Beruflich Dokumente

Kultur Dokumente

Product Specification Epm38031: Rhz1 19/33Kv 1X630Kcu+H50

Hochgeladen von

JFREY15040 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

181 Ansichten2 SeitenThis document provides the product specifications for a medium voltage cable with a copper conductor, XLPE insulation, copper screen, and polyolefin outer sheath. The cable is rated for 19/33kV and has a conductor diameter of 30.5mm. Key dimensions and electrical characteristics are listed such as maximum resistance, capacitance, current capacity and short circuit withstand.

Originalbeschreibung:

Originaltitel

CABELTE RHZ1 630CU

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides the product specifications for a medium voltage cable with a copper conductor, XLPE insulation, copper screen, and polyolefin outer sheath. The cable is rated for 19/33kV and has a conductor diameter of 30.5mm. Key dimensions and electrical characteristics are listed such as maximum resistance, capacitance, current capacity and short circuit withstand.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

181 Ansichten2 SeitenProduct Specification Epm38031: Rhz1 19/33Kv 1X630Kcu+H50

Hochgeladen von

JFREY1504This document provides the product specifications for a medium voltage cable with a copper conductor, XLPE insulation, copper screen, and polyolefin outer sheath. The cable is rated for 19/33kV and has a conductor diameter of 30.5mm. Key dimensions and electrical characteristics are listed such as maximum resistance, capacitance, current capacity and short circuit withstand.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

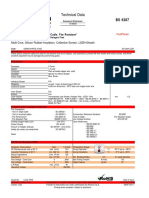

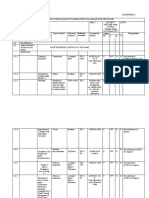

PRODUCT SPECIFICATION

EPM38031

Medium voltage cable RHZ1 19/33kV 1x630KCu+H50

Copper conductor

1

XLPE insulation (DIX 3 type) 2

Triple Extrusion – Dry curing 3

4

Copper wires and tape metallic screen

5

Polyolefin outer sheath, type DMZ1 6

7

Construction and testing according standards

Cross-sectional drawing

INS 56.48.01 (May.2013, Issue 3)

IEC 60228

UNE HD 620-S2 (10E-1, 10O-1)

1 – Circular stranded copper conductor, class 2

Rated Voltage according to IEC 60228.

A semi-conducting tape may be applied over the

Uo/U (Um) – 19 / 33 (36) kV

conductor.

Outer sheath colour 2 – Semi-conducting compound.

BLACK 3 – Cross-linked polyethylene (XLPE) insulation.

4 – Semi-conducting compound, fully bonded.

Marking

5 – Copper wires, helically applied.

According to INS 56.48.01. 6 – Copper tape applied in an open counter helix.

Plastic tape applied over copper screen.

7 – Polyolefin outer sheath, type DMZ1.

DEP 2016-04-18 Page 1/2

PRODUCT SPECIFICATION

EPM38031

RHZ1 19/33kV 1x630KCu+H50

Dime ns io nal C haract eris t ics

CONDUCTOR

Nominal area of core (mm2) 630

No. of cores ; shape (No.) 1 ; round

Diameter of conductor (mm) 30,5

CONDUCTOR SCREEN

Material Semi-conducting compound

Nominal thickness (mm) 0,5

INSULATION

Material XLPE (DIX 3)

Average thickness (mm) 8,0

Outside diameter (mm) 48,4

INSULATION SCREEN

Material Semi-conducting compound

Nominal thickness (mm) 0,5

METALLIC SHIELD

Material Copper Wires + Tape

Cross-sectional area (mm2) 50

OUTER SHEATH

Material Polyolefin (DMZ1)

Minimum thickness (mm) 2,40

CABLE

Approximated outer diameter of cable (mm) 58

Approximated weight of cable (kg/km) 7700

Elect rical C haract erist ics

Maximum DC conductor resistance, 20ºC ( /km) 0,0283

Maximum AC conductor resistance, 90ºC ( /km) 0,0405

Maximum DC screen resistance, 20ºC ( /km) 0,393

Reactance ( /km) 0,100

Capacitance ( F/km) 0,35

Charging current (mA/m) 2,07

Impedance ( /km) 0,068

Current carrying capacity, cables in trefoil (A):

