneNoch keine Bewertungen

- Detroit Diesel Mbe 900 Epa04 Service ManualDokument20 SeitenDetroit Diesel Mbe 900 Epa04 Service Manualcarlos100% (34)

- Manual Formacion D722-B, D1005-E, D1105-B y D1703-BDokument16 SeitenManual Formacion D722-B, D1005-E, D1105-B y D1703-BTerah Pio100% (1)

- Iveco Engine T3Dokument33 SeitenIveco Engine T3Marian Taras100% (1)

- Section 8 Cil. Boom, Linde C4230TL PDFDokument53 SeitenSection 8 Cil. Boom, Linde C4230TL PDFrodrigo belardyNoch keine Bewertungen

- MX Eng Brake System DescriptionDokument4 SeitenMX Eng Brake System DescriptionPablo PorrasNoch keine Bewertungen

- Sistema Hidraulico FanDokument11 SeitenSistema Hidraulico FanChristian MontesNoch keine Bewertungen

- Cylinder Cutout TestDokument3 SeitenCylinder Cutout TestPILAR MARTINEZ100% (1)

- Stihl ServiceManual FC 90 95 100 110 fs90 100 110 Etc PDFDokument66 SeitenStihl ServiceManual FC 90 95 100 110 fs90 100 110 Etc PDFAmazon FireTV100% (1)

- Tren de Potencia p5000Dokument12 SeitenTren de Potencia p5000jorge humberto arellano almaguer100% (1)

- ENGINE 1.4 FIRE 16V - 28 July 09 PDFDokument233 SeitenENGINE 1.4 FIRE 16V - 28 July 09 PDFPhillip van Dalen100% (1)

- Generator Diesel Engine PDFDokument5 SeitenGenerator Diesel Engine PDFAlisabel Muñoz de MoralesNoch keine Bewertungen

- Analysis of 4 Stroke 4 Cylinder Petrol EngineDokument36 SeitenAnalysis of 4 Stroke 4 Cylinder Petrol Enginesuri surendraNoch keine Bewertungen

- MS171 MS181 MS211 Service Manual REPAIRDokument102 SeitenMS171 MS181 MS211 Service Manual REPAIRcosmin1991100% (5)

- Section 2 Engine: Group 1 Structure and Function 2-1 Group 2 Fan Drive Circuit For Cooling System 2-9Dokument9 SeitenSection 2 Engine: Group 1 Structure and Function 2-1 Group 2 Fan Drive Circuit For Cooling System 2-9SergeyNoch keine Bewertungen

- Weber Carburetor With GovernorDokument11 SeitenWeber Carburetor With GovernorweldsaidiNoch keine Bewertungen

- MS311, MS391 SMDokument94 SeitenMS311, MS391 SMZeeNoch keine Bewertungen

- Engine Valve Lash - Inspect-Adjust C6,6Dokument6 SeitenEngine Valve Lash - Inspect-Adjust C6,6Leonardo PerezNoch keine Bewertungen

- S09 Air Oiler SLU 14-22Dokument12 SeitenS09 Air Oiler SLU 14-22martin medinaNoch keine Bewertungen

- Tyrone Gear Pump DiagnosisDokument20 SeitenTyrone Gear Pump DiagnosisMohamad SaremyNoch keine Bewertungen

- Crankshaft: Page NoDokument13 SeitenCrankshaft: Page NoAmit GauravNoch keine Bewertungen

- Service Manual - Stihl FS94 KM94 SP92 SP92TDokument94 SeitenService Manual - Stihl FS94 KM94 SP92 SP92TMichael100% (1)

- Customer Service Department: Komatsu Utility Europe Pag. 1 Di 24 WETT001304Dokument24 SeitenCustomer Service Department: Komatsu Utility Europe Pag. 1 Di 24 WETT001304juanito100% (1)

- S.P.K. Tractor 006 - Engine WB93R-5, WB97R-5 Komatsu Backhoe-Loader Workshop ManualDokument24 SeitenS.P.K. Tractor 006 - Engine WB93R-5, WB97R-5 Komatsu Backhoe-Loader Workshop Manualสมโภช แก้วเขียว100% (1)

- Ms 341361 Shop ManualDokument110 SeitenMs 341361 Shop ManualmealysrNoch keine Bewertungen

- PDFDokument60 SeitenPDFAdolfo Moscoso100% (1)

- Fuel SystemsDokument5 SeitenFuel SystemsTrần Quang TuyênNoch keine Bewertungen

- Removal and Installation Removal of Engine and Transmission Assembly (For Gasoline-Engine Trucks)Dokument10 SeitenRemoval and Installation Removal of Engine and Transmission Assembly (For Gasoline-Engine Trucks)Kristian FonNoch keine Bewertungen