- Directly buried; 15ºC; 1,2K.m/W; 0,8m deep 845

Max. adm. short-circuit current, conductor, 1sec. (kA) 90,1

Mecha nical C haract eris t ics

Maximum pulling effort (conductor) (daN) 3150

Minimum bending radius of cable, installation (mm) 1160

Minimum bending radius of cable, permanent (mm) 870

DEP 2016-04-18 Page 2/2

Das könnte Ihnen auch gefallen

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Dokument4 SeitenVedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Sasanka SekharNoch keine Bewertungen

- 33kv Cables GTPDokument3 Seiten33kv Cables GTPManohar Potnuru100% (1)

- Practical Metallography: Faculty of Production Engineering and ManagementDokument18 SeitenPractical Metallography: Faculty of Production Engineering and ManagementMassimo FumarolaNoch keine Bewertungen

- Lightning Protection Guide - Complete - DeHNDokument331 SeitenLightning Protection Guide - Complete - DeHNNeilfred Gerona Sio100% (2)

- AISI 1020 Low Carbon/Low Tensile Steel: Element ContentDokument4 SeitenAISI 1020 Low Carbon/Low Tensile Steel: Element ContentRatno WijayaNoch keine Bewertungen

- CMH17 - AIAA - STC100411-Military Handbook 17-Composite Material HandbookDokument37 SeitenCMH17 - AIAA - STC100411-Military Handbook 17-Composite Material Handbook楊宗棠Noch keine Bewertungen

- Lime BookletDokument58 SeitenLime BookletAiman Hashmi100% (1)

- Lightning and Surge Protection For Wind TurbinesDokument12 SeitenLightning and Surge Protection For Wind TurbinesJFREY1504Noch keine Bewertungen

- XHIOLE (Cbe) 1x"S"/35 12/20kV: Product Specification EPM100051Dokument2 SeitenXHIOLE (Cbe) 1x"S"/35 12/20kV: Product Specification EPM100051Fahad UsmanNoch keine Bewertungen

- Datos CableDokument3 SeitenDatos CablePablo Briceño NavarroNoch keine Bewertungen

- NA2XS (F) 2Y 12-20 KV 1x400Dokument2 SeitenNA2XS (F) 2Y 12-20 KV 1x400plavi10Noch keine Bewertungen

- NA2XS (F) 2Y 26-45 KV 1x120Dokument2 SeitenNA2XS (F) 2Y 26-45 KV 1x120plavi10Noch keine Bewertungen

- TDS, CSD - Iec 60502-2Dokument4 SeitenTDS, CSD - Iec 60502-2Ghiles AOUICHENoch keine Bewertungen

- APPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDSDokument4 SeitenAPPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDSSanjay GadhaveNoch keine Bewertungen

- Drawing 2nDokument1 SeiteDrawing 2nRasel AhmedNoch keine Bewertungen

- IEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONDokument7 SeitenIEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONmedazzNoch keine Bewertungen

- ZTT MV Power Cable Rev A 20181228Dokument5 SeitenZTT MV Power Cable Rev A 20181228Jean Pierre GoossensNoch keine Bewertungen

- Technical Specification-33KV 1X500 SQ - MM XLPE CableDokument5 SeitenTechnical Specification-33KV 1X500 SQ - MM XLPE Cableনাঈমুর রহমানNoch keine Bewertungen

- Xlpe Oscr Pe Swa PVC 1.5 Black 500vDokument2 SeitenXlpe Oscr Pe Swa PVC 1.5 Black 500vJason SecretNoch keine Bewertungen

- Technology Department Technical Data Sheet Low Voltage Power CableDokument2 SeitenTechnology Department Technical Data Sheet Low Voltage Power CableMuhammad ShahidNoch keine Bewertungen

- 33kV Cable GTPDokument2 Seiten33kV Cable GTPVipin Kr DhimanNoch keine Bewertungen

- TPG NA2XS2Y 1x300 mm2 20KVDokument2 SeitenTPG NA2XS2Y 1x300 mm2 20KVtees220510Noch keine Bewertungen

- Insulation Sheath Xlpe Lead Voltage 127 / 220 / 245 KV Short-CircuitDokument1 SeiteInsulation Sheath Xlpe Lead Voltage 127 / 220 / 245 KV Short-CircuitMena KamelNoch keine Bewertungen

- RHZ1 - Ol 66KV 1X1000 K+h95kneDokument3 SeitenRHZ1 - Ol 66KV 1X1000 K+h95kneJulian Palacios BarreroNoch keine Bewertungen

- Li# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraDokument2 SeitenLi# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraMuhammad ShahidNoch keine Bewertungen

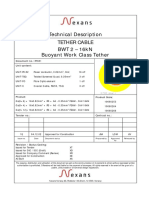

- Technical Description Tether Cable BWT 2 - 16kN Buoyant Work Class TetherDokument6 SeitenTechnical Description Tether Cable BWT 2 - 16kN Buoyant Work Class TetherRich ManNoch keine Bewertungen

- 1 - Specification 18th May 2021Dokument4 Seiten1 - Specification 18th May 2021JR DadisNoch keine Bewertungen

- Technical Spec NA2XSEYBY 3x300mm2Dokument2 SeitenTechnical Spec NA2XSEYBY 3x300mm2Suyanto Âñd Fámïly100% (1)

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDokument2 SeitenNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNoch keine Bewertungen

- SOUTHERN CABLE 630mmsq Cu XLPEDokument3 SeitenSOUTHERN CABLE 630mmsq Cu XLPERozaimi GhazaliNoch keine Bewertungen

- Universal Cable, AXCES 12/20 (24) KV 3x70/16: Product InformationDokument2 SeitenUniversal Cable, AXCES 12/20 (24) KV 3x70/16: Product InformationMiso MisoNoch keine Bewertungen

- Tehnički podatak-HSKP423HP9Dokument4 SeitenTehnički podatak-HSKP423HP9Nogalo99Noch keine Bewertungen

- TDS, CSD - Iec 502-1-3.Dokument6 SeitenTDS, CSD - Iec 502-1-3.Ghiles AOUICHENoch keine Bewertungen

- Freedm B2 Breakout Tight Buffer Indoor/ Outdoor Cable (2.4 MM)Dokument4 SeitenFreedm B2 Breakout Tight Buffer Indoor/ Outdoor Cable (2.4 MM)Franklin CabreraNoch keine Bewertungen

- Fire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Dokument1 SeiteFire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Cost RootsNoch keine Bewertungen

- PE Ins. Mylar Shielded-FR IS+OS 2Px1.0Dokument2 SeitenPE Ins. Mylar Shielded-FR IS+OS 2Px1.0Engr. Mehadi Hassan NahidNoch keine Bewertungen

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDokument2 SeitenMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- 300 RM 31.5 Ka 1sec SpecificationDokument4 Seiten300 RM 31.5 Ka 1sec SpecificationAbdullah Al AsikNoch keine Bewertungen

- RC - Local 4x70mm SCU-XLPE-PVC 1 KV (TD)Dokument2 SeitenRC - Local 4x70mm SCU-XLPE-PVC 1 KV (TD)HaikalNoch keine Bewertungen

- 012TEU-13188A2G - 12 Brins OM3 Armature en Mèches de VerreDokument4 Seiten012TEU-13188A2G - 12 Brins OM3 Armature en Mèches de Verremic68hc11Noch keine Bewertungen

- 33 KV 3 Core Aluminium XLPE CableDokument3 Seiten33 KV 3 Core Aluminium XLPE CableSai KumarNoch keine Bewertungen

- Universal Cable (M) Berhad: Schedule of Technical ParticularsDokument1 SeiteUniversal Cable (M) Berhad: Schedule of Technical Particularsmohd darusNoch keine Bewertungen

- Bahra CableDokument2 SeitenBahra CableMaya HafqNoch keine Bewertungen

- N1P-1.5 Mgt-Xosswah-LDokument2 SeitenN1P-1.5 Mgt-Xosswah-LRijo RajanNoch keine Bewertungen

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDokument1 SeiteSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNoch keine Bewertungen

- Technical Offer-SWE-298-23-V1Dokument1 SeiteTechnical Offer-SWE-298-23-V1Karim RahmaniNoch keine Bewertungen

- 2.5mm Two Core: Description Units DetailDokument2 Seiten2.5mm Two Core: Description Units DetailMuhammad Shabbir AwanNoch keine Bewertungen