- Perkins Diesel Engine 2006-12t1Dokument87 SeitenPerkins Diesel Engine 2006-12t1Armando OrtaNoch keine Bewertungen

- Hpi Function DescriptionDokument64 SeitenHpi Function DescriptionHari50% (4)

- NOA004使用维修手册 (1-3.5T内燃英文) Operating and Service ManualDokument145 SeitenNOA004使用维修手册 (1-3.5T内燃英文) Operating and Service ManualJose CamposNoch keine Bewertungen

- Stihl MS310 Service Manual PDFDokument82 SeitenStihl MS310 Service Manual PDFReginaldo100% (1)

- 6060HydMiningShvl M08 SwingSys enDokument20 Seiten6060HydMiningShvl M08 SwingSys enJonathan José Alvis GonzalesNoch keine Bewertungen

- 003 RH170B Superstructure 2010Dokument12 Seiten003 RH170B Superstructure 2010yordyNoch keine Bewertungen

- MA-CAT-D10N - 3.pdf Opt. (067-200)Dokument134 SeitenMA-CAT-D10N - 3.pdf Opt. (067-200)Willy GoldenbergNoch keine Bewertungen

- 5-1 Steering SystemDokument7 Seiten5-1 Steering SystemSumitomo Laos Sumitomo LaosNoch keine Bewertungen

- SECTION 2 - FuelDokument7 SeitenSECTION 2 - Fuelيوسف وليد عبد الرحيمNoch keine Bewertungen

- 2015-03-08 185528 Stihl Ms 210, 230, 250 PDFDokument74 Seiten2015-03-08 185528 Stihl Ms 210, 230, 250 PDFJavier GalvezNoch keine Bewertungen

- Nhom 8 - V184 Engine 2.4LDokument9 SeitenNhom 8 - V184 Engine 2.4LTrương Ngọc ThắngNoch keine Bewertungen

- Shangli CPYQD30 Operation & Service InstructionDokument104 SeitenShangli CPYQD30 Operation & Service InstructionЮрий ФеоктистовNoch keine Bewertungen

- 030402en PDFDokument55 Seiten030402en PDFdaniel_jorge_10Noch keine Bewertungen

- 12 - TM - Oiler OE370 TM 0660-1 en 0204Dokument14 Seiten12 - TM - Oiler OE370 TM 0660-1 en 0204Elfer Angell MllNoch keine Bewertungen

- ICE Lab ReportDokument34 SeitenICE Lab ReportUmair Ali RajputNoch keine Bewertungen

- Manual Formacion V3300-DI-TDokument20 SeitenManual Formacion V3300-DI-TTerah PioNoch keine Bewertungen

- Sistema de FrenoDokument37 SeitenSistema de FrenoFredy ReyesNoch keine Bewertungen

- 14 - Manual Motor WeichaiDokument220 Seiten14 - Manual Motor WeichaiJoão Paulo Gobbo AugustoNoch keine Bewertungen

- Course Komatsu Wb93 97r5 Backhoes Engine Fuel Injection Structure Operation Workshop Data TroubleshootingDokument24 SeitenCourse Komatsu Wb93 97r5 Backhoes Engine Fuel Injection Structure Operation Workshop Data TroubleshootingTriyono100% (1)

- 2361 D3DDokument10 Seiten2361 D3DHalil KaraNoch keine Bewertungen

- 460E - ADT - Uptime Maintenance PlannerDokument3 Seiten460E - ADT - Uptime Maintenance PlannerBassieNoch keine Bewertungen

- CAt 349E Electrical UENR04340001Dokument12 SeitenCAt 349E Electrical UENR04340001BassieNoch keine Bewertungen

- E-Series Articulate Dump Truck Sales TrainingDokument9 SeitenE-Series Articulate Dump Truck Sales TrainingBassieNoch keine Bewertungen

- Product Sales or Technical Training: Litho in USADokument6 SeitenProduct Sales or Technical Training: Litho in USABassie100% (1)

- E-Series Articulate Dump Truck Sales Training: Next We'll Take A Look at The Electrical SystemDokument7 SeitenE-Series Articulate Dump Truck Sales Training: Next We'll Take A Look at The Electrical SystemBassieNoch keine Bewertungen

- Ey Final Business Risks and Opportunities in 2022Dokument44 SeitenEy Final Business Risks and Opportunities in 2022BassieNoch keine Bewertungen

- CAT 349E Electrical UENR04270001Dokument12 SeitenCAT 349E Electrical UENR04270001Bassie100% (1)