- Lvis09axsfy23 5c300sa002sDokument1 SeiteLvis09axsfy23 5c300sa002sVishal SharmaNoch keine Bewertungen

- CATM3Dokument4 SeitenCATM3Shaswat JhaNoch keine Bewertungen

- Nextramicro 12 144g657a1 - 800 1000NDokument5 SeitenNextramicro 12 144g657a1 - 800 1000Ngeorgeta.dumitrache50Noch keine Bewertungen

- TDS 33KV 150sqmm X 3C+50 AL-XLPE-SCT-PVC ABC Refer TNB SpecDokument2 SeitenTDS 33KV 150sqmm X 3C+50 AL-XLPE-SCT-PVC ABC Refer TNB SpecShahril ShahibullahNoch keine Bewertungen

- 3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2Dokument2 Seiten3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2HaikalNoch keine Bewertungen

- 3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD)Dokument2 Seiten3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD)HaikalNoch keine Bewertungen

- 3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2Dokument2 Seiten3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2HaikalNoch keine Bewertungen

- 33 KV Single Core Copper XLPE CableDokument3 Seiten33 KV Single Core Copper XLPE CableSai KumarNoch keine Bewertungen

- 1C 630 MM (2xHSYRa2Y) 18 30 (36) KV CABLESDokument6 Seiten1C 630 MM (2xHSYRa2Y) 18 30 (36) KV CABLESanamulk-1Noch keine Bewertungen

- TDS 1x300 11kV CTS+LEADDokument2 SeitenTDS 1x300 11kV CTS+LEADNabeelNoch keine Bewertungen

- Data Sheets de Todos Cabos Da ListaDokument20 SeitenData Sheets de Todos Cabos Da ListaLaercio ChissicoNoch keine Bewertungen

- LPCB Fire Resistant CableDokument2 SeitenLPCB Fire Resistant CableArjunNoch keine Bewertungen

- Loose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJDokument5 SeitenLoose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJPetyo GeorgievNoch keine Bewertungen

- S.No Description/Test Offered ConductorDokument3 SeitenS.No Description/Test Offered ConductorMadhavNoch keine Bewertungen

- ZTTSC MV Power Cables XJ10078 SPECDokument5 SeitenZTTSC MV Power Cables XJ10078 SPECMarco VillalobosNoch keine Bewertungen

- 1x1.5 SIFCSI (Heat Resistance) 12-20KV-100%Dokument1 Seite1x1.5 SIFCSI (Heat Resistance) 12-20KV-100%amir kamaliNoch keine Bewertungen

- RC - Local1x120mm CU XLPE CUT AWA PVC20kV (TD) - 20230131122332.677 - XDokument2 SeitenRC - Local1x120mm CU XLPE CUT AWA PVC20kV (TD) - 20230131122332.677 - XAnonymous wx4I4YQONoch keine Bewertungen

- Fsis09cxswyl004c006sa (FR LSH)Dokument1 SeiteFsis09cxswyl004c006sa (FR LSH)pkNoch keine Bewertungen

- 1-V23834 L6 E1etc6 011001Dokument9 Seiten1-V23834 L6 E1etc6 011001brunobrambilla90Noch keine Bewertungen

- Sv08wind e PDFDokument12 SeitenSv08wind e PDFJFREY1504Noch keine Bewertungen

- DEHN Protects Wind TurbinesDokument20 SeitenDEHN Protects Wind TurbinesJFREY1504Noch keine Bewertungen

- Ejemplos Norma Asme PDFDokument55 SeitenEjemplos Norma Asme PDFCarlos Ramos MorenoNoch keine Bewertungen

- Catalogue Nxair Family enDokument32 SeitenCatalogue Nxair Family enViswa Nathan100% (1)

- ATPDraw v5 Presentation PDFDokument57 SeitenATPDraw v5 Presentation PDFJFREY1504Noch keine Bewertungen

- 7sa522 Catalog Sip E7Dokument37 Seiten7sa522 Catalog Sip E7JFREY1504Noch keine Bewertungen

- Live Sheet (01-11-2002)Dokument433 SeitenLive Sheet (01-11-2002)Omkar Balasaheb MetkariNoch keine Bewertungen

- Processing and Mechanical Properties of A Plasticised PVC Reinforced With Cellulose WhiskersDokument3 SeitenProcessing and Mechanical Properties of A Plasticised PVC Reinforced With Cellulose WhiskersatikmkaziNoch keine Bewertungen

- EPDM - Test by Romac Inc PDFDokument2 SeitenEPDM - Test by Romac Inc PDFRajendra Kumar SharmaNoch keine Bewertungen

- Analisis Kinerja Campuran Aspal Porus Menggunakan Aspal Pen 60/70 Dan Aspal Modifikasi Polimer ElvaloyDokument11 SeitenAnalisis Kinerja Campuran Aspal Porus Menggunakan Aspal Pen 60/70 Dan Aspal Modifikasi Polimer ElvaloyKurnia ZandyNoch keine Bewertungen

- 10 Mechanical Properties 2020Dokument23 Seiten10 Mechanical Properties 2020nadliriNoch keine Bewertungen

- 263 - HDGS, HLGs PH90 - E30-E90 K219A1703Dokument2 Seiten263 - HDGS, HLGs PH90 - E30-E90 K219A1703DarNoch keine Bewertungen

- What Is Meant by Striking Formwork - Removal of Formwork - Minimum Period - CivilDigitalDokument7 SeitenWhat Is Meant by Striking Formwork - Removal of Formwork - Minimum Period - CivilDigitalAnonymous DlVrxSbVk9Noch keine Bewertungen

- PVC Schedule 80 12 3Dokument1 SeitePVC Schedule 80 12 3Viet DangNoch keine Bewertungen

- Project PPT Sem 8Dokument27 SeitenProject PPT Sem 8Axit Patel0% (1)

- Pidicryl XD 4000 - Suggestive Formulation - WhiteDokument1 SeitePidicryl XD 4000 - Suggestive Formulation - WhiteCarlos Lizarraga FloresNoch keine Bewertungen

- Comparasion Characteristic Raw MaterialDokument1 SeiteComparasion Characteristic Raw MaterialLaili AzkiyahNoch keine Bewertungen

- SAE AMS 5521j-2012Dokument5 SeitenSAE AMS 5521j-2012Mehdi MokhtariNoch keine Bewertungen

- Chemistry InvestigationDokument12 SeitenChemistry InvestigationRanjeetNoch keine Bewertungen

- Ivan Wan ResinDokument3 SeitenIvan Wan ResinmuhannadNoch keine Bewertungen

- AluminumDokument7 SeitenAluminumcollenedesilvaNoch keine Bewertungen

- 310 Spec SheetDokument2 Seiten310 Spec Sheetsandry CANELONESNoch keine Bewertungen

- Model QAP For Plates1Dokument3 SeitenModel QAP For Plates1tarun kaushalNoch keine Bewertungen

- 8 - ENG 2 ET V1 S1 - LessonDokument12 Seiten8 - ENG 2 ET V1 S1 - LessonMaruf BillahNoch keine Bewertungen

- Catalogo CompletoDokument220 SeitenCatalogo CompletoWilliam Dante Mescco SaireNoch keine Bewertungen

- 2022 Electrical Steel NO Catalog - Eng - FinalDokument14 Seiten2022 Electrical Steel NO Catalog - Eng - Final雨庵우암Noch keine Bewertungen

- IPC-4101B Reference Chart PDFDokument1 SeiteIPC-4101B Reference Chart PDFMarlon CornejoNoch keine Bewertungen

- Mcode and Mname Commercial and Alternate Designations: Material - Cross - IndexDokument33 SeitenMcode and Mname Commercial and Alternate Designations: Material - Cross - IndexMohamedNoch keine Bewertungen

- ACI PRC 440-7-22 Externally Bonded Fiber Reinforced Polymer SystemsDokument77 SeitenACI PRC 440-7-22 Externally Bonded Fiber Reinforced Polymer SystemsYoukhanna ZayiaNoch keine Bewertungen

- Earthing Catalogue - Version2 - 2021Dokument4 SeitenEarthing Catalogue - Version2 - 2021Abdel Kareem MohdNoch keine Bewertungen

- Stress Analyses of Multi-Layered Composite Pipes Subjected To Internal PressureDokument7 SeitenStress Analyses of Multi-Layered Composite Pipes Subjected To Internal PressuremichaelNoch keine Bewertungen