- 14 Steps of A PM Optimization Process (PMO)Dokument5 Seiten14 Steps of A PM Optimization Process (PMO)BassieNoch keine Bewertungen

- Product Training: Rigid Dump Truck (RDT) TR45: TR60: TR70: TR100Dokument3 SeitenProduct Training: Rigid Dump Truck (RDT) TR45: TR60: TR70: TR100Bassie100% (2)

- CAT 349E Electrical UENR04260001Dokument12 SeitenCAT 349E Electrical UENR04260001BassieNoch keine Bewertungen

- SP 9124 Xh100 PrimaxDokument1 SeiteSP 9124 Xh100 PrimaxBassieNoch keine Bewertungen

- Murphy Guage Codes 1Dokument2 SeitenMurphy Guage Codes 1Bassie100% (1)

- Man Truck Fault Code Control Unit Air Suspension (Ecas)Dokument2 SeitenMan Truck Fault Code Control Unit Air Suspension (Ecas)BassieNoch keine Bewertungen

- SP 9124 Xh100 PrimaxDokument1 SeiteSP 9124 Xh100 PrimaxBassieNoch keine Bewertungen

- 218667micro Fuel Filter B50DDokument2 Seiten218667micro Fuel Filter B50DBassieNoch keine Bewertungen

- Timberjack Skidder-BrochureDokument24 SeitenTimberjack Skidder-BrochureBassie100% (1)

- ISX Fault Codes List - Cummins ECMDokument3 SeitenISX Fault Codes List - Cummins ECMBassie100% (1)

- OM 906 LA Torque SpecsDokument9 SeitenOM 906 LA Torque SpecsBassie100% (1)

- Warning: Installation and Operation Manual For Murphy Display and Diagnostic Module (MDDM)Dokument8 SeitenWarning: Installation and Operation Manual For Murphy Display and Diagnostic Module (MDDM)BassieNoch keine Bewertungen

- SP 9124 XH100 PrimaxDokument1 SeiteSP 9124 XH100 PrimaxBassieNoch keine Bewertungen

- BR Primax XH100Dokument1 SeiteBR Primax XH100Bassie100% (1)

- Power Supply GPMECU 1, Description and MeasuringDokument2 SeitenPower Supply GPMECU 1, Description and MeasuringBassieNoch keine Bewertungen

- 18000L B20D Parts Manual Rev 0Dokument9 Seiten18000L B20D Parts Manual Rev 0BassieNoch keine Bewertungen

- Battery Specifications: Extreme Series: Automotive Batteries - Performance and Performance PlusDokument3 SeitenBattery Specifications: Extreme Series: Automotive Batteries - Performance and Performance PlusBassieNoch keine Bewertungen

- R934-R934B Adjust Check ListDokument6 SeitenR934-R934B Adjust Check ListBassieNoch keine Bewertungen

- Faculty of Engineering and Technology: Sessional Test 1-February 2020Dokument2 SeitenFaculty of Engineering and Technology: Sessional Test 1-February 2020Sunny BhatiaNoch keine Bewertungen

- Now Available in - Stock Repair Kits & Components: Engine S6S - 3046Dokument1 SeiteNow Available in - Stock Repair Kits & Components: Engine S6S - 3046MichaelMonguiNoch keine Bewertungen

- Catalog Man 1Dokument116 SeitenCatalog Man 1Petrov AndreiNoch keine Bewertungen

- Ingenium I4 2.0l PetrolDokument1.502 SeitenIngenium I4 2.0l Petrolkhaledserag23Noch keine Bewertungen

- Tabela de Falhas Toyota EcdDokument5 SeitenTabela de Falhas Toyota EcdGilmar Barbaresco FilhoNoch keine Bewertungen

- 6BV 28197 3M 11 PDFDokument202 Seiten6BV 28197 3M 11 PDFAlex Vdbussche100% (1)

- 4D94 (L) E 4D98E: Service ManualDokument14 Seiten4D94 (L) E 4D98E: Service ManualLek MiniNoch keine Bewertungen

- ENGENIRINGDokument7 SeitenENGENIRINGMostafa Mohamed Adel0% (1)

- HiMSEN Technical Circular - Information For Combusion Diagram (Dokument6 SeitenHiMSEN Technical Circular - Information For Combusion Diagram (Sergey shapovalovNoch keine Bewertungen

- TMS2900Dokument10 SeitenTMS2900Nicolau FerreiraNoch keine Bewertungen

- History: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHDokument3 SeitenHistory: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHPatrizio MassaroNoch keine Bewertungen

- Piston Damage ReportDokument71 SeitenPiston Damage ReportQamar Uz Zaman100% (2)

- Yamaha Ft60dehd Ft60deht Ft60det 2012Dokument71 SeitenYamaha Ft60dehd Ft60deht Ft60det 2012Eduardo CortezNoch keine Bewertungen

- Auto-17002 Electronic Ignition SystemDokument97 SeitenAuto-17002 Electronic Ignition SystemNatty NuggetNoch keine Bewertungen

- C200 - E-Egr SystemDokument9 SeitenC200 - E-Egr SystemKada Ben youcefNoch keine Bewertungen

- Cat 3400 AdjustingDokument7 SeitenCat 3400 AdjustingaliNoch keine Bewertungen

- Amb ENGINE 1.8LDokument650 SeitenAmb ENGINE 1.8LNP100% (1)

- 9820gb180le 210Dokument31 Seiten9820gb180le 210BaggerkingNoch keine Bewertungen

- Lexus Engine 1UZ FE Service and Repair ManualDokument80 SeitenLexus Engine 1UZ FE Service and Repair Manualeamon100% (2)

- Turbo Charger and GasketDokument2 SeitenTurbo Charger and GasketDavid NguyenNoch keine Bewertungen

- Cambio Arbol de Levas Volvo D13Dokument37 SeitenCambio Arbol de Levas Volvo D13cheolll100% (3)

- Leega LG 75cDokument4 SeitenLeega LG 75cracso100% (1)

- Fig 1: Detroit Diesel Engine Performance Wiring Diagram (DDEC III & DDEC IV - Series 60 Without EGR - 1 of 2)Dokument3 SeitenFig 1: Detroit Diesel Engine Performance Wiring Diagram (DDEC III & DDEC IV - Series 60 Without EGR - 1 of 2)Andre VP100% (1)

- Omc Spark Plug WiresDokument7 SeitenOmc Spark Plug WiresMarine Parts ChinaNoch keine Bewertungen

- Imprimir PDFDokument20 SeitenImprimir PDFBoris Yeltsin Ramos BautistaNoch keine Bewertungen

- Cold Setting The Valves On A 1953 Dodge M37 Power WagonDokument2 SeitenCold Setting The Valves On A 1953 Dodge M37 Power Wagoncriag100% (1)

- Topic6 IceDokument17 SeitenTopic6 IceIsmail IbrahimNoch keine Bewertungen

- Intake Pulse CalculationDokument14 SeitenIntake Pulse CalculationShrikant Khating100% (5)

- Land Rover Fault CodesDokument4 SeitenLand Rover Fault Codesajac29630100% (2)

- Specification Sheet: Single Engine Clutch Drive OpuDokument2 SeitenSpecification Sheet: Single Engine Clutch Drive OpuIU LI ANNoch keine Bewertungen

- Automotive Wiring and Electrical SystemsVon EverandAutomotive Wiring and Electrical SystemsBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingVon EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingBewertung: 4.5 von 5 Sternen4.5/5 (9)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (54)

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsVon EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsBewertung: 5 von 5 Sternen5/5 (4)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsVon EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNoch keine Bewertungen

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionVon EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionNoch keine Bewertungen

- Automotive Electronic Diagnostics (Course 1)Von EverandAutomotive Electronic Diagnostics (Course 1)Bewertung: 5 von 5 Sternen5/5 (6)

- Why We Drive: Toward a Philosophy of the Open RoadVon EverandWhy We Drive: Toward a Philosophy of the Open RoadBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Data Acquisition from HD Vehicles Using J1939 CAN BusVon EverandData Acquisition from HD Vehicles Using J1939 CAN BusNoch keine Bewertungen

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceVon EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNoch keine Bewertungen

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (1)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionVon EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionBewertung: 5 von 5 Sternen5/5 (2)

- The Little Black Book of Motorcycle WisdomVon EverandThe Little Black Book of Motorcycle WisdomBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsVon EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsBewertung: 4.5 von 5 Sternen4.5/5 (17)

- Automotive Master Technician: Advanced Light Vehicle TechnologyVon EverandAutomotive Master Technician: Advanced Light Vehicle TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreVon EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreBewertung: 4.5 von 5 Sternen4.5/5 (11)

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Classic Car Museum Guide: Motor Cars, Motorcycles & MachineryVon EverandClassic Car Museum Guide: Motor Cars, Motorcycles & MachineryNoch keine Bewertungen

- Massey Ferguson 35 Tractor: Workshop Service ManualVon EverandMassey Ferguson 35 Tractor: Workshop Service ManualBewertung: 5 von 5 Sternen5/5 (4)

- Competition Engine Building: Advanced Engine Design and Assembly TechniquesVon EverandCompetition Engine Building: Advanced Engine Design and Assembly TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (7)